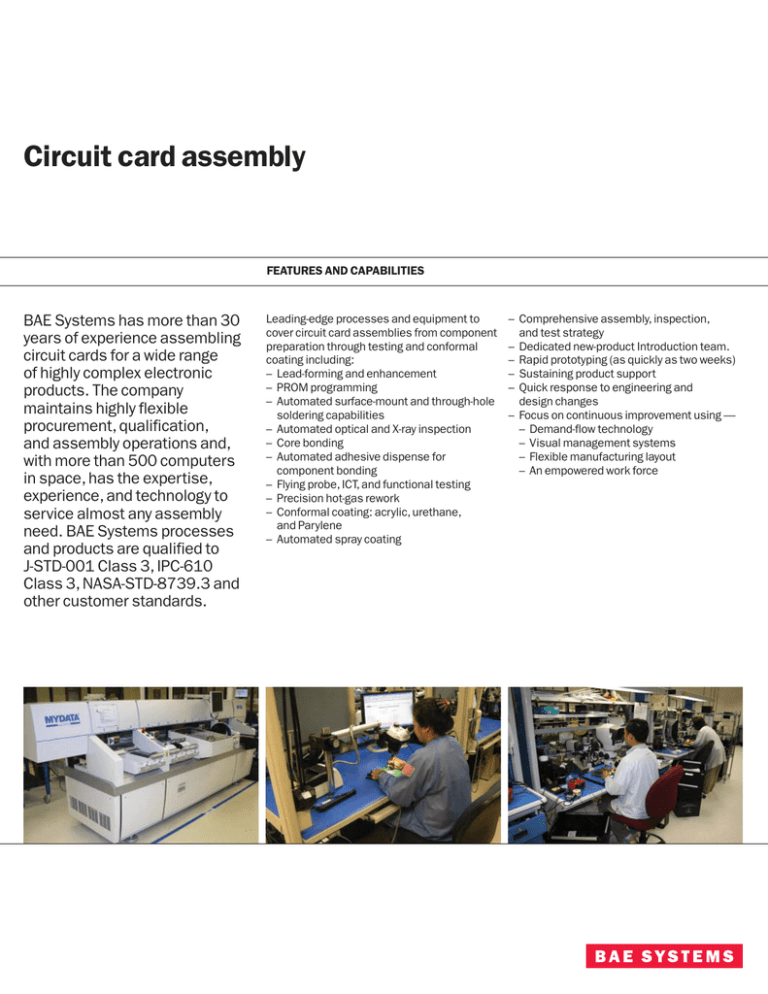

Circuit card assembly

advertisement

Circuit card assembly FEATURES AND CAPABILITIES BAE Systems has more than 30 years of experience assembling circuit cards for a wide range of highly complex electronic products. The company maintains highly flexible procurement, qualification, and assembly operations and, with more than 500 computers in space, has the expertise, experience, and technology to service almost any assembly need. BAE Systems processes and products are qualified to J-STD-001 Class 3, IPC-610 Class 3, NASA-STD-8739.3 and other customer standards. Leading-edge processes and equipment to cover circuit card assemblies from component preparation through testing and conformal coating including: – Lead-forming and enhancement – PROM programming – Automated surface-mount and through-hole soldering capabilities – Automated optical and X-ray inspection – Core bonding – Automated adhesive dispense for component bonding – Flying probe, ICT, and functional testing – Precision hot-gas rework – Conformal coating: acrylic, urethane, and Parylene – Automated spray coating – Comprehensive assembly, inspection, and test strategy – Dedicated new-product Introduction team. – Rapid prototyping (as quickly as two weeks) – Sustaining product support – Quick response to engineering and design changes – Focus on continuous improvement using — – Demand-flow technology – Visual management systems – Flexible manufacturing layout – An empowered work force INTEGRATED MANUFACTURING CYCLE Customer specifications Space material management Sample BAE Systems capabilities – Mission-specific material screening – Guaranteed material quality – Data review, management, and retention Customer designs Sample BAE Systems capabilities – QML ASIC fabrication line Customer designs Wafer fabrication BAE Systems’ expertise in radiation hardness, low-power design techniques, and qualifying designs for space flight can assist in optimizing algorithms, creating specifications and plans, and estimating size, weight, power, and performance. Component manufacturing BAE Systems products offer the building blocks to implement the design — e.g., RAD750 GP CPU, high-performance DSP, reconfigurable computing architecture, custom ASICs, advanced FPGAs, adaptive point-of-load power systems. Sample BAE Systems capabilities – QPL packaging line Customer designs Sample BAE Systems capabilities – Space card assembly line Space circuit card manufacturing Customer designs Sample BAE Systems capabilities – Environmental test facilities BAE Systems’ expertise in determining material screening needs based on mission requirements has yielded excellent material reliability. Testing BAE Systems’ semiconductor manufacturing line and flight card assembly line are co-located within the design facility, allowing interactive optimization of design, schedule, and cost criteria. Flight-certified test equipment and facilities accommodate test of materials and assemblies at all stages of manufacturing. FOR MORE INFORMATION, CONTACT: BAE Systems 9300 Wellington Road Manassas, Virginia 20110-4122 Telephone 800 RAD750A or 866 530 8104 www.baesystems.com Cleared for open publication on 07/09 This document gives only a general description of the product(s) or service(s) and, except where expressly provided otherwise, shall not form any part of any contract. From time to time, changes may be made in the products or the conditions of supply. ©2009 BAE Systems PUBS-09-D36