Investment Grade Audit (IGA) Report

advertisement

Bethany College

Guaranteed Energy Savings Project

Investment Grade Audit

Energy Conservation Measure Description

Date:

December 5, 2013

Prepared by:

Constellation New Energy

2090 Greentree Road

Suite 200

Pittsburgh, PA 15220

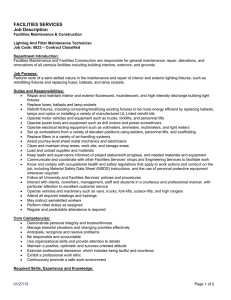

Energy Conservation Measure (1-3) SUMMARY

CUSTOMER:

Bethany College

PROJECT #:

111884

PROJECT NAME:

Bethany College

Incl.

ECM

(Y/N)

#

ECM DESCRIPTION

SELL PRICE

ENERGY SAVINGS

Turnkey

CONSUMPTION

ECM

Cost

Elec Dem Elec Con Steam Utililty UtilityNatural Gas

Propane Water

ECM

SAVINGS PAYBACK

TOTAL

Monthly

$

ECM 1

Lighting Retrofit/Exterior Lighting/Occ Sensors $1,639,685

ECM 2

Water Conservation

$354,284

ECM 3

Control Upgrades scheduling/night setback

$452,277

kW

kWh

1

2

282

1,192,232

614,812

mmBTU Unit Unit

3

MCF

Gal

kGal

6

7

8

-

-

-

-

32

-

-

10,074

-

4

5

-

$

yrs

-

$119,251

13.7 yrs

1,214

$18,009

19.7 yrs

$91,642

4.9 yrs

ECM 1: Lighting Improvements & Occupancy Sensor Installation

Overview

Constellation staff, in coordination with Bethany College, has completed a detailed line by line energy

audit of the specified lighting systems to provide the most beneficial design possible. The primary

design strategy includes upgrading existing T8 and T12 lighting components to a high efficiency T8

system (Sylvania 28 watt Supersaver/QHE) in an effort to maximize both energy and material savings.

Existing interior High Intensity Discharge (HID) will be replaced with new fixtures containing a high

efficiency T5 system (Sylvania 28 watt Pentron/QTP). Existing Exterior High Intensity Discharge (HID)

components will be replaced with a high efficiency Induction Lighting System (Sylvania ICETRON/QT

ICE). Induction Lighting is designed for long life, with a lamp life cycle up to 100,000 hours. It is an

energy efficient alternative to HID with instant on capabilities and very low operational maintenance

under normal operating hours.

Existing fluorescent fixtures which are in good condition and meet a certain level of efficiency will be

re-lamped and re-ballasted with proposed system. Existing fluorescent fixtures which may be

retrofitted to be more efficient will be upgraded with installation of reflector kits and the proposed

system. Existing fluorescent fixtures, which can’t be upgraded by re-lamp/re-ballast or retrofit, will be

replaced with new luminaries containing the proposed system.

Existing incandescent and compact fluorescent exit signs will be replaced with a new LED signs. Existing

incandescent and compact fluorescent illuminating fixtures will be replaced with high performance

compact fluorescent equivalents.

The proposed upgrade takes into account four major components of a lighting system – use, quality,

maintenance, and energy savings.

Bethany College IGA ECM Description

December 5, 2013

Page 1

Constellation uses a diversity factor to accommodate any holidays, vacation time or unscheduled

closures related to each buildings lighting operating hours. The energy savings guaranteed after the

implementation of the lighting retrofit are based on the application of such a diversity factor to the

energy calculations. Without applying the diversity factor, the lighting retrofit would generate a 10%

higher annual savings (not considering heating/cooling penalty).

Also, Constellation has only factored material savings in their calculations.

Present Condition

These facilities lighting systems are made up of fixtures which contain Primarily T12, T8, and HID lamps

and ballasts – all of these components will be replaced with a high efficiency lighting system.

Proposed Design/Condition

Constellation proposes to re-lamp re-ballast many existing fixtures which have suitable photometrics

for use in that specific area. All industrial fixtures such as hooded reflector types and strip fixtures with

exposed lamps will have a protective sleeve tube guard added for protection of the

lamps and as a safety component against breakage.

Constellation proposes to install several types of reflector kits throughout the facility

which will produce the necessary light output while using fewer lamps and ballasts.

Areas with 3 or more lamps in recessed fixtures will be the preferred lighting design

for reflector kits. This will reduce material cost while maintaining IES light levels

standards.

Constellation proposes to retrofit existing incandescent fixtures with compact

fluorescent equivalents. Recessed incandescent lighting will be replaced with

compact fluorescent lamps comparable to the existing incandescent wattage.

Surface mounted incandescent fixtures will be replaced with compact fluorescent fixtures aesthetically

designed for the location in which they will be installed.

Constellation proposes to replace existing fixtures which have deteriorated past the point of retrofit or

where a different style luminary would be more suitable.

Constellation proposes to replace existing interior HID fixtures with new high efficiency T5 HO fixtures.

The T5 HO high bay style fixtures will provide greater illumination and instant on capabilities. A high

efficiency Induction lighting system will be installed in various exterior HID fixtures where a T5

luminary is not feasible such as HID canopy fixtures, wall packs and pole lighting.

Constellation proposes to install several occupancy sensors to maximize possible energy savings in

specified areas which demonstrate an acceptable payback. Classrooms, offices and restrooms will be

the greatest energy savings opportunity areas as these type spaces will be utilized the most by

students, teachers and administrative staff. Constellation proposes to install occupancy sensors in

frequently occupied areas to automatically shut off lighting when the space is unoccupied. Ceiling

mount Dual Technology self adjusting occupancy sensors, which provide 360° of coverage and use

both passive infrared and ultrasonic technologies to sense occupancy will be installed. The occupancy

sensors will require power pack relays for interconnection with the lighting circuits. The design

Bethany College IGA ECM Description

December 5, 2013

Page 2

configuration in large open spaces may consist of a network of power pack relays for individual lighting

fixtures linked to a specific occupancy control. These controls will reduce energy consumption by

shutting off lighting when no occupants have been detected for a period of time.

Constellation proposes to replace existing incandescent and compact fluorescent exit signs with LED

exit signs and LED retrofit kits. LED exit signs have extremely low energy consumption and

maintenance with long LED lamp life.

Recommended Manufacturers

T8 Lamps

o

Sylvania 4’ FO28/SS/841XP 28w

o

Sylvania 3’ FO25/841XP 25w

o

Sylvania 2’ FO17/841XP 17w

T5 Lamps – Sylvania 4’ FP54/841HO 54w

Electronic T8 Ballasts – Sylvania QHE

High Output T5 Ballasts – Sylvania QTP

Linear T8 Retrofit Kits – On Time Lighting

LED Exit Signs – On Time Lighting

Compact Fluorescent Lamps – Sylvania CFLs

New Linear T8 Fixtures – On Time Lighting

New Linear T5 Fixtures – Philips Optimum Lighting

New Induction Fixtures – 1st Source Lighting

Occupancy Sensors – Leviton

Scope of Work

The following components and services shall be provided as part of the project

Final engineering analysis and design of existing lighting system at the buildings identified in

the preliminary assessment report

Develop the priority of work to be accomplished in conjunction with the facilities

Retrofit/install all required lamps, fixtures and other equipment as determined through IGA

Lamp and PCB ballast disposal/recycling to be provided by a certified and approved contractor

The following equipment provided:

i.

T8 Lamps and Electronic Ballasts as specified

ii.

T5 Lamps and Electronic Ballasts as specified

iii.

Compact Fluorescent Lamps as specified

Bethany College IGA ECM Description

December 5, 2013

Page 3

iv.

LED Exit Sign as specified

v.

New Linear Fluorescent Fixtures as specified

vi.

Linear Retrofit Kits as specified

vii.

New Induction Fixtures as specified

viii.

Occupancy Sensors as specified

Source of Utility Savings

Lighting is often the easiest and most cost-effective retrofit measure that

a facility can undertake. According to the U.S. Environmental Protection

Agency (EPA), approximately 25 to 30 percent of a building’s energy bill is

for lighting. In addition, lighting upgrades are considered low-risk and

typically have greater than 25 percent (less than four-year) rate of return.

Finally, these retrofits usually have other benefits including the reduction

in maintenance costs (because high-efficiency lamps tend to last longer)

and the enhancement of light levels and reduction of glare.

Energy-efficient fluorescent lamps save 15% to 20% of the wattage used by standard fluorescents

(T12-type) and last just as long. Although T8 lamps are more expensive than T12 lamps, the additional

costs are more than justified by energy savings. T8 lamps provide 98% as much light as do standard

lamps and consume approximately 40% less energy when installed together with electronic ballast.

Electronic ballasts operate at higher frequencies than do conventional electromagnetic ballasts, and

consequently convert power to light more efficiently. Electronic ballasts generate 75% less noise than

conventional electromagnetic ballasts, eliminating the flicker and hum commonly associated with

fluorescent lighting.

Induction lighting is fluorescent based technology that operates without the use of an electrode.

Energy is transferred to the lamp by an inductively coupled high frequency magnetic field which reacts

with phosphors to create illumination. The absence of an electrode eliminates the common failure

point found in most lamps, therefore providing an extremely long lasting light source. Induction lamps

and ballasts are rated at 100,000 hours, five times the rated life of traditional light sources. Electronic

induction ballasts operate at a high frequency rate for improved performance and a higher level of

efficiency. Full spectrum, high Kelvin induction lamps contain high grade phosphors to increase color

rendering (CRI). Compared to traditional light sources, induction lamp and ballast systems provide

better quality, highly visible white light for superior illumination with reduced wattage.

Light-Emitting Diode (LED) signs consume only about 2 watts of energy and last 20 years. The life-cycle

cost of LED signs is about one-half that of a compact fluorescent lamp and about one-quarter of an

incandescent lamp.

For each of the upgrades, calculations for the change in power, consumption and cost were completed

as follows:

Energy savings for this ECM is determined through the following equation:

Bethany College IGA ECM Description

December 5, 2013

Page 4

Savings kWh = (Annual Operation Hours x Lighting kWbase year) – (Annual Operation Hours

x Lighting kWpost-retrofit)

The difference between the kWh consumption for the existing lighting system and the new system is

the lighting energy reduction. Cost savings due to this measure are simply the kWh reduction

multiplied by the established cost per kWh.

The savings amount will be determined by the following equations:

Energy Reduction (in kWh) = Lighting kWhbaseyear –Lighting kWhpost-retrofit

Cost Savings ($/yr) = Energy Reduction (in kWh) x $/kWh (Electricity Rate)

Physical Changes

Existing fixtures scheduled to be retrofit will be wiped clean during the installation of the new lamps

and/or ballasts. Any broken or malfunctioning fixtures will be brought to the attention of facility

personnel. Fixtures scheduled for replacement, will be safely disconnected and removed from the site

for proper disposal. New fixtures will be installed in a similar location. All installation locations of new

fixtures will be included in the line by line audit.

Light Level Compliance

The proposed upgrades will meet all IES illumination level standards pertaining to light level

requirements based on the existing lighting system to which will be maintained. All linear fluorescent

lamps will have a color temperature of 4100 Kelvin which will provide a CRI of 85. Measurement and

verification including foot candle readings will be included in the M&V section of the proposed

documents.

Utility Interruptions

No building-wide utility interruptions are anticipated, however, individual areas will be impacted as

power is shut off to allow for either the fixture retrofit or installation of a new fixture.

Agency Support Required

Constellation will coordinate construction activities with Bethany College personnel to minimize

interruptions for day to day academic and administrative schedules.

Potential Environmental Impact

Lamps removed from the facility will be recycled. The reduction in electricity usage as a result of this

measure will lead to a reduction in electric power plant emissions. All ballasts, some of which may

contain PCB, will be disposed of according to local and Federal EPA rules, regulations and laws.

Documentation from an approved recycling company will be obtained from the subcontractor for

proper disposal of all lamps and ballasts removed from the facility.

O&M Impact

The installation of new, efficient lamps and ballasts will result in significant material savings due to

both – the manufacturer’s warranties and longer life of the new equipment.

Bethany College IGA ECM Description

December 5, 2013

Page 5

Estimated Life of Major Components (Based on Average Rated Life Hours per Start)

Component Name

Estimated Life

(Hrs)

Linear T8 Lamps

36,000 Hrs

Linear T5 Lamps

36,000 Hrs

Induction Lamps

100,000 Hrs

Compact Fluorescent Lamps

10,000 Hrs

Compact fluorescent Adaptor

10,000 Hrs

Electronic Ballasts

70,000 Hrs

Led Exit Signs and Retrofit Kits

100,000 Hrs

Fixture Luminaries

25 years Est.

Occupancy Sensors

70,000 Hrs

M&V Approach

Metering and Verification of savings shall be undertaken as described in the section “M&V

Methodology and Determination of Baseline”.

Owner Support Requirements

Once the installed ECMs are accepted by Bethany College, the college shall be responsible for the

operation and maintenance of all new ECM equipment and existing equipment that relates to the

Project. A Project specific Operations Manual shall be prepared once the new ECM equipment is

installed and any training is provided for the operations and maintenance of the new ECM equipment.

Bethany College shall follow all manufacturers’ recommendations for maintenance tasks and

schedules.

Bethany College IGA ECM Description

December 5, 2013

Page 6

The Environmental Impact of the Guaranteed Energy Savings Project

Not only does this project save money; it saves energy. Energy use is directly linked to the impact

Bethany College has on our environment. By reducing the annual electricity use by 1,192,232 kWh

through the Comprehensive Lighting Retrofit, the College will keep many tons of carbon dioxide and

other harmful pollutants out of the atmosphere. The table below lists the CO2 equivalencies from the

energy savings for this project.

Bethany College Lighting Upgrade

Electricity saved

CO2 emissions

saved

CO2 emissions

saved

Annual Emissions

1,192,232

kWh

841

Metric tons

1,854,483

Pounds

Which is equivalent to:

Greenhouse Gases

175

From

Passenger vehicles

CO2 Emissions From

94,303

Gallons of gasoline

CO2 Emissions From

CO2 Emissions

From

CO2 Emissions From

1,956

Barrels of oil

116

Homes' electricity use

42

Homes' energy use

Carbon

Sequestered From

21,569

Carbon

Sequestered From

689

Acres of US forests

CO2 Emissions From

35,049

Propane cylinders

CO2 Emissions From

3.6

Railcars of coal

Greenhouse Gas

Emissions Avoided

From

315

Tons of waste recycled vs. going to

landfill

Bethany College IGA ECM Description

December 5, 2013

Tree seedlings grown for 10 years

Page 7

ECM 2: Water Conservation

Overview

Constellation proposes to improve the operating performance and water efficiency of water

consuming systems found at Bethany College through the application of several water and related

energy conservation strategies. Water and sewer savings for this ECM are derived from reduced water

flow consumed by the water fixtures, either by fixture replacements or by rebuilding fixtures.

Present Condition

Below is a list of systems that are currently in use in the facilities:

Toilets: Toilets on site consume 3.5 GPF.

Urinals: Urinals range from 1.6 GPF to 2.5 GPF.

Sinks: Sink faucets range from 2.0 GPM to 3.5 GPM depending on the application.

Showerheads: Showerheads throughout the facilities have a flow rate of 2.5 GPM.

Proposed Condition

By retrofitting or replacing existing equipment with new low flow devices the school will realize

reduced water consumption and reduced domestic hot water generation demand. The following list

describes the equipment to be installed in the buildings:

Toilets: Existing toilets that have a flush rate greater than 1.6 GPF will either be retrofitted or

replaced with 1.6 GPF equipment.

Urinals: Existing urinals that have a flush rate greater than 1.0 GPF will be retrofitted or

replaced with 1.0 GPF equipment.

Sinks: Sink faucets will be retrofitted with a new 0.5 GPM faucet aerators. In addition to water

savings, the reduced flow will also provide thermal savings from reduced hot water usage.

Showerheads: Showerheads with a flow greater than 1.5 GPM will be replaced with new 1.5

GPM showerheads. Similar to the sinks, the reduced flow will provide water savings and

thermal savings from reduced hot water usage.

All Americans with Disabilities Act (ADA) compliant fixtures will be replaced with applicable

ADA fixtures.

Scope of Work

The following list provides the standard scope procedure for the measure:

Sink Aerators

a. Remove existing aerator and dispose of properly.

b. Furnish and install a new 0.5 gallons per minute (GPM) pressure compensating

aerator, according to audit and field verification.

c. Turn on water supply to sink. Test the faucet for leaks and proper operation.

Shower heads

a. Remove existing standard showerhead or handheld showerhead and dispose of

properly.

Bethany College IGA ECM Description

December 5, 2013

Page 8

b. Furnish and install a new 1.5 gallons per minute (GPM) standard showerhead or

handheld showerhead fixture, according to the audit and field verification.

c. Turn on the water supply to the shower. Test showerhead for leaks and proper

operation.

Toilets

a. Remove and dispose existing toilet, flush valve, and control stop properly.

b. Furnish and install a new 1.6 gallons per flush (GPF) tank toilet and 1.6 gallons per

flush (GPF) toilet china depending on the application and according to the audit and

field verification.

c. Retrofit or replace existing flush valves and control stops according to audit and field

verification.

d. Supply and install restroom shut off valves for each restroom water main.

e. Turn on water supply to toilets or flush valves. Test for leaks and proper operation.

Source of Utility Savings

In determining the savings for Bethany College, Constellation analyzed the water consumption of the

facility by breaking it up into groups to facilitate the analysis and to gain a better understanding of

where water can be best saved. The majority of the water use is broken up into the following areas:

domestic (bathrooms), kitchen use and lab / classroom areas.

Water use is determined by measuring the existing flow rates and gallons per flush of a statistically

derived sample of each fixture type. These flow rates and gallons used per flush are then multiplied by

the usage profiles for these fixtures in order to determine the yearly water use for each device. Usage

profile patterns are based on three parameters: population, occupancy schedules and the frequency of

use of these fixtures. The population consists of only full time personnel and students.

Once the existing annual water use of the plumbing fixtures is calculated, the post retrofit water use is

calculated based on the proposed flow rates and gallons used per flush for each fixture type. It is

assumed that the usage profile patterns will remain unchanged after the new equipment is installed.

The difference between the existing and proposed water use is the savings.

Energy savings associated with the reduction of domestic hot water use is calculated by determining

the reduction of water use of faucets and applying an estimate of the percent of hot water use each

time the faucet is used. This calculation is done for existing and post-retrofit conditions. Again, the

difference between these two conditions is the savings.

A comprehensive audit of all the plumbing systems of the facilities has been conducted to determine

the type, styles and quantities of the toilets, urinals, sinks and showers. The water audit coupled with

Constellation’s project developers’ knowledge and the facilities input on usage was used to determine

the proposed equipment. A summary of this information appears in the table to follow.

The following table lists the fixture quantities to be replaced or retrofitted at Bethany College:

Bethany College IGA ECM Description

December 5, 2013

Page 9

Building

New

1.28 GPF

Tank

Type

Toilet

New

1.28

GPF

Toilet

China

w/ FV

New

1.28

GPF

Toilet

FV

New

1.0

Urinal

FV

New

0.5

GPM

Aerator

New

1.5

GPM

Aerator

Bethany

College

138

119

28

26

647

110

New

0.5

GPM

Faucet

New

1.5

GPM

Shower

Head

New 1.5

GPM

ADA W/

Hand

Held

Sprayer

50

367

1

Variable

Assumption

# of Men & Women

in the Facility

The estimate of the number of women and men in the facility was assumed

based on the facility type and function. See detailed calculations for the

quantities of men and women used to determine the existing and post retrofit

usage.

Existing Number of

Flushes per Person

per Day

The number of flushes for the toilets and urinals was based on empirical data

obtained from the American Water Works Association (AWWA) and modeling

of the water use for each building. See detailed calculations for the number of

flushes per person for both the male and female occupants to determine the

existing and post retrofit usage.

Existing Minutes of

Faucet and Shower

Use per Person per

Day

The number of minutes for the faucets and showers based on empirical data

obtained from the American Water Works Association (AWWA) and modeling

of the water use for each building. See detailed calculations for the amount of

time that the occupants use the faucets and showers to determine the existing

and post retrofit usage.

Occupied Days per

Year

This information was obtained from information gathered during the site visits

and occupant surveys.

Existing Toilet GPF

Unless specifically labeled on the fixture, it is assumed that the existing toilet

consumes 3.5 GPF.

Existing Urinal GPF

Unless specifically labeled on the fixture, it is assumed that the existing urinal

consumes 1.6 GPF.

Existing Faucet

GPM

If the faucet aerators were missing, it is assumed that the existing water flow is

3.0 GPM. For fixtures where the aerators were present, nameplate data was

used in the calculations and will be field verified on a sample of fixtures.

Existing Shower

GPM

Unless specifically labeled, the water use for the existing showerheads was

assumed to be 2.5 GPM and will be field verified on a sample of fixtures.

Proposed Toilet GPF

The water use for the new tank toilets is assumed to be either 1.1 GPF or 1.6

GPF and 1.28 GPF or 1.6 GPF for the toilets equipped with flush valves.

Proposed Urinal

GPF

The water use for urinals is assumed to be 1.0 GPF.

Bethany College IGA ECM Description

December 5, 2013

Page 10

Variable

Assumption

Proposed Lavatory

Faucet GPM

The water use for lavatory faucets is assumed to be 0.5 GPM.

Proposed Kitchen

Faucet GPM

The water use for kitchen faucets is assumed to be 1.5 GPM.

Proposed Shower

GPM

The water use for the new showerheads is assumed to be 1.5 GPM.

Domestic Hot

Water System

Efficiency

The hot water system efficiency of 85% was used to quantify savings.

Temperatures of

Domestic Hot

Water and City

Water

It is assumed that the domestic hot water temperature is 120°F and the city

water temperature is 55°F.

% of Hot Water Use

for Faucets and

Showerheads

It is assumed that hot water makes up 85% of the total water use of the faucets

and showers.

The following calculation are for Water and Energy Savings:

Frequency of Use

(uses/yr),

(flushes/yr,

min/yr)

=

[(Number of Users (FT Male) x Fixture Uses/Day/Person) +(Number of Users

(PT Male) x Fixture Uses/Day/Person) + (Number of Users (FT Female) x

Fixture Uses/Day/Person )+ (Number of Users (PT Female) x Fixture

Uses/Day/Person )] x days/wk x wks/yr

Existing &

Proposed Water

Usage (gal/yr),

(toilets & urinals)

Existing Water

Usage (gal/yr),

(sinks & showers)

Proposed Water

Usage (gal/yr),

(sinks & showers)

Water Savings

(gal/yr)

=

Frequency of Use x [(Number of High Flow Fixtures / Total Number of

Fixtures) x High Flow Rate (GPF per fixture) + (Number of Low Flow Fixtures /

Total Number of Fixtures) x Low Flow Rate (GPF per fixture)]

=

Frequency of Use x Average Flow rate of Current Fixtures (gpm)

=

Frequency of Use x Proposed Flow rate (gpm)

=

Existing Water Usage - Proposed Water Usage

Sink & Shower

Energy Savings

(MMBTU/yr)

=

Water Savings (gal/yr) x 1/2 Hot Water x 8.34 lb/gal x (Domestic Hot Water

Temp. – City Water Temp.) x 1 Btu/lb-F x (1 MMBTU / 1,000,000 Btu)

O&M Impact

Bethany College IGA ECM Description

December 5, 2013

Page 11

While operation and maintenance (O&M) savings are not proposed, Bethany College will realize a

reduction in associated repair materials and labor due to the replacement of old equipment with new

equipment. The new toilets will eliminate the facility’s need to annually replace flappers, handles and

fill valves for a full maintenance cycle. Additional savings will also be realized through reduced energy

costs related to savings associated with showerheads and aerators.

Estimated Life of Major Components

Component Name

Estimated Life (years)

Toilets (china)

30

Flushometer

20

Urinal

20

Faucet Flow Control

8

Showerhead

8

M&V Approach

Metering and Verification of savings shall be undertaken as described previously in the section “M&V

Methodology and Determination of Baseline”.

Owner Support Requirements

Once the installed ECMs are accepted by Bethany College, the college shall be responsible for the

operation and maintenance of all new ECM equipment and existing equipment that relates to the

Project. A Project specific Operations Manual shall be prepared once the new ECM equipment is

installed and any training is provided for the operations and maintenance of the new ECM equipment.

Bethany College shall follow all manufacturers’ recommendations for maintenance tasks and

schedules.

Training

The following table summarizes our approach to training Bethany College personnel for this ECM:

Constellation Training Components

Bethany College IGA ECM Description

December 5, 2013

Page 12

Training Plan Components

Type(s) of Training Sessions

work procedure training for ECMs requiring a change in hands-on field sessions to familiarize

existing operating conditions

training appropriate Bethany College personnel in the

operation, maintenance, emergency shutdown / response

and repair of ECM equipment

training appropriate Bethany College personnel in all

Bethany College employees with the

ECMs installed, and to observe

hands-on

operating,

troubleshooting, maintenance and repair

procedures

operation,

maintenance,

repair

and

replacement

requirements to maintain savings achieved by proper

operation of each ECM

Specific to this ECM implemented, Constellation training materials will include the following:

a general discussion of installed equipment and controls;

operation and maintenance (O&M) and repair and replacement (R&R) practices and

procedures;

warranty documentation which is particularly important with new installations (because

manufacturers typically make R&R of malfunctioning equipment easy and straightforward as

long as the proper procedures for replacing and repairing failed equipment are carefully

followed); and

Constellation Post-Installation M&V Scope of Services to be performed.

Each Constellation training session will explain why we are implementing a particular measure, where

it is, how it works, and what to do in an emergency. Constellation takes great care to observe client

personnel during training, to make sure that effective training is provided and that results in the

efficient and safe operation of all ECMs.

The timing, location, and scheduling of training is customized for the client, based on the technologies

installed and the number and location of Bethany College personnel included in the training.

Training never stops during the course of a performance contract. As personnel changes within

Bethany College, Constellation is always willing to retrain new employees. Our team of Operations

engineers is available as an additional resource for your Facilities team.

Bethany College IGA ECM Description

December 5, 2013

Page 13

ECM 3: Control Upgrades and Scheduling

A majority of the mechanical systems on the campus operate via local control and are operational 24

hours per day seven days a week. Energy and cost savings can be achieved by scheduling the

mechanical equipment based on building occupancy. Additionally, there are several buildings with

DDC and or Pneumatic control systems. All of these systems are independent to each building and

there is no common front end interface for use by the facility maintenance staff.

Constellation is recommending the installation of new controls in Benedum Commons and on any new

boilers and chillers installed as part of the project. In addition, the following new control points and

functions are recommended for the existing control systems:

Provide programming for existing DDC systems to allow for time of day scheduling of air

handling units and exhaust fans

Provide new controls to allow for demand control ventilation on AHU-4 and AHU-5 in

Benedum Commons

Install new chilled water control valve and incorporate valve into the existing DDC system

for control of cooling coil on AHU-8 in Benedum Commons

Provide controls to monitor and enable and boilers chillers via the existing DDC systems

Measure Summary

During the site visit, it was stated that all of the existing systems in the facilities are allowed to operate

continuously, to maintain space temperature set points, regardless of occupancy.

Based on our baseline assessment of the buildings energy consumption, we can confirm the heating

and ventilating systems in the buildings are operating more than necessary, and energy savings from

scheduled operation will result in energy savings.

Baseline Conditions

All facilities in this analysis have some form of control. However, only a small proportion of the

systems benefit from digital control. New equipment has more updated controls, but depending on

the date of installation, the technology may be dated. While larger equipment benefits from yearly

inspections and calibrations, end devices such as unit ventilators and fan coils do not get any attention,

unless there is a cold or hot call.

All of the facilities have areas that would benefit from scheduled operation. Many of the buildings are

used on a scheduled basis and selected areas, in the main building, could also be scheduled to account

for the diversity between shifts. Additionally, all of the facilities were open to the idea of occupied

setback if proper temperature control could be achieved.

Proposed Conditions

An energy management system (EMS) has many capabilities not presently available in the facilities.

Such a system will allow maintenance personnel to monitor through a personal computer, either onBethany College IGA ECM Description

December 5, 2013

Page 14

site through the local LAN, or remotely by accessing the Internet. This allows personnel to view the

equipment parameters in real time and better diagnose any problems without having to having to see

the equipment. Through trending and alarms, information can be gathered over time to see how

systems work and react to changes. Alarms will call to attention any preset limits that have been

exceeded, hopefully alerting personnel to problems before it can affect comfort significantly.

Control of the equipment is another capability. Through direct digital control (DDC), control

algorithms can be customized and changed to adapt to new conditions. Control accuracy is also

improved through DDC. Pneumatic controllers will be eliminated; however, the end devices such as

valves and actuators may continue to be utilized.

The EMS is also a tool for energy conservation. While equipment in many areas is required to run

continuously, there are select pieces that can be shut down at night. By allowing these units to shut

down and remain off unless a preset unoccupied setpoint is exceeded, savings can be achieved. There

will also be savings by fine tuning the control algorithms and adjusting set points, but they are difficult

to quantify and are not included in our estimates.

For a majority of the buildings, time of day control will be implemented as described below.

TOD On/Off Control (Night Setback)

For this control strategy, the BAS will control the operation of the HVAC equipment in accordance with

a programmed schedule, based upon the occupied and unoccupied periods in a building. Automation

of the operating schedule provides for prompt starting and stopping of the equipment yielding savings

in thermal and electrical energy. The BAS Software will allow local unit controls to do selfprogramming and recalculation of their optimal start/stop time for morning warn-up. The program

may also be modified to reflect changes to building occupancy or seasonal loads. An operator will be

able to override the program to change occupancy mode of the building operation as needed.

During unoccupied periods, these thermostats will be used to cycle the air handlers on and off to

maintain setback (about 60 F) or setup (about 80 F) set points depending upon the time of year.

Additionally, the outside air dampers will be closed reducing the heating and cooling of outside air.

During occupied hours, the air handlers will remain under existing control sequence of operation.

Energy Savings Proposed

Energy savings for this measure derive from these factors –

Reduced fan operation;

Reduced Heating Energy Consumption

Reduced Unoccupied Ventilation

Reduced cooling energy consumption

Calculation Methodology

Calculations utilize bin temperature data for nearest WV weather station will be averaged over 30

years. For each temperature bin, the energy usage will be:

Fan power usage (kWh) = Σ [Fan power kW * hours of operation at bin temperature]

Bethany College IGA ECM Description

December 5, 2013

Page 15

Variable Speed Fan - The following equation is represented:

N 2 3

N1

BHP2 BHP1

Where:

BHP2 = Break Horsepower of less than 100% Load

BHP1 = Break Horsepower at 100% Load

N2

= RPM of the motor at less than 100% load

N1

= RPM of the motor at 100% load

Heating Energy Use - The following equation is represented:

Heating Energy (MMBtu) = Σ [supply fan CFM * 1.085 * (discharge temp (oF) – OA bin temp) *

hours operation in that bin temperature] * (1-heat recovery efficiency)/ (1,000,000

Btuh/MMBtu) / Heating efficiency of 100%

Cooling Energy Use - The following equation is represented: (though not included in savings number

due to no chilled water rate):

Cooling energy (mmBtu) = Σ[Supply fan CFM * 1.085 * (OAT – discharge temp (oF)) * 1/sensible

load ratio of .7 * hours operating in that bin temperature period)] * 1mmBtu/1,000,000 Btu

Energy Savings are based on the following formulas:

Fan savings = Σ[existing fan power consumption, kwh – proposed fan power consumption]

Heating Energy Savings are based on the following formulas:

Heating Savings = Σ[existing heating energy, MMBtu – proposed heating energy, MMBtu]

Cooling Energy Savings are based on the following formulas:

Cooling Savings = Σ{existing cooling energy, mmBtu – proposed cooling energy, mmBtu]

Measurement & Verification Plan

Constellation Energy will use Option “B” to determine the energy savings associated with the

implementation of time of day on/off control measure.

Bethany College IGA ECM Description

December 5, 2013

Page 16

An M&V Plan using IPMVP Option “B” is to be used for savings determination for this ECM. Preretrofit energy consumption is based on engineering calculations and verified with occupied hours

trend data collected over a period of approximately one month during the heating and cooling

seasons. Data will be collected on the applicable equipment / point types necessary. Post-retrofit

energy consumption will be based on engineering calculations and short-term trend data (over a

period of one to two months) or long-term trend data (up to one full year of data) collected via the

existing Building Automation System (BAS).

The first year Measurement and Verification Report will be presented one year after commissioning

of the BAS begins. The same points where pre-retrofit data was collected will be trended via the BAS

after commissioning to determine thermal energy savings.

Baseyear Energy Use

The baseyear energy use takes into account the following major factors –

Space temperature setpoint in effect

Outside air load

The baseyear energy use during unoccupied hours is basically due to the total shell and roof load, on

the basis of given setpoint during those hours and the outside air load. This would include cooling,

heating and humidification loads. The Baseyear setpoint is 74°F for cooling and 68°F for heating. The

formula used to determine cooling, heating and loads are presented below and apply to the

unoccupied hours for the building.

The formula to determine baseyear cooling energy for the unoccupied hours is as follows

BTUannual unoccupied hours cooling = Σ [4.5 x (Enthalpyoutside air – Enthalpydischarge air) x CFMoutside air]

x ΔT

Where ΔT is the difference between the outside air and the inside air setpoint of 74°F or 68°F

depending on the operating mode.

The formula to determine baseyear heating energy for the unoccupied hours is as follows

BTUannual unoccupied hours heating = Σ [1.08 x (Temperatureoutside air – Temperaturedischarge air) x

CFMoutside air) + Σ (1.08 x (Temperaturereturn air – Temperaturedischarge air) x CFMreturn air] x ΔT

Where ΔT is the difference between the outside air and the inside air.

Baseyear energy use for the AHU fans will be established by actual field measurements.

kW = (Voltagephase-to-phase x Amperage x Power Factor)/1000

The annual kW consumption for the fans is given by the following formula –

kWh = [(Voltagephase-to-phase x Amperage x Power Factor) x Hours of Operation]/1000

Bethany College IGA ECM Description

December 5, 2013

Page 17

Post-Retrofit Energy Use

During unoccupied hours in the post-implementation period, the heating setback set point will be 60°F

for all buildings. Cooling will not be supplied during scheduled unoccupied hours. Since cooling will

not be supplied during unoccupied hours, post-implementation cooling savings equals preimplementation cooling costs during those same hours for the night setback period.

The formula used to determine the post-retrofit heating load is similar to that used to determine the

pre-retrofit load with the exception that the night setback temperature of 60°F for all buildings except

is used in determining the ΔT instead of the daytime space temperature setpoint of 74°F. The formula,

then, becomes the following –

BTUannual unoccupied hours heating =

Σ [1.08 x (Temperatureoutside air – Temperaturedischarge air)

x CFMoutside air] + Σ [1.08 x (Temperaturereturn air – Temperaturedischarge air) x CFMreturn air] x ΔT

Where ΔT is the difference between the outside air and the night setback temperature of 60°F for all

buildings

After installation and commissioning, the post-retrofit energy use will be determined as –

Baseyear Energy Use + Correction to Post-Retrofit Condition

Routine Adjustments

Any changes to the buildings operating parameters and its building systems will require adjustments to

bring post-retrofit energy use to the conditions of the baseyear.

Savings

The amount of energy required for satisfying the base year requirements for heating and cooling

during unoccupied hours will be compared with the energy use for night setback points during

unoccupied hours post-retrofit, i.e. with the terminal units retrofitted with new controls.

The savings amount for heating & cooling will be determined by the following equation –

Savings (in BTUs) = (Existing Heating BTUannual unoccupied hours – Proposed Heating BTUannual

unoccupied hours)

+ BTUannual unoccupied hours cooling

Cost savings for the fans due to this measure are simply the kWh reduction multiplied by the

established cost per kWh.

The savings amount for the fans will be determined by the following equations –

Fan Energy Reduction (in kWh) = Fan kWhbaseyear –Fan kWhpost-retrofit

Staff Responsibilities

Constellation will train the facility maintenance staff in the necessary ongoing maintenance procedure

which will be provided in written form to Bethany College upon the conclusion of the construction of

the ECMs in this package. The new DDC points will have the same maintenance requirements as the

existing DDC points.

Bethany College IGA ECM Description

December 5, 2013

Page 18

The Environmental Impact of the Guaranteed Energy Savings Project

Not only does this project save money; it saves energy. Energy use is directly linked to the impact

Bethany College has on our environment. By reducing the annual electricity use by 614,812 kWh

through the DDC Control System Upgrade, the College will keep many tons of carbon dioxide and other

harmful pollutants out of the atmosphere. The DDC Controls Upgrade will also save 10,074 mcf in

natural gas consumption. The table below lists the CO2 equivalencies from the energy savings for this

project.

Bethany College DDC Control System Upgrade

Electricity saved

CO2 emissions

saved

CO2 emissions

saved

Annual Emissions

614,812

kWh

478

Metric tons

956, 323

Pounds

Which is equivalent to:

Greenhouse Gases

90.4

From

Passenger vehicles

CO2 Emissions From

48,630

Gallons of gasoline

CO2 Emissions From

CO2 Emissions

From

CO2 Emissions From

1,009

Barrels of oil

59.7

Homes' electricity use

21.7

Homes' energy use

Carbon

Sequestered From

11,123

Carbon

Sequestered From

356

Acres of US forests

CO2 Emissions From

18,074

Propane cylinders

CO2 Emissions From

1.9

Railcars of coal

Greenhouse Gas

Emissions Avoided

From

162

Tons of waste recycled vs. going to

landfill

Bethany College IGA ECM Description

December 5, 2013

Tree seedlings grown for 10 years

Page 19