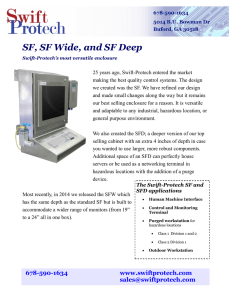

Class 1 Division 1 and Class 2 Division 1 X-Purged - Swift

advertisement

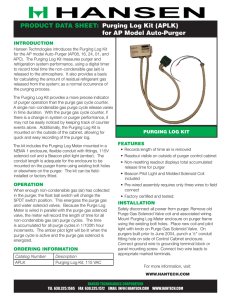

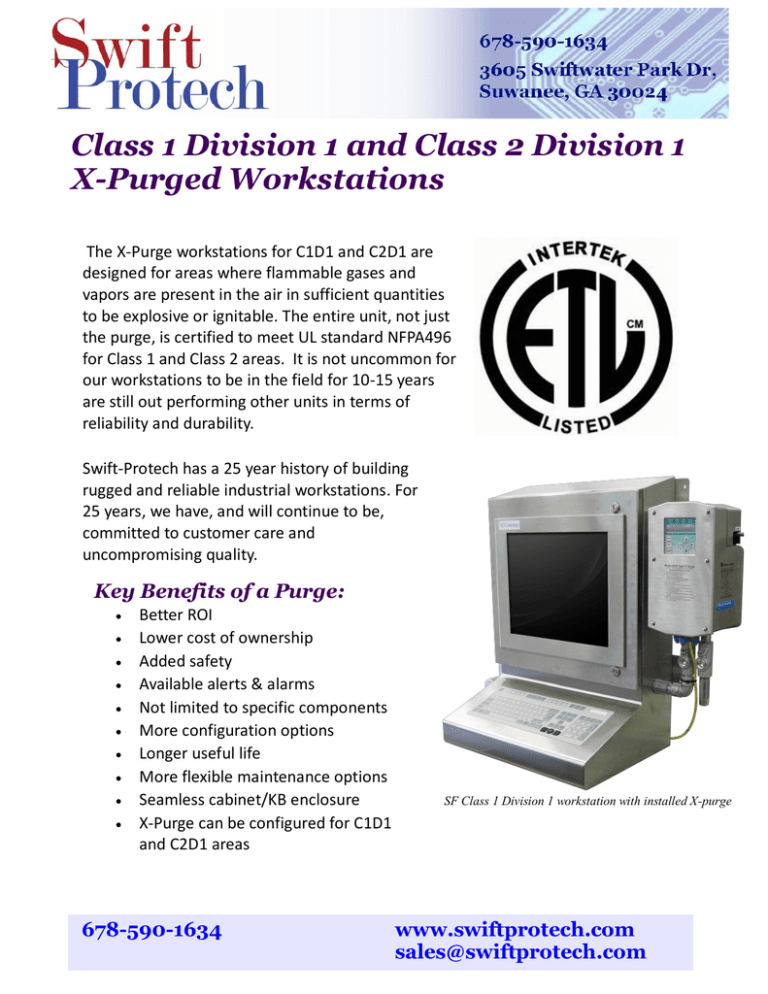

Class 1 Division 1 and Class 2 Division 1 X-Purged Workstations The X-Purge workstations for C1D1 and C2D1 are designed for areas where flammable gases and vapors are present in the air in sufficient quantities to be explosive or ignitable. The entire unit, not just the purge, is certified to meet UL standard NFPA496 for Class 1 and Class 2 areas. It is not uncommon for our workstations to be in the field for 10-15 years are still out performing other units in terms of reliability and durability. Swift-Protech has a 25 year history of building rugged and reliable industrial workstations. For 25 years, we have, and will continue to be, committed to customer care and uncompromising quality. Key Benefits of a Purge: Better ROI Lower cost of ownership Added safety Available alerts & alarms Not limited to specific components More configuration options Longer useful life More flexible maintenance options Seamless cabinet/KB enclosure X-Purge can be configured for C1D1 and C2D1 areas 678-590-1634 SF Class 1 Division 1 workstation with installed X-purge www.swiftprotech.com sales@swiftprotech.com The entire SF system has been tested by a third party to comply with UL standard NFPA 496. This not only acts as a proof of quality but also as a badge of safety and commitment to the highest standards of product excellence. Purge Information The 6000 series purge system reduces the classification within the protected enclosure from Zone 1 and 21 to non-hazardous area. General purpose equipment can be operated within the protected enclosure. Suitable for Class I and II, Division 1/ Zone 1 and Zone 2 and nonhazardous area applications Enclosure sizes up to 250 cubic ft. (7.01 cubic meters) The Type X/ Ex Px system conforms to ATEX, NFPA 496 and ISA 12.4 DEMKO, UL cULus, IEC 61508, SIL 2 Class 1 hazardous locations, according to NFPA 496, is an environment where flammable gas and/or vapors are present during normal operating conditions. Some typical Class I locations are: Petroleum refineries, and gasoline storage and dispensing areas; Dry cleaning plants where vapors from cleaning fluids may be present; Spray finishing areas; Aircraft hangars and fuel servicing areas; and Utility gas plants, and operations involving storage and handling of liquified petroleum gas or natural gas. A Class 2 environment is one where dust which is airborne and can be ignited. Even some substances, which when accumulated are inert, can be flammable when spread through the air. Some common Class 2 environments include: Grain elevators; Flour and feed mills; Plants that manufacture, use or store magnesium or aluminum powders; Producers of plastics, medicines and fireworks; Producers of starch or candies; Spice-grinding plants, sugar plants and cocoa plants; and Coal preparation plants and other carbon handling or processing areas.