HazLoc 101

HazLoc 101

Basics of US Hazardous Locations Requirements a condensed version

UL and the UL logo are trademarks of UL LLC © 2012

Seminar Modules

• Organization of Participant Manual

• Module 1: History of Hazardous Locations

• Module 2: Overview of Area Classifications

• Module 3: Class I Division and Zone Comparison

• Module 4: Overview of Protection Techniques

• Module 5: Class I, Division 1 Construction/Performance

Requirements

• Module 6: Class I, Division 2 Construction/Performance

Requirements

• Module 7: Class I, Zone 0 and 1 Construction/Performance

Requirements

• Module 8: Class I, Zone 2 Construction/Performance Requirements

• Module 9: Class II & III, Construction/Performance Requirements

• Module 10: Installation

• Module 11: European Compliance Overview/International Markets

Slide 2

Module 1 Objectives

• Discuss the history behind hazardous locations

• Explain the relationship between the history and the development of

Article 500 through 506 in the National Electric Code

Slide 3

Module 1 Objectives

• Discuss the history behind hazardous locations

• Explain the relationship between the history and the development of

Article 500 through 506 in the National Electric Code

Slide 4

1920 - National Electric Code (NEC) Timeline

• “Equipments in Extra Hazardous

Locations”

• Addressed rooms in which highly flammable gases, liquids, mixtures or other substances were used

•

At this time, UL had been certifying equipment for use in such areas for about 6 years

Slide 5

1960’s – National Electric Code (NEC) Timeline

• UL develops Westerberg Explosion Test Vessel (WETV)

• WETV is able to determine two quantities for any gas or vapor

• flame transmission properties by measuring the Maximum

Experimental Safe Gap (MESG)

• explosion pressure

•

WETV data enables classification of gases and vapors into defined groups by comparing the MESG and explosion pressure to those of materials already defining the group.

Slide 6

1969 – National Electric Code (NEC) Timeline

• UL publishes Bulletin of Research no. 58 which summarizes a UL investigation of fifteen flammable gases or vapors based on WETV data.

• Added to NEC in 1971

Slide 8

1996 – National Electric Code (NEC) Timeline

• NEC introduces International Zone Classification system in new Article 505

• covers Class I only

• includes 3 gas groups, IIA, IIB, & IIC

• includes 3 Zones- 0, 1, & 2

• UL begins certifying equipment for use in such areas

Slide 9

Basis for Product Compliance

• National Electrical Code (NFPA 70)

• Articles 500 through 506

•

Canadian Electrical Code (C22.1)

• Section 18

• IEC/EN 60079-series

• Special Applications

• Mine Safety and Health Administration (MSHA)

- Regulates mining locations

- Certifies equipment

- Governed by Federal Mine Safety and Health Act

• United States Coast Guard (USCG)

- Regulates off-shore locations

- Governed by USCG Regulations, 46CFR Parts 110-113 inclusive (based on NEC )

Slide 10

AHJs

• Authority Having Jurisdiction (AHJ)

• Determines acceptability of equipment

• Thousands nationwide

• International Association of Electrical Inspectors (IAEI)

• Fire marshals

• Other local authorities

• U.S. Certification Marks still basis for acceptance

(NRTL)

Slide 11

Listed

Western Electric Motors, Inc.

Cat. No. MNO

Listed

D3J8

Electric Motor for Hazardous Locations

Class I, Division 1, Group D

230 V, 60 Hz

3 phase

54 A

20 HP

1760 rpm

Insulation class B

This label indicates

Listing

From NEC:

Slide 12

Area Classifications

• Class I

• Flammable, gases, vapors or liquids

• Class II

• Combustible dusts

• Class III

• Ignitible fibers and flyings

Slide 13

Class I Division/Zone Area Classification

Comparison

Division 1: Where ignitable concentrations of flammable gases, vapors or liquids can exist all of the time or some of the time under normal operating conditions

Division 2: Where ignitable concentrations of flammable gases, vapors or liquids are not likely to exist under normal operating conditions

Zone 0: Where ignitable concentrations of flammable gases, vapors or liquids can exist all of the time or for long periods of time under normal operating conditions

Zone 1: Where ignitable concentrations of flammable gases, vapors or liquids can exist some of the time under normal operating conditions

Zone 2: Where ignitable concentrations of flammable gases, vapors or liquids are not likely to exist under normal operating conditions

Slide 14

Class I Division/Zone, Gas Group Comparison

Division 1 and 2

A (acetylene)

B (hydrogen)

C (ethylene)

D (propane)

Zone 0, 1 and 2

IIC (acetylene & hydrogen)

IIB (ethylene)

IIA (propane)

Slide 15

Class I Division/Zone Temperature Class

Comparison

Division 1 and 2

T1 (<450º C)

T2 (<300º C)

T2A,B,C,D

(<280º C, <260º C, <230º C, <215º C)

T3 (<200º C)

T3A,B,C,

(<180º C, <165º C, <160º C)

T4 (<135º C)

T4A (<120º C)

T5 (<100º C)

T6 (<85º C)

Zone 0, 1 and 2

T1 (<450º C)

T2 (<300º C)

T3 (<200º C)

T4 (<135º C)

T5 (<100º C)

T6 (<85º C)

T5 and T6 are optional for marking

Slide 16

Listing Mark

This panel is safe in a

Division 1 area.

Inside the panel are IS barriers, which provide power to an intrinsically safe device.

Slide 18

Classification Mark

ABC Enclosures, Inc.

Cat. No. XCX

As to explosion and fire hazard only

3IJ2

Enclosure for Use in Hazardous Locations

Class I, Group C and D

WARNING - To prevent ignition of hazardous atmospheres, all conduit runs must have a sealing fitting connected within 18 in . of the enclosure.

CAUTION - To prevent ignition of hazardous atmospheres, disconnect from the supply circuit before opening enclosure. Keep tightly closed when circuits are alive .

• Example: Explosionproof

Enclosures

• For this product, only the enclosure has been tested

• (electrical components have not been evaluated)

Slide 19

Recognized Component Mark

• This mark is for incomplete products

• The UL Report will include Conditions of Acceptability that must be checked during evaluation of the final Listed assembly

Slide 20

Comparison of Product Markings

U.S.

CANADA EUROPE IECEx

0539 II 2 G

Class I, Div. 1,

Group C,D

Class I, Zone 1

AEx d IIB T5 or

Class I, Zone 1

AEx d IIB T5 Gb

Class I, Div. 1,

Group C,D

Ex d IIB T5 or

EEx d IIB T5

Ex d IIB T5 or

Ex d IIB T5 Gb or

Ex db IIB T5

<Certificate No.>

Ex d IIB T5 or

Ex d IIB T5 Gb or

Ex db IIB T5

<Certificate No.>

Slide 21

Ordinary Location Requirements

• For all equipment:

• Risk of Fire

• Risk of Electric Shock

• Special Applications:

• Environmental Ratings

• Marine Ratings

• Signaling/Fire Alarm

Slide 22

Explosionproof Equipment

•

Equipment that has an enclosure capable of:

• withstanding an explosion of a specified gas or vapor within the enclosure,

• preventing the ignition of a specified gas or vapor surrounding the enclosure, and

• operating at an external temperature that will not ignite a specified gas or vapor surrounding the enclosure

Slide 23

Enclosure with enlarged gap, ready for an explosion test

1

2

3

Slide 24

Each frame = 1/2000 seconds

4

5

6

Slide 25

Joint Comparison Example

• Group C (IIB)

• Enclosure Volume 2000 cm³ (122 in³)

Explosionproof

Div 1 = zone 0 &1

19.1 mm (3/4 in)

Flameproof

Zone 1

12.5 mm Width

(min.)

Clearance

(max.)

0.05 mm (0.002 in) 0.2 mm

Slide 26

Explosionproof enclosure

Explosionproof enclosure

Slide 27

Slide 28

Explosionproof Pushbutton Switch

Cylindrical Joint --->

Flat Joint--->

Threaded Conduit Entries

<---Threaded Joint

Slide 29

Control Drawing

Hazardous (Classified)

Location

Unclassified (Non hazardous)

Location

18.8.8

Red

Black

I.S.

Transmitter

_

+

Dual Channel

Barrier

+24 V

Control

Equipment

SIGNAL

Equipment

Vmax (or Ui)

Imax (or Ii)

Ci + Ccable

Li + Lcable

Pmax

>

>

<

<

>

Barrier

Voc (or Uo)

Isc (or Io)

Ca (or Co)

La (or Lo)

Po

Sugar Refinery

After an Explosion

Slide 31

Slide 32

Preventing the Entrance of Dust Cont’d

• The suitability of these paths to prevent entrance is determined by the following requirements:

• Joint widths and clearances

• Shaft lengths and clearances

• Thread engagement

• Gasketing

• Dust Penetration testing

Slide 33

Dust Testing

• Nozzles are directed where the dust is most likely to enter the enclosure. Goes on for 30 h, during that time the device is powered on and off for 6 heating and cooling cycles. The heating/cooling cycle creates a partial vacuum that will possibly draw the dust into the enclosure .

Slide 34

Dust Testing

• Nozzles directed where dust most likely will enter into the motor.

• After test, the motor is opened and must not have any dust inside.

Slide 35

Articles 500 – 506 of the NEC

• Article 500 - General

• Article 501 - Class I, Division Locations

• Article 502 - Class II Locations

• Article 503 - Class III Locations

• Article 504 - Intrinsically Safe Systems

• Article 505 - Class I, Zone Locations

• Article 506 - Zone 20, 21 and 22 Locations

Slide 36

Specific Occupancies

• Covered in Articles 510 through 517

• Include such occupancies as:

• Commercial Garages (Art. 511)

• Aircraft Hangars (Art. 513)

• Motor Fuel Dispensing (Art. 514)

• Bulk Storage Plants (Art. 515)

• Spraying, Dipping, and Coating Applications (Art. 516)

• Health Care Facilities (Art. 517)

Article 501 – Class I, Division Locations

• Special requirements for equipment

• Wiring methods

• Sealing and drainage

• Flexible cords

• Grounding

Slide 37

Slide 38

Section 501.10(A) Wiring Methods, Division 1

• Threaded rigid metal conduit

• Threaded steel intermediate conduit

• Mineral Insulated (MI) cable

• Rigid non-metallic conduit

• encased in 2 in. of concrete, and

• buried under 2 ft. of earth

• Metal Clad (MC-HL) cable

• Listed for Division 1

• gas/vaportight continuous corrugated metallic sheath

• overall polymeric jacket

• separate grounding conductors

Slide 39

Section 501.10(A) Wiring Methods, Division 1

Cont’d

• Instrumentation Tray Cable (ITC-HL)

• Listed for Division 1

• gas/vaportight continuous corrugated metallic sheath

• overall polymeric jacket

• Flexible connections

• only permitted when necessary

• listed flexible fittings

• Intrinsically Safe Wiring – See Article 504

Slide 40

Flexible Connection

Slide 41

MI Cable (Mineral Insulated)

<---- MI Cable

Slide 42

MC-HL Cable Fitting

Slide 43

Section 501.10(B) Wiring Methods, Division 2

• Threaded rigid metal conduit

• Threaded steel intermediate conduit

• Enclosed gasketed busways

• PLTC cable

• ITC cable

• MI cable

• MC cable

•

MV cable

•

TC cable

•

Flexible connections

• flexible metal fittings

• flexible metal conduit

• liquidtight flexible conduit

• extra hard usage flexible cord

•

Non-incendive

Circui

ts

Slide 44

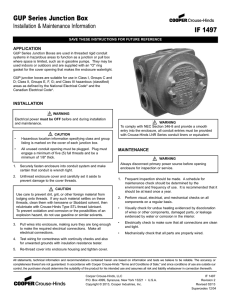

Conduit Seal

Factory Sealed Enclosure

Slide 45

Slide 46

Section 501.15(C) Requirements for Seals

• Seals shall be integral with enclosure or a separate sealing fitting must be provided

• Compound

• resistant to surrounding atmosphere

• melting point of 93º C or greater

• thickness equal to or greater than trade size of conduit but no less than 5/8 inches = 16 mm.

• No splices or taps allowed

• Conductor fill 25% maximum unless approved for greater

Slide 47

Section 501.140 Flexible Cord Cont’d

• Cord must be continuous

• Extra hard usage

• Grounding conductor

• Supported to avoid stress at terminal connections

• Sealed at entry to explosionproof enclosures

Slide 48

Section 501.30 Grounding

• Article 250 provisions apply

• Section 250.100 requires bonding in hazardous locations regardless of voltage

• Locknut bushing and double locknut contacts not acceptable for bonding

Slide 49

Article 504 Intrinsically Safe Systems

• Section 504.10(A)-control drawing

• Section 504.20-wiring methods

• any for unclassified areas permitted

• Section 504.30-separation of conductors

• Section 504.50-grounding

• Section 504.70-sealing

Slide 50

Section 504.30 Separation of Conductors

•

From non-intrinsically safe

• Open wiring- 50 mm (2 inches)

• In raceways-not permitted unless:

- 50 mm (2 in.) separation and secured or partition provided between

- where all conductors of intrinsically safe or nonintrinsically safe are in grounded metal sheathed or metal clad cables where sheathing or cladding is capable of carrying fault current to ground

• Within enclosures - 50 mm (2 in.)

Slide 51

* Thank You For Attending!

For more information on a private or public seminar on this topic or other topics please visit us at: http://www.ulknowledgeservices.com

Or Call

+45 44 85 65 65

UL International Demko A/S

Slide 53