Supercapacitors in power converter DC link

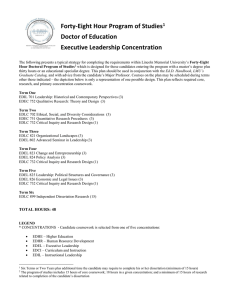

advertisement

Supercapacitors in power converter DC link A short overview of design and application issues B.Sc., E.E. Tihomir Čihak*, Ph.D., E.E. Željko Jakopović ** ** * KONČAR – Electrical Engineering Institute/Power Electronics and Control Department, Zagreb, Croatia Faculty of Electrical Engineering and Computing/Department of Electric Machines, Drives and Automation, Zagreb, Croatia tcihak@koncar-institut.hr Abstract - Very high values of efficiency in electric power conversion, electric energy saving requirements and power converter component optimization are priorities in design and construction of any type of modern power electronic converters. Moreover, if such power converters are connected to battery power source or other "weak" power source (as, for instance, fuel cells), additional design problems appear in sense of (battery) power source longevity, absorption of high peak power transients, provision of on-demand power bursts for load and other. EDLC, well known by their commercial name as Supercapacitors, are one of the possible solutions for aforementioned problems. Key words - Supercapacitors, ultracapacitors, EDLC, power converters, energy recovery, efficiency, energy saving, energy storage. I. INTRODUCTION Capacitor as a component that enables storage of energy is known since 18th century, when Leyden jar has been invented. Principles of capacitor operation, in other words electrostatic mechanism of energy storage has soon been explicitly defined. As a component, in essence two metal plates separated by dielectric material, capacitor has not been changed from the day of its invention. Only in 1957, with an invention by H. E. Becker [2], a truly innovative component, electrochemical dual layer capacitor, has appeared. In electrical view, this component is also a capacitor, but it's characteristic that separates it from the previously known capacitor types is its huge capacity. In consequence, this innovative component has extremely high specific power rating and specific energy rating in the same order of magnitude as, in that sense, weakest batteries. This properties enable electrochemical dual layer capacitors to be used as an energy buffer located in the DC link in high power systems, in systems with battery power source (or similar) as a component or a subsystem which corrects drawbacks of a weak power source, and even as a sole power source in the low power systems. II. an electrode is submerged into an electrolyte, on the interface between electrode and electrolyte charge separation occurs in immediate vicinity of the interface. Since two electrodes are needed for connection to external circuit, two of such interfaces appear. Looking more closely at an interface, on electrode surface excess (or deficiency on the other electrode) of electrons appears. To achieve neutrality, this excess (or deficiency) is balanced by electrolyte ions. Charge separation distance, or in other words distance between electrode surface and the center of the ions (possibly increased by a thickness of a solvation sphere around the ions) that form a layer in the near vicinity of the electrode is equivalent to the dielectric thickness of a normal capacitor. Therefore at each of the formed interfaces an equivalent to the capacitor appears, and the resulting device is equivalent to a series connection of two capacitors, which is shown in figure 1. ELECTROCHEMICAL DUAL LAYER CAPACITOR Electrochemical dual layer capacitor, EDLC in further text, is based on a phenomenon for which is believed that is observed for the first time by H. Helmholtz. In short, if C =ε⋅ S [F ] d (1) Since this distance is on the order of a nanometer or smaller, resulting capacitance is according to the (1), where S is electrode surface and d is a distance between charges, higher then a capacitance of an ordinary capacitor. But, besides the "dielectric thickness", EDLC have a very high specific capacitance due to electrode material used in their construction. This material is (in most cases) activated carbon which is a very porous material, as shown in picture 2. Due to its porous nature it has high effective surface area (on the order of 1000m2/g [1], but some manufacturers state surface are of over 2000m2/g and even 3000m2/g [44][45]). Also, carbon aerogels [10] and carbon nanotubes (shown in the picture 3) are used for EDLC construction for the same reason. These characteristics result in devices with a specific capacitance on the order of 250F/kg [1][17][31][34]. Typical EDLC is constructed, as shown in the figure 1 out of two metal plates, current collectors, on which electrode material is deposited. Current collector type and electrode material deposition can vary as shown in literature [1][31]. This two electrodes are stacked together and separated with a membrane which serves as an electric isolator between two electrodes, but must allow for electrolyte ions to pass through. An exploded view of a commercial EDLC is shown in picture 4. Figure 4. Construction of a commercial EDLC [24] Figure 1. EDLC diagram Figure 2. SEM images of activated carbon samples [18] Figure 3. Single wall carbon nanotube based EDLC material [19] III. SUPERCAPACITOR MODELS At the time of the writing, commercial supercapacitors still have three downsides which result from the EDLC design. Namely, low operating voltages, non-uniform nominal parameters and non-linear characteristics. Low operating voltages derive from its operating principles. Its breakdown voltage cannot be, unlike the conventional capacitor, easily "programmed", because, essentially, it depends on the electrolyte type and extremely small charge separation distance. Due to this problems EDLC are limited to operating voltages of about three volts [1]. Two other problems are closely connected and cannot be easily resolved. As shown in figure 2, typical electrode material has heterogeneous surface with variable width and depth of "valleys" which form the electrode surface and along which electrode-electrolyte interface occurs. For creating analytical model of such interface one should now dimensions of each valley to approximate the occurring process in electrical view [1][7]. Due to this, EDLC are sometimes modeled as a transmission lines. Furthermore, parameters and EDLC behavior depend on temperature, state of charge, charge and discharge intensity and frequency and other variables. To simulate a part, and sometimes most of the behavior many models where proposed [1][21][24]. Although these complex models show a good match between estimated and measured values, such complexity is not always needed. For instance, it has been noticed that a complex MATLAB/Simulink model, incorporating power electronics blocks, generator or motor blocks and control blocks already suffers from bad performance, long simulation times and other problems. Adding more complexity creates only adverse effects. Instead of developing already complex EDLC models, in some cases it is more appropriate to start with the most basic model and elaborate it up to the point where acceptable results are acquired. A model development sequence is shown in picture 5. A simple capacitor as a model cannot be used because EDLC ESR values cannot be ignored, and a series resistor-capacitor connection is therefore the most basic EDLC model. For applications where long term variables are observed (for instance, long term storage of charged supercapacitors), self discharge properties must be modeled and this model should be further expanded with at least a leakage resistance as shown. Frequency domain analysis shows that a typical EDLC shows different behavior in several distinct frequency ranges, as shown in picture 6. To distinguish different parameters in low and medium frequency ranges, supercapacitor model is therefore expanded with a parallel branch that contains an series resistor-capacitor connection. This model type is known in literature [7] as a "two branch model". For separation into more frequency ranges, model is further expanded with another RC series connection into "three branch model" [5]. Theoretically, with this approach, EDLC model can be expanded indefinitely [7]. Also, it is shown that such a linear RC network can be transformed between a series, parallel and Figure 6. Typical commercial EDLC frequency response [29] Figure 5. EDLC models: A - ideal capacitor, B – series RC model, C – model B with added leakage resistor, D – model C with added high frequency inductance component, E – model D expanded with n-branch RC circuits and voltage dependent main capacitance transmission line network type [7]. For modeling in very high frequency range, shown behavior is usually modeled with a series connected inductance. It is stated that this addition to the model should be used for pulse applications [8]. EDLC capacitance is not constant and it is (among other variables) dependent on the EDLC state of charge, or in other words, on EDLC voltage. This capacitance variation is not linear and can be seen on charge and discharge graphs and cyclic voltammetry results. For modeling this nonlinearity, main model capacitance is variable, as shown, and it is usually split into two parts, a constant and voltage variable part [21]. Charge-discharge measurement results and Bode plots of aforementioned models are given in pictures 7 and 8. There are other variables that influence EDLC parameters, such as temperature [16][33][35], and although they are not considered within this work, they should be investigated for practical implementations. IV. HIGH POWER APPLICATION ISSUES Unlike EDLC model, which is less important for actual operation of supercapacitors in power electronic systems, low operating voltages and non-uniform nominal parameters create several implementation problems. For high power applications, with power rating from tens of kilowatts up to megawatt range, DC link voltage levels from several hundreds of volts up to more then a kilovolt are used. Even the simplest implementation solution requires stacking (series connection) of several supercapacitors. Main problem appears from the EDLC parameter non-uniformity, in other words, non equal Figure 7. Comparison of linear and nonlinear model in charge/discharge test Figure 8. Comparison of EDLC linear model frequency responses capacitance of the used supercapacitors. Due to this, voltage balancing circuits are required. Basic solution is resistor or so called passive balancing [49]. This solution is not optimal due to energy wasted in resistors, so active voltage balancing circuits, for which many solutions are proposed [50][51], are most common. Two basic approaches are used for such circuits, centralized system which monitors whole EDLC assembly and a distributed solution where a number of voltage monitoring and balancing circuits (each connected between two supercapacitors from the stack) are used. One commercial solution is shown in picture 9. Other common issue that needs to be taken into account when designing supercapacitor are EDLC rated values (ESR, capacitance and value tolerances being the most important) and their variation through usage. When these are observed, it can be seen that all commercial EDLC-s have similar problems [29][48]. Due to its construction and method of operation, EDLC-s show notable aging through use which cannot be bypassed (this is also one of the reasons for comparison with batteries). Therefore, commercial EDLCs have actual capacitance higher or the same as rated and ESR values lower or the same as rated. After the specified number of cycles, these values inevitably change up to the values defined with tolerances. In other words, high tolerance values are necessity to insure that EDLC has parameters within rated values after the rated number of cycles. Furthermore, even higher tolerance values would allow for longer operational lifetime. Also, it should be noted that EDLC is not faulty after the rated number of cycles, unlike batteries which are chemically changed and, depending on the type, completely unusable after the rated number of charge and discharge cycles or even sooner. EDLC-s can be further used, but they must be retested and new rated values must be computed V. Figure 9. Commercial EDLC active balancing circuit [47] POWER CONVERTER TOPOLOGIES AND DESIGN If EDLC assembly is used directly in power converter DC link, passive as shown in picture 10-A, according to (2) and (3), only a part of total available energy can be used for performance improvements. Therefore, power converter circuits are used as an interface between supercapacitor banks and main DC link, as sketched in figures 10-B and 10-C. It should be noted that passive capacitor bank connection is nevertheless used in some applications, as for instance in forklifts and other lowpower drives, where good results have been obtained. EC = U 2 ⋅C 2 ∆EC = EC (U1 ) − EC (U 2 ) = (2) C ⋅ (U12 − U 22 ) 2 (3) When connecting EDLC banks to DC link through converters, its nominal voltage is lower then DC link voltage. Therefore, for discharging energy into DC link, voltage needs to be stepped up, and for opposite energy flow direction it needs to be stepped down. Power converters for these operations are usually combined into one circuit, and so far several different topologies are presented, including converters using high frequency AC link (shown in picture 10-C) and more exotic solutions as stacked converters [13][14][20]. But, for high power application, for instance tram traction, literature shows that favored commercial solution is non-isolated buckboost converter, shown in pictures 10-B, 11 and 12. Operation of such converter is straightforward, and it is broken down into basic boost converter when power switches are operated as shown in figure 11, and into buck converter when operated as in figure 12. Usage of this topology is understandable as all of the required power electronic components are commercially available, already combined as a half-bridge assembly which is Figure 10. Connection of EDLC stacks to DC link: A passive, B - non-isolated DC/DC converter, C - converter with galvanic isolation through medium frequency transformer widely used in traction and renewable energy applications which cuts down production costs considerably. Also, these assemblies can be easily paralleled allowing for higher currents to be used in converters. Voltage and current rating of these assemblies are also satisfactory and they are suited for PWM controlled circuits. For designing a supercapacitor system, rough estimation on the power converter requirements needs to be done first and from which supercapacitor parameters assessment can be made. As a first step, rated voltage levels of a whole supercapacitor system must be defined. If using individual supercapacitors instead of commercially available assemblies, any voltage level can be chosen, but voltage balancing circuits must be used and lifetime parameter degradation must be taken into account. During EDLC discharge, voltage should fall up to no more then a minimum predefined level. Minimum voltage to operating voltage ratio is sometimes called discharge voltage ratio [14][52] and it is given with (4). For further design total amount of energy that needs to be pumped from the supercapacitor storage into the DC link must be known. In its simplest form, this will be equal to the sum of products of the required DC link required power during faults (voltage drop) and the corresponding fault time periods for the worst case. Practically, required power in these periods will usually be variable and not constant, so energies must be computed through integration. When the maximum energy that will be used is known, from the equations (3) and (4), total amount of energy that EDLC bank must have is given with (5). du = Vmin ⋅ 100 [%] Vmax Etot = (4) EC d 1− u 100 2 (5) It is obvious that the total amount of energy is always higher then the used amount of energy. For the buck mode operation (DC overvoltage case), the equations are the same, but care must be taken on choosing the EDLC bank operating voltage prior to the fault. In other words, for the worst case scenario, EDLC bank must be able to provide total discharge energy and must be able to absorb total amount of energy during DC overvoltages from the same starting voltage level. Practically, this scenario almost never occurs, as the charge and discharge cycles occur alternately [9]. Therefore, EDLC bank size cannot be efficiently designed unless converter operating cycles (drive cycles for traction systems) are not known. For chosen voltage levels, static duty cycles and the duty cycle variation with EDLC voltage are given with (6) and (7) for the boost and buck mode operation respectively. D = 1− D= Figure 11. Converter operation in boost mode – lower half bridge IGBT is PWM controlled (switch B), and upper switch is constantly off. UC U (t ) ⇒ D(U C ) = 1 − C U DC U DC (6) U (t ) UC ⇒ D(U C ) = C U DC U DC (7) U C min,max ⋅ Dmax,min Lmax = max ∆I L ⋅ f PWM U DC ⋅ Dmin,max ⋅ (1 − Dmin,max ) Lmax = max ∆I L ⋅ f PWM (8) (9) For the chosen converter parameters, inductor size must be chosen according to switching frequency and required current ripple. Equations for this calculations are given in (8) and (9) for the boost and buck mode respectively (indicated min/max values are found from input requirements on both converter operating extremes). Care must be taken since, because of the electrical power conservation rules, currents on both converter sides are inverse proportional to voltage levels. Power electronic components must also be chosen according to required Figure 12. Converter operation in buck mode– upper half bridge IGBT is PWM controlled (switch A), and lower switch is constantly off. current ratings, and this step is rarely straightforward and requires optimization between EDLC bank voltage utilization ratio and the resulting EDLC bank, power converter, inductor and cooling components size and price. It should be mentioned that for high power applications cooling becomes a great problem, especially for the space restrained applications as for instance tram on-board systems [11][13][15]. Also, supercapacitors are not a high temperature enduring components, and besides possible electrolyte deterioration when working in prolonged overtemperature periods, EDLC lifetime shortens considerably with temperature [16]. Simple design procedure shown here refers to a buckboost topology. It should be noted that there is more than one correct solution to these design problems depending on the application. Chosen solution must be validated, both electrically (basic operation and component requirements) and mechanically (space constrained application), but also economically. VI. CONCLUSION AND FURTHER WORK EDLC, or so called supercapacitors are relatively old components, but their application is yet to become widespread. For better understanding of these components, an overview of EDLC design and characteristics has been given. Furthermore, complex behavior and accompanying simulation problems and several examples have been displayed. Also, a series of both positive and negative EDLC traits have been mentioned. Simple design guidelines and important practical implementation problems have also been discussed. Aforementioned design problems are one of the main topics that will be elaborated in further work. Automated procedure for defining optimal parameters for both converter switching components and supercapacitor assembly will be developed. This procedure will address electrical variables, but also mechanical variables (for instance, required supercapacitor assembly size for mobile applications) and thermal variables. Also, measurements and validations of given views on the usage of EDLC models will be made. LITERATURE [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] B.E. Conway, "Electrochemical Supercapacitors – Scientific Fundamentals and Technological Applications", New York, Kluwer Academic / Plenum Publishers, 1999. H.I. Becker, "Low Voltage Electrolytic Capacitor", U.S. Patent 2,800,616, July 23, 1957. N. Mohan, T.M. Undeland, W.P. Robbins, "Power Electronics – Converters, Applications and Design", John Wiley & Sons, Inc., 2003. D. Žarko, “Projektiranje uzlaznog istosmjernog pretvarača”, FER, 2006. Y. Zhang, L. Wei, X. Shen, H. Liang, „Study of Supercapacitor in the Application of Power Electronics“, WSEAS TRANSACTIONS on CIRCUITS and SYSTEMS, Issue 6, Volume 8, June 2009 M.Y. Ayad, M. Becherif, A. Henni, A. Aboubou, „Energy Management of a Fuel Cell and Supercapacitors by PassivityBased Control and Sliding Mode Control“, AEDIE, 2009. L. Shi, M.L. Crow, “Comparison of Ultracapacitor Electric Circuit Models”, IEEE Power and Energy Society General Meeting Conversion and Delivery of El. Energy in the 21st Century, 2008. J. Schonberger, “Modeling a Supercapacitor using PLECS”, Plexim GmbH, version 04, 2010. D. Iannuzzi, P. Tricoli, “Metro Trains Equipped Onboard with Supercapacitors: a Control Technique for Energy Saving”, International Symposium on Power Electronics, Electrical Drives, Automation and Motion, 2010. “High power aerogel supercapacitors enable new pulse, bridge and main power applications”, Whitepaper, Cooper Bussman, 2006. R. Barrero, X. Tackoen, J.Van Mierlo, “Analysis and configuration of supercapacitor based energy storage system onboard light rail vehicles”, 13th International Power Electronics and Motion Conference, 2008. “Basics of Electrochemical Impedance Spectroscopy”, Application note, Gamry instruments, 2007. M.B. Camara, F. Gustin, H. Gualous, A.Berthon, “Supercapacitors and Battery power management for Hybrid Vehicle Applications Using multi boost and full bridge Converters”, EPE conference, Aalborg, 2007. L.M.P. Fanjul, „Some new applications of supercapacitors in power electronics systems”, M. Sci. Thesis, Texas A&M University, Aug. 2003. Z. Gizinski, M. Gasiewski, I. Mascibrodzki, M. Zych, K. Zymmer, M. Zulawnik, “Hybrid – type system of power supply for a trolleybus with an asynchronous motor”, 13th International Power Electronics and Motion Control Conference, 2008. G. Alcicek, H. Gualous, P. Venet, R. Gallay, A. Miraoui, "Experimental study of temperature effect on ultracapacitor ageing", EPE conference, Aalborg, 2007. G.J. La O', H.J. In, E. Crumlin, G. Barbastathis, Y. Shao-Horn, “Recent advances in microdevices for electrochemical energy conversion and storage”, International Journal of Energy Research, 31:548-575, 2007. H. Aripin, L. Lestari, D. Ismail, S. Sabchevski, “Sago Waste Based Activated Carbon Film as an Electrode Material for Electric Double Layer Capacitor”, The Open Materials Science Journal 4, 117-124, 2010. K. Hyeok An, K.K. Jeon, J.K. Heo, S.C. Lim, D.J. Bae, Y.H. Lee, “High-Capacitance Supercapacitor Using a Nanocomposite Electrode of Single-Walled Carbon Nanotube and Polypyrrole”, Journal of The Electrochemical Society, 149 (8) A1058-A1062, 2002. A. Rufer, „Power-Electronic Interface for a Supercapacitor-Based Energy-Storage Substation in DC-Transportation Networks.“, conference EPE 2003 – Toulouse, 2003. Luis Zubieta, and Richard Boner,” Characterization of doublelayer capacitors for power electronics applications,” IEEE Transactions on Industry Applications, vol. 36, No. 1, Jan./Feb. 2000. V. Musolino, „How to Design the Supercapacitor Storage System“, A study activity in collaboration with the Electrical Department of the Politecnico di Milano, 2009. J.R. Miller, A.F. Burke, „Electrochemical Capacitors: Challenges and Opportunities for Real-World Applications“, The Electrochemical Society Interface, Spring 2008. V. Musolino, „Supercapacitor modelling“, unpublished whitepaper, 2009. [25] “EnerGstor Wayside Energy Storage”, Bombardier Transportation, 2010. [26] M. Lindgren, “Modeling and Control of Voltage Source Converters Connected to the grid”, Technical Report No. 351, Chalmers University of Technology, Goteborg, Sweden, Nov. 1998. [27] P. Thounthong, S. Rael, B. Davat, „Analysis of Supercapacitor as Second Source Based on Fuel Cell Power Generation“, IEEE Transactions on Energy Conversion, Vol. 24, No. 1, Mar. 2009. [28] T.D. Burchell, “Carbon Materials for Advanced Technologies”, Oxford, United Kingdom, Elsevier Science Ltd, 1999. [29] Maxwell Technologies, “Product guide - BOOSTCAP ultracapacitors product guide”, Doc. No. 1014627.1, 2009. [30] D. Iannuzzi, P. Tricoli, „Optimal Control Strategy of Onboard Supercapacitor Storage System for Light Railway Vehicles“, IEEE International Symposium on Industrial Electronics, 2010. [31] P. Jampani, A. Manivannan, P.N. Kumta, “Advancing the Supercapacitor Materials and Technology Frontier for Improving Power Quality”, The Electrochemical Society Interface, Fall 2010. [32] M Jayalakshmi, K Balasubramanian, “Simple Capacitors to Supercapacitors - An Overview”, Int. J. Electrochem. Sci., 2008. [33] R. Kotz, M. Hahn, R. Gallay, “Temperature behavior and impedance fundamentals of supercapacitors”, Journal of Power Sources, Vol. 154, Issue 2, March 2006. [34] A.M. Namisnyk, “A survey of electrochemical supercapacitor technology”, University of Technology, Faculty of Engineering, Sydney, Autumn 2003. [35] F. Rafik, H. Gualous, R. Gallay, A. Crausaz, A. Berthon, “Frequency, thermal and voltage Supercapacitor characterization and modeling”, Journal of Power Sources 165, 928-934, 2007. [36] S. Basu, T.M. Undeland, G. Guidi, “Voltage and Current Ripple Considerations for Improving Ultra-Capacitor Lifetime While Charging with Switch Mode Converters”, EPE conference, Aalborg, 2007. [37] M. Steiner, M. Klohr, S. Pagiela, “Energy Storage System with UltraCaps on Board of Railway Vehicles”, EPE conference, Aalborg, 2007. [38] G.L. Bullard, H.B. Sierra-Alcazar, H.L. Lee, J.L. Morris, “Operating principles of the ultracapacitor”, IEEE Transactions on Magnetics, vol. 25, no. 1, Jan. 1989. [39] A.F. Burke, E.J. Dowgiallo, J.E. Hardin, "Application of ultracapacitors in electric vehicle propulsion systems", Power Sources Symposium Proceedings, 1990. [40] Z. Chen, "High pulse power system through engineering batterycapacitor combination", Energy Conversion Engineering Conference and Exhibit, 2000. [41] F. Gagliardi, M. Pagano, G. Maestri, M. Martone, A. Tarantino, "Experimental Results of on-board Battery-Ultracapacitor System for Electric Vehicle Applications", ISIE conference 2002. [42] U. Fischer, R. Saliger, V. Bock, R. Petricevic, J. Fricke, "Carbon Aerogels as Electrode Materials in Supercapacitors", Journal of Porous Materials 4, 281-285, 1997. [43] M. Kaempgen, C.K. Chan, J.Ma, Y.Cui, G. Gruner, "Printable Thin Film Supercapacitors Using Single-Walled Carbon Nanotubes", Nano Letters, American Chemical Society, April 2009. [44] Cap-XX company web site, http://www.cap-xx.com/, 2010.-2011. [45] Maxwell Technologies web site, http://www.maxwell.com/, 2010. [46] Nesscap Co., Ltd., home page, http://www.nesscap.com/, 2010. [47] Maxwell Technologies, “User manual – Integration kit”, 2007. [48] "Nesscap Ultracapacitor Technical Guide", Nesscap Co., Ltd., 2008. [49] P. Barrade, “Series Connection of Supercapacitors: Comparative Study of Solutions for the Active equalization of the Voltages”, Conference paper, Electrimacs, 2002. [50] K. Matsui, T. Nakashima, M. Hasegawa, "Analyses of Voltage Equalizer for Supercapacitors Using CW circuit having Buckboost Chopper", WSEAS conference 2010. [51] A.Rufer, P.Barrade, "A Supercapacitor-Based Energy Storage System for Elevators with Soft Commutated Interface", ESA conference, 2001. [52] P.Barrade, A.Rufer, "Supercapacitors as energy buffers : a solution for elevators and for electric busses supply", PCC conference, 2002.