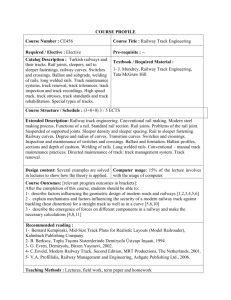

Track Mechanization Seminar: Indian Railways Maintenance

advertisement