BioPharm

Volume 28 Number 6

BioPharm International

INTERNATIONAL

June 2015

The Science & Business of Biopharmaceuticals

JUNE 2015

www.biopharminternational.com

Fill/Finish

I

Host-Cell Proteins

SCALE-UP

AND TECH

TRANSFER

ADVANCED

TECHNOLOGIES FACILITATE

THE IMPROVEMENT

OF AGING FACILITIES

I

Biosimilars

Volume 28

Number 6

DOWNSTREAM

PROCESSING

STERILE FILTRATION

TECHNIQUES FOR OPTIMAL

MICROBIAL RETENTION

magenta

cyan

yellow

black

OUTSOURCING

ANOTHER

IN-HOUSE OPERATION

GETS OUTSOURCED

MULTIVARIATE

DATA ANALYSIS

USE OF MULTIVARIATE

DATA ANALYSIS IN

BIOPROCESSING

ES624105_BP0615_cv1.pgs 05.29.2015 18:43

ADV

Every mAb is unique.

Your Protein A should be as well.

TOYOPEARL® AF-rProtein A HC-650F

High Capacity Protein A Resin for Monoclonal Antibody Purification

80

1 g/L

70

DBC for IgG (g/L)

60

5 g/L

10 g/L

Resin:

Column size:

Mobile phase:

Residence time:

Detection:

Sample:

50

40

30

TOYOPEARL AF-rProtein A HC-650F

5 mm ID × 5 cm

0.02 mol/L sodium phosphate, 0.15 mol/L NaCl, pH 7.4

2, 3.5, 5 min

UV @ 280 nm (10% breakthrough)

human IgG @ 1, 5, 10 g/L in mobile phase

20

10

0

2

3.5

5

Residence time (minutes)

TOSOH BIOSCIENCE LLC • Customer service: 866-527-3587 • Technical service: 800-366-4875, option #3

Tosoh Bioscience and TOYOPEARL are registered trademarks of Tosoh Corporation.

www.tosohbioscience.com

magenta

cyan

yellow

black

ES622175_BP0615_CV2_FP.pgs 05.27.2015 20:36

ADV

BioPharm

I N T E R N AT I O N A L

The Science & Business of Biopharmaceuticals

EDITORIAL

Editorial Director Rita Peters rpeters@advanstar.com

Senior Editor Agnes Shanley ashanley@advanstar.com

Managing Editor Susan Haigney shaigney@advanstar.com

Science Editor Randi Hernandez rhernandez@advanstar.com

Science Editor Adeline Siew, PhD asiew@advanstar.com

Community Editor Ashley Roberts aroberts@advanstar.com

Art Director Dan Ward dward@media.advanstar.com

Contributing Editors Jill Wechsler, Jim Miller, Eric Langer,

Anurag Rathore, Jerold Martin, Simon Chalk, and Cynthia A. Challener, PhD

Correspondent Sean Milmo (Europe, smilmo@btconnect.com)

ADVERTISING

Publisher Mike Tracey mtracey@advanstar.com

West/Mid-West Sales Manager Steve Hermer shermer@advanstar.com

East Coast Sales Manager Scott Vail svail@advanstar.com

European Sales Manager Chris Lawson clawson@advanstar.com

European Sales Manager Wayne Blow wblow@advanstar.com

Direct List Rentals Tamara Phillips tphillips@advanstar.com

Reprints 877-652-5295 ext. 121/ bkolb@wrightsmedia.com

Outside US, UK, direct dial: 281-419-5725. Ext. 121

PRODUCTION

Production Manager Jesse Singer jsinger@media.advanstar.com

AUDIENCE DEVELOPmENT

Audience Development Rochelle Ballou rballou@advanstar.com

UBm LIfE SCIENCES

Joe Loggia, Chief Executive Officer Tom Ehardt, Executive VicePresident, Life Sciences Georgiann DeCenzo, Executive Vice-President

Chris DeMoulin, Executive Vice-President Rebecca Evangelou, Executive

Vice-President, Business Systems Julie Molleston, Executive VicePresident, Human Resources Mike Alic, Executive Vice-President,

Strategy & Business Development Tracy Harris, Sr Vice-President

Dave Esola, Vice-President, General Manager Pharm/Science Group

Michael Bernstein, Vice-President, Legal Francis Heid, Vice-President,

Media Operations Adele Hartwick, Vice-President, Treasurer &

Controller

UBm AmERICAS

EDITORIAL ADVISORY BOARD

BioPharm International’s Editorial Advisory Board comprises distinguished

specialists involved in the biologic manufacture of therapeutic drugs,

diagnostics, and vaccines. Members serve as a sounding board for the

editors and advise them on biotechnology trends, identify potential

authors, and review manuscripts submitted for publication.

K. A. Ajit-Simh

Jerold Martin

President, Shiba Associates

Rory Budihandojo

Sr. VP, Global Scientific Affairs,

Biopharmaceuticals

Pall Life Sciences

Director, Quality and EHS Audit

Boehringer-Ingelheim

Hans-Peter Meyer

Edward G. Calamai

VP, Special Projects Biotechnology

Lonza, Ltd.

Managing Partner

Pharmaceutical Manufacturing

and Compliance Associates, LLC

K. John Morrow

Suggy S. Chrai

David Radspinner

President and CEO

The Chrai Associates

Global Head of Sales—Bioproduction

Thermo Fisher Scientific

Leonard J. Goren

Tom Ransohoff

Global Leader, Human Identity

Division, GE Healthcare

Vice-President and Senior Consultant

BioProcess Technology Consultants

Uwe Gottschalk

Anurag Rathore

Vice-President,

Purification Technologies

Sartorius Stedim Biotech GmbH

Biotech CMC Consultant

Faculty Member, Indian Institute of

Technology

Fiona M. Greer

Susan J. Schniepp

Global Director,

BioPharma Services Development

SGS Life Science Services

Fellow

Regulatory Compliance Associates, Inc.

Rajesh K. Gupta

Managing Director

Arlenda, USA

Jean F. Huxsoll

Paula Shadle

Senior Director, Quality

Product Supply Biotech

Bayer Healthcare Pharmaceuticals

Principal Consultant,

Shadle Consulting

Denny Kraichely

UBm PLC

Associate Director

Johnson & Johnson

Stephan O. Krause

Principal Scientist, Analytical

Biochemistry, MedImmune, Inc.

Steven S. Kuwahara

© 2015 Advanstar Communications Inc. All rights reserved. No part of this publication may

be reproduced or transmitted in any form or by any means, electronic or mechanical including

by photocopy, recording, or information storage and retrieval without permission in writing from

the publisher. Authorization to photocopy items for internal/educational or personal use, or the

internal/educational or personal use of specific clients is granted by Advanstar Communications

Inc. for libraries and other users registered with the Copyright Clearance Center, 222 Rosewood Dr.

Danvers, MA 01923, 978-750-8400 fax 978-646-8700 or visit http://www.copyright.com online.

For uses beyond those listed above, please direct your written request to Permission Dept. fax 440756-5255 or email: mcannon@advanstar.com.

UBM Life Sciences provides certain customer contact data (such as customers’ names,

addresses, phone numbers, and e-mail addresses) to third parties who wish to promote relevant

products, services, and other opportunities that may be of interest to you. If you do not want UBM

Life Sciences to make your contact information available to third parties for marketing purposes,

simply call toll-free 866-529-2922 between the hours of 7:30 a.m. and 5 p.m. CST and a customer

service representative will assist you in removing your name from UBM Life Sciences’ lists. Outside

the U.S., please phone 218-740-6477.

BioPharm International does not verify any claims or other information appearing in any of the

advertisements contained in the publication, and cannot take responsibility for any losses or other

damages incurred by readers in reliance of such content.

BioPharm International welcomes unsolicited articles, manuscripts, photographs, illustrations,

and other materials but cannot be held responsible for their safekeeping or return.

To subscribe, call toll-free 888-527-7008. Outside the U.S. call 218-740-6477.

magenta

cyan

yellow

black

Tim Schofield

Vaccinnologist and Microbiologist

Sally Shankland, Chief Executive Officer Brian Field, Chief Operating

Officer Margaret Kohler, Chief Financial Officer

Tim Cobbold, Chief Executive Officer Andrew Crow, Group Operations

Director Robert Gray, Chief Financial Officer Dame Helen, Alexander

Chairman

President, Newport Biotech

Principal Consultant

GXP BioTechnology LLC

Eric S. Langer

President and Managing Partner

BioPlan Associates, Inc.

Howard L. Levine

President

BioProcess Technology Consultants

Herb Lutz

Principal Consulting Engineer

EMD Millipore Corporation

Alexander F. Sito

President,

BioValidation

Michiel E. Ultee

Principal

Ulteemit BioConsulting

Thomas J. Vanden Boom

Vice-President, Global Biologics R&D

Hospira, Inc.

Krish Venkat

CSO

AnVen Research

Steven Walfish

Principal Statistician

BD

Gary Walsh

Professor

Department of Chemical and

Environmental Sciences and Materials

and Surface Science Institute

University of Limerick, Ireland

ES621152_BP0615_003.pgs 05.26.2015 20:53

ADV

BioPharm

I N T E R N AT I O N A L

BioPharm International integrates

the science and business of

biopharmaceutical research, development,

and manufacturing. We provide practical,

peer-reviewed technical solutions

to enable biopharmaceutical professionals

to perform their jobs more effectively.

Contents

Volume 28 Number 6

June 2015

fEATURES

Scale-up and

Tech TranSfer

Advanced Technologies

Facilitate Scale-up and

Technology Transfer

mulTivariaTe

daTa analySiS

Use of Multivariate Data

Analysis in Bioprocessing

global markeT reporT

Market Access

Outlook for Australia

Anurag S. Rathore and Sumit K. Singh

Cynthia A. Challener

The authors review major developments in

use of MVDA in bioprocessing applications.

26

The Australian pharmaceutical

market offers opportunities for

manufacturers despite challenges.

Single-use and modular technologies

are increasingly important to

biopharma scale-up and tech transfer. 20

downSTream proceSSing

Sterile Filtration

Techniques for Optimal

Microbial Retention

Ashley Roberts

Removal of microorganisms is crucial when

working with biologics. Sterile filtration

offers a reliable, safe, and effective way

to ensure product integrity.

24

hoST-cell proTeinS

Host-Cell Protein

Measurement and Control

Fengqiang Wang, Daisy Richardson,

and Mohammed Shameem

This article reviews the definition of HCPs,

risks posed by HCPs, regulatory concerns,

commonly accepted ELISA methods for

HCP measurement and their limitations,

and orthogonal methods available for

HCP characterization.

32

Jill E. Sackman and Michael J. Kuchenreuther

40

TroubleShooTing

Stress and Protein

Instability During

Formulation and

Fill/Finish Processes

Mark Yang

This article reviews factors

that affect protein stability

and strategies to minimize

their impact on product quality.

46

COLUMNS AND DEPARTMENTS

6

From the Editor

Objective, peer-reviewed

papers and technical

articles can help advance

biopharmaceutical

development.

Rita Peters

8

Regulatory Beat

Regulators and industry

seek to streamline and

harmonize oversight of

postapproval changes.

Jill Wechsler

12 Inside Standards

Will biosimilars share

a compendial identity

like generic drugs do?

Randi Hernandez

16 Perspectives on Outsourcing

Biopharma companies on

both sides of the Atlantic

ship more of their assay testing

to outside service providers.

Eric Langer

48 BIO Convention

Exhibitor Guide

49 Product Spotlight

50 mAb Development Update

50 Ad Index

Cover: Maria Toutoudaki/Getty Images; Dan Ward

BioPharm International is selectively abstracted or indexed in: • Biological Sciences Database (Cambridge Scientifc Abstracts) • Biotechnology

and Bioengineering Database (Cambridge Scientifc Abstracts) • Biotechnology Citation Index (ISI/Thomson Scientifc) • Chemical Abstracts (CAS)

• Science Citation Index Expanded (ISI/Thomson Scientifc) • Web of Science (ISI/Thomson Scientifc)

BioPharm International ISSN 1542-166X (print); ISSN 1939-1862 (digital) is published monthly by UBM Life Sciences 131 W. First Street, Duluth, MN 55802-2065. Subscription rates: $76 for one

year in the United States and Possessions; $103 for one year in Canada and Mexico; all other countries $146 for one year. Single copies (prepaid only): $8 in the United States; $10 all other countries.

Back issues, if available: $21 in the United States, $26 all other countries. Add $6.75 per order for shipping and handling. Periodicals postage paid at Duluth, MN 55806, and additional mailing offices.

Postmaster Please send address changes to BioPharm International, PO Box 6128, Duluth, MN 55806-6128, USA. PUBLICATIONS MAIL AGREEMENT NO. 40612608, Return Undeliverable Canadian

Addresses to: IMEX Global Solutions, P. O. Box 25542, London, ON N6C 6B2, CANADA. Canadian GST number: R-124213133RT001. Printed in U.S.A.

4

BioPharm International www.biopharminternational.com June 2015

magenta

cyan

yellow

black

ES621150_BP0615_004.pgs 05.26.2015 20:53

ADV

Perfect timing.

Every time.

Cell banking

done right.

The art of mastering cell bank production requires

expertise, innovation and exquisite attention to detail

where every minute counts. With more than 50 years

of combined experience, our passionate, and often

nocturnal, scientists obsess 24/7 to ensure your cell

banks become masterpieces. To that, we offer you:

• Direct access to your scientist for any question, any time.

www.EurofinsLancasterLabs.com

• Constant

Winner of the CRO Leadership Award for

quality, reliability, productivity and innovation.

oversight and monitoring of your cell banks.

• Continual

troubleshooting and status updates during

expansion.

For the most accomplished service in the industry,

trust our cell bank experts to be on your watch.

Leading experts in:

Chemistry

Biochemistry

Microbiology

magenta

cyan

yellow

black

Global Services:

Molecular &

Cell Biology

Virology

Method Development/Optimization

Validation/Qualification/Transfer

Product Release Testing

Stability Storage & Testing

Raw Materials Testing

Impurities & Residuals Testing

Characterization

Cell Banking

Cell Line Characterization

Viral Clearance

Bioassays

Professional Scientific Services

ES624109_BP0615_005_FP.pgs 05.29.2015 18:54

ADV

From the Editor

Your Insight Can Create Industry Benefits

F

Rita Peters is the

editorial director of

BioPharm International.

Objective,

peer-reviewed

papers and

technical articles

can help advance

biopharmaceutical

development.

DA’s Center for Drug Evaluation and Research (CDER) has been encouraging industry to invest in quality drug production methods and improve

processes, facilities, and equipment. Such advances in processing are built

on an exchange of scientific and technical information.

Players in biopharmaceutical development and manufacturing—from biopharma companies and industry suppliers—have a wealth of scientific and

technical expertise about biopharmaceutical formulation, development, and

manufacturing. Sharing this knowledge—in an objective format—is vital to

the growth and improvement of the biopharma industry.

BioPharm International was founded with the purpose of sharing information about emerging biopharmaceutical development and processing methods, technologies, and practices. With a dedication to providing objective,

informed content, the magazine and www.BioPharmInternational.com are excellent media channels for this information exchange.

Article formats vary from peer-reviewed papers, non peer-reviewed technical

papers, and business-focused articles. The editors welcome contributions from

experts in the biopharmaceutical development community, with these four

key guidelines in mind:

Objectivity. Articles and papers must be based on technical and scientific

fact, supported by references to published literature or data. Marketing-driven

content, unsupported claims, or promotional language are not acceptable in

editorial features.

Originality. Manuscripts are reviewed with the understanding that the

content has not been published previously in any format, including print or

electronic publications, conference proceedings, whitepapers, application

notes, posters, or company-created marketing or sales literature. In addition,

the submission should not be ghostwritten or under consideration for publication elsewhere, including on the Internet.

Ownership. The author must own the rights to the submitted content,

including all images, tables, and figures. Graphics from other sources or thirdparty sources will not be accepted for publication. Before a manuscript is

accepted for publication, all authors must sign a license agreement to provide

BioPharm International permission to publish the original article and its associated figures/tables in print and online. Authors retain the copyright to the

article, as it was originally submitted.

On topic. The editors seek objective articles on technical and regulatory

subjects including upstream processing functions of protein expression, fermentation and cell culture; downstream processing including separation and

purification; process development; drug formulation and delivery; validation;

GMP compliance and quality control; analytical technologies; scale-up strategies; and facilities design. The magazine also covers business topics such as

supply-chain management, sourcing and outsourcing, project management,

partnerships, and intellectual property management.

How to contribute

If you have an important technical, regulatory, or process improvement

topic to share with peers in the industry, I encourage you to share it through

BioPharm International. To learn more about contributing a peer-reviewed or

technical article, view www.BioPharmInternational.com/contribute and review

the author’s guidelines and editorial calendar. Then, send me a message or give

me a call. I would be happy to discuss your ideas for contributions. ◆

6

BioPharm International www.biopharminternational.com June 2015

magenta

cyan

yellow

black

ES621140_BP0615_006.pgs 05.26.2015 20:51

ADV

Cell Line Development in CHO, NS0 & Sp2/0

with enhanced PQA assessment for biosimilar development

Enhanced PQA assessment

Continuous assessment of product quality attributes

(PQA) during cell line development helps ensure

biosimilars retains the desired product characteristics and

function, avoiding redevelopment costs and delays to the

market. PQA assessment includes:

• Product integrity

• Product activity

• Product aggregation

• Product glycan pro7ling

• QC testing

Antitope ofers CHO, NS0 and Sp2/0

biosimilar cell line development

programmes with bespoke quality

assessment tailored to individual projects

Meeting modern expectations

Efcient production is key to biosimilar development and

Antitope has developed technologies such as Composite

CHOTM and pANT vectorsTM to ensure key cell line

development requirements can be met, including:

• High expression levels of your antibodies or proteins

• Free of animal derived products throughout the

process in a chemically de7ned medium

• Management of transfer to a GMP facility for a

smooth transition to scale-up

Visit www.antitope.com/cell-line-development

magenta

cyan

yellow

black

ES622151_BP0615_007_FP.pgs 05.27.2015 20:31

ADV

Regulatory Beat

Quality Systems Key to Lifecycle Drug Management

Regulators and industry seek to streamline and

harmonize oversight of postapproval changes.

T

he submission and review of manufacturing supplements is costly and time

con su m i ng for biopha r mace ut ic a l

companies and for regulatory authorities in

all regions, and a concerted effort is underway

to devise more efficient approaches. There’s

renewed support for developing an international

quality standard for regulating postapproval

changes. And new policies and procedures at

FDA aim to streamline oversight of manufacturing changes for firms that adopt modern production methods able to ensure the continued

safety and efficacy of products after alterations

in systems, formulations, or test methods. These developments reflect the struggle for

regulators trying to review thousands of supplements, and for manufacturers implementing

changes in products and manufacturing facilities around the world. Pfizer is involved with

some 24,000 postapproval changes a year for

its 30,000 products, noted vice-president Roger

Nosal at the April 2015 CMC Workshop sponsored by the Drug Information Association (DIA). FDA officials have long proposed that manufacturers implementing quality-by-design (QbD)

approaches and quality controls should be able

to manage postapproval changes with

less regulatory oversight. This goal

has not been realized, though, as seen

in a continued rise in manufacturing supplements that require agency

approval, and in multiple drug shortages linked to low quality manufacturing operations. T he rev iew of ma nu fac t u r i ng

supplements by the Center for Drug

Evaluation and Research (CDER)

Jill Wechsler is BioPharm has increased over the past decade,

International’s Washington editor, partly due to the practice of “lockchevy chase, Md, 301.656.4634, ing in” an applicant’s manufacturing

jwechsler@advanstar.com. process before it is fully optimized.

8

Field inspection is not connected to knowledge

gained from product review, and there can be

a significant disconnect between clinical batch

data and commercial production.

CDER’s new Office of Pharmaceutical Quality

(OPQ) seeks to tackle these problems through

more seamless integration of review, inspection,

and surveillance throughout the product lifecycle, commented OPQ deputy director Lawrence

Yu at the DIA workshop. The goal for OPQ is to

ensure that all new and generic drugs meet the

quality standards and clinically relevant specifications through pre- and post-approval. Robert

Iser, senior scientific advisor in OPQ’s Office

of Process and Facilities (OPF), acknowledged

that confusion over the level of detail needed to

support postapproval changes leads to unnecessary submission of supplements and discourages

continual improvement in drug manufacturing

processes. OPF acting director Christine Moore noted

that differing change filing requirements

among multiple health authorities are costly

and discourage adoption of “continual improvement” models. She emphasized the importance

of appropriately evaluating the potential risks

of changes and of rewarding responsible quality management by allowing manufacturers to

make changes under quality systems with little

or no prior approval. More guidance

Manufacturers have been looking for FDA to

streamline the post-approval change process

by “down-regulating” reporting requirements

for low-risk changes. Industry seeks a “do-andtell” approach that permits companies to make

changes and then list them in annual reports

or in changes-being-effected (CBE) supplements.

FDA issued a guidance in March 2014 that sought

to expand the range of manufacturing changes

BioPharm International www.biopharminternational.com June 2015

magenta

cyan

yellow

black

ES621667_BP0615_008.pgs 05.27.2015 01:32

ADV

A critical control

parameter is down.

Technician || Don R. || 4:31 PM

Is Incyte still online?

Sent 4:35 PM

Yes and cells are

growing as expected.

Technician || Don R. || 4:38 PM

Then we are OK to

keep running!

Sent 4:41 PM

Detect Process Deviations

Incyte Measures Viable Cell Density in Real Time

Incyte is insensitive to media changes, microcarriers,

dead cells and floating debris. It can be used to monitor

changes in cell physiology, cellular respiration, viral infection

timing, automated harvesting and much more.

Learn more at www.ham-info.com/0996

ELECTRIC

FIELDS

PLATINUM

ELECTRODES

VIABLE

CELLS

POLARIZE

DEAD CELLS HAVE DAMAGED

MEMBRANES AND

DO NOT POLARIZE

1-888-525-2123

www.hamiltoncompany.com

© 2015 Hamilton Company. All rights reserved.

magenta

cyan

yellow

black

ES622148_BP0615_009_FP.pgs 05.27.2015 20:31

ADV

regulatory Beat

that can be documented in annual

reports, but the list was fairly limited, and industry has found it

inconsistent and confusing (1).

In most situations it’s easier to

design a new drug than to update

existing analytical methods and

tech nolog y, noted Ga napat hy

Mohan, head of global CMC at

Merck, Sharp and Dohme. Global

approva l of a ma nu fac t u r i ng

change can take more than five

years, he said, and changing a polymer supplier or reformulating an

oral solution can be complex, particularly for products manufactured

at multiple sites that have to meet

differing regulatory requirements. FDA officials plan to try again

to offer regulatory relief in filing

supplements and also in undergoing plant inspections for those

biopharma companies that implement QbD and advanced manufacturing technologies. New draft

guidance is expected this year that

will clarify which elements of an

application are considered “established conditions” (or regulatory

commitments) and should help

manufact urers manage postap proval changes in a general way.

FDA also hopes to revise guidance

on providing CMC information

in comparabilit y protocols for

approved drugs to encourage adoption of innovative test methods

and new approaches to change

management. HarMonizing cHanges

Regulatory authorities and manufac t urers also are collaborating through the International

Conference on Harmonization

(ICH) to produce a new Q12 quality standard for managing postapproval manufacturing changes

over the lifecycle of drugs and

biologics. An ICH expert working group discussed a Q12 concept paper in Lisbon, Portugal

in November 2014, and a more

detailed proposal is scheduled

10

for further discussion at the June

ICH steering committee meeting

in Japan. The aim is to publish a

document by June 2016 that builds

on other ICH quality guidelines

to strengthen quality assurance

through harmonized management

of post-approval CMC changes. Agreement and publication of

Q12 is a high priority for both

i ndust r y a nd reg u lator s, sa id

M o h e b N a s r, v i c e - p r e s i d e n t

for CMC regulatory strateg y at

GlaxoSmithKline, a former FDA

official and rapporteur for the

Q12 working group. Nasr observed

at the DIA workshop that lack of

agreement on change management

regulation has inhibited continual

improvement and manufact uring innovation and has increased

reg ulator y work loads for both

industry and authorities. While

previous ICH quality standards

have focused on using science- and

risk-based approaches in new drug

development, the Q12 document

aims to address more directly the

commercial manufacturing phase

of lifecycle product management. A more flexible change management approach has been encouraged in the European Union as part

of an effort to reduce “variations”

that require prior approval, pointed

out Jean-Louis Robert, head of the

pharmaceutical chemistry unit at

the National Health Laboratory in

Luxembourg. Many minor changes

can be implemented under a doand-tell approach, while manufacturers contemplating more complex

changes over the product lifecycle

are encouraged to prepare a postapproval change management protocol (PACMP) to accelerate and

gain more predictability in regulatory response. PACMPs may be

appropriate for certain changes to

biological products, such as adding a new cell-culture facility, and

should be most useful for drugs

developed using QbD principles,

Robert commented. LifecycLe revieW at fda

In the US, the new OPQ structure

aims to better combine oversight

of drug development with postapproval changes to achieve a more

seamless adherence to quality standards throughout the life of a drug

or biotech therapy. OPQ’s Office

of Lifecycle Drug Products (OLDP)

now is responsible for assessing

post-approval changes for new

drugs and generic drugs, as well

as CMC submissions for generic

dr ugs. The plan is for reviewers in OPQ’s Office of New Drug

Products (ONDP) to hand off to

OLDP oversight of new molecular

entities (NMEs) after three years,

and for standard new drugs after

one year. This plan will allow the

original reviewers to evaluate initial

scale-up and formulation changes

for more innovative products. Postapproval changes for biotech therapies will continue to be managed

by OPQ’s Office of Biotechnology

Products.

A smooth hand-off from new

drugs to lifecycle is important,

commented ONDP acting director Sarah Pope-Miksinski, as is

close collaboration with Moore’s

OPF to ensure parity in oversight

of changes involving drug process,

facility, and sterility. OPF evaluates drug manufacturing process

design and controls for commercial production and participates in

pre-approval inspections to ensure

appropriate implementation of

control strategies (2). references

1. FDA, Guidance for Industry, CMC

Postapproval Manufacturing Changes To

Be Documented in Annual Reports

(CDER, March 2014), www.fda.gov/

downloads/Drugs/GuidanceCompliance-RegulatoryInformation/

Guidances/UCM217043.pdf.

2. More information on OPQ operations

provided in CDER “Pharmaceutical

Quality Oversight” report, April 2015,

www.fda.gov/downloads/AboutFDA/

CentersOffices/OfficeofMedicalProductsandTobacco/CDER/

UCM442666.pdf. ◆

BioPharm International www.biopharminternational.com June 2015

magenta

cyan

yellow

black

ES621668_BP0615_010.pgs 05.27.2015 01:32

ADV

BD Media Solutions

End-to-End Services and Support – from Research Through Commercialization

In bringing biologics

to market today,

Time, Cost and Quality

are a constant juggle.

Let us keep your process

development running smoothly.

As leaders in customizable media solutions, BD has the expertise to define the unique drivers in your cell

culture to allow for consistency in your biopharmaceutical development process. Combining this experience

with our proven methodology and analytical capabilities, our Media Enrichment, Media Design, and

Media Bioproduction Services provide a variety of solutions to meet your timeline and budget needs.

BD’s Media Enrichment Services include a supplement screening, base medium enhancement, and feed

strategy development, while our Media Design Services feature a comprehensive media library panel screen,

full base medium design and full base medium design and feed development. BD’s Scalable Bioproduction

Media Solutions offer rapid media development, pilot media production and GMP custom media production.

To learn more about BD’s Media Solutions, please call

877-272-7191 or go to www.bdbiosciences.com/advbio

BD and BD Logo are trademarks of Becton, Dickinson and Company. ©2015 BD.

magenta

cyan

yellow

black

BD

7 Loveton Circle

Sparks, MD 21152

bdbiosciences.com/advbio

ES623798_BP0615_011_FP.pgs 05.29.2015 01:29

ADV

Inside Standards

What’s In a Name? For Biosimilars, A Lot

Will biosimilars share a compendial identity like generic drugs do?

T

NamiNg for small-molecule drugs

BioPharm: What is current practice for smallmolecule generic drugs in terms of a product’s

name and its monograph? How do monograph

and name typically relate?

USP: USP’s mission is to improve global

health through public standards and related

programs that help ensure the quality, safety,

and benefit of medicines and foods. Our flagship compendia of public standards—United

States Pharmacopeia–National Formulary (USP–

NF)—play a key role in the adulteration and

misbranding provisions of US federal food and

drug law.

International Nonproprietary Names (INNs)

are given to most drugs early in the

Randi Hernandez is science editor d r ug- development process, even

at BioPharm International. though many of these drugs never

12

BioPharm International

magenta

cyan

yellow

black

www.biopharminternational.com

Whenever two products

share the same compendial

identity, they are covered

by the same monograph.

make it onto the market. The INN is established

by the World Health Organization’s expert

group on nonproprietary names. In the United

States, the United States Adopted Names Council

(USAN) next names medicinal articles, usually

also well before approval. When FDA approves a

product, it assigns an interim established name,

and generally (but not always) follows the USAN

name. While USP provides expert representation

in both INN and USAN deliberations, USP’s role

in naming comes into play after approval of a

drug, when a USP monograph is developed and

is given an official title, which then becomes the

established name for that drug.

Small-molecule generic drugs fall under the

same USP monograph and must use the same

name as the innovator product (assuming a

monograph exists for that product) because they

share the same compendial identity. Whenever

two products share the same compendial identity (meet the same identification tests and other

aspects of identity in the monograph), they are

covered by the same monograph—understanding

that the monograph tests and acceptance criteria

describe a subset of the quality attributes of the

articles in question and do not make a statement

about their regulatory status, clinical attributes,

or interchangeability, all of which are for FDA

to determine. Once a product is determined to

share the same identity as a drug recognized in

the compendium (a drug for which there is an

existing monograph), it is required to use the same

123render/E+/Getty Images

here is still some uncertainty surrounding whether a biosimilar will share the

same compendial identity—or biological

product monograph—as its reference product.

It has been reported that FDA determined that

the United States Pharmacopeial Convention’s

(USP’s) monograph for filgrastim does not apply

to the first-ever approved biosimilar product,

Zarxio (filgrastim-sndz). This determination

may ultimately factor into future FDA policy

or guidance documents on biosimilar naming.

While FDA and USP work closely on nomenclature policy, “USP naming is not directly implicated under either USP rules, or Federal law,

until a compendial standard applies to an article,” according to presentation notes from USP,

and “shared compendial identity does not necessarily imply or mandate an FDA determination

of sameness or interchangeability” (1). BioPharm

International spoke to USP to find out a bit more

about how the naming process for a drug occurs

and who truly will have the final say when it

comes to biosimilar nomenclature.

June 2015

ES621370_BP0615_012.pgs 05.26.2015 23:04

ADV

Performance. Consistency.

Homogeneity.

Cellvento™ CHO chemically

defined cell culture media.

Selecting the right medium for your cell line can

be challenging. With Cellvento™ CHO chemically

defined cell culture media, we now offer a

platform of media and companion feeds that

deliver superior cell growth and productivity for

recombinant CHO suspension cells. Our milling

and mixing expertise provides excellent powder

homogeneity and consistency for our products.

Comprehensive regulatory information on the

manufacture, characterization, and control of

our media greatly simplifies your registration

processes. The products are available in powder

and liquid form for use in batch and fed-batch

mode or perfusion applications.

For more information, visit:

www.emdmillipore.com/cellvento

EMD Millipore Corp. is a subsidiary of

Merck KGaA, Darmstadt, Germany

EMD Millipore and the M mark are registered trademarks of Merck KGaA, Darmstadt, Germany.

Cellvento is a trademark of Merck KGaA, Darmstadt, Germany.

© 2015 EMD Millipore Corporation, Billerica, MA, USA. All rights reserved.

magenta

cyan

yellow

black

ES622485_BP0615_A13_FP.pgs 05.27.2015 23:32

ADV

Be a superhero.

You can with our unmatched

chromatography portfolio.

Process scale chromatography can be challenging –

even for a superhero. But with the broadest portfolio

of chromatography resins, columns, and unparalleled

support from Merck Millipore, you can make it happen.

Whether you’re tackling higher and higher titers, racing

the clock, or conquering bottlenecks, we can help

you be the superhero.

Affinity. Ion Exchange. Reversed Phase. Expertise.

Your cape is waiting at

www.merckmillipore.com /chromatography

Learn more about our new

Chromabolt® prepacked columns at:

www.merckmillipore.com/Chromabolt

Merck Millipore, the M logo and Chromabolt are registered trademarks of Merck KGaA, Darmstadt, Germany. © 2015 EMD Millipore Corporation, Billerica, MA USA. All rights reserved. PS-SBU-13-09113. 2/2015

magenta

cyan

yellow

black

ES624282_BP0615_B13_FP.pgs 05.29.2015 21:34

ADV

Inside Standards

monograph title (the official title) as

its non-proprietary name, unless FDA

chooses to establish a different name

via regulation. Conversely, if a drug

does not share the same identity as a

drug recognized in the compendia, it

must use a ‘clearly distinguishing and

differentiating name.’ For details, see

21 Code of Federal Regulations 299.5.

Name deSIgNatIoN

BioPharm: Who has the final

say when it comes to naming?

USP or FDA?

USP: FDA has the final say, but

only if it chooses to establish a name

via notice and comment rulemaking. Under section 502(e) of the Food

Drug and Cosmetic Act (FDCA), a

drug is misbranded if its label does not

include the ‘established name’ of the

drug and of each ingredient. Section

502(e) specifies that the ‘established

name’ of a drug or ingredient is:

(A) The official name designated by

FDA in accordance with section

508 of the FDCA;

(B) The official title used for the

drug or ingredient in an official compendium such as USP or

NF, if FDA has not designated a

name under; or

(C) If no name has been established

under (A) or (B), the common

or usual name of the drug or

ingredient.

Under this provision, unless FDA

has designated an ‘official name’

under section 508, the ‘official title’

used in the USP–NF becomes the

established name. In order to designate an official name under section

508, FDA must go through a multistep process including rulemaking,

and it has never done so. Recent case

law confirmed that while FDA might

assign a name upon drug approval,

this name is considered an ‘interim’

established name until an established

name is provided in the USP–NF.

(Novartis v. Leavitt, 435 F.3d 344) (2).

BioPharm: Will naming conventions for biosimilars merely be suggestions, or will they be enforceable by law?

14

BioPharm International

magenta

cyan

yellow

black

USP: The statutory and regulation

provisions described previously relating to naming apply the same way

to biosimilars as they do to other

drugs, and USP’s role in establishing

standards and names for products

similarly is the same with respect to

biosimilars as it is for other drugs.

USP has no role in enforcement,

which falls under the purview of

FDA and other regulatory bodies.

BioPharm: How will the naming of a biosimilar interplay with an

innovator product’s monograph?

USP: As stated previously, if two

products share the same compendial identity, they must use the same

monograph title as their nonproprietary name. This is true for all drugs

regardless of their regulatory status;

as noted previously, compendial

identity speaks to common quality

attributes and does not make any

statement about regulatory status.

RefeReNceS

1. M.B. Van Hook, “Role of USP Quality

Standards in the Nonproprietary Naming

of Biologic Drugs,” webinar on Biosimilar

Naming & Substitution through FDLI–

Food and Drug Law Institute, March

10, 2014, www.fdli.org/docs/defaultdocument-library/combinedvan-hooknaming-slides.pdf?sfvrsn=0, accessed

April 10, 2015.

2. Novartis v. Leavitt, 435 F.3d 344 (2006),

www.gpo.gov/fdsys/pkg/USCOURTScaDC-04-05414/pdf/USCOURTScaDC-04-05414-0.pdf, accessed April

13, 2015. ◆

The Alliance for Health Reform Hosts Expert Panel on Biosimilars

The Alliance for Health Reform hosted an event on the topic of biosimilars on May

20, 2015 featuring panelists from FDA, Amgen, and Hospira. The presentations at

the meeting centered specifically around naming, extrapolation, and the coding and

reimbursement of these biologic products.

There is concern that the unique naming of a biosimilar will put it at a disadvantage

to innovator products, said Sally Howard, JD, deputy commissioner for policy,

planning, and legislation at FDA at the event. She said a naming policy from FDA

will be released in late 2015, but reminded the audience that levers outside of FDA

control—such as payers, formularies, and state pharmacy substitution laws—could

influence biosimilar adoption as well. Sumant Ramachandra, MD, PhD, senior

vice-president and chief scientific officer of Hospira, said that Hospira supports

the use of the same international non-proprietary name (INN) for biosimilars, and

that the use of unique INNs would add more complexity and is “not recommended.”

Pharmacovigilance can exist in the absence of unique INNs, Ramachandra said; this

has already been the case in European markets.

When asked by an audience member if INNs should apply retrospectively, Howard

said this issue is something FDA is struggling with and is the reason “why you don’t

see a naming guidance out yet.”

While Geoff Eich, executive director, external affairs for Amgen Biosimilars said,

“I don’t need the reference product to have a change in its name,” Ramachandra

commented, “if there is going to be a change of policy, it should encompass the field.”

He said that if additional qualifiers for biosimilars are added, to keep the field “even

and competitive,” reference products should have qualifiers as well.

When it comes to naming, a major concern is how a biosimilar will be identified

when there are adverse events. Eich said that pharmacists report 5% or less of

adverse events to FDA and that a disproportionate majority of reporting is from

patients or other healthcare providers. Eich said that accurate patient histories are

a must, and that early adoption of biosimilars will rely on “credible transparent data.”

–Randi Hernandez

www.biopharminternational.com

June 2015

ES621712_BP0615_014.pgs 05.27.2015 01:59

ADV

Emergent Contract Manufacturing:

Enhancing Life in Every Single Dose

Pre-Clinical

Development

BDS

Manufacture

Lyo Cycle

Development

Emergent BioSolutions has a proven

track record as a world-class provider

of contract manufacturing services for both

bulk drug substances and sterile injectable

drug products. Our team has successfully

launched 20 commercial products and

developed/manufactured over 200

clinical candidates for our clients.

Aseptic

Fill/Finish

Clinical

& Commerical

Emerging Capability

State-of-the art fexible single-use facility

enables turnkey upstream and downstream

solutions for clinical and commercial scale

biopharmaceutical drug development.

info_contractmanufacturing@ebsi.com | 1 800 441 4225 | emergentcontractmanufacturing.com

magenta

cyan

yellow

black

ES623789_BP0615_015_FP.pgs 05.29.2015 01:29

ADV

Perspectives on Outsourcing

Another In-House Operation Gets Outsourced

Biopharma companies on both sides of the Atlantic ship

more of their assay testing to outside service providers.

16

BioPharm International

magenta

cyan

yellow

black

www.biopharminternational.com

tr y cited “analy tical testing: other bioassays.” This percentage was double the share

of respondents indicating they expect greater

levels of fill/finish outsourcing (19.7%), the

next highest activity in terms of future outsourcing growth. Beyond assay testing and

fill/finish, other activities in the top five for

f uture outsourcing activit y include downstream process development, validation services, and API biologics manufacturing (see

Figure 1).

Bioassay testing stands out

relative to 24 other common

bioprocessing activities.

Furthermore, of the 10 most popular activities projected for future outsourcing growth,

only three were cited by a higher share of

respondents in 2015 compared to 2014. Aside

from bioassay testing (40.9% vs. 33.9% in

2014), the others were cell-line development

and upstream process development, each

with only slight increases. In other words,

while enthusiasm for outsourcing appears to

have flattened out for most activities, it’s still

going strong for analytical testing of bioassays.

Most likely, this may be the result of continued outsourcing of analytical methods

based on the need to have costly, high-maintenance equipment in almost constant operation, as well as the need for specialized staff

able to run the assays and prepare the requisite regulatory filings, which may occur only

intermittently.

Don Farrall/Getty Images

A

number of recent workforce surveys

have shown that professional workers are continuing to put in longer

hours. The Great Recession is partly to blame;

professional workers were laid off, and those

remaining today continue to do the work of

two or more. But as the global economy has

improved, the number of employees has not. Therefore, to get the needed productivit y,

outsourcing is becoming a standard strategy. Biopharmaceutical manufacturers

already outsource plenty of activities, and

they’re clearly indicating this trend is not

likely to be reversed. According to BioPlan

Associates’ 12th Annual Report and Survey of

Biopharmaceutical Manufacturing Capacity and

Production (1), the push to outsource is being

institutionalized. Non-core functions, such

as assay testing, are a bellwether: Once again,

the industry has voted this activity the most

likely to be dumped.

Each year, BioPlan’s survey brings in more

than 200 qualified biopharmaceutical manufacturers who share their perspectives on

market trends and opportunities. Back in

2012, the survey showed a large jump in the

share of survey respondents who

projec ted sig n if ica nt ly g reater

levels of outsourcing of bioassay

testing. Since then, this has consistently ranked as the top area of

projected outsourcing increases.

In the 2015 sur vey, however,

bioassay testing stands out relative to 24 other common bioprocessing activities. Indeed, when

respondents were asked which

Eric Langer is president of activities will be outsourced at

BioPlan Associates, sig n i f ic a nt ly h ig he r le ve l s at

tel. 301.921.5979, t hei r fac i l it y du r i ng t he ne xt

elanger@bioplanassociates.com. 24 months, 40.9% of the indus-

June 2015

ES621711_BP0615_016.pgs 05.27.2015 01:59

ADV

Predictable process scaling.

Xcellerex™ bioreactor platform.

Xcellerex XDR systems offer the benefits of single-use technology in a stirred-tank

bioreactor design. Developed for scalability and robustness, the XDR platform

provides the performance and flexibility needed from process development to

large-scale biopharmaceutical manufacturing.

upstream

downstream

single-use

services

When you need a flexible and scalable cell culture solution, we are a partner

like no other.

GE works.

www.gelifesciences.com/BioProcess

GE and GE monogram are trademarks of General Electric Company. Xcellerex is a trademark of General Electric Company or one of its subsidiaries.

© 2014 General Electric Company - All rights reserved. First published Oct. 2014.

GE Healthcare Bio-Sciences AB. Björkgatan 30, 751 84 Uppsala, Sweden

29-1333-79 AA 10/2014

magenta

cyan

yellow

black

ES622150_BP0615_017_FP.pgs 05.27.2015 20:31

ADV

Perspectives on Outsourcing

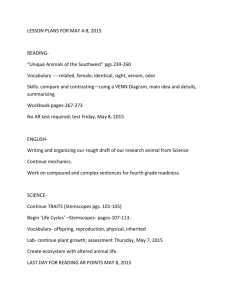

Figure 1: Selected activities: Future outsourcing growth.

Outsourcing activities projected to be done at

‘signifcantly higher levels’ in future

“Which activities will be done at signifcantly higher levels

at your facility over the next 24 months?”

(Where will the greatest changes occur? - % Indicating)

40.9%

Analytical testing: Other bioassays

Fill/Finish operations

19.7%

API biologics manufacturing

16.7%

Validation services

16.7%

Downstream process development

Cell line development

16.7%

15.2%

Figure 2: Average percentage of activity outsourced.

Estimated average percentage of activity outsourced

by facilities

“How much outsourcing of the following activities is done by your facility today?”

(Approx percent of activity currently outsourced)

34.5%

Fill/Finish operations

27.2%

Analytical testing: Other bioassays

26.1%

Testing: Toxicity testing

22.4%

Plant maintenance services

18.5%

API biologics manufacturing

US vS. EUrOPEAn

OUtSOUrcing Of ASSAyS

Staffing requirements may be a

larger influence in Europe than

in the United States. In the 2014

study, Western European respondents were twice as likely as US

respondents to report difficulties

in hiring high-tech assay staff

(15.8% vs. 7.3%) at their facilities. Perhaps it’s not a coincidence

that in the 2015 survey, European

respondents were pa r t ic u la rly

enthusiastic about future outsourcing of assay testing, at almost four

times the rate of any other activity.

While this activity was also projected for future increases by the

largest proportion of US respondents, it didn’t distance itself from

the pack at nearly the same level.

18

BioPharm International

magenta

cyan

yellow

black

Future increases in outsourcing

of assay testing may also be due

to most companies currently only

outsourcing this activity to a minor

degree (see Figure 2). While assay

testing is again the most commonly outsourced activity, it tends

to be outsourced at fairly low levels in relation to other activities. A

look at the five most commonly

outsourced activities reveals that:

• Approximately 86% of respondents are outsourcing analytical testing of other bioassays

to some degree, and an average

of 27% of these operations are

outsourced.

• 73% are outsourcing validation services, with an average

of 18% of this activity being

outsourced.

www.biopharminternational.com

• An equal 73% are outsourcing

some fill/finish services, but

with these respondents estimating outsourcing an average of

35% of these operations overall.

• Some 72% outsource toxicity

testing, for an average of 26%

outsourced. T he s e r e s u lt s i nd ic ate t h at

while toxicit y testing is a less

commonly outsourced activ it y,

it is outsourced on average to

almost the same degree as assay

testing. Meanwhile, more than

one-third of facilities’ fill/finish

operations are currently being

outsourced, despite nearly threequarters outsourcing this activity

to some degree.

While toxicity testing

is a less commonly

outsourced activity,

it is outsourced on

average to almost

the same degree

as assay testing.

As such, the increase in future

assay testing outsourcing may be

the result of those already outsourcing this activity planning

to do so at higher levels in the

future.

trEndS in OthEr

OUtSOUrcing ActivitiES

The BioPlan survey shows that

the popularity of some outsourcing activities has flattened out, a

fairly understandable result given

the extent of growth witnessed

in recent yea rs. Some notable

June 2015

ES621713_BP0615_018.pgs 05.27.2015 02:00

ADV

Perspectives on Outsourcing

declines in terms of outsourcing popularity

include toxicity testing (72% outsourcing to

some degree, down from 87% in 2014) and

fill-finish operations (73%, down from 80%

in 2014). Still, higher proportions of respondents this year reported having outsourced

activities including:

• contract research–laboratory

(66%, up from 59%)

• project management services

(52%, up from 43%)

• downstream process development

(41%, up from 36%).

In terms of outsourcing levels, most activities appear to be outsourced to a slightly

lesser degree in 2015, with the only standouts

in terms of decreased levels being toxicity

testing (26.1% of these activities on average

being outsourced, down from 35.4%) and cell

line stability testing (13.4% on average, down

from 19.6%). Nevertheless, for the most part,

reported levels of outsourcing are in the range

set in prior years.

level of spending increase, though most of those will

be limiting their increases to less than 25%. Overall,

it is estimated that spending on outsourcing of R&D

and manufacturing will grow by 13% in 2015; this is a

healthy growth rate, and it’s consistent with the growth

in overall biopharmaceutical sales. While some increases in outsourcing budgets are targeting the more common outsourced services, such as

assay testing and fill/finish operations, other activities

are showing increasing importance, such as DoE and

quality by design. These activities represent smaller

budgets, so in years to come, their growth rate may

likely be even greater than the big-ticket outsourcing

activities.

rEfErEncE

1. BioPlan Associates, 12th Annual Report and Survey of

Biopharmaceutical Manufacturing Capacity and Production

(Rockville, MD, April 2015), www.bioplanassociates.com/12th ◆

Join the discussion

Which activity has your company previously performed in-house that is now

outsourced? Has outsourcing this activity benefted your processes?

Post your comments on www.biopharminternational.com/linkedin

to join the conversation.

it is expected that the slight

dip in levels of validation

services being outsourced

will be temporary.

Additionally, it is expected that the slight

dip in levels of validation services being outsourced will be temporary, as the increasing

penetration of single-use devices will likely

spu r more spend ing in t h is a rea. Fina lly,

wh i le more resp ondent s a re out sou rc i ng

design of experiments (DoE), this activity is

being outsourced to a lesser overall degree,

suggesting that companies newly outsourcing

this quality activity are testing the waters. cOncLUSiOn

A lt hough su r vey resu lts sug gest t hat t he

market g row th for outsourcing of cer tain

activities is flattening, the overall outsourcing market appears to be healthy, as many

respondents predict spending increases to

come. In fact, a slight majority forecast some

June 2015

magenta

cyan

yellow

black

www.biopharminternational.com

BioPharm International

ES621720_BP0615_019.pgs 05.27.2015 02:00

19

ADV

Scale-up and tech transfer

advanced technologies facilitate

Scale-up and technology transfer

Cynthia A. Challener

Maria Toutoudaki/Getty Images/Dan Ward

Single-use

and modular

technologies

plus continuous

manufacturing

are increasingly

important to

biopharma

scale-up and

tech transfer.

I

t is hard to believe, but the biopharmaceutical industry is already

old enough to have aging facilities that are decades old. FDA’s

focus on the need for updates is creating both opportunities and challenges

for biologics manufacturers involved in

the scale-up and transfer of production

technologies. Single-use and modular

technologies, along with continuous

processing approaches, are helping the

industry both modernize old processes

and facilities and minimize the risks

associated with making significant

changes to existing systems.

Cynthia A. Challener, PhD,

is a contributing editor to

BioPharm International.

20

aging facilitieS

attract fda attention

Just as time passes more quickly as

people age, it seems time goes by more

rapidly as industries mature. While the

biopharmaceutical industry is young

compared to the small-molecule pharmaceutical sector, it has been of significance for several decades. Some of the

processes that are running today utilize

the technologies developed when the

industry was first established. “Many

of these processes were licensed long

ago and are quite complex, contain

open steps, and are inefficient in many

places,” notes Parrish Galliher, CTO of

BioProcess Upstream at the Life Sciences

business of GE Healthcare.

FDA has recognized the need to

upg rade these older processes and

facilities and is imposing updates (1).

Equipment suppliers are working closely

with biopharmaceutical manufacturers to develop plans for implementing

BioPharm International www.biopharminternational.com June 2015

magenta

cyan

yellow

black

ES621368_BP0615_020.pgs 05.26.2015 23:04

ADV

Fuel

SUPER powerful

advances.

Biotech is more than just a job. It’s a mission to feed, fuel and heal the world. And there’s no

better place to connect with biopharma’s top people and most innovative technologies than

at BIO 2015. The ideas and information shared at BIO go beyond professional development.

You’ll experience powerful business partnering, benefit from invaluable education sessions

and have the chance to network with 15,000 of the industry’s best and brightest. See how

the everyday becomes extraordinary — at BIO 2015.

Register today at convention.bio.org #BIO2015

SUPERcharge your BIO experience.

convention.bio.org

magenta

cyan

yellow

black

ES622152_BP0615_021_FP.pgs 05.27.2015 20:31

ADV

Scale-up and tech transfer

the needed changes. “This situation provides a great opportunity

to update those systems, facilities,

and practices, but also presents the

challenges associated with changing any process, including the risk

of affecting product quality in

some way. Fortunately, by working

closely with tools and technologies

suppliers and the regulators, biopharmaceutical manufacturers are

better positioned to overcome such

challenges,” Galliher asserts.

Single-uSe SolutionS

One of the most efficacious ways

to reva mp older processes as

required by FDA is to upgrade with

single-use technologies, according

to Helene Pora, vice-president of

single-use technologies at Pall Life

Sciences. “Single-use systems have

proven to not only reduce capital investment, but also minimize

turndown time, resulting in more

effective and higher-quality manufacturing processes for scale-up

and tech transfer,” she states. In

fact, biopharmaceutical contract

manufacturers routinely assess

single-use technologies as options

when new equipment is introduced

to meet a process need, according

to Paul Bird, head of the manufacturing engineering group at

Fujifilm Diosynth Biotechnologies’

Billingham, UK site.

Fujifilm develops and manufactures biologics using both microbial and mammalian production

systems, and although single-use

technolog y is a relatively new

introduction, it has had an impact

on mammalian manufacturing at

the company. Mammalian cultures

do not tend to be intensive; they

do not have high oxygen demand

and do not grow in very high cell

densities, Bird explains. In addition, the culture growth takes place

over a long period of time. As a

result, a reactor for mammalian cell

culture is not required to have high

heat removal or provision for high

22

oxygen supply; as such, single-use

systems are well suited.

The situation is different for

m ic robi a l c u lt u r e s b a s e d on

Escherichia coli and yeast, for example. These processes have high

growth rates and densities, and thus

the demand for oxygen is high,

making it difficult to replicate a

high-productivity process in a disposable reactor, according to Bird.

“Because these cultures require very

good heat removal, high oxygen

transfer, and other rigorous conditions, stainless steel tends to remain

the best possible option for microbial processes today,” he notes.

Advances in single-use technologies

designed specifically for microbial

systems may, however, lead to their

greater use in the future.

Galliher agrees that single-use

technologies are not a panacea for

the upgrading of older processes.

“Most older facilities use stainless-steel manufacturing systems,

so the conversion to disposable

technologies is not automatically

straightfor ward,” he obser ves.

When single-use systems are chosen, however, he adds that they

are fairly rapid to install and startup, particularly relative to older

legacy technologies, so the impact

on facilities and utilities support

systems is minimized. In addition,

because the running costs are less

for single-use systems, they can be

considered enabling technologies.

Modular approach

proveS flexibility

While modular systems are a wellestablished concept a nd have

been available in some form for

several decades, they are attracting increasing attention in the

biopharmaceutical industry today.

In fact, the increasing availability of modular processing units is

bridging the gap for many manufacturers with both established

traditional facilities and new sites

under construction, according to

Pora. “For established facilities,

modular processing units enable

a quick and easy transition to the

hybrid facility format, while for

new facilities, they are making the

fully flexible single-use facility a

reality,” she says.

The popularity of modular systems is not just being driven by

FDA mandates; Pora also notes that

manufacturers have realized that

modular solutions can help them

overcome bottlenecks and become

more efficient with less investment

of time and money.

T he global interest in standardizing facilities, harmonizing

designs, and moving to a distributed facility model with a series of

smaller identical facilities around

the world is also driving interest in modular systems. “For this

model to be successful, the facilities need to be identical in order to

facilitate tech transfer, documentation, training, and essentially

everything that needs to be commissioned to run these facilities

in remote territories. Due to this

trend, the demand for duplicate

cookie-cutter-type modules has

increased,” Galliher comments.

Another trend driving interest

in modular technologies is a reduction in production volumes due

to the switch to distributed production, increasing yields, and the

trend towards personal medicine.

“Smaller facilities require smaller

production systems, which makes

modularity increasingly possible,”

says Galliher. He does note, however, that modularity will compete

with stick-built facilities in places

where labor is cheap. “Companies

will have to consider the quality

standards they want to reach and

whether modules already constructed to meet cGMP and other

industry requirements will better

meet their needs,” he adds.

Modular technologies are also

increasingly available on the production equipment level and are

BioPharm International www.biopharminternational.com June 2015

magenta

cyan

yellow

black

ES621482_BP0615_022.pgs 05.26.2015 23:35

ADV

Scale-up and tech transfer

used to build systems and processes that are identical in different locat ions, wh ich aga in

simplifies maintenance, documentation, training, and validation.

“The modular nature of machinery makes modifying or adding

options possible; their plug-andplay designs allow for easy modification with additional or different

functions,” Galliher observes.

Fujifilm is a good example of a

biopharmaceutical manufacturer

that is taking advantage of modular production systems. In particular, the company designed a

single system for the final bulk

f illing of cGM P produc ts that

replaces numerous existing filling

systems. “By adopting a modular

technology approach, we generated a unique capability for biologic drug product filling that for

the first time provides f lexible

a nd adapt ive ma nu fac t u r ing,”

asserts Bird. He notes that the

system is flexible because the production process supports bespoke

op e r at ion s me et i ng c u stome r

requirements in full, and adaptive because the modular nature

of the system enables point-ofu se i nc rea ses or de c rea ses i n

production capacity. “This ambitious project has extended the

benefits for the most critical unit

operation—f inal bulk f illing—

and has standardized the operator experience without impacting

the flexibility to meet customer

requirements,” he adds.

Consistent, flexible, yet rigorous

business processes that introduce

dependable operations on-time

and in full are necessary for effective technology transfer, according

to Bird. “In addition to effective

technology transfer between R&D

sites and various business units,

companies must have the ability to

site, develop, and deliver into manufacturing correctly the first time.

The collaboration of highly motivated and highly skilled people

across multiple programs of activity is the key to success in both

areas,” Bird states.

As one example of how Fujifilm

is using technology to address current challenges, Bird cites the company’s “TAG” system for digitally

managing the capture, conveyance,

and retention of manufacturing

knowledge to improve technology

transfer, which provides controlled

publication and distribution of

manufacturing system standards

and operational best practice. Scale-down Modeling

for SucceSSful Scale-up

and tech tranSfer

One of the benefits of the use of

smaller production facilities is a

reduction in the scale-up factor

for many biopharmaceutical processes. No longer are manufacturers required to scale-up from the

lab to 20,000 L; more commonly

processes are scaled up to 2000

or sometimes 5000 L. As a result,

scale-up is less of a technological

leap and therefore more predictable and lower-risk than in the

past, according to Galliher.

The use of scale-down modeling, in which a large-scale system

is reverse-engineered down to the

lab scale so that it can be operated

to model the large-scale process,

has also significantly reduced the

difficulties associated with process scale-up. With this approach,

data that are representative of large

process behavior can be collected

early in the development process

and at lab-scale costs, according

to Galliher. He adds that betterdesigned model bioreactor, chromatography, and filtration systems are

allowing for even smoother scaleup and tech-transfer operations.

Raw material choices are also

being adjusted to improve scale-up

processes. “Instead of buying small

amounts of lab quality reagents and

then moving to large-scale suppliers once a process has been devel-

oped, today some manufacturers

are beginning the development

process with materials purchased

from their eventual large-scale suppliers. This approach eliminates the

need to change their raw materials

at the point of tech transfer and

scale-up and thus avoids any potential impact on performance and

product quality,” Galliher explains.

continuouS proceSSing

haS potential to

overcoMe Scale-up

and tech-tranSfer iSSueS

The adoption of continuous processes and intensified manufacturing may have a significant impact

on technology transfer and process scale-up. Pora believes that

single-use technologies can also be

aligned with the concept of continuous processing to address scale-up

issues. “Many of the recent investments at Pall have been driven by

this expectation, and our new single-pass tangential flow filtration

modules and systems and inline

concentrator are examples of technologies that have resulted from

our recent efforts,” she says.

Galliher sees both advantages

and disadvantages associated with

continuous processing, and he

remains uncertain whether these

techniques and technologies will

graduate to the commercial manufacturing stage. He does, however,

believe that with their knowledge

and skills, service providers can

support biopharmaceutical manufacturers with the assessment of

these new technologies and help

them with scale-up and tech transfer into their own facilities. “When

you drill down,” concludes Pora,

“the particular challenge is reducing complexity.”

referenceS

1. J. Wechsler, “Modern Manufacturing

Systems Key to FDA Quality

Initiative,” Pharmaceutical

Technology 39 (4) 2015. ◆

June 2015 www.biopharminternational.com BioPharm International

magenta

cyan

yellow

black

ES621374_BP0615_023.pgs 05.26.2015 23:04

23

ADV

Downstream Processing

Sterile Filtration Techniques for

Optimal Microbial Retention

Ashley Roberts

Removal of

microorganisms

is crucial when

working with

biologics.

Sterile filtration

offers a

reliable, safe,

and effective

way to ensure

product

integrity.

24

I

n many circumstances, sterile filtration is necessary to remove particles or microorganisms that may

affect the safety or efficacy of a biologic. Various processes and tests can be

implemented to ensure that filtration is

successful. BioPharm International spoke

with Dr. Jens Meyer, product manager,

filtration technologies at Sartorius Stedim

Biotech; Cindy Neeley, PhD, application

scientist at Thermo Fisher Scientific; and

Tom Watson, global product manager at

Pall Corporation, about ensuring filter

validation, determining the correct filter

pore size, and the importance of keeping

filtration processes up to date.

THE FILTRATION PROCESS

BioPharm: How can one ensure that all

sterile filtration equipment and processes are up to date?

Meyer (Sartorius Stedim Biotech): Because

sterilizing-grade filters consist of a very

thin membrane that functions as a sterile

barrier, any mechanical impact must be

avoided as much as possible. In addition,

wetting of a filter membrane plays a crucial role in integrity testing. Due to limitations on temperature and differential

pressure, all sensors need to be routinely

calibrated and checked. Obviously, the

entire equipment and product-contacted

surfaces have to be steam-sterilized before

starting a filtration run.

Neeley (Thermo Fisher Scientific): A welldesigned filtration system begins with

choosing a filtration membrane appropriate for your fluid. Differences in how

a filter is manufactured, the material

components used, and how it performs

will have a direct impact on your work.

Always double-check the type of containers you entrust with valuable samples and

solutions. Storage bottle and cap systems,

such as the Thermo Scientific Nalgene

bottles and caps, are constructed to minimize gas permeability and maintain sample integrity over time.

Watson (Pall Corporation): Given the

continuing and rapid adoption of single-use systems, it is important that any

filters currently being tested at benchtop or pilot scale are available in configurations that are compatible with

gamma irradiation. Their performance

should be validated by the filter supplier, and any process-specific filter

validation studies should be performed

using filters that have been sterilized by

the method intended at process scale.

From an applications standpoint,

newer, complex parenteral formulations

using nanoparticles and liposomes tend

to be harder to filter than traditional

formulations. For those engaged in the

manufacture of hard-to-filter formulations, it is worthwhile to identify a sterilizing-grade filter that will have good

throughput capacity for these fluids. It’s

also critically important to ensure that

bacterial retention is confirmed early

through filter validation studies.

In addition to securing a reliable sterilizing-grade filter, it can be useful to work

with suppliers who can offer state-of-theart integrity test equipment, a whole suite