Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

Page 1 of 16

Document ID: QM-001

Revision:

AE

1. PURPOSE

This document defines the requirements, processes, structure and documentation for the

Teledyne DGO Quality Management System.

2. SCOPE

The Teledyne DGO Quality Management System has been designed and implemented for

effective management, customer satisfaction, and continual improvement. It has been

implemented to meet the requirements of ISO 9001:2008. The QMS governs the design,

development and manufacture of electrical and optical connectors, cable assemblies,

penetrators, and servo control devices used in hostile environments for military and

commercial applications, including sales, testing and technical support functions.

3. REFERENCES

•

ISO 9001-2008 International Organization for Standardization

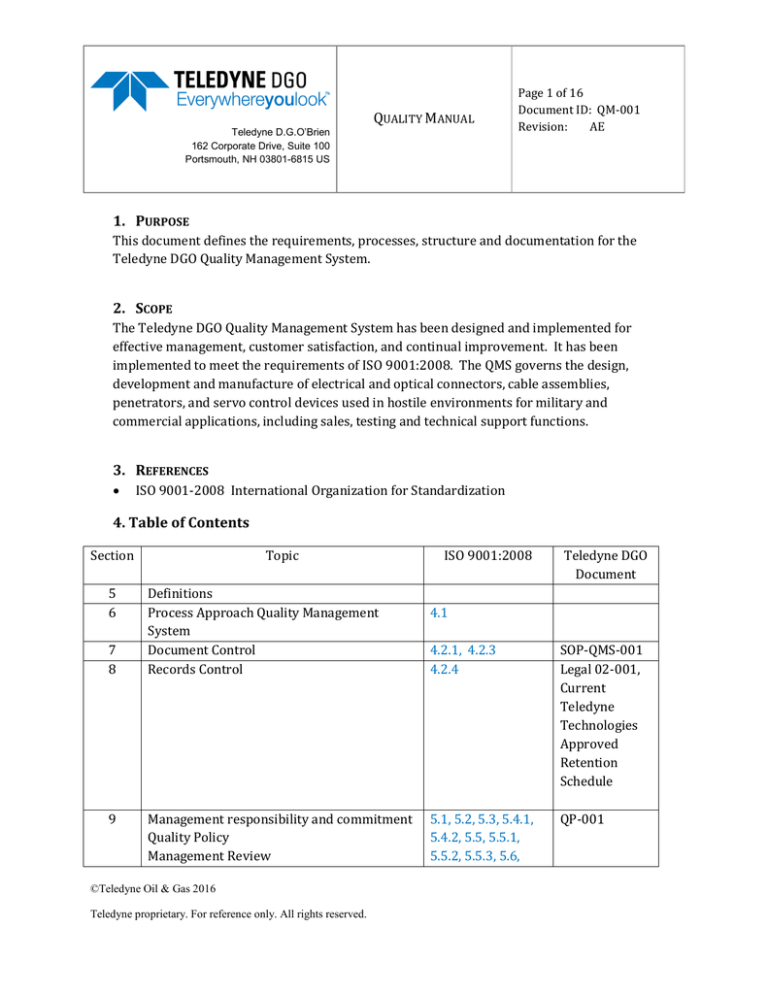

4. Table of Contents

Section

Topic

5

6

Definitions

Process Approach Quality Management

System

Document Control

Records Control

9

Management responsibility and commitment

Quality Policy

Management Review

7

8

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

ISO 9001:2008

4.1

4.2.1, 4.2.3

4.2.4

5.1, 5.2, 5.3, 5.4.1,

5.4.2, 5.5, 5.5.1,

5.5.2, 5.5.3, 5.6,

Teledyne DGO

Document

SOP-QMS-001

Legal 02-001,

Current

Teledyne

Technologies

Approved

Retention

Schedule

QP-001

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

10

11

12

13

14

Provision of Resources

Human Resources Training

Infrastructure

Planning of product realization

Design Control

16

17

Production and Process Controls

Process Validation

15

18

19

20

21

22

23

24

25

26

27

28

QUALITY MANUAL

Purchasing Process

Identification and Traceability

Customer Property

Preservation of Product

Inspection, Measuring and Test equipment

Customer Feedback

Internal Audit

Nonconforming Product

Analysis of data

Continual Improvement

Corrective and Preventative action

Revision History

Page 2 of 16

Document ID: QM-001

Revision:

AE

5.6.1, 5.6.1, 5.6.2,

5.6.3

6.1

6.2.1, 6.2.2,

6.3, 6.4

7.1, 7.2

7.3.2, 7.3.3, 7.3.4,

7.3.5, 7.3.6, 7.3.7,

7.4, 7.4.1, 7.4.2,

7.4.3,

7.5.1

7.5.2

7.5.3

7.5.4

7.5.5

8.1

8.2.1

8.2.2

8.3

8.4

8.5.1

8.5.2, 8.5.3

SOP-QMS-021

SOP-QMS-020

SOP-QMS-005

SOP-SCM-006

SOP-QMS-011

WI-SCM-0005

or

SOP-QMS-011

SOP-QMS-015

SOP-QMS-019

SOP-QMS-004

SOP-QMS-002

SOP-QMS-003

5. DEFINITIONS

Unless otherwise specified, all terms used in this document are defined in ISO 9001-2008

Term

Definition

TDGO

Teledyne D G O’Brien

TOG

Teledyne Oil & Gas

Concession

a special approval that is granted to release

a nonconforming product for use or delivery

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

PPM

QMS

SOP

Page 3 of 16

Document ID: QM-001

Revision:

AE

Policy and Procedure Manual

Quality Management System

Standard Operating Procedure

6. PROCESS APPROACH

Quality System Process Approach: TDGO applies a system of processes, their interactions

and their management to ensure the ongoing control over the linkage between the

individual processes and within the system of processes. This approach emphasizes the

importance of understanding and meeting requirements, considering processes in terms of

added value, obtaining results of process performance and effectiveness, and improving

processes based on objective measurement.

Figure I. Diagram of Process-based QMS:

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

Page 4 of 16

Document ID: QM-001

Revision:

AE

7. DOCUMENT CONTROL

Document Control: TDGO shall determine which documents shall be controlled and which shall

be managed. The document control process shall ensure that only the correct revision of

controlled documents are available for use and that obsolete documents are not available for

use.

To align with industry standard documentation structure, TDGO has adopted QMS SOPs as

Level 2 documents and Work Instructions as Level 3 documents. During the transition from

PPM’s to SOP’s, and PPM’s to Work Instructions, all new released documents shall adopt the

new document labels. All other documents with PPM labels shall be renamed at their next

revision. An electronic link will be established for any PPM document that has been renamed or

superseded to facilitate document user’s in locating renamed or superseded documents.

Figure 2: TDGO QMS Document Structure:

L1

Manual

Policy

L2

SOP (Standard

Operating

Procedures)

L3

PPM & WI (Work instruction)

L4

Forms & Records

These requirements and process are further defined in the document(s) listed for this section in the

Table of Contents.

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

Page 5 of 16

Document ID: QM-001

Revision:

AE

8. RECORDS CONTROL

Records Control: Records established to provide evidence of conformity to requirements and of

the effective operation of the QMS shall be controlled. Records shall remain legible, readily

identifiable and retrievable.

Where customer requirements for records retention conflict with the Teledyne Approved

Retention Schedule, the longer retention requirement shall take precedence.

These requirements and process are further defined in the document(s) listed for this section in the

Table of Contents.

9. MANAGEMENT RESPONSIBILITY AND COMMITMENT

Customer Focus: Top Management shall ensure that customer requirements are determined

and are met with the aim of enhancing customer satisfaction.

Quality Policy: TDGO management shall establish a quality policy that shall be communicated

and implemented across the organization to describe management’s intentions with respect to

Quality. As a part of TOG, TDGO implements the TOG Quality Policy and reviews it for adequacy

at each Management Review.

These requirements and process are further defined in the document(s) listed for this section in the

Table of Contents.

Quality Objectives: TDGO management shall establish Quality objectives that define the specific

quality goals that the organization is committed to achieving. The Quality Objectives shall be

measurable and consistent with the Quality Policy. TDGO is provided annual Quality Objectives

Management Representative: TDGO shall appoint a management representative who has the

responsibility and authority that includes

a) Ensuring that processes needed for the QMS are established and maintained

b) Reporting on the performance of the QMS and needs for improvement

c) Ensuring the promotion of awareness of customer requirements throughout the

organization.

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

Page 6 of 16

Document ID: QM-001

Revision:

AE

Internal Communication: TDGO management shall ensure that internal communication

processes are established and that communication takes place regarding the effectiveness of the

quality management system.

Management Review: TDGO management with executive responsibility shall review the

effectiveness of the quality management system at least annually.

ISO Management Representative shall;

o Schedule and conduct management reviews

o Reports on the performance of the quality management system and any need for

improvement, to top management.

Attendees:

o All members of the general manager’s staff (top management) participate and attend

management reviews. Where a member is unable to attend, advance written notice

must be provided to the ISO Management representative and a delegate named to

participate in the review.

o Assemble and forward all required and relevant data to the Management

Representative(s) prior to the scheduled meeting for inclusion into the summary to be

presented at the Management Review.

o Complete any assigned actions resulting from the Management Review.

Management Review Inputs:

o Results of Audits

o Customer Feedback

o Process performance and product conformity

o Status of preventative and corrective actions

o Follow-up actions from previous management reviews

o Changes that could affect the quality management system

o Recommendations for improvement

o Review of Quality Policy and Quality Objectives

Management Review Outputs:

o Attendance record

o Record of the content reviewed

o Action items and a summary of decisions pertaining to:

- Quality Management System improvements

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

-

QUALITY MANUAL

Page 7 of 16

Document ID: QM-001

Revision:

AE

Product improvements

Resource needs

These requirements and process are further defined in the document(s) listed for this section in the

Table of Contents.

10. PROVISION OF RESOURCES

Provision of Resources: TDGO shall determine and provide the resources needed to implement,

maintain and continually improve the QMS and maintain its effectiveness, and to meet

regulatory and customer requirements.

11. HUMAN RESOURCES

Personnel: TDGO shall ensure that all personnel are competent, adequately trained and

equipped to correctly perform their roles and that each employee is made aware of the

relevance and importance of their activities and how they contribute to the achievement of the

quality objectives. They shall also be made aware of how product defects may occur from

improper performance of their specific jobs. Appropriate records of education, training, skills

and experience shall be maintained.

These requirements and process are further defined in the document(s) listed for this section in the

Table of Contents.

12. INFRASTRUCTURE

Infrastructure: TDGO shall ensure that infrastructure, including buildings, workspaces, utilities,

process equipment and supporting services are sufficient to ensure conformity to product

requirements is consistently achieved.

Equipment: TDGO shall ensure that all equipment used in the manufacturing process, including

inspection and test equipment, meets specified requirements and is appropriately designed,

constructed, placed and installed to facilitate maintenance, adjustment, cleaning and use. TDGO

shall ensure that equipment maintenance schedules are established and maintained, periodic

equipment inspections are conducted and documented, and that adjustments are made

correctly as needed.

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

Page 8 of 16

Document ID: QM-001

Revision:

AE

13. PLANNING OF PRODUCT REALIZATION

Product Realization TDGO determines the following, as appropriate:

a) Quality objectives and requirements for the product;

b) The need to establish processes and documents, and to provide resources specific to the

product;

c) Required verification, validation, monitoring, measurement, inspection and test

activities specific to the product and the criteria for product acceptance

d) Records needed to provide evidence that the realization processes and resulting

product meet requirements

The output of this planning shall be in a form suitable for the methods of the organization.

Customer Related Processes: TDGO shall define product, customer, statutory and regulatory

requirements and shall establish processes to review and understand these requirements. This

review shall be conducted prior to the organizations commitment to supply a product to the

customer and shall ensure that

a) Product requirements are defined

b) Contract or order requirements differing from those previously expressed are resolved,

and

c) The organization has the ability to meet the defined requirements

Records of the results of the review and actions arising from the review shall be maintained.

Where product requirements are changed, the organization shall ensure that relevant document

is amended and that the relevant personnel are made aware of the changed requirements.

14. DESIGN CONTROL

Design Control: TDGO shall plan and control the design and development of product to include

design and development stages, the review, verification and validation that are appropriate to

each design and development stage, and the responsibilities and authorities for design and

development.

Design Inputs: The organization shall plan and control the design and development of the

product. These inputs shall include

a) Functional and performance requirements

b) Applicable statutory and regulatory requirements

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

Page 9 of 16

Document ID: QM-001

Revision:

AE

c) Where applicable, information derived from previous similar designs and

d) Other requirements essential for design and development

Design Outputs: The outputs of design and development are provided in a form that enables

verification against the design and development input and shall be approved prior to release.

These outputs shall:

a)

b)

c)

d)

Meet the input requirements for design and development

Provide appropriate information for purchasing, production and for service provision

Contain or reference product acceptance criteria, and

Specify the characteristics of the product that are essential for its safe and proper use.

These requirements and process are further defined in the document(s) listed for this section in the

Table of Contents.

Design Review: At suitable stages, systematic reviews of design and development shall be

performed in accordance with planned arrangements. Participants in such reviews shall

include representatives of functions concerned with the design and development stage (s) being

reviewed. Records of the results of the review shall be maintained.

Design and development verification: Verification shall be performed to ensure that the design

and development outputs have satisfied the input requirements. Records of the verification and

any necessary actions shall be maintained.

Design and development validation: Validation shall be performed in accordance with planned

arrangements to ensure that the resulting product is capable of fulfilling the requirements for

the specified or known intended use or application. When practical, validation shall be

completed prior to delivery of the product. Records of the results of the validation or any

necessary actions shall be maintained.

Control of design and development changes: Design and development changes shall be

identified and records maintained.

These requirements and process are further defined in the document(s) listed for this section in the

Table of Contents.

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

Page 10 of 16

Document ID: QM-001

Revision:

AE

15. PURCHASING PROCESS

Supplier Selection and Management: TDGO shall evaluate and select potential suppliers,

contractors and consultants on the basis of their ability to meet specified requirements,

including Quality requirements. TDGO shall establish and maintain records of acceptable

suppliers, contractors and consultants in an Approved Supplier List (ASL).

Purchasing Data: TDGO shall ensure that suppliers are provided with accurate and complete

requirements, including quality requirements and that changes to these requirements are

delivered to the supplier in writing, and records of these changes shall be retained in

accordance with Records Control requirements.

Verification of purchased product: The organization shall establish and implement the

inspection or other activities necessary for ensuring that purchased product meets specified

purchase requirements.

These requirements and process are further defined in the document(s) listed for this section in the

Table of Contents.

16. PRODUCTION AND PROCESS CONTROLS

Process Controls: TDGO shall ensure that production and service provision are conducted

under controlled conditions. Production process controls shall be established where deviations

from specifications could occur as a result of the manufacturing process. Production and

process controls shall be defined in procedures and in product specific control plans as

appropriate.

Production and Process Changes: TDGO shall ensure that process changes are reviewed,

approved and verified or validated, as appropriate, prior to implementation.

17. PROCESS VALIDATION

Validation Documentation: Where the results of a process cannot be fully verified by

subsequent inspection and test, TDGO shall ensure that the process be validated with a high

degree of assurance. Process validations shall be conducted according to documented and

approved procedures, validation protocols and reports and performed by qualified individuals.

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

Page 11 of 16

Document ID: QM-001

Revision:

AE

Process Control Data: TDGO shall ensure that validated processes are monitored and controlled

to ensure requirements are consistently met on an ongoing basis. The data collected as a result

of ongoing monitoring shall be documented.

Revalidation: TDGO shall ensure that when changes or process deviations occur that processes

are reviewed and evaluated and where appropriate, revalidation is performed and documented.

18. IDENTIFICATION AND TRACEABILITY

Identification: TDGO shall ensure that product is identified by suitable means throughout all

stages of receipt, production, distribution and installation to prevent mix-ups. Teledyne shall

also ensure that product status is maintained throughout all stages to ensure that all product

that has passed the required inspections and tests are accepted and released.

Traceability: TDGO, directly or through its suppliers, contractors and service providers, shall

establish, document, and maintain procedures for identifying each unit, lot, or batch of finished

products and components, where appropriate, with a unique control number. These controls

shall be used to facilitate corrective action when and if required.

19. CUSTOMER PROPERTY

Customer Property: TDGO shall exercise care with customer property, including intellectual

property, while it is under the control of the organization or being used by the organization. The

organization shall identify, verify, protect and safeguard customer property provided for use or

incorporation into the product. If any customer property is lost, damaged or otherwise found to

be unsuitable for use, the organization shall report this to the customer and maintain records.

20. PRESERVATION OF PRODUCT

TDGO shall preserve the product (and any components) during processing and delivery to the

intended destination in order to maintain conformity to requirements. As applicable,

preservation shall include:

o Identification

o Handling

o Packaging

o Storage

o Protection

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

Page 12 of 16

Document ID: QM-001

Revision:

AE

21. INSPECTION, MEASURING AND TEST EQUIPMENT

TDGO shall determine the monitoring and measurement to be undertaken and the monitoring

and measuring equipment needed to provide evidence of conformity of product to determined

requirements.

Where necessary to ensure valid results, measuring equipment shall:

o

o

o

o

o

Be safeguarded from adjustments that would invalidate the measurement result.

Be adjusted or readjusted as necessary

Be identified to enable calibration status to be determined

Be protected from damage and deterioration during handling, maintenance and storage

Evaluated for impact to finished product quality where equipment is found to be out of

tolerance

Calibration records shall be maintained.

These requirements and process are further defined in the document(s) listed for this section in the

Table of Contents.

22. CUSTOMER FEEDBACK AND COMPLAINTS

TDGO shall establish methods for communicating with customers in relation to:

a) Product information

b) Enquiries, contracts or order handling, including amendments and

c) Customer feedback, including customer complaints.

23. INTERNAL AUDIT

Internal Audit: TDGO shall conduct internal audits to determine whether the QMS:

a) Conforms to the requirements of ISO 9001 and to the established quality system and

external requirements,

b) Is effectively implemented and maintained.

The audit schedule shall be defined by the designated Quality Audit Leader. The schedule shall

be planned taking into consideration the status and importance of the processes and areas to be

audited, as well as the results of previous audits. The audit criteria, scope, frequency and

methods shall be defined. Audits shall be conducted by trained auditors who are independent of

the work being audited.

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

Page 13 of 16

Document ID: QM-001

Revision:

AE

Audit Documentation: Audit reports are company confidential. Additional audit records that

provide objective evidence of audit execution shall be maintained and available for outside

review as needed.

These requirements and process are further defined in the document(s) listed for this section in the

Table of Contents.

24. NONCONFORMING PRODUCT

Nonconforming product includes nonconforming product occurring in TDGO’s own facilities as

well as nonconforming product received or delivered by the organization.

TDGO shall ensure that product that is nonconforming or is suspected of being nonconforming

is identified, and controlled to prevent its unintended use or delivery.

TDGO shall ensure that procedures are established for review and disposition of

nonconforming product and that responsibility and authority for disposition is defined within

these procedures.

TDGO shall also ensure that actions are taken to identify, document and eliminate the root

cause of nonconforming product.

These requirements and process are further defined in the document(s) listed for this section in the

Table of Contents.

25. MEASUREMENT AND ANALYSIS:

TDGO shall collect and analyze appropriate data to demonstrate the suitability and

effectiveness of the QMS, process and product quality to evaluate if improvements are needed.

This shall include data generated as a result of monitoring and measurement and from other

relevant sources. The analysis of data shall provide information relating to:

a) Customer satisfaction

b) Conformity to product requirements

c) Characteristics and trends of processes and products, including opportunities for

preventive action

d) Suppliers

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

Page 14 of 16

Document ID: QM-001

Revision:

AE

26. CONTINUAL IMPROVEMENT

TDGO shall continually improve the effectiveness of the QMS through the use of:

a)

b)

c)

d)

e)

f)

g)

Quality Policy

Quality Objectives

Audit results

Analysis of data

Corrective and Preventive Actions

Management Review

Quest for Excellence Teams utilizing continuous improvement tools and techniques

27. CORRECTIVE AND PREVENTIVE ACTION

TDGO shall ensure that action is taken to identify, correct and ensure that nonconformities that

have already occurred do not recur, and to prevent potential nonconformities. CAPA

investigations shall focus on the cause of nonconformities (or potential nonconformities)

relating to product, processes or the QMS. A summary of CAPA activity shall be included in

Management Reviews.

These requirements and process are further defined in the document(s) listed for this section in the

Table of Contents.

28. REVISION HISTORY

Revision G Released 10/01/03 Per ECO 20250 Revised to meet the new requirements of ISO

9001 revision 2000.

Revision H Released 12/12/03 Per ECO 20372 Revised to change procedure numbers into PPM

numbers.

Revision J Released 03/11/05 Per ECO 21194 Revised to correct administrative errors.

Revision K Released 06/06/08 Per ECO 36950 to change logo to Teledyne logo; changed job

title; deleted reference to QATM.

Revision L Released 06/19/08 Per ECO 37010 Added servo control devices to scope.

Revision M Released 02/04/09 per ECO 37745 Changes per Management Review

Recommendation.

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

QUALITY MANUAL

Page 15 of 16

Document ID: QM-001

Revision:

AE

Revision N Released 09/21/09 Per ECO 38177 to reflect ISO 9001:2008.

Revision P Released 04/22/11 Per ECO 40901 to reflect current titles.

Revision R Released 01/08/14 Per E3476 to reflect current titles and removal of address.

Revision T Released 04/21/14 per E4019 Total Re-Write of Manual.

Revision V Released 05/12/14 Per E4053 to Include Customer – Specific Record Retention

guidance.

Revision W Released 05/30/14 per E4174 Legal Requirements for DGO.com

Revision Y Released 07/15/14 Per E4388 Multiple Changes

Revision AA Released 9/24/15 Per E4554 Clarification of Section 7

Revision AB Released 10/08/15 Per E6025 Updated references in section 4

Revision AC Released 12/15/15 Per E6801 Added Figure 1 to section 6, updated verbiage in

section 9

Revision AD Released 01/26/16 Per E6954 Added dates to revision history

Revision AE Released 03/07/16 Per E7179 Added “And Quality Objectives” to Management

Review inputs

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

QUALITY MANUAL

Teledyne D.G.O’Brien

162 Corporate Drive, Suite 100

Portsmouth, NH 03801-6815 US

Revision

Author

Y

K. Peek

AC

K. Peek

AA

AB

AD

AE

Page 16 of 16

Document ID: QM-001

Revision:

AE

Sections Affected

Reason for Revision

K. Peek

K. Peek

References, Document

control and Definitions

Section 7

Section 4

K. Peek

Section 28

Updates to change to new

document system

Clarification of Section

Update documentation references

Added figure 1 to section 6, update

verbiage in section 9

Updated dates on revision table

K. Peek

Section 6 and 9

©Teledyne Oil & Gas 2016

Teledyne proprietary. For reference only. All rights reserved.

Section 9

“And Quality Objectives” to

Management Review inputs