C7- RINA Paper_EBDIG_The Marine Design Manifesto

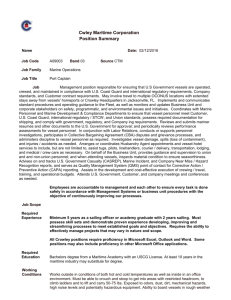

advertisement