Integrated system for safe and future-proof power

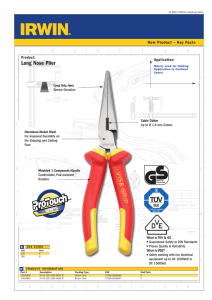

advertisement

etz_sonderdr_lay8-GB 30.07.2004 13:21 Uhr Seite 1 www.moeller.net/xenergy Special Publication Integrated system for safe and future-proof power distribution Authors: Dipl.-Betriebswirtin Jutta Zacharias, Dipl.-Ing. Heinrich Moog With power requirements increasing all over the world and the continued increasing pressure to cut costs, there is an even greater need for secure investments through which efficient planning, assembly, installation and operation are ensured. To meet these requirements, cost-efficient and standardised power distribution systems are needed that customers can adapt to the individual requirements of their projects. In short what is needed is maximum flexibility, economy and reliability. Think future. Switch to green. green Integrated system for safe and future-proof power distribution Jutta Zacharias • Heinrich Moog With power requirements increasing all over the world and the continued increasing pressure to cut costs, there is an even greater need for secure investments through which efficient planning, assembly, installation and operation are ensured. To meet these requirements, cost-efficient and standardised power distribution systems are needed that customers can adapt to the individual requirements of their projects. In short what is needed is maximum flexibility, economy and reliability. Extensive safety requirements and special standards have to be observed in the power distribution sector. The consistent use of the extensive assembly and testing regulations as stipulated by DIN EN 60439-1 (VDE 0660 Part 500): 2000-08 [1, 2] is therefore an important requirement for the reliable and safe operation of a switchgear and controlgear assembly, i.e. a type-tested (TTA) and partially type-tested (PTTA) assembly for power and service distribution boards (DIN EN 60439-3 (VDE 0660 Part 504):2002-05 [3, 4]). In compliance with DIN EN 60204-1 (VDE 0113 Part 1):1998-11 [5, 6] the switchgear and controlgear assembly, or switchboard system for short, can likewise be used as a type-tested/partially low-voltage Jutta Zacharias is head of the Power Distribution business unit at Moeller GmbH in Bonn. e-mail: jutta.zacharias@moeller.net Dipl.-Ing. Heinrich Moog is head of xEnergy product management at Moeller GmbH in Bonn. e-mail: heinrich.moog@moeller.net 2 Picture 1. In the divide between the demand for greater safety, flexibility and load capability on the one hand, and pressure to cut costs on the other, Moeller's switchboard system is a future-proof platform for resultoriented solutions control panel for machines. Apart from the basic assembly and test requirements, the relevant standards and regulations also lay down the safety requirements for electrical equipment, personnel and system protection and also the selection and dimensioning of electrical equipment. The extensive type testing for lowvoltage switchboard systems contains the following seven tests areas: • Limit overtemperature, • Dielectric strength, • Short-circuit current capability, • Efficiency of the protective devices, • Creepage and air clearances, • Mechanical functions, • IP protection. The following functions are tested in the switchgear and controlgear assembly in the degree of protection for the corresponding current class: • Maximum current carrying capacity of the electrical function units, • Switching and protective devices in mechanical and electrical combination with the mounting systems including the main busbars, dropper bars and busbar links, • All system components as integral units in their functional mounting. An additional test is carried out in the protective conductor circuits of the system panels in accordance with IEC/EN 60 439-1, section 8.2.4 - Verification of the effectiveness of the protective circuit with the following tests: • Section 8.2.4.1: Verification of the effective connection between the exposed conductive parts of the assembly and the protective circuit by measurement and • Section 8.2.4.2: Verification of the short-circuit strength of the protective circuit by test. Both tests must be verified by the manufacturer (of each) and are particularly important for personnel protection. The results for the assembly of the switchboard system are documented for practical application by system suppliers, such as in product catalogues; selection and dimensioning documents; assembly manuals; configuration and engineering tools; certification of the completed type tests for the declarations of conformity by the system supplier. The tests therefore guarantee reliable system assembly, as well as verifying the basic features with successfully completed type tests (TTA). At the same time, the reliable functioning of a switchboard system during operation is also verified – an important factor for a future-proof and reliable power supply. TTA/PTTA switchgear assemblies also include those that are engineered and assembled by local panel builders in Heft 7/2004 • xEnergy – in the divide of panel building Moeller's Kit system for the panel builder is a single-source development that has been designed and thought through to meet the needs of the panel builder. xEnergy offers outstanding efficiency, flexibility and stands out with its simplicity and functionality. Technical system features Standards DIN EN 60439-1 (VDE 0660 Part 500) Type testing TTA Internal separation Form 1 to Form 4 Rated operational voltage Ue 690V / 50Hz ... 60 Hz Rated operational current Ie to 4 000 A Rated short-time withstand resistance Icw bis 100 kA (Effektivwert), 1 s Ambient temperature 35 °C (40 °C) to 45 °C (50 °C) Degree of protection IP31/IP55 Network system TN-C / TN-C-S / TN-S / IT Colour RAL 7035 (other colours on request) Dimensions h 2 000 mm basic height without plinth, w 425/600/800/1 000/1 200 mm, d 400/600/800 mm xEnergy – technical data Mounting of Moeller IZM and NZM circuit-breakers up to 4000 A - application benefits: • Clear and symmetrical design with only one circuit-breaker per section reduces the number of busbar connections and saves mounting requirements, • Internal separation up to Form 4 increases personnel and system protection, • Circuit-breaker mounting kits for optimum assembly and packed as a unit, • Fast and direct allocation of mounting kits for the mechanical fastening of circuitbreakers, • High level of flexibility in the terminal area thanks to alternative connection options: Cable terminal system, straps or busbar adapters. Mounting of Moeller switching and protective devices up to 630 A - application benefits: • Max. 38 fixed compartment modules in one section (h = 50 mm), to 40 A • Max. 19 fixed compartment modules in one section (h = 100 mm), to 160 A • Optimum device utilisation despite high packing density • Simple module mounting to Form 2 on one mounting depth, • Flexible module mounting to Form 4 with different device mounting depths, with standard operating front, • Highly flexible combination possible for functional areas and busbars in accordance with EN 60439 (VDE 0660 Part 500) and national installation practice. xEnergy – the new system offer in panel building – application benefits of the optimised system platform up to 4 000 A: • Low number of individual parts and modules, • Suitable for universal use (DIN VDE, IEC, NF [France], UNE [Spain]), • Can be combined flexibly, • Low earth transition resistance for personnel protection, • Efficient selection and configuration using Moeller ConFix • Functionally packed into individual assemblies, supplied as flat pack • Easy and fast to install – 30 minutes per section, • Fully type-tested and designed for future requirements. accordance with binding documents and supplier specifications. The construction of partially type-tested assemblies (PTTA) involves the use of both type-tested and non type-tested functional assemblies. Test certificates • Heft 7/2004 are equally required for PTTAs. These can be provided by means of additional type testing or by the derivation of similar systems from type-tested assemblies. Additional calculations are also required depending on the type of PTTA involved: Short-circuit (DIN IEC 1117 (VDE 0660 Part 509):1993-09 [7, 8]) and temperature rise (IEC/TR 60890). 1987-07 [9]). Future-proof switchboard system – the platform for results-based solutions The project business is defining and shaping the market for low-voltage switchboard systems. End customers require individual solutions for their specific requirements with an optimum price-performance ratio. This kind of financially flexible solution can only be offered by a modular power distribution system that is based on an intelligent platform concept. The divide between ever increasing demands in terms of engineering and safety on the one hand, and cost reduction on the other can only be bridged by means of an innovative generation of switchboard systems (Picture 1). xEnergy – the new power distribution system generation xEnergy, Moeller's new integrated system range, stands for power distribution systems that are specially designed for the building infrastructure up to 4 000 A. Moeller are single-source suppliers of an intelligent system platform for switching and protective devices that panel builders can customise, assemble quickly and handle easily. Based on many years of practical experience in the building of switchgear assemblies, Moeller has developed the latest generation of switchboard systems that incorporates the latest trends and essential features. The individual switching and protective devices, the associated mounting system design and also the switchgear are combined to form one technical unit. This kind of system is both economical and reliable at the same time, as perfectly matched and type-tested functional units have been developed as a modular system. Exactly tailored function modules that have been type-tested in accordance with DIN EN 60439-1 (VDE 0660 Part 500), and available with internal separation from Form 1 to Form 4, comply with national installation requirements (DIN VDE, IEC, NF [France], UNE [Spain]) (Picture 2). The system range consists of: • Feeder and coupling sections for circuit-breakers up to 4 000 A, • Individually equipped outgoer sections with fixed compartment modules for switching and protective devices in- 3 Picture 2. xEnergy XP power sections, XF outgoer sections and XG system section cluding motor starter combinations up to 630 A, • Outgoer sections up to 630 A for switch-fuse strips, fuse rails and fuse switch-disconnectors with different mounting depths, • Control sections and empty sections for ancillary components such as motor starters, PFC modules, frequency inverters, soft starters or for automation solutions, • Mounting systems for rail-mounted service installation devices for conventional service distribution boards up to 630 A. Moeller supplies the full range, functionally packed in individual elements (flat pack) or according to customer requirements as pre-assembled switchboards. The system platform enables panel builders to create individual solutions that can be optimally designed to meet the requirements of the end customer. The basis of this is formed by Moeller's integrative device world. The Moeller system range offers more than the sum of the individual components. For this integrated system platform, Moeller developed components that can be integrated into a technical unit without any problems. Two features included are communication-enabled circuit-breakers and the motor starters with the combination plug connector design. These components illustrate how products can play their part in the reliability and future investment security of a modern switchboard system. None of the components are overdesigned even though the range offers the 4 flexibility required with only a few product types, giving panel builders the required degree of freedom to meet a wide range of customer demands. Open for networked switching and protective devices In the Moeller system, each individual component plays its part in the reliability and future investment security of the power distribution system. The trend towards communication-enabled circuit-breakers is one example of this. Circuit-breakers of Moeller's new NZM device series direct the power to the connected loads and disconnect them in the event, for example, of an overload or short-circuit. These systems are designed for use in system and cable protection, motor protection or selective and generator protection. The core of an NZM - the electronic release- detects the actual currents and determines from this important operating and diagnostics data. This means, for example, that load warnings or overloads can be indicated via the communication system and measures can be initiated in time, before these faults lead to a failure. The wide range of the tripping parameters allows them to be adapted to the loads as required. This also increases selectivity, thus allowing the planned disconnection of individually failed building sections or areas. Current and status monitoring, as well as the remote operation of switches and any possibly connected motor starters, provide the basis for cost-effective load and energy management systems or the cost centre related allocation of the energy used. These new features are made possible by means of the communication functions and the software. The FDT (Field Device Picture 3. xEnergy communicative up to the power management system Heft 7/2004 • Tool) technology here simplifies system integration (Picture 3). Reliable and fast planning Components on their own are not enough. A future-proof planning of low-voltage switchboard systems must be supported and documented with suitable tools – such as for network calculations, dimensioning and configuration. This provides a verifiable guarantee of the quality required for safe and reliable power distribution. Moeller offers a toolbox with this in mind, enabling panel builders to plan and document all their projects simply. This ranges from tools for network calculation, configuration, quotations, system engineering to order handling. The use of manufacturer tools, regardless of the system data involved, allows the switchboard system required to be selected and configured precisely and quickly, in accordance with international requirements (Picture 4). The future xEnergy - the integrated and freely combinable system range - consists of switching and protective devices, the mounting system, the switchboard system including the planning and calculation tools. The Moeller Kit system is ideally tailored for safe and reliable power distribution. Individual projects, either in functional buildings, office and industrial buildings can be implemented quickly and economically. Not only do customers save time, money and space, they also benefit from Moeller's excellent reputation for safety – and without restriction in the entire world of IEC/EN applications. Literature [1] DIN EN 60439-1 (VDE 0660 Teil 500):2000-08 Niederspannungs-Schaltgerätekombinationen – Teil 1: Typgeprüfte und partiell typgeprüfte Kombinationen. Berlin: Beuth [2] IEC 60439-1:2004-04 Low-voltage switchgear and controlgear assemblies – Part 1: Typetested and partially type-tested assemblies. Geneva/ Switzerland: Bureau Central de la Commission Electrotechnique Internationale [3] DIN EN 60439-3 (VDE 0660 Teil 504):2002-05 Niederspannungs-Schaltgerätekombinationen – Teil 3: Besondere Anforderungen an Niederspannungs-Schaltgerätekombinationen, zu deren Bedienung Laien Zutritt haben – Installationsverteiler. Berlin · Offenbach: VDE VERLAG [4] IEC 60439-3:2001-05 Low-voltage switchgear and controlgear assemblies – Part 3: Particular requirements for low-voltage switchgear and controlgear assemblies intended to be installed in places where unskilled persons have access for their use – Distribution boards. Geneva/ Switzerland: Bureau Central de la Commission Electrotechnique Internationale [5] DIN EN 60204-1 (VDE 0113 Teil 1):1998-11 Sicherheit von Maschinen – Elektrische Ausrüstung von Maschinen – Teil 1: General Requirements. Berlin · Offenbach: VDE VERLAG [6] IEC 60204-1:2000-05 Safety of machinery – Electrical equipment of machines – Part 1: General requirements. Geneva/Switzerland: Bureau Central de la Commission Electrotechnique Internationale [7] DIN IEC 1117 (VDE 0660 Teil 509):1993-09 Niederspannungs-Schaltgerätekombinationen – Verfahren zur Ermittlung der Kurzschlußfestigkeit von partiell typgeprüften Schaltgerätekombinationen (PTSK). Berlin · Offenbach: VDE VERLAG [8] IEC/TR 61117:1992-02 A method for assessing the short-circuit withstand strength of partially type-tested assemblies. Geneva/Switzerland: Bureau Central de la Commission Electrotechnique Internationale (ISBN 2-8318-2210-6) [9] IEC/TR 60890:1987-07 A method of temperature rise assessment by extrapolation for partially type-tested assemblies (PTTA) of low-voltage switchgear and controlgear. Geneva/ Switzerland: Bureau Central de la Commission Electrotechnique Internationale (ISBN 2-8213-1346-8) [10] Moeller GmbH, Bonn: www.moeller.net Picture 4. ConFix: xEnergy configuration tool for fast quotation and order processing. • Heft 7/2004 5 etz_sonderdr_lay8-GB 30.07.2004 13:21 Uhr Seite 2 www.moeller.net/xenergy Moeller GmbH Hein-Moeller-Str. 7-11 D-53115 Bonn E-Mail: xenergy@moeller.net Internet: www.moeller.net © 2004 by Moeller GmbH Änderungen vorbehalten VER 4810-941 GB eye Printed in the Federal Republic of Germany (07/04) Artikel-Nr.: 285583 Xtra Combinations Xtra Combinations from Moeller offers a range of products and services, enabling the best possible combination options for switching, protection and control in power distribution and automation. Using Xtra Combinations enables you to find more efficient solutions for your tasks while optimising the economic viability of your machines and systems. It provides: n Flexibility and simplicity n Great system availability n The highest level of safety All the products can be easily combined with one another mechanically, electrically and digitally, enabling you to arrive at flexible and stylish solutions tailored to your application - quickly, efficiently and cost-effectively. The products are proven and of such excellent quality that they ensure a high level of operational continuity, allowing you to achieve optimum safety for your personnel, machinery, installations and buildings. Thanks to our state-of-the-art logistics operation, our comprehensive dealer network and our highly motivated service personnel in 80 countries around the world, you can count on Moeller and our products every time. Challenge us! We are looking forward to it! Think future. Switch to green. green