From 200 Million to 2 Billion kWh in a Single Year

advertisement

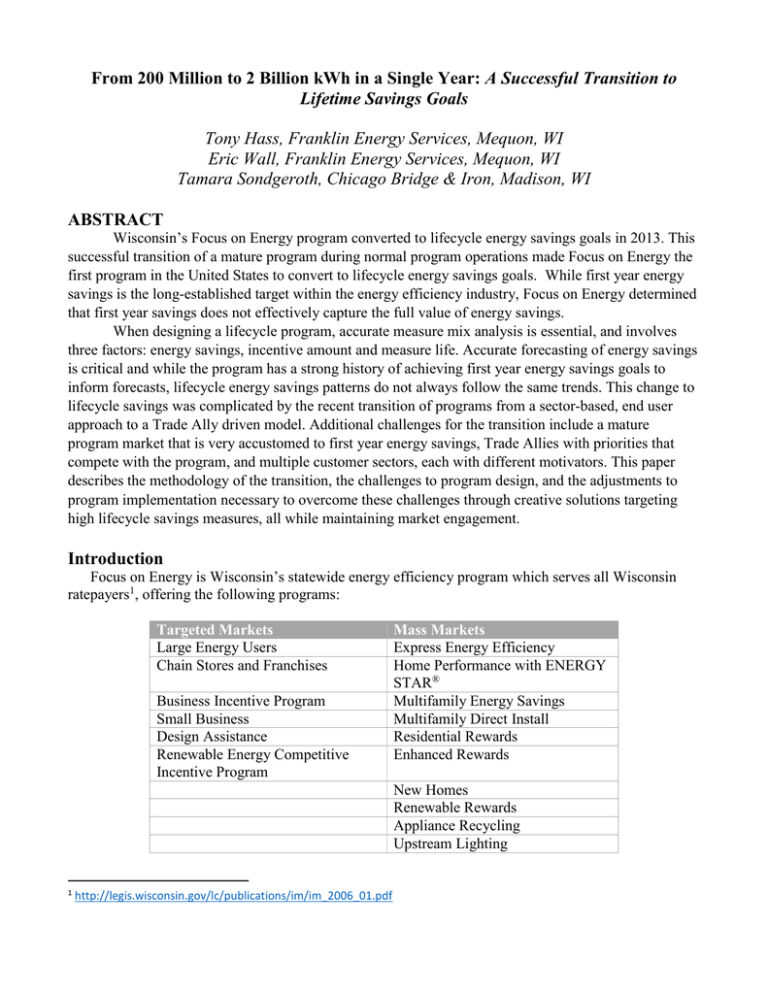

From 200 Million to 2 Billion kWh in a Single Year: A Successful Transition to Lifetime Savings Goals Tony Hass, Franklin Energy Services, Mequon, WI Eric Wall, Franklin Energy Services, Mequon, WI Tamara Sondgeroth, Chicago Bridge & Iron, Madison, WI ABSTRACT Wisconsin’s Focus on Energy program converted to lifecycle energy savings goals in 2013. This successful transition of a mature program during normal program operations made Focus on Energy the first program in the United States to convert to lifecycle energy savings goals. While first year energy savings is the long-established target within the energy efficiency industry, Focus on Energy determined that first year savings does not effectively capture the full value of energy savings. When designing a lifecycle program, accurate measure mix analysis is essential, and involves three factors: energy savings, incentive amount and measure life. Accurate forecasting of energy savings is critical and while the program has a strong history of achieving first year energy savings goals to inform forecasts, lifecycle energy savings patterns do not always follow the same trends. This change to lifecycle savings was complicated by the recent transition of programs from a sector-based, end user approach to a Trade Ally driven model. Additional challenges for the transition include a mature program market that is very accustomed to first year energy savings, Trade Allies with priorities that compete with the program, and multiple customer sectors, each with different motivators. This paper describes the methodology of the transition, the challenges to program design, and the adjustments to program implementation necessary to overcome these challenges through creative solutions targeting high lifecycle savings measures, all while maintaining market engagement. Introduction Focus on Energy is Wisconsin’s statewide energy efficiency program which serves all Wisconsin ratepayers1, offering the following programs: Targeted Markets Large Energy Users Chain Stores and Franchises Business Incentive Program Small Business Design Assistance Renewable Energy Competitive Incentive Program Mass Markets Express Energy Efficiency Home Performance with ENERGY STAR® Multifamily Energy Savings Multifamily Direct Install Residential Rewards Enhanced Rewards New Homes Renewable Rewards Appliance Recycling Upstream Lighting 1 http://legis.wisconsin.gov/lc/publications/im/im_2006_01.pdf The Focus on Energy programs offer a combination of professional advice, training, and incentives to produce energy savings and long-term market transformation. While this paper discusses lifecycle savings requirements and the transition in general, the focus of the paper and analytics are based on the Business Incentive Program. Business Incentive Program The Business Incentive Program is Focus on Energy’s program serving medium business customers in the Agriculture, Commercial, Industrial, Schools and Government sectors. The program serves all customers under 1MW, but targets customers between 100kW and 1MW, as customers under 100kW are eligible for the Small Business Program. Focus on Energy’s market research indicates that there are approximately 13,700 business in this target range of eligible customers. The Business Incentive Program offers a comprehensive prescriptive and custom program design which is offered consistently across the three core business programs: Business Incentive Program, Chain Stores and Franchises, and Large Energy Users. Prescriptive measures are offered in the following categories; Lighting Variable Frequency Drives (VFDs) HVAC Agricultural Irrigation Information Technology (IT) Grain Drying Domestic Hot Water (DHW) Dairy and Livestock Compressed Air Greenhouse Food Service Industrial Process Refrigeration Custom incentives are available for measures not meeting the prescriptive requirements but still falling between a 1.5 to 10 year simple payback and meeting all other program pre-approval requirements. Custom incentive rates for the programs are: kW kWh Therms $125/kW $0.04/kWh $0.40/therm The program has also been offering a bonus of $0.40/therm for a total incentive rate of $0.80/therm since April 2013. The primary outreach mechanism for the program are contractors, consultants and distributors, collectively known as Trade Allies. Approximately 1,200 Trade Allies are each assigned to individual program staff. Trade Allies vary greatly based on the technologies they support, customers they serve, geographic coverage and many other factors. Therefore, the program has made Trade Ally assignments that address as many of these variations as possible. Lifecycle Energy Savings In 2009, the Public Service Commission ordered a change to the accounting for the Focus on Energy program savings, tracking future savings goals in terms of lifecycle targets2. Lifecycle savings equal the annual energy savings times the Effective Useful Life (EUL) of a measure. The program’s previously existing database and tracking system summed annual savings on a measure-by-measure basis. Every measure, such as a 13W compact fluorescent bulb, already had an annual energy savings value associated with it. To convert to lifetime savings, each measure had to be 2 PSC Order 5-GF-191 analyzed and the EUL had to be determined. Complicating the transition, the Program Implementers, Program Administrator, and the Evaluator all had to agree on the EUL for each measure before it could be applied. EULs were derived from many sources including; evaluation reports, Technical Resource Manuals (TRMs) from other programs and engineering estimations based on decades of practical experience. Program Transition The Focus on Energy Program began the transition to lifecycle savings targets in 2011 with 100% conversion accomplished in December of 2013. Program Administration, Implementation, Evaluation and Information Management resources executed the changes on independent timelines resulting in staggered functionality as noted below. Program Administration converted to lifecycle savings targets for the 2011 program year (program years are concurrent with calendar years for the Focus on Energy portfolio). Program Implementers did not have lifecycle savings targets until the 2013 program year. Implementers planning for goal attainment was challenging due to the lag between converting to lifecycle targets and the evaluation process that would determine realization rates and measure lives. The first evaluation that included lifecycle impacts was completed in April of 2012. This report provided insight on whether or not targets were met, but came too late to provide implementation course corrections for that program year. This process was repeated with the 2012 impacts being quantified in April of 2013 limiting course corrections for that program year. These challenges persisted into 2013 until the completion of the prescriptive EUL database in April 2013 and the custom and hybrid measure EUL database in December 2013. Lifecycle savings for 2011 and 2012 were not impacted by the EUL databases as these had values established by the evaluation reports for those years. The savings accrued to date for the 2013 program year were assigned values according the EUL database. The CRM database that serves as the accounting system for the portfolio was migrated to lifecycle savings using the EUL database in August of 2013 with values finalized in December of 2013. This conversion allowed for real time tracking of progress to goals under lifecycle savings for the first time, providing much greater control to the Program Administrator and Program Implementers. As a result of real time tracking, the Program Administrator and Implementers were able to make slight changes to programs during program planning for 2014, allowing the programs to meet the 4 year lifecycle target in 2014. Measure Mix At the beginning of the quadrennial period, Program Implementers proposed a mix of measures which would meet the annual savings target based on first year energy savings. This was the strategy because the EUL databases had not begun development and the tracking system could not report progress against a lifecycle target. During the planning process for 2014, for the first time, Implementers could estimate the lifecycle savings of the measure mix, which has the potential to change the measures dramatically. Adding EUL to the equation can quickly take a cost effective measure and make it much more or less attractive. Measures that have rather small annual energy savings may have a long life, like 20 years, which make them very cost effective in terms of lifetime savings. The immediate effect for short-lived measures like boiler tune ups is they become unattractive. The amount that could be paid to incentivize those measures becomes so small that it is not enough to move the market and free ridership becomes a major concern. Longer-lived measures, like LED’s and boiler replacements, can be incentivized at a higher rate. This can be a good side-effect of changing to the lifecycle reporting as it encourages changes that will be long lasting and can push true market transformation. Changes to measure mix are not always popular or understood by customers or Trade Allies. End use customers tend to think in terms of simple payback time, which equals project cost divided by annual energy cost savings. This creates a gap between program goals and the customer’s dominant mindset. Historic Measure Mix Considerations The key considerations for a comprehensive measure mix for a first year energy savings program are: Variety of measures Market needs and demands Cost/kWh Cost/therm Focus on Energy has developed a comprehensive measure mix portfolio over the 13 years of program operation that meet as many of these needs as possible. Being Trade Ally driven, it is very important for the Business Incentive Program to have a robust prescriptive offer as it simplifies the sales process for Trade Allies. The following graphs display the first year energy savings by major categories for the Business Incentive Program in 2013. As seen in the chart above, only two categories represent greater than 10% of the program’s first year electric savings: lighting fixtures, motors & drives. Together, these two categories represent over 57% of the programs total electric savings. Four categories represent greater than 10% of the program’s first year natural gas savings: steam traps, HVAC equipment, tune-ups and building envelope. Together, these four categories represent 82% of the programs total natural gas savings. Lifecycle Measure Mix Considerations A lifecycle savings program has all of the same considerations as a first year energy program but adds in measure life and lifecycle costing. Variety of measures Market needs/demands Cost/kWh, cost/therm Measure life Cost/lifecycle kWh, cost/lifecycle therm When evaluating measures with wide ranging measure lives the impact on lifecycle savings is apparent. The graphs below represent electric and natural gas measures with a low, medium and high EUL values. The quantity of each measure was set to represent similar first year energy savings. This comparison shows how the savings difference between measure types is multiplied even further when adding in the EUL of the measure. The following graphs display the lifecycle energy savings by major categories for the Business Incentive Program in 2013. Again, the same two categories represent greater than 10% of the program’s lifecycle electric savings: lighting fixtures and motors & drives. Together, these two categories represent over 60% of the programs total lifecycle electric savings. With the variety of measures contained in each of these categories and the smaller range of measure life values for electric measures, many of these categories do not see a major change. The categories with the greatest change in total program savings are represented in the table below. Category Compressed Air HVAC – Equipment Lighting – Lamps Lighting - Controls Motors & Drives Tune-ups % of First Year kWh Savings 4.3% 4.5% 1.4% 3.8% 13.9% 5.1% % of Lifecycle kWh Savings 5.1% 5.9% 0.6% 2.7% 16.0% 1.1% Difference 0.8% 1.4% -0.8% -1.1% 2.1% -4.0% Only three categories represent greater than 10% of the program’s lifecycle natural gas savings: HVAC equipment, building envelope and steam traps. Together, these three categories represent over 69% of the programs total lifecycle natural gas savings. Natural gas measures have a much greater variation when comparing first year savings and lifecycle savings due to the low measure life of tune-up measures (2 years) and the high value of equipment measures (15-20 years) and building shell measures (25 years). The categories with the greatest change in total program savings are represented in the table below. Category Building Envelope* Compressed Air HVAC - Equipment Steam Traps Tune-ups % of First Year Therm Savings 18.5% 4.1% 21.2% 21.5% 20.8% % of Lifecycle Therm Savings 24.6% 8.3% 32.9% 11.6% 4.0% Difference 6.1% 4.2% 11.6% -9.9% -16.9% *This category also contains comprehensive whole building new construction projects Goal Impacts When these individual measure EULs are incorporated into the program design and the portfolio of measures is rolled up into an entire program goal the effects are significant. kW 22,000 2014 Business Incentive Program Goals Electric Natural Gas kWh* Lifecycle kWh Therms* Lifecycle Therms 170,000,000 2,000,000,000 5,400,000 62,500,000 *First year energy savings goals are estimates as Program goals are lifecycle in 2014 Program goals in the hundreds of millions make it hard enough for program staff to understand their individual impact, and when these become billions, staff can feel even more disconnected. The Business Incentive Program leadership has provided regular training and analysis to program staff to help them understand the new tracking metric. The team was also well informed on the measures with the highest lifecycle values so they could seek out these opportunities with customers and Trade Allies. In addition to this staff education, the program has developed special offers which target high value lifecycle measures. This tactic serves as a tool for program staff, a short term update to incentive values based on lifecycle savings, and a driver for the market without the market having to understand what lifecycle savings is. Conclusions Since Focus on Energy was the first program to convert to a lifecycle savings framework there were many lessons to be learned. With the timeline of the conversion during the first three years of the quadrennial, the goals were centered on tracking and having systems in place for consistent use of EULs. After these major undertakings were completed, the Program Administrator and Program Implementers finally had the tools and data necessary to start to review larger changes based on lifecycle savings. Some of the potential program changes are obvious, such as the review of short EUL measures including lamps and tune-ups. As displayed in the measure mix graphs, some of these measure categories represented a significant amount of program savings on a first year basis and some still represent a significant portion of program savings in the lifecycle framework. If there are not new longer life measures to replace these shorter life measures, programs can hesitate to remove a productive measure. When this is the case programs must dig deeper in their analysis of a measure and review items such as: Does the lifecycle energy savings for the measure outweigh the cost to process the application? Can the incentive for the measure be reduced to minimize the incentive cost to the program? o Will a reduction result in a high enough value to offset incremental costs? o Does this reduction cause a freeridership concern? Does the market still demand the measure? o Will removing a prescriptive measure increase implementation costs by shifting the measure to the custom path? This analysis can become very complex and one analysis of a measure may lead a program to remove it while another analysis of the same measure determines that it should remain. As with all program design there is a delicate balance between overall program goals, Program Implementer goals, Trade Ally desires and end-use customer needs. In many cases there is not a clear answer that will meet all of these needs so the analysis aims to find the best case scenario given all of the constraints. Tune-up Measures Tune-up measures can provide programs significant first year energy savings and also a gateway into customers which can lead to implementation of additional projects. Tune-up measures also carry evaluation risks of verified savings and high freeridership. This combination of benefit and risk can be a great challenge for programs to weigh out. The analysis of the Focus on Energy business programs tune-up measures included a review of; Lifecycle savings vs. application processing time Trade Ally feedback Customer feedback Select Trade Allies have been vocal about tune-up incentives as they don’t agree with some of the requirements (ex. Combustion testing) and the time it took them to collect the required data vs. the incentive to the customer. However, customers typically appreciate and demand tune-up measures from the Trade Allies, as they are a small financial investment with good annual savings. Program staff often use tune-up measures to capture some level of savings from a customer and tune-ups can be leveraged to inform the need for a capital improvement, such as boiler replacement. Since these factors didn’t lead to a clear conclusion and the measures represented good savings on an annual basis they had remained in the measure mix until the lifecycle conversion was complete in 2013. After this was complete the measures were analyzed again. In 2013 tune-up measures represented 16.8% of the applications received by the Business Incentive Program, but only 1.1% of the lifecycle kWh and 3.9% of the lifecycle therm savings. Tune-up measures were costing the program more implementation dollars than they were providing value in lifecycle savings. This, combined with the Trade Ally feedback, made it an easy decision to remove HVAC tune-up measures from the program for 2014. Since cooling and refrigeration tune-up measures had a longer measure life and represented a smaller portion of the measure mix they remained in the mix for 2014. Cooling and refrigeration tune-up measures were evaluated again in 2014 after the program had a longer track record of lifecycle savings, and the program has also decided to remove these measures from the mix for 2015. The one tune-up measure that will remain in the 2015 mix is the compressed air leak survey and repair as this measure maintains an average lifecycle savings and more often leads to other compressed air system improvements. Prescriptive Incentive Rates To date the Focus on Energy programs have not modified any individual measure incentive rates due solely to lifecycle energy savings, however new measures have been evaluated based on lifecycle energy savings. At a high level rewarding longer life measures with a greater incentive than short life measures seems to be in line with the markets needs and understanding as long life measures are usually larger capital projects with a greater incremental cost. The program is currently evaluating measures based on lifecycle savings for updates to prescriptive incentive rates in 2015. Initial findings are that incentive values developed throughout the program history vary widely on a dollar per lifecycle kWh or therm value. The team is also finding that the lack of accurate full and incremental cost data is creating a challenge of including this key variable in the analysis. Custom Incentive Rates To date the Focus on Energy programs have decided to maintain the custom incentive structure that was already in place. This structure gives incentives to the business customer’s custom project based on annual savings. The team believes that introducing EULs into the custom incentive would create significant pushback from manufacturers and Trade Allies on the EUL value. Since using consistent EULs by measure type is critical to program consistency the team does not anticipate making any changes to these rates. The one change this is being considered is a change to the payback criteria used for longer life measures. As mentioned previously longer life measures typically have a greater cost which means that they are included in most customer’s capital budgeting process. Projects funded through the capital budgeting process can have different evaluation criteria than projects funded through operations budgets which may allow for a longer payback. The program is now evaluating stretching the maximum payback criteria above 10 years for projects with a long measure life (20+ years). This would allow customers with long term business plans to still receive incentives for these capital projects and the program will obtain high value lifecycle savings while minimizing the freerider risk. Baselines Measure baselines are an important factor to all programs as accurate baselines ensure accurate program savings and high verified savings from evaluations. Depending on the evaluation of a lifecycle program the measure baseline can become a more complex decision than a first year program. For example, if a linear fluorescent fixture has a measure life of 15 years and the program influences an upgrade from a T-12 fixture to a High Performance (HP) T-8 fixture 10 years into the T-12 fixture life, what is the real baseline? If you consider the lifetime of the measure then the real savings would be a T12 baseline for the remaining 5 years of the measure life and then a standard T-8 baseline for the 10 additional years of the HP T-8 fixture lifetime. However, this is only considering the measure lifetime and doesn’t account for any other code, federal or local standards that may change during the measure life. It also doesn’t consider that the customer may have chosen to replace that fixture without the program influence before the end of the T-12 measure life. The dual baseline discussion is an interesting one but very complex when considering all of these factors. To date the program has only had evaluations that consider the source of the measure life and do not consider all of these additional factors, however this may be something that Program Evaluators consider as an area of interest as more programs convert to lifecycle savings. Recommendations As with any major program change, communication of the plan including objectives and timelines is critical to this process. Based on our experience the timeline below outlines the teams recommended order of events for a conversion to or development of a lifecycle savings program. CEC & Measure Mix Conversion Develop EUL Database Integrate Lifecycle Savings Conversion to Lifecycle Goals The timing of accountability for lifecycle savings goals for the utility or Program Administrator and Program Implementers is the key variable for the start of this timeline. There are three items that should be in place before any parties are held accountable for lifecycle savings. The first item is a EUL database that has received input and agreement from all involved parties from program design to evaluation. Once EULs have been confirmed for all measures and a methodology is created for approval of new measure EULs the program should integrate lifecycle savings into the tracking system. Prior to or in parallel with the tracking system development should be development of a planning tool (ex. Cost effectiveness calculator) that allows program design teams to build a lifecycle energy savings measure mix that achieves all program objectives. Once these three key items are in place the programs will be in a position to be accountable for lifecycle energy savings. Further evolution of the program based on lifecycle savings can take place within normal program operations with little to no measureable effect on the market. These additional changes may be marketing strategies that target high lifecycle savings measures, incentive changes based on measure lives or even new measures that are more attractive under the lifecycle energy savings framework. In the end, Focus on Energy sees the change to lifecycle savings as a more accurate way to track and capture the full value of energy savings. As the programs evolve with their measure design we also believe that tracking and rewarding measures based on lifecycle savings will more accurately align with customer expectations.