Section 16450 - Electrical Wiring

advertisement

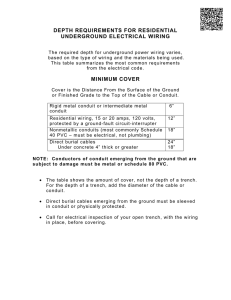

SECTION 16450 - ELECTRICAL WIRING PART 1 - GENERAL 1.01 RELATED DOCUMENTS The General Provisions of the Contract, including General, Supplementary and Special Conditions, apply to the work specified in this Section. 1.02 GENERAL INSTALLATION REQUIREMENTS A. All electrical work dealing with electrical circuits or power requirements of 110 volts or higher shall be performed by a licensed journeyman electrician supervised by an on site master electrician. B. All cables not installed in conduit shall be plenum rated. C. All conductors and cable shall be properly labeled at both ends and at any intermediate splice. D. All low voltage cables shall be installed in continuous length without splice. E. All plenum rated cables shall be supported from and near structure with nylon straps or D-rings. Do not weave through joists for support. F. Install conduit sleeves for all masonry penetrations of plenum rated cables. G. In areas of remodeling, remove all conduit and wire that is not to be reused. H. Provide grounding bushings for all connections at concentric and eccentric knockouts, and where reducing washers are used. I. All junction boxes and other devices above ceiling that may require maintenance shall be located within 18” of the ceiling. J. All exterior junction boxes in the ground shall be concrete type with traffic rated tops. K. All junction and pull boxes shall be marked noting electrical circuits contained. Additionally, boxes containing emergency or exit circuits shall have housing painted red. Boxes containing normal high voltage circuits shall have housing painted yellow. Boxes containing normal low voltage circuits shall have housing painted blue. Do not paint the covers. PART 2 - MATERIALS AND METHODS 2.01 A. RACEWAY SYSTEMS REQUIRED: Complete raceway systems for all wiring. This includes, but is not limited to feeders, branch circuit wiring, temperature controls wiring, data cabling, video cabling, sound system wiring and fire alarm system wiring. Generally auxiliary system and controls wiring is plenum rated so conduit system would consist of junction boxes and conduit in walls or above inaccessible ceilings only. Control and interlock wiring shall be provided under the Mechanical Section. 16450 Electrical Wiring Page 1 Project 1325 B. RACEWAY CAPACITY: It shall be the Contractor's responsibility to determine the correct sizes of all types of raceway, to be installed, as instructed in the NEC and all applicable Codes. Runs of underground conduit longer than 80 feet shall be one size larger than NEC requirement, 4" maximum. C. INSTALLATION: 1. LOCATION: Conceal all raceway systems in ceilings, walls and floors, except feeders serving equipment in mechanical and electrical equipment rooms, and in such other areas as indicated where conduit may be exposed. Keep at least 8" away from any heat producing items. Do not install conduit below grade or in floor slabs unless there is no other way to conceal conduit. Equipment feeders in mechanical rooms or mechanical yards shall be run above grade. Major feeders from switchboard to distribution panels containing 4/0 or larger wire may be run underground. Do not install conduit on roof unless specifically shown to be on the roof or authorized in writing by the Engineer. All junction and pull boxes above accessible ceilings shall be mounted so that the access panel is no higher than 18” above the ceiling. 2. ROUTING: Conduit shall be installed parallel to building coordinates, except for underground feeders from panel to panel may be installed in the most direct manner. Install all horizontal conduit at structure unless mounted to a wall. 3. EXPOSED RACEWAY: Run parallel to walls, ceiling or structural members, in a manner to present a neat appearance. Before installation, explain to the Inspector the proposed method of routing and obtain his approval. Hold all horizontal conduit at ceiling or structure, unless mounted on wall. 4. SUPPORT: Provide adequate and sturdy support for all parts of raceway system. Conduit concealed in walls or slabs may be supported with wire hangers, provided they are of heavy gage and spaced to give adequate strength. Exposed conduit must be supported with materials specifically made for this purpose; do not use wire hangers. Do not attach any parts of raceway system to air conditioning ducts or ceiling systems. Wiring above ceiling without conduit shall be supported from structure or wall with J hooks or other manufactured devices designed for this service. Unless described by detail on the drawings, provide Tolco Pipe Pier Supports four foot on center to support conduit on the roof. Select for proper weight loading. 5. CONTINUITY: Make all joints and connections in a manner which will insure mechanical strength and electrical continuity. Use double locknuts and insulated bushings for rigid conduit, and insulated type connectors for EMT conduit 1” and larger for connections to boxes. Use insulated grounding bushings wherever connection is subject to vibration or moisture, such as near mechanical equipment, when internal ground wire is installed, and when concentric or eccentric knockouts are encountered, as well as where reducing washers are used. 6. PULL BOX LOCATIONS: As required by the National Electrical Code. 7. EXPANSION FITTINGS: Install O. Z. or equal expansion fitting in each run of conduit which crosses building expansion joint, and in all runs longer than 200 feet. 8. CORROSION PROTECTION: For all non-coated metal raceway in contact with concrete or mortar, tape with 3M corrosion protective tape, or equal. Tape shall extend for approximately 6" before entering and after exiting concrete. Conduit through slabs at grade shall be PVC coated rigid galvanized steel. 16450 Electrical Wiring Page 2 Project 1325 9. PULL WIRE: Install nylon pull cord in all empty electrical power raceway systems. 10. OPENINGS: Keep all raceway openings closed in a manner to prevent entry of moisture and foreign materials until conductors are installed. 11. FIRE PROOFING: All power and telephone raceway components passing through or installed within U. L. fire rated walls, ceiling or floor structures shall be fireproofed in the manner prescribed by the U. L. Fire Resistive Index and local building codes. All penetrations shall be fireproofed with 3M Fire Barrier CP25WB caulk, moldable putty or FS195 wrap/strip installed per the manufacturer's recommendations. 12. SEALING: All conduit, junction box, outlet box and other penetrations of the building envelop shall be sealed with non-hardening caulking or other non-hardening material as required by the International Energy Conservation Code. D. 2.02 A. B. MANUFACTURERS: All components of raceway systems must be made in U.S.A. and bear U. L. label. CONDUIT CONDUIT TYPES 1. RIGID GALVANIZED STEEL – Threaded fittings 2. PVC COATED RIGID GALVANIZED STEEL - Plasti-Bond REDH2OT with ETL Verified PVC-001 label or equal with ETL label. Provide Plasti-Bond coated couplings, fittings and pulling elbows. 3. PVC CONDUIT – Schedule 40 4. EMT – Steel conduit with diecast or steel watertight fittings 5. FLEXIBLE METAL CONDUIT – Greenfield, galvanized steel conduit for field installation of conductors 6. LIQUID TIGHT FLEXIBLE METAL CONDUIT – SealTite Type UA galvanized steel conduit with PVC waterproof coating for field installation of conductors 7. MC CABLE – Flexible steel conduit with factory installed, stranded, color coded copper conductors, green insulated ground wire and polypropylene sheath/tape. Conduit exterior shall be color coded for contained conductors. AFC MC Tuff 8. SURFACE RACEWAY – Wiremold steel raceway, ivory finished and mechanically connected to walls or casework. Type based on application. 9. CABLE TRAYS – Cooper B-Line 36 Series aluminum, ladder type cable tray with 9” rung spacing. Width based on application. Support per manufacturer’s recommendations. TYPE OF CONDUIT FOR VARIOUS LOCATIONS: 1. UNDERGROUND: Rigid galvanized steel or Schedule 40 PVC. Conduit in contact with concrete shall be PVC coated, rigid galvanized steel. Install PVC coated, rigid galvanized steel, long radius elbows where conduit turns up to grade including straight length section to a minimum of 6” above concrete or to panel connection. Encase underground conduit not under building slab in a 3" red concrete envelope located a minimum of 24" below finished 16450 Electrical Wiring Page 3 Project 1325 grade to top of envelope (48" if above 600 volts). Where more than one conduit is installed in the same trench, provide manufactured conduit support spacers to organize conduit and ensure proper concrete encasement. Notify Inspector for inspection of duct bank at least 24 hours prior to concrete placement. Conduit below building slab or conduit for telephone, data, etc. do not require concrete encasement. Conduit 1” and smaller under the building slab may be run just under the concrete. Larger conduit shall be 24” below finished floor. 2. IN POURED CONCRETE WALLS: PVC coated, rigid galvanized steel or Schedule 80 PVC. Install PVC coated rigid steel fittings on PVC conduit prior to conduit exiting concrete. 3. IN MASONRY WALLS: Galvanized steel EMT with steel, watertight fittings. 4. EXPOSED OUTSIDE OF BUILDING: Rigid galvanized steel. For conduit in mechanical courtyard within 50 feet of a cooling tower provide PVC coated, rigid galvanized steel conduit and fittings. 5. INSIDE OF BUILDING IN CEILING CAVITIES, IN EXPOSED FLOOR OR ROOF STRUCTURE AREAS, OR IN DRY WALL TYPE CONSTRUCTION: Galvanized steel EMT or rigid galvanized steel. 6. EXPOSED ON EXISTING MASONRY OR PLASTER WALLS IN FINISHED AREAS: Do not install surface mounted conduit in finished areas. 7. IN CONCRETE SLABS: Do not install conduit in concrete slabs. 8. FLEXIBLE METAL CONDUIT CONNECTIONS: Use only for connection to lights, motors and transformers from rigid conduit system. Do not loop flexible conduit between light fixtures or receptacles. Provide liquid tight construction and fittings in wet, damp or outside areas. Connections to mechanical equipment in main mechanical or boiler room, and kitchen equipment shall be in liquid tight. Do not install inside an air handling unit room. Minimum length shall be 18”. Minimum length shall be 18”. Maximum length shall be three feet except light fixture whips may be up to six feet. 9. LIGHT FIXTURE WHIPS: MC cable not to exceed six feet in length. C. MINIMUM CONDUIT SIZE: 1/2", all homeruns shall be 3/4” minimum. D. FITTINGS: E. 1. RIGID CONDUIT: All rigid galvanized steel conduit shall have threaded fittings with insulated bushings. 2. EMT CONDUIT: Provide insulated bushings for all EMT conduit 1" or larger or housing #6 or larger wires. 3. GROUNDING: Provide fitting with grounding lug where conduit attaches to a painted box (disconnect switch, starter, transformer case, etc), conduit attaches to a box through a knockout which has an associated larger knockout or a reducing washer is used, or conduit contains a feeder from switchgear to switchgear or between switchgear and transformer. 4. TELEPHONE AND DATA CONDUIT: Provide protective bushing on the end of telephone, data, sound system or other conduit stubbed into the ceiling cavity. SPARE CONDUIT: Provide five empty 1” conduit from all recessed electrical panels to above the nearest accessible ceiling. 16450 Electrical Wiring Page 4 Project 1325 F. 2.03 LOW VOLTAGE CONDUCTORS: Low voltage conductors may be run in accessible ceilings without conduit. Provide conduit sleeve with protective end fittings through all walls and floors where raceway system is not installed. All exposed conductors shall be in conduit. All splices shall be in supported junction boxes. Low voltage conductors installed without conduit shall be independently supported on ring hangers, and plenum rated. Low voltage conductors for audio and data wiring shall be stranded unless otherwise recommended by the manufacturer. PULL BOXES A. REQUIRED: Pull boxes, junction boxes, wiring troughs and cabinets wherever required for proper installation of various electrical systems. B. CONSTRUCTION: Made of code gage steel with sides formed and welded, screw covers unless shown to have hinged doors. Hinged doors to be same as furnished on panel boards, with same locking device. Knockouts shall be factory made or formed in field with a cutting tool which will provide a clean, symmetrically cut hole. Do not gang boxes or use extension rings to increase capacity. Boxes outside shall be steel NEMA 3 Type. 2.04 OUTLET BOXES A. REQUIRED: For all switches, light fixtures, receptacles and the various other outlets shown. B. CONSTRUCTION: Galvanized steel, one piece construction, in all cases suitable for intended use. Provide "gang" boxes where devices are shown grouped. Use hot dipped galvanized cast iron for floors or exterior locations. Boxes outside shall be steel NEMA 3 Type. C. TYPES FOR VARIOUS LOCATION: D. 1. CEILINGS: 4" square, 2-1/8" deep. 2. DRY WALLS: 4" square, 2-1/8" deep standard galvanized switch box. Provide shallow boxes where necessary. Provide tab to align box with studs. 3. MASONRY WALLS: Galvanized switch boxes designed especially for masonry installations. Depths of boxes must be properly coordinated for each specific installation. Box shall be installed within 1/8” of surface of block. 4. FLOOR: Watertight, adjustable, cast iron. 5. SURFACE MOUNTED: Boxes surface mounted on walls or floor shall be Bell, cast aluminum box with appropriate plate and threaded hubs. 6. BACK-TO-BACK OUTLETS: Outlets shown back-to-back on the drawings are to be installed with a minimum of 6" of lateral separation between outlets for minimum sound transmission. "Through-the-wall" type boxes are not permitted. 7. SPECIAL: Boxes for VGA outlets shall have 1.25” knockouts/lugs. MOUNTING PLATES: Boxes mounted in drywall construction shall have extension plates matched to wall thickness so the box can be mounted flush with the metal stud and the wiring device mounts flush with the wall. 16450 Electrical Wiring Page 5 Project 1325 2.05 CONDUCTORS A. REQUIRED: A complete system of conductors in all raceway systems except where shown otherwise. No conductors are to be installed in telephone conduit. Emergency or exit circuitry shall be installed in a separate raceway system. B. BUILDING WIRE: 600 Volt, soft drawn annealed copper, 98% conductivity, continuous from outlet to outlet. Minimum wire size #12 except remote control wire may be #14. All wire shall be stranded Type THHN, THW-2 or THWN-2 (wet rated for 90 C). All wires shall be color coded with same color connected to same ungrounded phase throughout the installation. C. BURIED GROUND WIRE: Conductors used to interconnect ground rods of a grounding triad or supplemental ground loop shall be minimum #2, bare, tinned, solid copper wire. Connect this wire to rod with short length of same wire, thermo-welded to loop and rod. D. MANUFACTURERS: Collier, General Cable, General Electric, Simplex, Triangle and Southwire Co. E. CONNECTORS: Make all connections on #10 and smaller wire with Code approved solderless pressure type insulated connectors; Ideal Wingnut. Solderless lugs must be used for all terminations. F. TEST: After installation of all conductors, and before final acceptance, make such tests as are required to determine proper functioning of all circuits. Furnish all necessary instruments required to make such tests and correct any deficiencies found. 2.06 CONNECTIONS TO MOTORS, EQUIPMENT AND DEVICES A. POWER WIRING: Make wiring connections to all mechanical, plumbing and other equipment being installed as a part of this Contract. In addition, make connections to Owner furnished equipment as shown. B. CONTROL WIRING: Control and interlock wiring for HVAC Systems will be provided by the Mechanical Contractor. Motorized dampers of the same voltage as the associated fan shall be wired by the electrical contractor when the damper is in close proximity to the fan. Under this section provide a 20 amp, 120 volt circuit to the control panel in each mechanical room from the local low voltage panel. C. CONNECTIONS TO EQUIPMENT: Make connection to each motor and to each piece of equipment subject to vibration with not less than 18" nor more than 24” of flexible conduit. All horizontal runs of conduit (not strapped to walls) must be kept above 7 feet high, with a vertical drop to equipment. Conduit blocking walk and service space is not acceptable and will require relocation. Conduit on and adjacent to equipment must be located to allow free access to all removable panels for equipment service. Wire adjacent to heat producing equipment, such as boilers and electric heaters, must be of a type approved for this use. D. CONNECTIONS TO TRANSFORMERS: Install not less than 18" nor more than 24” of flexible conduit at each connection to floor mounted transformers. E. CONNECTIONS TO RECEPTACLES: All multiple devices on a circuit such as receptacles shall be back wired with pigtail so device does not provide continuity path. 16450 Electrical Wiring Page 6 Project 1325 2.07 GROUNDING A. GENERAL: Permanently and securely ground the mechanical and plumbing equipment and piping systems, conduit system, panel boards and all other components of the electrical system installed or connected by the Sub-contractor. Follow NEC and building code requirements. B. CIRCUIT GROUNDS: Provide a green ground wire sized per the NEC for every circuit. C. EQUIPMENT ENCLOSURES: Make firm ground to raceway system. For equipment connected with flexible conduit or sealtite shall have the specified ground wire installed inside conduit. Do not install on the outside of the conduit. Where enclosure is painted, remove paint where ground lugs are installed. D. TRANSFORMERS: Each transformer shall have its enclosure and secondary neutral terminal (except when a neutral terminal does not exist) bonded to the building steel and local, driven ground rod. E. GROUND WIRE CONDUIT: Conduit containing a service or transformer grounding wire shall be grounded at each end to the grounding wire. Use conduit grounding fitting at ground rods. 2.08 CIRCUITRY A. The intent of the drawings is to indicate schematically the circuitry required. B. Do not install more than four current carrying conductors in a conduit except eight #12 may be installed in 3/4”C. Install a dedicated neutral for each circuit requiring a neutral. Install a green ground wire for each circuit or group of circuits in one conduit. Segregate data processing circuits and stage dimming circuits from other types of circuits. Do not install 480/277 volt conductors in the same conduit with 208/120 volt conductors. C. The work performed in grouping conductors in a single raceway shall comply with all applicable articles in the latest edition of the NEC and Local Codes which shall include, but shall not be limited to, ampacity de-rating of conductors and maximum capacities of raceways. 2.09 A. POWER CONDUCTOR COLOR CODING 480/277 VOLT SYSTEM: Conductors shall have insulation of the proper color as listed below: Phase A Phase B Phase C Neutral Ground Isolated Ground B. - Brown - Purple - Yellow - Natural Gray - Green - Green w/yellow stripe 208Y/120 VOLT SYSTEMS: Conductors shall have insulation of the proper color as listed below: Phase A Phase B Phase C Neutral Ground Isolated Ground - Black - Red - Blue - White - Green - Green w/yellow stripe 16450 Electrical Wiring Page 7 Project 1325 C. 240/120 VOLT DELTA SYSTEMS Phase A Phase B Phase C Neutral Ground Isolated Ground - Black - Orange (high leg of delta) - Blue - White w/colored stripe - Green - Green w/yellow stripe D. Contractor may use colored tape marking for size 8 and larger phase and neutral conductors, and size 4 and larger ground conductors. E. Switch legs are to be color coded the same as the un-switched phase, i.e., all wiring from lighting control panels and contactors shall retain the phase color. F. If existing construction has a consistent but different color coding, match existing. 2.10 SPECIAL SYSTEMS CABLE COLOR CODING A. Fire Alarm Red B. P/A Communications White C. Misc Low Voltage/Sound Gray D. Data Cabling Refer to Structured Cabling and Data Racks Specifications E. Telephone Cabling Refer to Telephone Systems Specifications D. Other Wiring Consult with Engineer/Owner. Do not use one of the assigned colors without authorization. END OF SECTION 16450 Electrical Wiring Page 8 Project 1325