Orris Market City

advertisement

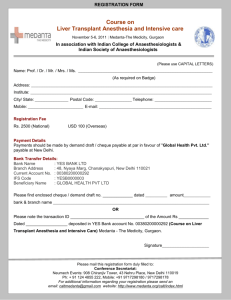

“Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. Environmental Report OF “Orris Market City” At Vill-Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed By: M/s Orris Infrastructure Pvt. Ltd. Prepared by: M/s Perfact Enviro Solutions Pvt. Ltd. (NABET Registered wide list of accredited consultants organizations/ Rev. 37(A)/07th January, 2016 at S.No-116) 502-507, NN Mall, Sector-3, Rohini, New-Delhi-85 Phone: 011-47528467; 011-47021086 Fax: - 011-47528434 48 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. 3.1 EXECUTIVE SUMMARY OF THE PROJECT 3.1.1 Activities: The project will include: 1. Service Apartment 2. Shops 3.1.2 Description & Details of Project: Project details are given in Table 3 Table 4: Project Details S. No. Particulars Total 1. 2. 3. 4. Total Plot Area Ground Coverage (Permissible) (50%) Ground Coverage (Proposed) (40.39%) F.A.R (Permissible) (1.75) 15620.84 sq m 7810.42 sq m 63.511 sq m 27336.47 sq m 5. F.A.R (Proposed) (1.73) 27040.418 sq m 6. 7. 8. 9. 10. Non F.A.R Area 1376.268 sq m First Basement level 8333.067 sq m Second Basement level 8703.225 sq m Total Basement area 17036.292 sq m Total Built up Area (FAR+ Non 45452.978 sq m FAR+ Basement Area) Green Area (25 %) 3905.21 sq m Road & open area (18.76 %) 2930.119 sq m No. of Floors G+13 No. of Block 4 Levels of Basement 2 No. Height of Building 56.6 m Total Population 3204 Total Power load 3778.50 KW No. of DG sets 4 x 1250 KVA, 1 x 1010 KVA No. of rainwater harvesting pits 4 Total water requirement 230 KLD STP capacity 190 KLD Waste water generation 156 KLD Parking Provision 541 ECS Parking Requirement 541 ECS 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 49 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. 3.2 INTRODUCTION OF THE PROJECT / BACKGROUND INFORMATION 3.2.1 Brief Description of the Nature of the Project: The proposed project “Orris Market City” is proposed in Sector- 89-90, at VillageHayatpur & Badha, Gurgaon. The project will be developed by M/s Orris Infrastructure Pvt. Ltd. The “Orris Market City” is a part of Residential Township. The Environmental Clearance has already been granted for Residential Township vide letter no SEIAA/HR/2014/1246 dated 17/10/2014. The proposed project will have ground coverage 63,511 sq m and FAR of 27040.418 sq m with total basement area of 17036.292. thus, the built-up area of complex is 45452.978 sqm, which is greater than 20000 sqm. So it will be covered under EIA Notification 2006.ther shall be 3.3 PROJECT DESCRIPTION 3.3.1 Land Use and Ownership of the site land Licence has been granted to M/s Orris Infrastructure Pvt. Ltd. for development of Residential Township Project. The “Orris Market City” is part of the licence area, building plans for complex is approved to M/s Orris Infracture Pvt. Ltd. The land use proposed at the site will be as given in Table 5: Table 5 Landuse Area Details Land use Ground Coverage Green Area Surface Parking Road, Paved & open Area Total Area (sq m) 6310.511 3905.21 2475.00 2930.119 15622.751 sqm Percentage (%) 40.39 25 15.85 18.76 100 % 50 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. Landuse Area Details 18.76 Ground Coverage 39.39% 15.85% Green Area Surface Parking Road, Paved & open Area 25% 3.3.2 Location of the project with connectivity 3.3.2.1 Geographical Information of Site Latitude 28°25'24.32"N Longitude 76°56'13.27"E Elevation 222 3.3.2.2 Map on Google& Connectivity Location Map with site connectivity is given below: 51 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. The connectivity to the site is given in Table 5: Table 6: Connectivity to the Site S. No. Accessibility Description 1. Highway/ Road NH-8 NH- 236 State Highway 26 2. 3. Railway Station Airport Distance & Direction 5.32 Km SE 14.34 Km NE 0.17 Km N Gurgaon Railway Station Garhi Harsaru Junction Rly Station Basai Dhankot Rly. Station 10.29 Km NE 1.73 Km NW Indira Gandhi International Airport 21.71 Km NE 6.41 Km NE 3.3.2.3 Topographical Map The topographical Map is as under:-. 52 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. 3.3.2.4 Layout Plan The layout plan is given below: I NO RT H H E G S W K F E D J L M O C N B A P 3.4 Resources 3.4.1 Water Resource Management 3.4.1.1 Present Quality The present quality of the water environment shall be provided. 3.4.1.2 Water Requirement During construction phase, treated water was arranged on temporary basis through the tankers water supply. During operation phase, water requirement will be met through HUDA. The total water requirement breakup for the complex is given in Table 7: Table 7: Water Management S. No. 1. Domestic Service Apartment Maintenance Staff Population Factor in LPCD Requirement in KLD 288 172 50 265 45.0 12 Waste Water in KLD 53 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. Visitor Kitchen staff Total 2651 15.0 40 1 Domestic= 51 Flushing= 51 3288 Domestic= 41 Flushing= 51 3. 4. 5. Food court Gardening D.G & HVAC Cooling Misc. Total 960 70 230 67 12 54 Nil 36 13 Nil 10 To STP= 156 KLD WATER BALANCE 3.4.1.3 Source of Water The water will be resourced through HUDA. 3.4.1.4 Disposal Total waste water generated (i.e.156 KLD) will be treated in the STP of 190 KLD capacity from which 153 KLD treated water will be generated. Out of which 99 KLD 54 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. of the treated water will be re-used for flushing, gardening & cooling purposes. It is zero discharge unit. 3.4.2 Energy Resource Management 3.4.2.1 During Construction DG sets of 62.5 kVA will be used for construction works. 3.4.2.2 During Operation During operation phase, 3778.50 KW of electric load from Dakshin Haryana Bijli Vitran Nigam shall be supplied to the Complex. Power backup shall be provided by DG capacity of 4 x 1250 KVA, & 1x1010 KVA. 3.4.3 Energy Conservation Following are the measures adopted to conserve the energy: Day light provision shall be made in service apartments by using openable windows (use of sunlight in lieu of conventional power). We shall provide LED & T5 in common areas like corridors, lifts, and lobby. We shall use Low loss electronic ballast for all lights used in the basements and electrical rooms. Solar lights shall be provided. Energy efficient motors shall be used for water pumping. Transformer will be having efficiencies as per ECBC Norms. Solar Water Heater will be used to meet 19% of hot water requirement of the complex. Quantification of Energy About 15-18% of energy shall be conserved. 3.4.4 Air Quality at Site The present quality of the air shall be provided. 3.4.5 Noise Quality at Site The present Noise quality of the site shall be provided. 55 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. 3.5 SITE ANALYSIS 3.5.1 Eco-sensitive areas with distance from project location The eco sensitive zones with distance from the project location are given in Table 7: Table 8: Eco sensitive sites around the project site Areas protected under international conventions, national or local legislation for their ecological, landscape, cultural or other related value Areas which are important or sensitive for ecological reasons - Wetlands, watercourses or other water bodies, coastal zone, biospheres, mountains, forests Areas used by protected, important or sensitive species of flora or fauna for breeding, nesting, foraging, resting, over wintering, migration. None None Water Bodies Najafgarh Jheel Water Pond New Water Pond 9.04 Km N 7.58 Km NE 8.20 Km NE Sultanpur Bird Santuary 5.80 Km NW 3.5.2 Annual Windrose Diagram: The Wind Rose Diagram of Annual Average (1991-2007) is given below: 56 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. 3.5.3 Social Infrastructure available The social infrastructure available at site is given as under: Table 9: Social Infrastructure near the project site Hospital Civil Hospital, Vikas Nagar, Sector-10 ESI Hospital, Sector-3 Rockland Hospital Sector-5 Post Office Post Office, Khandsa Road, Sector-37 Post office Basai Village IMT Manesar Post Office Places of worship Shiv Mandir Sector-90 Mandir, Harsaru Ashutosh Temple Sector-37 School Pranavananda International School, Sector-92 Basant Valley Public School, Sector-89 Govt. Senior Secondary School,Sector-36 6.96 Km NE 7.11 Km SW 6.29 Km S 6.73 Km NE 6.13 Km NE 7.97 Km S 1.70 Km SW 2.19 Km NE 7.20 Km NE 1.95 Km SW 2.12 Km N 5.36 Km SE Bank Allahabad Bank, Garhi Harsaru Indian Bank , 2.14 Km NW 2.47 Km SW SH-15A,Wazirpur 5.65 Km SE Kotak Mahindra Bank ATM Sector-8 3.6 PROPOSED INFRASTRUCTURE 3.6.1 Types of Buildings & Activities Proposed The proposed project will have Service Apartment & Shops. 3.7 ENVIRONMENT MANAGEMENT PLAN The Environment Management Plan (EMP) is a site specific plan developed to ensure that the project is implemented in an environmentally sustainable manner where all stakeholders including the project proponents, contractors and subcontractors, including consultants, understand the potential environmental risks arising from the proposed project and take appropriate actions to properly manage that risk. Adequate environmental management measures need to be incorporated during the entire 57 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. planning, construction and operating stages of the project to minimize any adverse environmental impact and assure sustainable development of the area. The EMP presented below should be followed and regular monitoring of relevant parameters as stated in post project-monitoring schedule shall be carried out. The EMP is to be proactive in nature and will be upgraded if new facilities or modification of existing facilities, with environmental concerns, come up at a later stage. EMP includes four elements: Commitment and Policy: Proposed project will strive to provide and implement the Environmental Management Plan that incorporates all issues related to air, land and water. Planning: This includes identification of environmental impacts, legal requirements and setting environmental objectives. Implementation: This comprises of resources available to the developers, accountability of contractors, training of operational staff associated with environmental control facilities and documentation of measures to be taken. Measurement and Evaluation: This includes monitoring, corrective actions, and record keeping. 3.7.1 ENVIRONMENT MANAGEMENT DURING CONSTRUCTION 3.7.1.1 AIR ENVIRONMENT Air quality around the project was adversely impacted during the construction stage. Various construction activities especially related to lose material likely to cause generation of dust that adversely impacts the air quality of the surrounding area of the project site. To minimize such impact, following measures were taken: All the loose material either stacked or transported shall be provided with suitable covering such as tarpaulin, etc. and kept in and specific place. Dust suppression systems (water spray) shall be done as per requirement at the construction site. Wind breaking walls shall be provided around the construction site. Fly ash based cement / bricks shall be used in the construction only in side walls. Building under construction shall be covered with the green cloth and net screen shall be provided on every floor throughout the construction. Water sprinkling shall be done at the location where dust generation shall be anticipated. To minimize the occupational health hazard, proper masks shall be provided to the workers who are engaged in dust generation activity. 58 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. Wet jet system shall be used for the stone cutting and grinding to avoid the emission from the dry stone cutting. Wheel washing arrangement of construction vehicle shall be provided at site. DG sets of capacity 62.5 KVA shall be installed acoustically enclosed with adequate stack height above roof level of DG sets. The construction activity results in fugitive dusts. These fugitive dusts was controlled by carrying out construction by covering the boundary of the proposed project site and as well by polythene cover to a particular height and also by intermittent spraying of water. 3.7.1.2 WATER MANAGEMENT During the construction of the proposed project, the services required like water supply and sewage facilities were arranged on a temporary basis and the same will be maintained without any adverse impact on the environment. The water required for curing and other construction purpose was arranged on temporary basis from treated water from nearby STP. During the construction period, runoff from the construction site was allowed to stand (water logging) or enter into the roadside or nearby drain. Adequate measures were taken to collect such run off and will be disposed off at the designated construction waste disposal location. 3.7.1.3 NOISE ENVIRONMENT During the construction stage, expected noise level was in the range of 70 dB (A), which decreases with increase in distance. Hence all the construction activities were carried out during the daytime. As stated earlier, due to the construction activity undertaken for the project there would be some noise generation due to the movement of vehicles carrying construction materials and as this would only be a temporary phenomenon, it would be managed by properly regulating the movement of vehicular traffic so that the ambient air quality with respect to noise is adversely affected. To prevent any occupational hazard, ear muff / ear plug were given to the workers working around or operating the plant and machinery emitting high noise levels. Operation of such plant or machinery were strictly be prohibited during night hours. Careful planning of machinery operation and scheduling of operations shall be done to minimize such impact. 59 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. 3.7.1.4 SOLID WASTE MANAGEMENT During the construction, the soil had been excavated approx.34406.08 Cubic meter. This soil will be used upto extent possible for backfilling, levelling& other purposes and the rest will be stacked and disposed off in authorized recycler for recycling the waste which shall not cause any disturbance to the surrounding environment. Trucks to the site transport the construction materials. At site, it will be handled manually and by tractor trolley. As most of the materials are dry solids, there is air pollution during their handling at different stages for which all mitigation methods will be adopted. 3.7.2 ENVIRONMENT MANAGEMENT DURING OPERATION 3.7.2.1 AIR ENVIRONMENT DG sets of capacity 4 X 1250 KVA & 1 x 1010 KVA Capacity will be installed for emergency use during power failure. Proper stack height of D.G Set will be maintained which will help in reducing the air pollution. The DG sets will be installed with acoustic enclosure. D. G. Set. Capacity 1250 1010 No 4 1 Stack Height 6 meters above roof level 6 meters above roof level As per the specifications from D.G. Set manufacturer following emissions shall be maintained, as given in Table 10: Table 10: DG Set emission standards D.G Sets No. PM mg/Nm3 NOx mg/Nm3 HC mg/Nm3 CO mg/Nm3 1250 KVA 1010 KVA 3 2 75 75 887.5 887.5 100 100 150 150 3.7.2.2 WATER MANAGEMENT Total water requirement has been estimated to be 230 KLD for the proposed project and will be met by HUDA supply. Water shall be used mainly for domestic, flushing, gardening, DG cooling & HVAC, Filter back wash & Misc. purposes. Total quantity of wastewater generation will be 88 KLD for the proposed project. The generated sewage will be treated in Sewage Treatment Plant capacity 190 KLD based on FAB technology. 60 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. The treated water 153 KLD shall be generated from STP, out of which 99 KLD will be reused for flushing, gardening & cooling purposes. It is zero discharge unit. 3.7.2.2.1 WASTEWATER TREATMENT The Sewage Treatment Plant of 190 KLD based on FAB technology offered has some distinct advantages over conventional activated sludge processes. The scheme is proven, under a variety of operating conditions, and is highly flexible in operation. The characteristics of raw sewage and the characteristics required for the treated water will be as given in Tables below respectively. RAW SEWAGE CHARACTERISTICS FLOW PH BOD COD OIL & G TSS 190 7.5-8.0 200-300 400-500 10 100 mg/l mg/l mg/l mg/l The Sewage Treatment Plant (STP) can give treated water, which can be reused for Flushing, Gardening & Cooling purposes. TREATED SEWAGE CHARACTERISTICS FLOW PH BOD COD OIL & G TSS 190 6.5-8.5 <10 <60 NIL <10 mg/l mg/l mg/l mg/l Specification of each units of sewage treatment plant:ELECTRO MECHANICAL EQUIPMENT S.NO DESCRIPTION QTY SPECIFICATION 1 2 3 BAR SCREEN AIR GRID EQUALIZATION & SHT 1 SUITABLE SIZE MOC MS FLAT, EPOXY PAINTING 1 SUITABLE SIZE HDPE FEED PUMP 2 8.64 CUM /HR CI @ 10 mwc 61 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. 4 FAB REACTORS 2 5 TUBE SETTLER 1 6 FLUDIZED BED REACTOR LOT 7 a. MEDIA b. AIR GRID c. AIR BLOWER TUBE SETTLER MEDIA a. MEDIA b. COLLECTION TROUGHS HYPO DOSING TANK FILTER FEED PUMP LOT CHEVRON TYPE PVC LOT MS EPOXY 8 9 2.8 2.8 3 2.3 2.3 3 M M M M M M LENGTH BREATH SWD LENGTH BREATH SWD RCC RCC SPECIAL MEDIA SS CI 2 1 863.64 2 17.27 LTS CUM /HR HDPE CI @ 10 mwc 10 MULTI GRADE FILTER 11 ACTIVATED CARBON FILTER 12 SLUDGE DISPOSAL PUMP 13 PIPE AND VALVES 14 15 U.V TREATMENT FILTER PRESS 2 2.0 2.0 2 M M M LENGTH BREATH SWD 2.0 2.0 2 M M M CUM /HR LENGTH BREATH SWD 14.00 CI @ 10 mwc CIVIL UNITS S.NO DESCRIPTION LOT 1 1 MS/HDPE STANDAR D PP SUITABLE LOT QTY 1 SCREEN CHAMBER 1 2 OIL & GREASE 1 3 EQUALIZATION TANK 1 SPECIFICATION MOC 1.2 0.8 0.5 0.6 1.9 1.5 M M M M M M LENGTH BREATH SWD LENGTH BREATH SWD RCC 4.0 4.0 M M LENGTH BREATH RCC RCC 62 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. 4 FILTER FEED TANK 1 3 2.0 2.0 2 M M M M SWD LENGTH BREATH SWD RCC 5 SLUDGE HOLDING TANK 1 1.1 1.1 3 M M M LENGTH BREATH SWD RCC 6 TREATED WATER TANK 1 2.8 2.8 3 M M M LENGTH BREATH SWD RCC FOUNDATIONS SUITABLE Following description gives the salient features of the STP: 1. Small space requirement The concept of compact sewage treatment plant is promoted so that expensive conventional treatment is dispensed herewith. The treatment scheme is also versatile, in the sense that units can be re-arranged in any way in which the space and pile caps are available. 2. Lower operating power requirements The system utilizes aeration tanks of much smaller size, thereby reducing the overall power required in aerating the raw sewage. Since the bio-reactor depth is more, efficient transfer of oxygen takes place, thereby reducing the overall power consumed in treatment. 3. Simplicity in operation and maintenance The system adopted has much less moving parts (only pumps and blowers). Further there is no moving part inside the bio-reactor. This gives the advantage of continuously running the bio-reactor system, under widely fluctuating conditions. All the maintenance on the mechanical systems can be done with normal skilled mechanics available. The system is unique in operation, such that, only inlet and outlet parameters (i.e. raw sewage BOD / COD / TSS /TP and treated sewage BOD / COD / TSS / TP etc.) need to be analysed. Since the bio-reactor is self-sustaining, there is no requirement of recycling the biomass from the secondary clarifier. Hence, analysis such as MLSS / MLVSS / SVI (sludge volume index) / F / M ratio etc. is not required to be done. This greatly reduces the analytical load on the plant chemist / supervisor, and makes the system very simple to operate and control. 4. Removal of Nutrients & coliform The bio-reactor system adopted in the FAB based STP is provided with nutrients removal, and removal of disease causing E-coli bacteria. 63 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. Nutrient removal The bio-reactor system operates at very food to micro-organisms ratio (F / M ratio). This helps in totally converting the Ammonicals nitrogen to nitrate nitrogen. In the process of synthesis of organic substrate, about 40 – 50% of the total phosphates load is also reduced. The remaining phosphates can be precipitated by addition of aluminum ions dosed in form of Poly Aluminum Chloride (PAC). Phosphates react with aluminum ions and precipitate as aluminum phosphate, which is an insoluble salt. Thus the total phosphates load can be easily reduced by more than 90%. Coliform removal The outlet BOD of the bio-reactor system being very low (in other words, hardly any food is available to the E-coli), most of the coliform are killed in the reactor itself. The treated sewage outlet coliform count will conform to WHO standards. 5. Sludge handling The sludge generated in the bio-reactors is totally digested. Since the F / M ratio in the bio-reactors is very low, the excess sludge generation is lower than compared to the conventional ASP system. Normally, this sludge is anaerobically digested to stabilize the organic matter. The present system does not envisage any sludge digestion (since the sludge is aerobically stabilized in the bioreactors itself), making the system more suitable for operation with less manpower. The excess sludge is separated in the secondary clarifier, and then disposed off either on drying beds, or can be directly used as soil conditioner. 3.7.2.2.2 HYDRAULIC FLOW DIAGRAM OF SEWAGE TREATMENT PLANT 64 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. 3.7.2.2.3 TREATMENT PROCESS The sewage is first passed through a Bar Screen Chamber & an Oil & Grease Chamber where any extraneous / floating matter gets trapped. The sewage is then collected in a Receiving Sump where the variations in flow and characteristics are dampened, which otherwise can lead to operational problems and moreover it allows a constant flow rate downstream. Here the sewage is kept in mixed condition by means of coarse air bubble diffusion. The equalized sewage is then pumped to the Fluidized Aerobic Bed Reactors(FAB) where BOD/COD reduction is achieved by virtue of aerobic microbial activities. The FAB reactors run in series. The oxygen required is supplied through coarse air bubble diffusers. The excess bio-solids formed in the biological process, which are separated in the downstream Plate Settler Tank. The clear supernatant is sent to the tertiary treatment section comprising of a Dual Media Filter and an Activated Carbon Filter, and UV disinfections system. If needed Softener shall be provided. The biological sludge generated from the FAB, which is settled in the Plate Settler, is drained through the Filter Press. 3.7.2.2.4 Rain Water Harvesting The main source of ground water recharging in the study area is rainwater, which infiltrates into the ground through various lithological units present in the study area. 4 nos. of RWH pits are proposed in the shopping complex to recharge the ground water. The runoff from the rooftop and storm water shall go to the recharge pits. Scheme for Ground Water Recharging The rainwater is diverted from the rooftop using rain water pipes to the surface / underground drainage network. The entire campus is sub divided for recharging structures. The rainwater is diverted into the desilting tank to remove inorganic impurities and the outflow of the desilting tank is taken into the recharge well. Desilting Tank The desilting tanks are used to remove silt and other floating impurities from rainwater. Desilting tank is like an ordinary container having provision for the inflow, outflow and overflow. Apart from removing silt it holds the excess amount of water till it is soaked up by the recharge structure. The bottom of tank will have unpaved surface (layers of coarse sand) to allow standing water to percolate into the soil. The rainwater collected in these desilting chambers shall be utilized for horticulture. Recharge well The recharge well consists of percolation pits with boreholes in the middle of the pit. UPVC pipe perforated will be lowered in the middle of the boreholes and the pit will be filled with gravel and pebbles in three layers consisting of boulders, gravel and 65 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. coarse sand. The mouth of the UPVC pipe shall be protected to avoid silt getting into it. The depth of the bore will depend on the soil condition/water strata. The schematic diagram is enclosed. It should be therefore concluded that there is no significant impact on surface water quality & hydrology of the area. The proposed rainwater-harvesting scheme will stabilize the groundwater table in the area. 3.7.2.2.5 RAIN WATER HARVESTING CALCULATION:Rain Water Harvesting Calculation: Soil Quality : Silt Loam Infiltration rate : 20.3 mm/hr Porosity : 35% Annual Rain fall : 723 mm Peak Hourly Rain fall : 45 mm/hr No. of rain water harvesting pits :4 Size of each pit : 3.0 m x 3.0 m x 3.0 m Table 11: Rain Water Harvesting Calculation S. No. Description of Area Area Considered (Sq. M) 1 Water Available from Terraces of Apartment buildings and other roof-top surfaces Paved Surfaces, Roads & other Built-up Areas Lawns, Gardens & all other Open Areas GRAND TOTAL 2 3 Retention time capacity of recharge tank in 15 min (60 mm) Total Volume of Water Available for Rain Water Harvesting (cu. m/15 min) 6310.511 sq m 0.85 11 59 5405.119 sq m 0.65 11 39 3905.21 sq m 11 9 15620.84 Harvesting Factor / Collection Efficiency per area 0.20 107 66 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. Diagram of Rain Water Harvesting Pits:- ² 3.7.2.3 NOISE ENVIRONMENT:The main sources of the noise pollution will be D.G sets. DG sets of 4 X 1250 KVA capacity & 1 x 1010 KVA will be installed in the shopping complex which shall be bought acoustically enclosed and shall meet the norms prescribed by CPCB. Planting of the trees at the boundary of the Complex will help in reducing the level of the noise within the Complex. 3.7.2.3.1 Noise Pollution Control System DG sets of 4 X 1250 KVA capacity & 1 x 1010 KVA Capacity will be installed for power backup during power failure. Location of DG sets: Basement 67 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. 3.7.2.3.2 ACOUSTIC ENCLOSURE / TREATMENT There are two methods to reduce noise from DG Sets. 1. Acoustic Enclosures [when DG Set is kept outdoor] 2. Acoustic Treatment [when DG Set is kept indoor] ACOUSTIC TREATMENT: (a) MAIN FRAME: 3’ 1.5” rectangular pipe will be used to make main frame of the panel covered with 18 gauge MS sheet from one side. Insulation by Glass Wool: 3” thick glass wool pad of high density covered with tissue paper will be used for absorption of sound. Covering Layer: Finally, the insulated material is covered with perforated galvanized (GI) sheet (24SWG) to prevent damage to insulating material. (b) AIR VENTILATION SYSTEM The acoustic lining defined in above results in accumulation of heat generated by DG Set. Therefore the temperature of the treated room may increase which may adversely affect the life of DG Set. To overcome the said problem, a proper ventilation system should be designed. As per calculation of heat generated by DG Sets a regular fresh air is continuously sucked from the enclosure with the help of two 20” axial fans. There have been two 24” axial fans for the supply of fresh air. The pressure difference inside and outside of the room has been less than 8 mm WG, which does not affect the normal running condition of DG Sets. (c) INSULATION OF AIR INLET AND OUTLET POINTS The sound travels along with air therefore it is necessary to control the traveling sound with the help of insulated ducts [2” glass wool pads and perforated sheets] and louvers at inlet and outlet air points. The ducts have S-type shape to prevent any direct escape of noise. (d) INSULATED SERVICE DOOR The maintenance and servicing of DG Set is done using a suitable service door of 5’ x 7’ size. The door is made of MS sheet and frames fully insulated with 3” thick glass wool pad followed by perforated aluminium sheets. The schematic layout of acoustic enclosure is given below: 68 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. ACOUSTIC TREATMENT FOR D. G. SET ROOM 3.7.2.4 PARKING MANAGEMENT: A. Parking Required: PARKING MANAGEMENT PARKING REQUIREMENT Total Parking Required FAR / 50 = 541 ECS B. Parking Provided: Parking provided are 541 ECS. Table 12: Parking Calculation Parking Calculation Area (sq m) Basement Parking-1 Basement Parking-2 Surface Parking TOTAL Parking Provision 8833.1 8703 Services Area (sq m) 1561.0 1574.5 Net Parking Area (sq m) 6772.0 7128.8 2475.0 Factor 35 35 25 Total Parking (ECS) 193 203 99 541 ECS 3.7.2.5 WASTE MANAGEMENT 3.7.2.5.1 MUNICIPAL SOLID WASTE The Total population of Complex will be 3800 person for which 580 kg/day solid waste will be generate. The solid waste categories and disposal method is shown is given below: 69 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. Table 13: Municipal Waste Management Type of Waste Colours of Bins Category Organics Green Bio Degradable Recyclable Items Total Blue Recyclable Disposal Method The waste shall be treated in organic waste converter and converted to manure Recycler Total Waste (Kg) 406 174 580 kg/day 3.7.2.6 Hazardous waste management Hazardous waste is a waste with properties that make it dangerous or potentially harmful to human health or the environment. The universe of hazardous wastes is large and diverse. Hazardous wastes can be liquids, solids, contained gases, or sledges. They can be the by-products of manufacturing processes or simply discarded commercial products, like cleaning fluids or pesticides. All hazardous wastes are required to be treated and disposed off in the prescribed manner. The main objective is to promote safe management and use of hazardous substances including hazardous chemicals and hazardous wastes, in order to avoid damage to health and environment. HAZARDOUS WASTE Type of Colours Category Waste of Bins Used Oil Black With Label E-waste Black With Label Disposal Method Total Waste Waste shall be collected in leak proof containers at isolated place and then it Hazardous will be given to approved vender of Waste CPCB as per Hazardous Wastes 54lit/month (Management/ Handling/Transboundry Movement) Rules, 2008, as amended in 2011. Hazardous E-Waste (Management & Handling) Waste 2 Kg/Month Rules, 2011. 70 “Orris Market City” at Hayatpur & Badha, Sector-89 & 90, Gurgaon, Haryana Being Developed by M/s Orris Infrastructure Pvt. Ltd. 3.7.2.7 PLANTATION Green belt planning will be done with ecological perspectives for the project taking into consideration and availability of space and other aspects. This will help in increasing the aesthetic effect of the environment. Since tree trunks are devoid of foliage, scrub should form there to give coverage to the trunks. The trees maintain the regional ecological balance and conform to soil and hydrological conditions. Indigenous species would be preferred. Green belt/greenery has been developed along most of the periphery of the project area as well as along roads. Area under plantation/greenery is 3905.21 sq m (25% of plot area) with trees and plants. The trees planted are of adequate height. Any trees that do not survive are replaced. The plantation/greenery programme will be completed, simultaneously along with the project. 3.7.2.7.1 PLANTATION PROGRAMME LAYOUT Plantation in the project area helps to arrest the particulate matter in the area and hence attenuate the pollution to a great extent and contribute positively to the environment. The trees also help in maintenance of regional ecological balance and conform to soil and hydrological conditions. Indigenous species are preferred for the purpose. Proposed Trees to be planted in the Complex Premises S. No. 1. 2. 3. 4. 5. 6. 7. 8. Botanical Name Azadirachta indica Polyalthia longifolia Dalbergia sisso Cassia fistula Delonix regia Jacaranda mimosaefolia Schliechera trijuga Tabebuia argentia Common Name Neem Ashoka Shisham Amaltas Gulmohar Nili gulmohar Kusum Yellow cedar 71