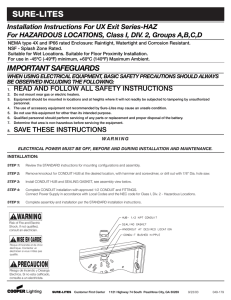

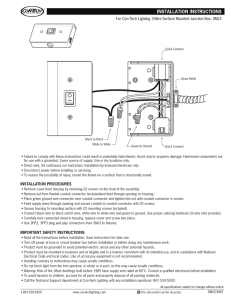

Division 26 Electrical Requirements

advertisement