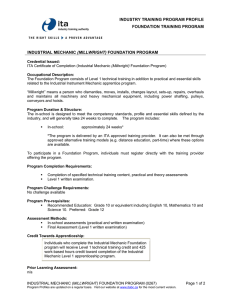

- Industry Training Authority

advertisement