BPG - NZ Arboricultural Association Inc

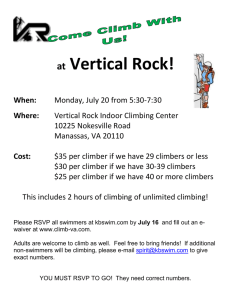

advertisement