Controlled Clockwise-counterclockwise Motion of the Ring

SUPPORTING INFORMATION for bm-2011-00829t.R1

Controlled Clockwise-counterclockwise Motion of the

Ring-shaped Microtubules Assembly

Akira Kakugo

1, 2,*

, Arif Md. Rashedul Kabir

3

, Natsuki Hosoda

3

, Kazuhiro Shikinaka

4

, and Jian Ping

Gong

1,*

1

Faculty of Advanced Life Science, Hokkaido University, Sapporo 060-0810, Japan.

2

PRESTO, Japan Science and Technology Agency, 4-1-8 Honcho, Kawaguchi, Saitama 332-0012,

Japan

3

Division of Biological Sciences, Graduate School of Science, Hokkaido University, Sapporo 060-

0810, Japan

4

Graduate School of Engineering, Tokyo University of Agriculture and Technology, Koganei 184-8588,

Japan

*Authors to whom correspondence should be addressed.

E-mail: gong@mail.sci.hokudai.ac.jp; kakugo@sci.hokudai.ac.jp

Telephone/fax: +81-11-706-2774

1

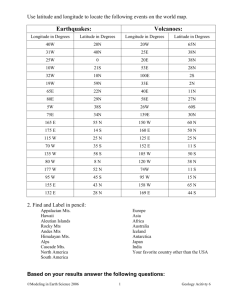

Supporting Figure 1. Representative fluorescence microscopic image of MTs ring showing rotation with time at: (a) counter clockwise (CCW), and (b) clockwise (CW) direction. Brightness and contrast were adjusted to visualize the ring-shaped MTs assembly using Image Pro 5.1J and Image J 1.41 software.

2

0.4

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0

a 30 min

3 6 9 12

Ring diameter (

µ

m)

15

0.45

0.4

0.35

0.3

0.25

0.2

0.15

0.1

0.05

0 b 24 h

3 6 9 12

Ring diameter ( µ m)

15

Supporting Figure 2.

Relationship between MTs ring size and their rotational velocity. MTs for AcSO were prepared by: (a) 30 min and (b) 24 hours incubation at 37

0

C in the presence of 0.64 M DMSO without using taxol. Straight line in the figure was drawn following the least square fit method. The correlation factors (CFs) between the MTs ring size and rotational velocity at 30 min and 24 hours were

0.22 and 0.32 respectively, where, − 1 ≤ CF ≤ 1 and positive and negative values correspond to positive and negative correlation, respectively.

3

Supporting Figure 3.

Size distribution of MTs ring rotating in CW and CCW direction. MTs for AcSO were prepared from 34 µ M tubulin without taxol, incubating for (a) 30 min and (b) 24 hours at 37

0

C in the presence of 0.64 M DMSO.

4

100

90

80

70

60

50

40

30

20

10

0 n=63 n=32

-Taxol +Taxol

CCW

CW

Supporting Figure 4 . The effect of taxol on the preferential rotation of the ring-shaped MTs assembly.

MTs ring rotating in counter clockwise (CCW) and clockwise (CW) directions are shown as percentage of total number of rings; –Taxol (left) and +Taxol (right) correspond to the assays in which MTs were polymerized without and with taxol respectively. The rotating direction was confirmed by observing the real time images with naked eyes and the successive images of rings at 5 sec intervals for at least 15 sec.

‘n’ stands for the number of MTs ring considered for analyses.

5

100 n=134 n=54

80

60

40

20 n=86

CCW

CW

0

0.38

0.64

0.90

Concetration of DMSO (M)

Supporting Figure 5.

The effect of DMSO on the preferential rotation of the ring-shaped MTs assembly. MTs ring rotating in counter-clockwise (CCW) and clockwise (CW) directions are shown as percentage of total number of rings. The rotating direction was confirmed by observing the real time images with naked eyes and the successive images of rings at 5 sec intervals for at least 15 sec. MTs were prepared from 34 µ M tubulin without taxol incubating for 3 hours at 37

0

C in the prescribed

DMSO concentration. ‘n’ stands for the number of MTs ring considered for analyses.

6

50

40

30

20

10

0

100 n=155

90

80

70

60 n=54 n=96

25 37 45

Temperature ( o

C)

CCW

CW

Supporting Figure 6: The effect of incubation temperature on the preferential rotation of the ringshaped MTs assembly. MTs ring rotating in counter clockwise (CCW) and clockwise (CW) directions are shown as percentage of total number of rings. The rotating direction was confirmed by observing the real time images with naked eyes and the successive images of rings at 5 sec intervals for at least 15 sec.

MTs were prepared from 34 µ M tubulin without using taxol and incubating for 3 hours at different temperatures in the presence of 0.64 M DMSO. ‘n’ stands for the number of MTs ring considered for analyses.

7

30

25

0.38 M DMSO

20

15

10

5

0

11 12 13 14 15 16 17

Number of PFs

30

25

0.9 M DMSO

20

15

10

5

0

11 12 13 14 15 16 17

Number of PFs

Supporting Figure 7: Effect of DMSO concentration on the distribution of number of PFs of MTs.

MTs were prepared from 34 µ M tubulin without taxol, incubating for 30 min at 37

0

C.

8

Supporting Information 8: Summarized relation among the effect of experimental conditions, number of PFs and direction of rotation of MT ring.

9