Current Technology Integrated vs. Non

advertisement

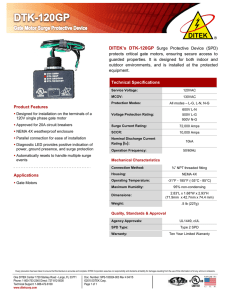

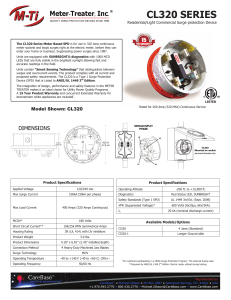

White Paper • CT1003 Integrated vs Non-Integrated By: Chris Martin SPD Product Manager 2 current technology ® Integrated vs Non-Integrated Hard wired surge protection is typically installed two ways, internally or externally to the switch gear. The benefits of internally mounted units have been touted by the panel board manufacturers. This benefits are overstated, as these manufactures sell their own SPD devices. This paper will dispel key benefits of internally installed units and demonstrate the advantages of externally mounted Surge Protection Devices (SPD) units. Shortest Lead Length All SPD manufacturers suggest in their installation instructions to keep the lead length as short as possible, realizing the impact lead length has on the installed performance of surge devices. Per UL 1449 and IEEE C62.45, all surge manufacturers evaluate their products with six inches of lead length. The six inch lead length is chosen so that all SPD products can be evaluated based on the same test setup and criteria. The diagram below illustrates how the test is performed. The surge is injected here Figure 1 Clamping characteristics are recorded by an Oscilloscope The test is performed by providing 6 inches of lead length outside of the enclosure of the unit under test. A surge is applied across a mode, such as line to neutral. The surge current will flow through the phase conductor and travel a path inside the surge device, with any remaining current flowing back through the neutral conductor. An oscilloscope will also be attached across the leads of the mode being tested to capture how the surge unit effectively mitigated the effects of the surge. The lead length of the phase conductor and the lead length of the neutral conductor will both have an impact on the overall performance of the surge device. The key point is that the surge has to travel not only through the line conductor, but also through the neutral conductor. In this example, the surge current travels a minimum of twelve inches; the length of the neutral conductor plus the length of the phase conductor and distances internal to the SPD. Tests have shown that every foot of standard cabling added to the installation length of an SPD increases the clamping levels (or let-through voltage) by as much as 100–150 volts per foot, severely impacting the installed performance of the surge device. This exposure to higher let-through voltages can put the downstream loads at serious risk. Figure 2 tnbpowersolutions.com/current_technology 3 current technology ® Integrated vs Non-Integrated The overall installed system lead length required to install the surge device dictates the let-through voltage capability (or performance) of the installed SPD. An integrated SPD tapped directly to the bus may have very short connections to the phases but the installed clamping levels must also take into account the lead length of the Neutral and Ground conductors that are part of the installation. Most integrated SPDs are installed at the top or bottom of an extended panel board where the Neutral and Ground buses are typically at the opposite end. If you follow the path the surge would have to take, the overall length for this type of installation can be up to six feet or longer, which is a significantly longer lead length than most integrated surge manufacturers mention in their marketing material. The overall lead length for this internally mounted surge protective device will have a negative impact on the installed performance of the surge device. With proper installation, it is possible for an externally mounted SPD to be tapped to the bus or occupy a breaker position close to the Neutral and Ground bus. This provides a shorter overall system lead length, allowing for better clamping performance and a better performing unit than an integrated SPD. Surge Handling Capability Some internally mounted surge protection devices are being listed as Type 2 SPDs to the UL 1449 3rd Edition standard. Type 2 SPDs must be installed behind an upstream, overcurrent protection device because the SPD cannot pass the UL 1449 tests without having the upstream OCPD to remove it safely from the circuit. These devices are relying on the upstream device to trip or open, removing the SPD from the circuit before it fails destructively. If an SPD that is rated at 200kA per mode is installed behind a 30A breaker, the single surge rating of that system will be reduced to the lowest single surge rated component of that installed system. Breaker manufacturers publish an SCCR (short circuit current rating) or kAIC value which is based on how much 60Hz current the device can handle before tripping or opening. Surges are subcycle events and typically last as long as 20 microseconds, so the breakers SCCR rating has no bearing on how it will respond to a surge event. Figure 3 depicts a circuit breaker’s trip and fail kA levels when subjected to an 8 x 20 microsecond wave shape. A 200kA SPD installed behind a 30A breaker would only be able to handle a 62kA surge before the breaker trips and removes it from the circuit. Figure 3 SPD Failures SPD devices have a finite life. In UL 1449 (February, 2007), changes to the safety regulations that pertain to SPDs addressed real world concerns regarding catastrophic failures of SPDs. Prior to the introduction of intermediate fault currents that were included to expose the metal oxide varistor’s weakness to temporary over voltage events, SPDs subjected to a temporary over voltage event would continually conduct and go into thermal runaway, potentially catching fire and causing damage. SPDs internal to the gear that failed in this manner ended up, in most cases, taking out the entire panel. Fortunately UL 1449 was changed to include testing that would ensure this kind of failure does not happen. However even a benignly failed SPD must be repaired or replaced. Replacing any part of an internally mounted SPD device leaves the end user with the following options: Option 1: An internally mounted surge device is typically mounted behind the dead front to the panel. The safest method for repairing or replacing the defective SPD requires shutting (Continued) 4 current technology ® Integrated vs Non-Integrated down the main breaker to the panel, terminating power to all down stream equipment, so that all power is off during the repair or replacement of the internally mounted SPD. Summary Option 2: Leave the failed SPD installed and do nothing. It is common for failed integral SPDs to be left un-repaired because they are attached to a panel feeding a critical load that cannot be shut down, or they are located in common public areas where it would be unsafe to repair or replace them. Option 3: The operator must work on the panel live because critical equipment connected to the panel cannot be shut down. The operator must wear the appropriate personal protective equipment based on equipment ratings and available fault current, which may require the operator to wear tinted glasses, gloves, protective clothing, or a hood. Working on live gear is never a safe option. Statistics based on hospitalization records suggest that every day in the United States, five to ten arc flash events occur that involve a fatality or serious injury to an employee. Internally mounted SPDs do not necessarily offer a better performing system. When taking into consideration the total surge path of the integral SPD, a long neutral or ground connection may have an adverse affect on the installed performance. Internally mounted SPDs may fail in a safe, benign manner, but may require unnecessary exposure to the worker who must repair or replace the unit. Type 2 SPDs must be mounted behind an over current protection device, limiting the overall surge current rating of the installation. Externally mounted SPDs can have lead lengths just as short, if not shorter, than internally mounted SPDs. The repair or replacement of an externally mounted SPD does not require the shut down of the entire panel or unnecessary exposure to live voltage. An externally mounted Type 1 SPD is a more robust offering that does not limit the surge rating of the device by requiring an upstream over current protection device. OSHA and the NFPA are taking arc flash issues very seriously and suggest to all building owners that personnel working on live gear must wear the appropriate protective personal equipment. Externally Mounted SPD Replacement An externally mounted surge unit eliminates the concern for the safety of the operator who must perform the service or repair. If the unit is connected to the panel through a breaker, then the breaker can be turned off that feeds the surge device without disrupting power to the rest of the load. If the unit is equipped with an option integral disconnect, ensure that the line side of the disconnect is covered by a barrier. In each of these scenarios the surge unit can be repaired or replaced without exposing the operator to live voltage and without disrupting power to down stream equipment. Thomas & Betts Power Solutions 5900 Eastport Blvd. • Richmond, VA U.S.A. 23231-4453 USA Tel: (804) 236-3300 • Toll free: (800) 238-5000 • Fax: (804) 236-4841 tnbpowersolutions.com/current_technology © 2011, Thomas & Betts Power Solutions, LLC. • Thomas & Betts Power Solutions, LLC., is a wholly owned subsidiary of Thomas & Betts Corporation (NYSE: TNB). Current Technology® is a registered trademark of Thomas & Betts Corporation • Specifications are subject to change without notice. • Visit our website for latest revisions. 103111