Cataloge Wastewater - J

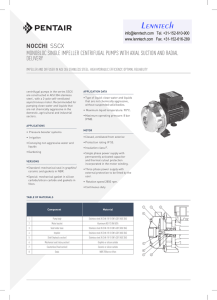

advertisement