1.0 Operatinq Voltaqe, freouency and Watt loss - Best E

advertisement

I

THE BOMBAY ELECTRIC SUPPLY & TRANSPORT

UNDERTAKING

(OF THE MUNICIPAL

CORPORATION

OF GREATER MUMBAI)

SPECIFICATION OF BALLASTS SUITABLE FOR HPSV LAMPS

SPECIFICATION NO.SL/213/HPSVBallast DATED: 01/11/2006

This sDecifica(ion is for ballasts suitable for 70,150,250 and 400-Watt

high-pressure Tubular Sodium Vapour lamps. Ballasts are required to

be used with street lighting Integral lanterns of various makes and in

control gearbox, which are used by the Undertaking. This specification

covers mClgnetic ballast enclosed in metal box and filled \'lith epoxy.

00

IMPORTANT INSTRUCTIONS TO TENDERER:

0.1

Only ballast manufacturer or his authorised distributor shail particip.::!te

In the tender If the tenderer is authorised distributor. valid certificate

In support of the sameshall be submitted along-with the offer.

0.2

The tenderer shall give all the information asked for in the specification

especially the following, without which offer may not be considered.

0.2.1

Details regarding

Specification)

0.2.3

The tenderer should sign on each page of this specification and also

the declaration (clause 10.0) includin9 drawing and submit along with

offer.

(

testing

facility

available (clause 9'.0 of

the

I

1.0

Operatinq Voltaqe, freouency and Watt loss:

The ballast shall conform to the following parameters also in addition

to the general conformity of the IS 6616 (1982) and IS 9974(part II).

I

Watts

Sr.

Watts

Watts' I I Watts :I Watts ;

50Hz

f-\s per

IS-9974

ii)

Description

I1~

45(Part!400

No. 25

,

150W

I 250W

1.1

Voltage

1.2

___ F_.re_quency

~I

!

i'-

I

:

1.3

i

I

Rated lamp wattage.

at 240V when used

with standard lama

_I

----1

, --.J

I

±S,j/o

±6% iI Table NO.1

50HzI 240V

50Hz

240V

HPSV

HPSV

HPSV I Tolerance

±10%

!

I 240V

400W

I

70

I W-tt

I

Q

S

r---~~~--l-Maximum

loss Ballast'-l--18

__

I Watts

!

!

1. 5

'--

T

Other electrical

L__

P.5lI:_a..~_e

__te_r__

s

--'-

_

Page

~ of b pages.

t

.....J

2.0

Construction & DesiQn:

The ballast shall be rated for, /.·10V 50Hz supply, with an additional

tapping at novo The ballast shall be copper wound, without TW &

delta t markinQ. The ballast shall generally conform to IS: 6616-

1982.

2.1

The ballast shall be mechanical!y robust and shall be designed and

constructed

so as to minimise the effects of humidity and

temperature changes during its use and should be enclosed in metal

box.

2.2

The terminals shall be unexposed, readily accessible and identifiable

and shall be located slightly above the base plate as shown in the

enclosed drawing. The outer casing of the ballast shall be painted

with Grey enamel paint.

2.3

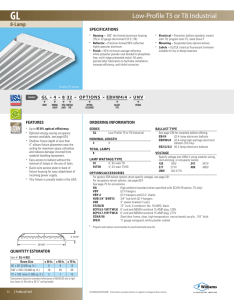

Dimensions: Dimensions and fixing arrangement

enclosed drawing.

2.4

Name plate and markinQ: The outer casing of ballast shall have

non removable (the tenderer shall not use adhesive stickers for

nameplate: marking) markings indicating the following:

2.4.1 Manufacturer's

shall be as per the

name.

2.4.2 Year and month of manufacture.

(This date should not be earlier

than two months from the date of supply).

2.4.3 Rated voitage.

2.4.4 Rated wattage.

2.4.5 Connection diagram.

2.4.6 The maximum peak value of pulse voltage to which the ballast can be

subjected.

2.4.7 BEST P.O. Number.

2.5

EarthinQ: The Earthing terminal

identifiable:

shall be clearly marked and easily

,.

Page 2 of 6 pages .

..

.

3.0

Test Procedures for ballast loss measurement:The ballast under test shall be connected as bellow.

~40V

240 V. AC

~~O\'

(Stabilised)

I

:'\

C

Figure

"A", "'VV" and "V" are ammeter, wattmeter and voltmeter respectively

of suitable ratings. The test current as given bellow (table no. 2) for

respective wattage will be adjusted through the variac, and ballast losses

will be measured.

l

I

Ratina in watts

250

watts

150 70

watts

watts I I

400 watts

Table no. 2

4.6

3.0

Test Current in Ampere

1.800.98

I

I

4.0

Tests:

4.1

Tests on Tender Samples and Lot samples:

I

The following tests will be carried out on tender samples as well as on

samples selected at random from each lot for conformity to this

specification.

4.1.1

Visual examination as per Clause No.9~4 of 15-6616/1982:

4.1.2

Insulation

Resistance

6616/1982.

4.1.3

High voltage test as per Clause no. 9.6:~ of 15-6616/1982.

(dry)

as

per ~Clause

no.

9.6.3

of

15-

Page -' of (, pages.

1.· •

4.1.4

Limitation of ballast heating test as per; clause no. 9.12 of IS 6616 of

1982. The tolerance of 1-degree C in the temperature rise will be

considered to compensate for reading error.

4.1. 5 The lumens per watt. Lumen output of the reference lamp is

measured using reference ballast and ballast under test by applying

rated voltage. Lumen/watt will be calculated for reference ballast and

sample ballast by dividing the lumen output of reference lamp by

total input wattage (lamp watts + ballast watts) in each case. The

sample ballast should not give lumen per watt less than 95% with

that of reference ballast.

4.1.6

Ballast loss (refer 1.0). Ballast loss should not be more than that

given in clause 1.0 (Table 1) of this specification.

5.0

Preferred

lot size and Criteria

for conformity:

Generally lot size shall be 100 ballasts and criteria of acceptance shall

be as given in 7.2.

(

6.0

Tender

Si:H1;ples:

The tenderers shall submit 2 identical

clause 3 of "General Tender Conditions".

7.0

7.1

Criteria

Tender

samples.

Please also refer

for conformity.

sample.

Only one sample will be tested. If the tender sample fails in any test

given under 4.0, the sample will be considered as failed.

7.2

Lot:

The lot shall considered to be failed if more than one sample fails in

single requirement

or more than two sample fail in different

requirements given under clause 4.0.

/

8.0

Guarantee:

If the ballast fails within 18 months from the date of

acceptance, the failed ballast should be replaced free of cost by the

tenderer.

Page 4 of 6 pages.

t ••

9.0

Details of the testing facility (testing equipment).

9.1

DeTails or the testing facility (testing equipment) for lot inspections

or the orfered ballast. List of equipment should be enclosed.

9.2

Location

9.3

Name or nearest

railway station.

9.4

Name of nearest

Airport.

of testing

facility.

railways and distance

airport

and distance

to the testing

racility

from the testing

from

facility

from

1

'1

9.5

Name of person

telephone numbers

9.6

E-mail Address

10.0

Declaration:

I have read

and understood

to be

(Office

contact

at testing

& residential)

Drawing

along-with

(if any):

all the

no. SL-EQ-213

clauses

of the

specification.

of Te.'-.derer

REV.S Date~. 05-01-2004.

Pcge 5 of G

t .•

,.

\

-;

Signature

Ehclosed:

facility

"'--1

H

I

I

I

B,

I

I"

[

I'

!

I

L..-:-_ ._

I

~"

i

I

I

~.-

c.ou.

II N.T.sl-;;'12.2001

C

F

G

D

~ ~H.M.s. EI

:";OTES :

II

.....

t-- -!

•......

-~I

l"

/0... ••

STREET UGHTING

"'oc"

II

II

SPECIFIED Dn\!F.J\'SIOl'lS FOR HPSV BALLAST

TOL£R,'/Io'CI:

~DRAW-lOG

( ....

fU~'

10

10

1.5

MAXIMUM

150

400W

110

I10

AS

AS

!.S

~S

~0.5

110

f°"",

MINIMUM

~

95

,·t

!to

75

1.5

!110

1.5

;1

US

~J

•••.

;5

a "'!.sO

00 D.•NO.

'5

I!.S

B• ..

105

;1

55

70W

:U:TTT.~----uPS\'

U.A.~T,"ap.~

SL.cQ/213

:

,.••.

u..IOOHOE

Dl\£E.,"StO:-;S

ARE

MM.5.015

NN{G

~

ICODI:

I OVERALL

I 22.,KV

~EX AQ(Nt.YA

BU>O...P.lKAK.AAE

OOY

8:JS ~W\.,aIaAJ...oo

B.E.S.&

T.UNDERTAKING

DIMENSIONS

OF

BALLAST

W,J..:JO

W SV.

70

W,150

W,250

•...

I

' I

I .

II I

i

,

,JI

I,

DEPARnlENT

II

(

!',.

.

I

t ••