WHITE PAPER

A Systems Approach to the Design and Manufacture of

Solid State Lighting Fixtures

TE Connectivity

NEVALO Product Lighting Team

Introduction

Why Solid State Lighting is Important

Welcome to the world of Solid-State Lighting (SSL). Unlike

In 2009, the lighting industry generated sales of $75 billion glob-

the incandescent / fluorescent lamp world of today’s electrical

ally with less than 5% being solid-state lighting. However, more

lighting fixtures, solid-state lighting is in the realm of electron-

efficient solid-state products are poised to grow rapidly. Sales

ics with multiple interdependent ancillary systems. The purpose

of new and retrofit SSL fixtures are projected to increase to over

of this white paper is to provide an informative summary of the

half of the $91 billion in lighting sales in 2014 and further rise

elements that comprise these new electronic systems and to

to 75% market share by 2019. Regulations coupled with higher

introduce a holistic new systems approach to the design and

energy cost and lower SSL costs will dictate the pace of this

manufacturing of SSL fixtures.

change. Governments most aggressively pursuing the elimination of incandescent bulbs include those in the European Union,

1. The Solid State Lighting System

The ability to keep up with the increasing need for electrical

energy is causing a global pull towards more energy-efficient

products. Lighting consumes over 25% of the electricity generated in the United States. Most industrial nations have a similar

high percentage of energy production consumed by lighting.

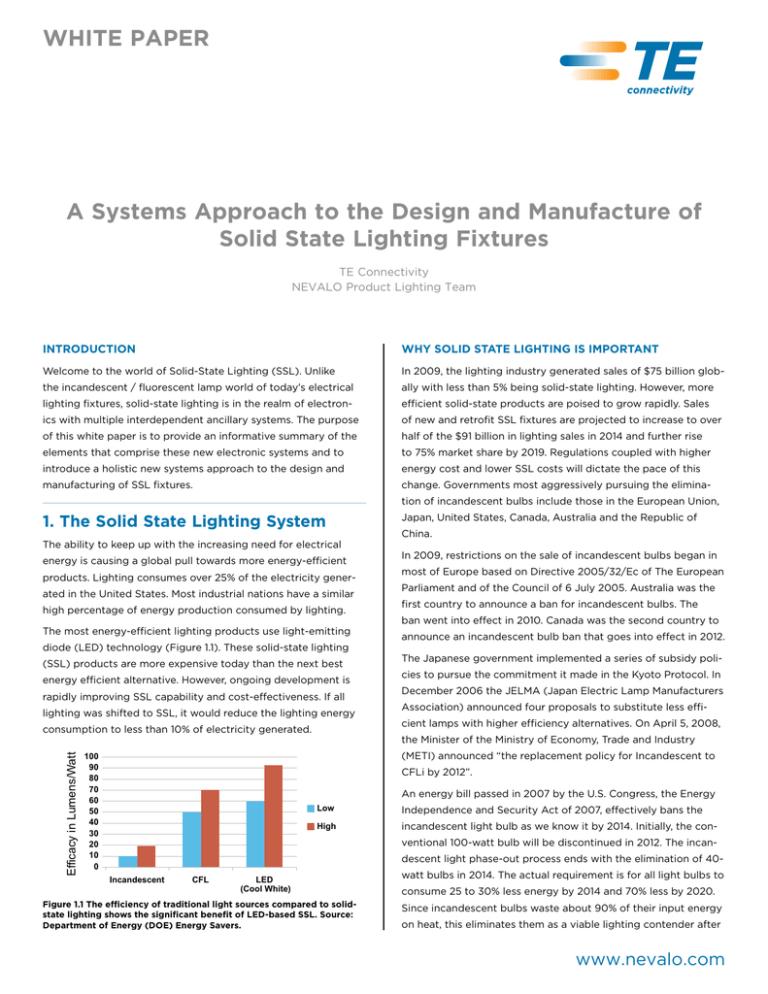

The most energy-efficient lighting products use light-emitting

diode (LED) technology (Figure 1.1). These solid-state lighting

(SSL) products are more expensive today than the next best

energy efficient alternative. However, ongoing development is

rapidly improving SSL capability and cost-effectiveness. If all

lighting was shifted to SSL, it would reduce the lighting energy

Efficacy in Lumens/Watt

consumption to less than 10% of electricity generated.

Japan, United States, Canada, Australia and the Republic of

China.

In 2009, restrictions on the sale of incandescent bulbs began in

most of Europe based on Directive 2005/32/Ec of The European

Parliament and of the Council of 6 July 2005. Australia was the

first country to announce a ban for incandescent bulbs. The

ban went into effect in 2010. Canada was the second country to

announce an incandescent bulb ban that goes into effect in 2012.

The Japanese government implemented a series of subsidy policies to pursue the commitment it made in the Kyoto Protocol. In

December 2006 the JELMA (Japan Electric Lamp Manufacturers

Association) announced four proposals to substitute less efficient lamps with higher efficiency alternatives. On April 5, 2008,

the Minister of the Ministry of Economy, Trade and Industry

(METI) announced “the replacement policy for Incandescent to

100

90

80

70

60

50

40

30

20

10

0

CFLi by 2012”.

An energy bill passed in 2007 by the U.S. Congress, the Energy

Low

Independence and Security Act of 2007, effectively bans the

High

incandescent light bulb as we know it by 2014. Initially, the conventional 100-watt bulb will be discontinued in 2012. The incandescent light phase-out process ends with the elimination of 40-

Incandescent

CFL

LED

(Cool White)

Figure 1.1 The efficiency of traditional light sources compared to solidstate lighting shows the significant benefit of LED-based SSL. Source:

Department of Energy (DOE) Energy Savers.

watt bulbs in 2014. The actual requirement is for all light bulbs to

consume 25 to 30% less energy by 2014 and 70% less by 2020.

Since incandescent bulbs waste about 90% of their input energy

on heat, this eliminates them as a viable lighting contender after

www.nevalo.com

2014. High-efficiency incandescent light bulbs are being pursued

as such, create a hazardous waste condition when they are

that may extend a small portion of the incandescent market but

discarded. In contrast, LEDs do not contain hazardous materials

their cost is quite high. California Title 24 has established energy

and products can be disposed of without concern.

standards for residential and nonresidential buildings that are

LED technology is improving rapidly. Haitz’s Law predicts “that

dictating energy standards for the rest of the country.

every decade, the cost per lumen (unit of useful light emitted)

With the world’s supply of non-renewable energy from fossil

falls by a factor of 10 and the amount of light generated per LED

fuels depleting rapidly, the need to reduce energy consumption

package increases by a factor of 20.” The improvements made

is a global imperative. Developing countries want to experience

over the last 30 years of the twentieth century (Figure 1.2) have

the same advantages that developed countries have enjoyed.

continued into the 21st century. (See Section 2 for more details).

However, developed countries have shown that the insatiable de-

As cost-effective lighting evolves, any company or individual

mand for energy-hungry products has exceeded their capacity

with a stake in the future of the lighting industry should be

to generate sufficient energy to support them, especially when

intimately aware of LED-based lighting’s current status and

the energy must come from clean energy sources. China has

progress toward becoming the dominant lighting source for

announced plans to phase out incandescent bulbs that could be

residential, commercial and industrial lighting.

completed by 2017.

Country

The rapid improvements in LED technology that fulfill Haitz’s

Initial Phase-out

Law have generated recent SSL growth that is attributable to

Target Completion

Brazil

2005

2005

Venezuela

2005

2005

European Union

2009

2012

Switzerland

2009

2009

Australia

2009

2009

Argentina

2012

2012

Russia

2012

2012

Canada

2012

2012

United States

2012

2014

India

--

2012

Japan

-- 2012

China

-- 2020

compelling applications that are emerging for solid state lighting

such as commercial refrigeration and street lighting. Commercial

refrigeration lighting is a perfect application for LEDs. This very

cold environment typically has the lighting on continuously. The

longer life of LEDs make them a natural for avoiding frequent

bulb replacement. In addition, LEDs function better at lower

temperatures compared to fluorescent bulbs that have to be

overdriven and start to lose arc requiring an increasing amount

of energy. This requires the refrigeration units to expend even

more energy to overcome the increased heat generated by the

lighting.

For street lighting and in many industrial and consumer applications, the maintenance avoidance issue alone is sufficient to

Table 1.1 The statutory elimination of incandescent bulbs is taking place

on a global basis.

warrant the use of solid state lighting. The cost to replace a bulb

Without the increased implementation of energy efficient

include the disruption (loss of sales) for shoppers in commercial

alternatives, the insatiable demand for more electrical energy

environments or loss of productivity in industrial situations. As

can only be solved by building more electrical power plants.

early adopters take advantage of the unique capabilities of SSLs

Unfortunately, it takes about 10 years to build a plant in the US

and Haitz’s Law continues its downward trend, the technology

to provide additional power generating capacity. In the U.S.,

will expand to broader applications.

in some environments is as high as $200/hour and that does not

the projected increase in demand of 135,000 megawatts versus

the projected additional capacity of 77,000 megawatts results

in a shortfall of 58,000 megawatts. [Data courtesy of NERAC.]

As a result, subsidizing more efficient technology is a preferred

alternative. Prof. Michael Siminovitch, Director of the California

Lighting Technology Center notes that, “Solid state lighting

equipment provides significant long-term energy savings and

is much less costly to buy than the generating facilities used to

provide power for ordinary wasteful lighting fixtures. As a result,

utilities, federal and state governments are providing an ever

widening array of utility incentives for the adoption of solid state

lighting devices.”

Initially, compact fluorescent lighting was the solution to

Figure 1.2 According to Haitz’s Law, the amount of light generated per

LED package will predictably increase and the cost/lumen of light will

predictably decrease each decade. Source: The Case for a National

Research Program on Semiconductor Lighting.

improved efficiency and replacement of incandescent bulbs

because of its lower cost. However, CFLs contain mercury and,

-2-

www.nevalo.com

The Transition to Solid State Lighting

simplified approach. Before discussing the details of the TE

NEVALO SSL system, the changing capabilities, challenges and

As in many other industries, consumers expect the leading tech-

design aspects associated with each of the areas in Figure 1.3 as

nology companies to respond to global imperatives with new

well as other critical solid state lighting issues will be explored.

products that use the latest technologies. Solid state lighting

is and has been promoted as the solution for improved efficiency and leading companies need to deliver on this promise.

The Future with Solid State Lighting

However, certain aspects such as cost and complexity have lim-

What can users do with the next generation of solid state light-

ited the industry’s response.

ing? It’s not just cheaper lighting over the life of the bulb. It’s

not just a matter of incrementally greater efficiency. All of the

Lighting suppliers have closely monitored how poorly the tran-

next generation SSL fixtures will take advantage of digital con-

sition from incandescent lighting to the obviously more efficient

trol to enable many more desirable features. For example, the

compact fluorescent lamp (CFL) technology has been handled.

next generation of luminaires made with solid state lighting will

The lessons learned from this process are being applied to solid

be able to provide color mixing within the white spectrum for

state lighting. Among the key observations is the difficulty sup-

warmer light in the morning and cooler lighting in the afternoon

pliers have had in coping with a new technology. SSL is even

or whatever the end user desires. Next-generation SSL-based

more complex than CFL, so a new approach is required.

street lighting will increase in intensity and/or flash when a 911

Complete solid state lighting solutions involve technical exper-

(or police) call is made to brighten the area for first responders.

tise in myriad technologies. As shown in Figure 1.3, several

SSL-fixtures will automatically dim within 15% to save energy

distinct, high-level areas are easily identified. Knowledge in one

and reduce peak energy demand – without occupants even

area can be quite unique and the successful application of that

knowing it happened. These and many other exciting possibili-

know-how must be brought together at the systems level to

ties can and will occur with solid state lighting. And, they are

achieve an optimum lighting solution that takes into account

not possible with existing lighting sources. With SSL technol-

the interaction between the technologies.

ogy, the future is approaching rapidly.

The number of different areas of expertise required and the

interaction between them has been among the factors that

have hindered the development of solid state lighting. With its

broad technical expertise, TE Connectivity (TE) has addressed

the complexity of today’s SSL design process and created a

Figure 1.3. Several essential and interconnected technology areas of

solid state lighting (SSL) must be brought together at the systems

level for a successful SSL solution. (The SSL Orbit: Courtesy of TE

Connectivity).

-3-

www.nevalo.com

2. LEDs – SSL’s Enabling Technology

LED packaging and its semiconductor contents deserve a closer

look. High power LEDs are currently offered in 1 to 5-W encapsu-

Light-emitting diodes (LEDs) have been produced since the

lated packages as well as hybrid or chip-on-board / array pack-

1960’s. Early applications were primarily for indicator lamps,

ages that can exceed 50-W levels. As Figure 2.2 demonstrates,

since the power output was quite low and colors were restricted

this packaging is not standard for high power LEDs.

to red, yellow, orange and green. White LEDs did not appear

until the late 1990s. Recent advancements in much higher output

LEDs have made LEDs useful in illumination. The term high

brightness or HB LED is used frequently to describe these higher

power LEDs however, it is not clearly defined and as such tends

to create more confusion instead of increased clarity. Understanding the different types of LEDs can help to select the right

LED for the application.

Figure 2.1 shows a comparison of an incandescent bulb and compact fluorescent lamp to a lighting-class, multi-chip LED in a surface mount package. The obvious visual distinction is just one of

the major differences between these light sources. In contrast to

the others, LEDs are essentially a point light source that provides

a unidirectional light that serves to put the light where a user

needs it rather than backscattered in a fixture. Further, LEDs are

typically low voltage devices and require only a constant current

source unlike fluorescent and high-intensity discharge (HID)

lamps that require a high-voltage ignition source. As an added

benefit, LEDs do not generate high inductive spikes or surges

like magnetically ballasted HID lamps that often necessitate ad-

Figure 2.2 Available high-power LED packaging is anything but

standardized. The Lumileds Rebel is an example of a discrete LED. The

others shown are examples of LED array packages.

ditional filtering devices to prevent wreaking havoc on AC power

distribution systems.

Figure 2.1 A visual comparison of an incandescent bulb and compact fluorescent lamp to Cree’s XLamp

MC-E single multi-chip LED shows the physical differences between conventional and solid-state

lighting technology. Source: Big Stock Photo and Cree.

-4-

www.nevalo.com

LED packaging has optical, electrical, thermal and mechanical

cent lamp which approximates the ideal black body source and

design considerations. All these elements are accommodated

yields a CRI of 100 against which other light sources are mea-

within the very small space of the LED package. To start, the

sured. This is a somewhat subjective analysis that attempts to

semiconductor chip or die needs to be mounted to a thermally

accommodate the tri-chromic nature of human vision.

conductive surface that allows the generated heat of the die to

A Color Quality Scale is being developed at the National Institute

be efficiently transferred to a separate heat sink. Also within the

of Standards & Technology (NIST) to address the problems of

package, electrical connections between contact pads on the

the CIE Color Rendering Index for solid state light sources and

package to the die are made with small gold wires called bond

to meet the new needs of the lighting industry and consumers

wires that need to be protected from mechanical damage. To

for communicating color quality of lighting products. With the

protect the bond wires, the die and to focus the light, an opti-

advent of LED sources, this new color reference measurement

cal lens or encapsulant is attached to the top side of the LED

technique attempts to correct chromatic saturation deficiencies

assembly.

in the CRI method. As opposed to the single number CRI, the

CQS results in a composite number that more accurately defines

LED Capabilities

a lamp’s ability to render colors in a manner pleasing to most

Key performance metrics for LEDs include luminous efficacy

consumers.

(the amount of light provided in lumens, per watt of electricity

Another important LED parameter is its correlated color tem-

consumed (lm/W), total power consumption, maximum current

perature (CCT) specified in degrees Kelvin. The CCT provides a

capability and the associated luminous output, and Correlated

relative color appearance of a white light source when compared

Color Temperature (CCT), Color Rendering Index (CRI) or Color

to a theoretical black body source. As shown in Figure 2.3, eight

Quality Scale (CQS). In this section, additional details on these

typical color classifications extend from 2,700K to 6,500K with

metrics are provided.

the lower color temperatures often referred to as “warmer”

The CIE (Commission Internationale de l’Eclairage) established

colors and the higher color temperatures referred to as “cooler”

a color rendering index (CRI) that rates how well a light source’s

colors. As a comparison, incandescent bulbs are approximately

illumination of sample patches compares to the illumination from

2,700-3,000K, fluorescent bulbs are typically 2,700-5,500K and

a reference source. The reference source is typically an incandes-

natural daylight often referenced as 5000K. White LEDs are

therefore also identified as warm, neutral and cool based on CCT

rating.

Figure 2.3 The CIE 1931 chromaticity diagram depicts the eight nominal CCT quadrangles. Source: ENERGY STAR

Program Requirements for Solid State Lighting Luminaires, Eligibility Criteria – Version 1.1.

-5-

www.nevalo.com

As noted in Section 1, improvements in these key metrics are oc-

must select the proper mix of LEDs to arrive at a consistent,

curring at a rapid pace. The industry is in a never-ending pursuit

comfortable, color rendition or with a supplier that makes this

of ever-increasing performance requirements, yet one of the

complex issue transparent to them.

most confusing parts of this specsmanship is the broad chasm

Achieving Cost-effective LEDs

that often separates laboratory performance from the practical

performance of available products.

While performance is improving rapidly, the cost of LEDS is

Manufacturers continue to announce ever-increasing perfor-

decreasingly rapidly as well. When will the cost of LED-enabled

mance from their LEDs. In 2010, Cree announced its XLamp® XM

lighting decrease enough for wide-spread general illumination

LED that delivers 160 lumens/watt at 350 mA and 750 lumens at

adoption? Many think the time is imminent.

2 A. The later rating is equivalent to the light output of a 60W in-

According to Strategies Unlimited 2010 report on High Bright-

candescent light bulb but requires less than 7W. Recently, Philips

ness LEDs, the HB LED market is forecast to grow at average of

Lumileds announced a Luxeon Rebel LED that delivers in excess

29.5% per year, reaching over $19 billion by 2014. The highest

of 300 lm with a 1A drive current. Bridgelux RS Array Series

forecast growth rate is 60.6% for signs/displays. Illumination has

deliver between 3400 and 5000 lumens under normal operating

the next-highest growth rate, with a projected CAGR of 45.4%.

conditions (Tc= 25°C). Based on the highly competitive envi-

This growth is based on cost reductions. As shown in Figure 2.4,

ronment and current market status, continued high-power LED

the DOE Report Solid State Lighting Research and Development:

improvements are expected in the future as the industry moves

Manufacturing Roadmap, September 2009, projects packaged

toward the maximum achievable range of 220 to 250 lm/W (ver-

LED cost in 2015 to be almost 10% of 2009 levels.

sus the theoretical limit of 300 lm/w).

Several factors are in the LED’s favor to offset the initial cost difference when compared to other light sources. LEDs:

LED Binning Issues

•Are inherently compliant to Restriction of Hazardous

Substances (RoHS) as opposed to CFLs which have

compliancy issues due to mercury content

White LEDs actually use phosphor to create white light from a

blue LED. The color and output variations of both the die and

the phosphors that occur during manufacturing cause suppliers

•Provide significantly longer life (50,000 full-power hours or

about 11 years @ 12 hours/day to 70% of rated lumens) than

CFLs

to sell products using a binning approach. According to the DOE

Report Solid State Lighting Research and Development: Manufacturing Roadmap, September 2009, “Understanding issues

•Operate at high efficacies (70-120 lumens/watt) rather than

10 lm/W or less exhibited by incandescent lights

such as how much performance variability can be tolerated and

which performance parameters are critical for the development

•Are available in broader ranges of warm and cool white than

CFLs

of luminaires of consistent performance is crucial. Color consistency of the LEDs to be used in the luminaires was seen as the

most important binning issue.” The National Electrical Manufac-

•Are easier to control than CFLs with better dimming

performance and no flicker

turers Association (NEMA) recently published High-Power White

LED Binning for General Illumination that provides standardized

•Start without the delay associated with CFLs

categorization areas (bins) for the colors of “white” LEDs used

for general lighting.

Even though solid state lighting is produced in very sophisticated processing facilities there are many variations between the

LEDs produced, even during the same run. Variations in forward

voltage occur throughout the production simply due to normal

statistical distributions inherent in all products. To provide repeatable and dependable systems, the LEDs must be electrically

sorted based on this forward voltage. A similar sorting is done to

accommodate variations in the color of the blue LED chips and

phosphor chemistry and density. This sorting results in the “bins”

in which all LEDs are offered.

The quality producer of LED systems will take all of these differences into account as the LEDs are matched for consistent color

and performance. While the current ANSI binning standards

allow variation of up to seven Macadam ellipses, most viewers

Figure 2.4: Packaged LED costs are projected to continue to decrease

rapidly. Source: Solid State Lighting Research and Development:

Manufacturing Roadmap, September 2009.

are bothered by variation of more than four. A system producer

-6-

Some of these differences are subtle but extremely significant.

bodies. In contrast, LEDs are mounted on a flat surface and emit

Because LEDs are so much different than traditional incandes-

light from the top and sides in a hemispherical pattern. In many

cents or fluorescent bulbs, light fixtures can now be designed

applications, the LED’s inherent directional light pattern adds to

with a “clean sheet of paper” approach. This will provide a lot

its lighting efficiency.

more design freedom for new form factors and thinner designs

In addition to the primary optics that protects the LED chip in its

and should result in a considerable cost saving at the fixture

device-level package, secondary optics provide greater func-

level.

tionality at the system level. Without secondary optics, the LED’s

Lambertian and other light distributions (Figure 3.1) make them

The Heat is On

less useful for lighting applications. Secondary optics optimize

Increasingly higher output LEDs mean increasingly higher power

the distribution of the LED light for specific applications such

densities and tougher thermal challenges. In addition to de-

as down lighting, broadly disbursed or focused lighting. Some

creased life with increasing LED temperature, LED light output

system manufacturers offer easily interchanged optics to achieve

decreases, dominant and peak wavelengths increase and color

different distributions within the same package that allow the

temperature shifts. Addressing the system issues of thermal

user to adjust the system for the specific application.

R E L AT I V E I N T E N S I T Y %

where TE plans on making a significant difference by introducing innovative tools to aid in fixture design. Section 8 will delve

into more details regarding the thermal aspects of LEDs and SSL

systems.

3. Optics

Optics is the science of controlling and redistributing light. Tradi-

BATWING

RADIATION PATTERN (WITHOUT OPTICS)

100

60

20

-100

0

100

ANGULAR DISPLACEMENT (DEGREES)

R E L AT I V E I N T E N S I T Y %

challenges is of critical importance. This is specifically an area

LAMBERTIAN

RADIATION PATTERN (WITHOUT OPTICS)

100

60

20

-100

0

100

ANGULAR DISPLACEMENT (DEGREES)

tional light sources emit light in all directions. As a result, optical

systems for these sources are typically less efficient because

Figure 3.1: LEDs batwing (a) or Lambertian (b) distribution requires

secondary optics to provide the required light distribution. Source:

Lumileds presentation at the Institute for Energy Efficiency FastTracking Widespread Adoption of LED Lighting, Feb 2010.

some light bounces within the optics components or luminaires’

Figure 3.2 LED lamp products for different levels of power dissipation and lumen output require different optics

designs. Source: 2009, NEMA published Solid State Lighting—The Need for a New Generation of Sockets

and Interconnects.

-7-

www.nevalo.com

Challenges of Secondary Optics

supply and the driver converts this AC input into a controlled DC

current or voltage for most applications. Since the driver’s power

Secondary optics has a direct impact on several performance as-

requirements detract from the overall efficiency of the SSL

pects of the SSL product. Improperly designed secondary optics

system, very low power consumption drivers must be used for

can significantly reduce the light efficiency of the LED and lead

the most efficient lighting. (Note: luminous efficacy published by

to inferior performance. However, light efficiencies within the tar-

LED manufacturers typically refers only to the LED and does not

geted illumination area can exceed 90% or better with properly

include driver or optical losses.)

designed optics.

Figure 4.1 shows an example of the functions provided by a

There are several designs of corrective optics for LEDs. They

typical LED driver module. The capabilities include protection

range from reflectors to TIR (Total Internal Reflection) polymeric optics and to free-form polymeric optics. The selection of

the correct optic is based on efficiency, color shift, application

requirements and cost. Free-form optics for large array LEDs are

difficult to create. The size and volume of such an optic requires

a lot of material and a substantial time for it to set up in the

mold. Even though a free-form optic may give superior beam

control, cost, weight and stability, applications often require the

selection of an alternate optic. Reflectors show high efficiency in

conventional tests. However, because the light is often bounced

several times within the reflector, the edges of the beam may

Figure 4.1: The driver module provides several system-level functions.

lack definition and accuracy. The selection of optics must be

made by considering all of these factors.

features such as temperature protection, current detection and

In addition to the specific angle and lighting efficiency, other

power factor correction (PFC), as well as several system level

system design considerations for the secondary optics include,

functions. Input control/communications provides the ability

diffusers, lenses, prisms, multiple LEDs and the ability to ac-

to interface with AC line or 0-10VDC dimmers as well as facility

commodate unusual footprint LEDs as well as form factor. Since

management systems (FMS) and other emerging electronic con-

optics are the corrective lenses for LEDs, these different aspects

trols such as daylight harvesting, occupancy detection, ambient

all become an important part of the SSL design process for the

light sensing and more.

supplier and decision process for the fixture designer. Figure 3.2

LED driver module design must handle design challenges and

shows three different optics designs.

tradeoffs such as efficiency and life expectancy as part of its

performance criteria. All of these design aspects are handled

4.0 Driving LEDs

in a driver module assembly to avoid burdening lighting fixture

With semiconductor technology at its core, SSL transitions light-

companies with electronic circuit design and system concerns.

ing from an electrical to electronics-based industry. In contrast

While there are several off-the-shelf driver modules available

to fluorescent lighting with simple ballast control, solid-state

to address some of the design requirements, lighting fixture

lighting is a true power electronics system with extensive ca-

companies certainly need to be comfortable with and verify how

pabilities. As a result, lighting system manufacturers have an

well all of these concerns are addressed at the system level. This

additional electronics component to consider – the LED driver

includes matching the driver module with the interface require-

module. Replacing the basic electrical circuit for incandescent

ments of the LED module and the appropriate thermal response,

and fluorescent light sources in solid-state lighting fixtures in-

overvoltage, over temperature, overcurrent and surge protection.

volves a sophisticated electronic design.

The driver module has two additional criteria: it must be small

and easily integrate into SSL fixtures to simplify the entire light-

Since they are semiconductor devices, LEDs require additional

ing design process. As in most electronic power systems design,

circuitry to make them useful. The primary function of the driver

smaller form factors and higher power density are part of the

module is supplying a controlled power level over the operating

ongoing improvements. Projected and expected improvements

temperature range for the LED or LEDs in order to maintain a

are essential aspects of the extended capabilities that semicon-

consistent light output. Power for the driver comes from the AC

ductor technology provides to lighting.

-8-

www.nevalo.com

5. Solid State Lighting Controls

DALI (Digital Adressable Lighting Interface), other digital controls and pulse-width modulation (PWM) can also dim LEDs. For

In lighting, control ultimately results in some level of dimmabil-

solid state lighting, the right driver technology makes dimming

ity. There can be control at the local level, the light fixture itself,

easy. SSLs can provide a profiled dim to avoid lighting problems,

as well as at the building level. The control can be based on

especially in automated lighting situations. With LEDs, color

occupancy, existing light level, safety, comfort and many other

mixing can be performed for lighting that mimics the natural

factors. LEDs work extremely well with these types of controls

changes in coloration of sunlight during the day, providing en-

and enable improved functionality well beyond improved energy

hanced productivity and health benefits.

efficiency. Building controls at the light level including Facil-

FMS provide computer-based automated technologies to moni-

ity Management Systems and an increasing number of wireless

tor and control the operation of a building’s lighting, heating

control options are among the control techniques being applied

ventilating and air conditioning, safety and security systems.

to solid state lighting.

Lighting obviously has a critical role in occupancy as well as the

In fact, controllability is one of the attributes of solid state light-

safety and security aspects. Certain drivers can interoperate with

ing that distinguishes it from all other light sources. LEDs are

existing facility management systems.

instantaneously and broadly controllable.

For increased lighting efficiency, sensing techniques are used.

Incandescent light dimmers can produce audible hum. Fluores-

These include daylight sensing to reduce or turn off unnecessary

cent and discharge lights are difficult to control. As a result dim-

lighting in bright sunlit environments and occupant detection

ming systems are complex, very expensive and have a limited

that turns off lighting when no motion is detected in the room or

dimming range. In addition, color consistency (shifting to blue)

automatically turns on the lighting if motion is detected. In some

within the dimming range is poor. The ability to easily dim SSLs

cases, the sunlight entering a room can even power the ambient

provides advantages to Smart Grid and Facility Management

light sensing technologies that monitor the indoor light level.

Systems (FMS) and an enabling technology for several unique

Other advanced sensing methods such as near-field or local oc-

lighting situations. For example, human eyesight, especially in

cupancy sensing can detect an individual in a smaller area such

the elderly, become less efficient and requires higher levels of

as a single cubicle and control only the lighting for that specific

light. Also, many situations, such as presentations in a work

area. Light sensing and control is becoming increasing sophisti-

environment benefit from reduced lighting levels in certain areas.

cated to provide optimized, energy-efficient lighting.

User-controlled solid state lighting can allow lower levels of

light for user comfort as well as energy savings. Color tempera-

Digital Control Aspects

ture control, i.e., the dynamic adjustment of the hue of the light

source, is a unique aspect of some advanced solid state lighting

For solid state lighting to replace incandescent and fluorescent

systems.

lighting in networks, SSL products must be compatible with all

existing and emerging network controls. Fortunately, SSL lends

Traditional lighting control has been restricted to dimming using

itself ideally to these communication techniques and, in fact may

AC line dimming (TRIACs) and other techniques to reduce the

be used to establish a new wireless communication technique

current to the bulb. For retrofit applications, SSLs need to be

similar to infrared (IR) technology commonly used for remote

controlled by TRIACs as well. Specially designed LED drivers

controls. Table 5.1 shows a summary of the controls that impact

enable LED control from TRIACs. Besides reducing power con-

today’s solid state lighting systems. SSL technology works ex-

sumption, dimming of LEDs can extend the lifetime. In addition

tremely well with advanced sensing control and the various com-

to TRIACs, control technologies such as 0-10V analog,

Control Standard

munication systems.

Function

Control Standard

Function

TRIAC

dimming

Ethernet

networking

0-10V

dimming

BACnet

networking

FMS

dimming/switching

Modbus

networking

Demand

dimming/switching

PLC

networking with existing wiring

Daylight sensing

dimming/switching

LonWorks

networking with existing wiring/wireless

Occupancy sensing

dimming/switching

ZigBee

wireless networking

DALI

lighting-specific network

Z-Wave

wireless networking

DMX

lighting-specific network

X10

wireless networking

Enocean

wireless networking

6LoWPAN

wireless networking

Table 5.1 SSL lighting controls address a variety of functions and network communications techniques.

-9-

www.nevalo.com

Advanced lighting systems are part of the digital age. Unlike

in a consumer electronics product compared to an industrial

their 20th Century predecessors, today’s lighting systems can be

product or a personal computer. The wiring and connectors

networked together. Digital electronics such as microcontrollers,

have a significant impact on the cost, manufacturability, opera-

the brains inside any digital product including computers, cell

tion and overall reliability of the system. Early versions of solid

phones and automotive controls, provide the intelligence. As

state lighting use solder connections but they cause several

part of a network, today’s lighting systems communicate with

problems including limiting the flexibility of the design for future

standard digital communication languages that can include

upgradability. Interconnects have system design implications and

DALI, DMX512 and others.

complexity well beyond the traditional lamp holder and lighting

socket.

DALI is a protocol defined in IEC 62386 for lighting control systems. It allows the mix and match of components from different

Unlike traditional lighting systems that are basically non polar-

suppliers. DMX 512 was initially developed as a standard means

ized AC electrical products, a solid state luminaire is a highly

for controlling light dimmers in stage lighting. Today, it handles

electronic product. Some of the common problems of electronic

digital data transmission between controllers and lighting equip-

systems that system-level connectors can avoid are the mis-

ment and accessories.

connection of components as well as grounding, electrostatic

discharge (ESD) and polarity issues. For example, a first-make

Unlike the lighting-specific protocols, Ethernet is a communica-

last-break for the ground connection is necessary to achieve a

tion network commonly used in factory automation and comput-

continuous path for static discharge to protect static sensitive

er applications, standardized as IEEE 802.3. However, it is also

semiconductor junctions. A properly designed interconnect sys-

used to control lighting. Communication with building lighting is

tem can avoid ESD problems and bring together all the protec-

an integral part of several industry network control systems such

tion aspects of the system as well.

as BACnet, ASHRAE’s data communication protocol for building

Even though several subassemblies need to be interconnected

automation and control networks.

in an SSL fixture, solid state lighting does not have standards

Increasingly, communications with external systems are per-

for wiring or connectors. However, in 2009, NEMA published

formed using wireless techniques including control standard

Solid State Lighting—The Need for a New Generation of Sockets

ZigBee, Z-Wave, X10, Enocean and more. Besides wireless

and Interconnects. One of the more complex systems that uses

techniques, power-line communication (PLC) uses the existing

numerous connectors and sizes of wire, the computer, demon-

wiring to transmit data. PLC is also being applied to lighting. For

strates an excellent example of the benefits of standardization.

example, Echelon’s LonWorks protocol is used for power line

A standardized approach to connectors and wiring not only pro-

network control.

vides a cost-effective solution, it can prevent assembly problems

As smart grid and smart metering systems are implemented for

of inadequately mated connectors, and readily identify/avoid

more effective control of the power generation, distribution and

mistakes through color coding and keyed design features. (See

use of electricity, the ability to communicate through a variety of

Figure 6.1). With a system level approach to SSL interconnects,

networks with the lighting system will be critical. This communi-

more than two wires are required, since more than power must

cation will allow the control of lighting and other loads to reduce

be connected throughout the fixture.

electricity consumption and cost, especially as utility rates vary

based on peak load demands. SSL has the ability to respond

to demand emergencies with energy reductions of 15 to 20%

without perception by lighting system users.Properly designed

SSL technology can readily accommodate both the control in

digital networks as well as modern sensing techniques for improved lighting efficiency. In fact, SSL designed with a systems

approach can provide a finer granularity of control for building

lighting designers.

6. Interconnects in the SSL System

For the most part, the interconnects (cables and connectors)

have been a critical but unaddressed challenge for solid state

Figure 6.1: Connector designs for SSL must address inadequately mated

connectors with a snap design or detent latch and have keyed design

features.

lighting systems. As system designers have found in electronic

systems of all types, the wiring and connections are quite unique

- 10 -

www.nevalo.com

7. SSL Protection

As noted in Solid State Lighting—The Need for a New Generation of Sockets and Interconnects, new generation interconnects

Fault protection is a requirement for successful implementa-

must provide:

tion and problem avoidance for any electronic circuitry and

– Improved efficacy over traditional bases

solid state lighting is no exception. As noted previously, since an

– Replacement capability

SSL fixture is an electronic and not an electrical assembly, the

– Upgrade path in performance

protection requirements are much more sophisticated. The SSL

– Optimized performance

orbit first described in Section 1 of this paper, identified the need

for this protection.

– New lighting options

Typically, an LED driver module includes some level of protective

– Prevent substitution of low efficacy lamp sources

circuitry to handle common faults that can occur in electronic

– Communications and network potential for integrated

energy systems

systems such as short circuits, overvoltage, reverse polarity in

DC circuits and overtemperature. (Note: Common LEDs are a po-

Reducing cost is a major challenge for solid state lighting in all

larity-sensitive device that requires a DC and not an AC voltage

areas. The connectors can do their part by avoiding costly as-

source. However, even AC LEDs require much greater protection

sembly procedures that require special tooling and stripping and

than ordinary electrical devices.)

cutting assembly techniques. Insulation displacement connec-

In addition to standard electronic circuit protection, an SSL can

tors (IDC) are a proven technique for quality low-cost reliable

be exposed to extreme surge conditions including lightning.

connections in many applications.

Any power-line coupled transients can reduce LED lifetimes,

The new ENERGY STAR standards differentiate between fixtures

and, in the worst case, result in immediate failure. As a result, a

where the source and the systems are the separable or integral.

variety of overvoltage-protection devices, such as MOVs (metal-

There are different levels of performance associated with each.

oxide varistors), ESD surge-protection devices, resettable PPTC

Integral designs cannot be upgraded or replaced. As a result,

(polymeric-positive-temperature-coefficient) circuit-protection

integral designs have to perform 20 to 30% better than other

devices like TE’s PolySwitch device and integrated overcurrent/

systems. Avoiding solder interfaces in the connectors is one

overvoltage devices, such as PolyZen devices are frequently

means of achieving interchangeability, increased reliability and

incorporated into the circuit design.

future upgradeability.

Adequate thermal protection for temperature-sensitive LEDs

Moreover, reliable connections are essential to assure that the in-

requires localized temperature measurements to provide a suf-

terconnect system is as robust as the solid state lighting sources.

ficiently quick response to limit excessive temperature and shut

A properly made interconnect system allows the LED light

down if necessary to avoid stressing LEDs or contributing to

module (LLM) to be easily installed, exchanged, upgraded and

early-life failure. In systems with several LED sub-assemblies,

replaced if necessary. It can be dependably installed by typi-

each LED sub assembly must be accounted for as a single point

cal assemblers with a minimum of training. A properly designed

of potential failure if its localized temperature exceeds the maxi-

interconnect system can last through more than one LED life

mum safe operating level. As a result, temperature detection at a

cycle securing the investment of the buyer. It maintains a quality

centralized location is insufficient to protect an overheating LED

connection through thermal changes and power cycles that can

module. An alternate temperature sensing approach is required.

be expected during the life of a lighting fixture.

Section 8 will delve deeper into the temperature issues associated with solid state lighting.

SSL connectors add a design problem that is common in portable consumer electronic products – the connectors must be

8. Temperature - The Ultimate SSL

Challenge

small and unobtrusive. However, the connectors and wiring are in

close proximity to heat-generating LEDs so their operating temperature environment more closely resembles industrial applica-

As pointed out in several of the previous sections, excessive

tions. Interconnects must solve the mechanical, electrical, ther-

temperature is detrimental to the performance, lifetime and

mal and optics issues that arise in an SSL system. Consequently,

reliability of LEDs. It also affects nearby circuitry and connectors.

interconnects certainly represent an opportunity for improving

To keep LED temperatures within safe operating limits, large

solid state lighting and if properly designed can result in:

heat sinks are often required to remove the heat generated.

–Rapid growth and adoption of SSL

Advanced SSL lighting designs incorporate a comprehensive

–Modular approach economics

thermal management system to provide monitoring, detection

–Rapid fixture and luminaire innovation

and protection for the light source. The critical LED temperature

–Innovative product platform designs

is called the junction temperature and it is deep within the

package — far from the surface of the chip. Since this is not eas-

- 11 -

www.nevalo.com

ily measured, a package (or case) temperature is normally read

and the actual junction temperature is calculated. The maximum

junction temperature, for some LEDs, can be up to 150°C and

the normal operating case temperature is between -40 to 135°C

( Source: Philips Lumileds). Each LED manufacturer determines

the maximum junction temperature for their LEDs with the value

growing on newly introduced devices.

Figure 8.1 shows that with the proper design considerations,

LEDs can last well over 50,000 hours. The projected lifetimes are

based on B50, L70 data. This means that 50% of the products

will have at least 70% of the lumen output for the projected

number of operating hours. At 350 mA, at least 70% of initial lumens are expected for 60,000 hours if the junction temperature

is maintained at about 160°C or lower. With a higher operating

Figure 8.2 The relative light output decreases with increasing thermal

pad (case) temperature. Data is from Philips Lumileds Luxeon Rebel ES

DS61. Source: Philips Lumileds.

current of 700 mA, the temperature would have to be reduced

to about 140°C. Note: As LED efficacy increases in the future,

thermal requirements will diminish for equivalent lumen output.

In Recommendations for Solid State Lighting Sub-Assembly

Interfaces for Luminaires, the NEMA authors provide detailed

recommendations for temperature test points for LEDs. Figure

8.3 shows the acceptable location for temperature sensors in

multiple LED design. With properly located temperature sensors,

the temperature must be measured, monitored and controlled by

additional circuitry. The added circuitry increases the complexity

of the SSL design but it also adds to the performance, reliability

and lifetime of the luminaire. With the importance of temperature to the overall system design and complexity of making accurate temperature measurements, specially-designed test tools

that accurately record temperatures can simplify the task of

verifying that the temperature design has been done correctly.

While thermal management is essential for the electronics portion of SSLs, thermal design is one of the key factors that im-

Figure 8.1 Increasing current requires lower junction temperatures to

achieve extended operating life. Source: LED Device Lifetime.

pacts fixture aesthetics. The challenge for luminaire designers is

making a piece of aluminum aesthetically pleasing. In combination, the thermal management and a slick heat sink provide the

In addition to reducing the operating life, increasing temperature

performance and long term reliability that make SSLs the ideal

reduces the performance of LEDs. Figure 8.2 shows the reduc-

technology for energy-efficient lighting.

tion of relative luminous flux (light output) with increasing temperature. At a case temperature of 130°C, the output is reduced

about 80% or more depending on the color temperature rating.

Increased temperature causes other performance changes

including increases in dominant and peak wavelengths and color

temperature shifts.

Temperature Measurements/Thermal

Management

In LED Luminaire Reliability, the authors point out that LED luminaire life is not identical to estimated LED life. As a result, they

stress the need to understand how temperature was measured

and how it relates to the expected life of the system. Centrally

Figure 8.3 For multiple LED assemblies, multiple test points provide

a more thorough means of verifying proper system operating

temperatures. Image source: TE Connectivity’s thermal evaluation tool.

located temperatures are not sufficient to monitor, detect and

protect multiple LED designs.

- 12 -

www.nevalo.com

9. Lighting Fixtures / Luminaires

organization for standardization, has previously established

lighting requirements for luminaires. Other regulatory and stan-

Historically, lighting fixture design has essentially involved

dards organizations that impact solid state lighting include:

mechanical and industrial design expertise. To create a success-

•American National Standards Institute (ANSI) / National

Electrical Manufacturers Association (NEMA) efforts include

industry norms, guidelines and standards for SSL products.

ful light fixture, the lighting designer had to consider color, light

output, controls, aesthetics (including the environment) and

manufacturability aspects. In contrast, solid state light fixtures

•Illuminating Engineering Society of North (IESNA) is

the recognized North American technical authority on

illumination and currently publishes LM-79 and LM-80 SSL

standards. IESNA is developing a specification (EN 21) for

long term reliability of fixtures.

require the addition of electronics technology. However, this is

just the beginning of the totally different design approach that is

required for successful SSL products.

In addition to the electronics, the LED, driver module and control, all of the issues discussed in earlier sections, the thermal

•IESNA has partnered with American Society of Heating,

Refrigerating and Air-Conditioning Engineers (ASHRAE)

to develop efficient lighting for buildings. ASHRAE has a

lighting subcommittee that generates standards.

aspects including heatsinks, interconnects, optics and protection need be addressed in the design. The complexity of these

various areas and broad range of expertise required to address

each of them has been a barrier to entry, especially for smaller to

•International Commission on Illumination (CIE) has several

standards for lighting performance including SSL.

medium-sized lighting fixture suppliers.

•Federal Communications Commission (FCC) is involved with

radio frequency aspects of SSL.

Simplifying the design process for light fixture/luminaire manufacturers requires an integrated approach for solid state lighting systems. The ideal systems design approach should provide

•Federal Trade Commission (FTC) is pursuing more accurate

labeling for light bulbs.

manufacturers of lighting fixtures with a plug-and-play solution

including all the components required to convert from incandes-

•Department of Energy (DOE) Commercially Available LED

Product Evaluation and Reporting (CALiPER) program tests

and reports on available SSL products.

cent or fluorescent lighting to solid state lighting design. A systems design solution enhances the lighting designer’s capability

with a flexible light output and color and the ability to focus and

•Environmental Protection Agency (EPA) has the ENERGY

STAR qualified LED lighting.

distribute light in different places. In addition to the components

and design methodology, a complete systems approach should

This is actually a rather short (and by no means complete)

include a toolbox to allow lighting fixture suppliers of any size

summary of what is occurring today in the area of SSL regula-

to easily design the latest, high-efficiency solid state lighting

tions and standards. In a few years, the list will be completely

fixtures with confidence and bridge the technology gap.

different. While light fixture suppliers may be well aware of and

With the appropriate overall systems design methodology,

readily capable of dealing with traditional and even fluorescent

luminaire manufacturers can avoid the extensive engineering

lighting regulations, meeting any one of these and other orga-

and qualification involved to embrace this new technology. This

nizations’ new requirements for solid state lighting can prove

includes addressing the global differences in light fixtures and

to be a challenge. Complying with all of them, especially in a

requirements. Instead, manufacturers can focus on the esthetics

coordinated, harmonized manner could be a daunting task and

and performance of the lighting fixture with the confidence that

provide a considerable delay to market entry. For example, the

the technology inside their fixtures works and meets industry

ENERGY STAR Solid State Lighting (SSL) Luminaire program

regulations.

went into effect on September 30, 2008. Warranty is one of the

requirements for ENERGY STAR conformance. Unlike conven-

10. Regulatory Issues

tional lighting that has a typical 90-day warranty, ENERGY STAR

requires a three year warranty that is expected to increase to

In addition to existing lighting standards and regulatory issues,

five years in the near future. An enhanced and expanded version

solid state lighting represents a dynamic area where standards

is in the final comment phase before its publication.

are changing and new standards are being issued on a continuous basis. Several regulatory agencies have already modified or

In addition to lighting-specific changes, the difference in lighting

established requirements for solid state lighting.

design requirements for SSLs (DC instead of AC) may eventu-

These standards address performance, radio frequency emis-

ally change the way that buildings are wired. For example, 24

sion/interference, testing, safety and other issues. For example,

VDC could become a standard for distributed lighting within

Underwriters Laboratories Inc. (UL) Class 2 Power Units (UL

buildings. For this to happen, significant changes and modifica-

1310) and Light-Emitting Diode (LED) Light Sources for Use in

tions to building codes will have to occur. Leading LED and SSL

Lighting Products (UL 8750) have recently been issued. The

suppliers will be intimately involved in and well aware of the

International Electrotechnical Commission (IEC), a worldwide

changes that could occur long before they are implemented.

- 13 -

www.nevalo.com

11. The NEVALO SSL System

System Applications

The NEVALO SSL system from TE addresses the challenges fac-

The NEVALO SSL system allows flexibility of system design and

ing SSL manufacturers with a new, holistic and simple approach

optimization by application. A few examples of the NEVALO

that delivers application flexibility, speed (time to market), and

system in some common applications are shown in Figure 11.2,

confidence to SSL design (Figure 12.1). The NEVALO SSL sys-

11.3 and 11.4.

tem is the product of TE’s extensive experience in electronics,

electro-mechanical design and manufacturing. With the NEVALO

SSL system, manufacturers have the tools and components

needed to respond quickly and competitively to market demand

for innovative lighting solutions.

Figure 11.2 Down light and typical NEVALO CN88 socket shown.

Application Flexibility

•Simplify SSL system integration with a menu of state-of-theart plug & play components

– System configurations are optimized by application

• down lights

• wall mounted fixtures (sconces)

• track lights

• others to follow

Figure 11.3 Wall Sconce and typical

NEVALO LN24x100 system shown.

– Configurations are almost limitless

Speed

•Define a complete system in minutes with the web-based

NEVALO system configurator

•Configure a system in a matter of hours with off-the-shelf components

Figure 11.4 Track Light and NEVALO CN58 socket shown.

•Eliminate painstaking thermal testing and validation with the

NEVALO thermal test system product

NEVALO System Components

•Facilitate luminaire safety agency approval with agencyapproved NEVALO product components

A solid state lighting fixture can be designed and built with the

NEVALO SSL system product set as shown in Figure 11.5 starting

•Speed production with NEVALO product components that

with:

are designed to eliminate improper assembly

(1) LED Light Boards (LLBs) which are printed circuit subas-

Confidence

semblies that combine LEDs and thermal monitoring.

•Back your product designs with warranted TE’s NEVALO

SSL System components

(2) Sockets for circular assemblies

(3) Optics that can be selected specifically for the application

•Expect long life with NEVALO system components designed

for 50,000+ hours of operation

(4) Drivers that power one or more LLM(s) and provide interface to control electronics

(5) An intuitive wiring system ties it all together, and finally

(6) Heat sinks matched to the LLM(s) designed to provide appropriate thermal performance.

The NEVALO SSL system toolbox includes thermal evaluation

tools and an SSL system budget calculation that makes designing easy.

LED Light Module

TE defines the LLM in the NEVALO System as a subassembly

Figure 11.1 The NEVALO System simplifies and speeds the design and

production of SSL fixtures.

that includes the LED Light Board (PCB with LEDs mounted),

thermal interface material, a socket (for circular

NEVALO product) and matching optics as depicted in Figure 11.6.

- 14 -

www.nevalo.com

Optic

LLM

LED Board

Socket

Wiring

Thermal

Driver

Control

Figure 11.5 The key elements of solid-state lighting come together as a

system in the NEVALO SSL system approach.

TE has designed several standard form factors of LLM which are

Figure 11.7 NEVALO CN58 socket (L) Finished assembly and (R) the

components of the assembly (Base, LLM, Thermal Gap Pad, Attachment

Screws, Optic, Outer Ring, Thermal Protective Device and Polarity

Protection Device.

each optimized for certain applications, such as down lights, wall

sconces, and track lights. TE has selected LEDs for each light

module that reflect the latest in commercially available LEDs.

Recognizing the rapid advances in LED technology, future proofing of NEVALO LLMs will assure the ability to incorporate next

generation LEDs into the LLMs as they become available, thus

providing state of the art lumen output, color and CRI, efficiency

(L/W) and cost. It is our objective to always maintain leadership

in performance, efficiency and cost.

Figure 11.8 NEVALO CN88 socket (L) Finished assembly and (R) the

components of the assembly (Base, LLM, Thermal Gap Pad, Attachment

Screws, Optic, Outer Ring, Thermal Protective Device and Polarity

Protection Device.

Figure 11.6 A typical NEVALO circular LED light board contains LEDs,

thermal monitoring, protection circuitry and special connectors.

Optics

Sockets

The NEVALO circular modules are sold with optics included.

Sockets have been designed for use with the NEVALO LLMs.

There are several optics available for each LLM style. Optional

Sockets provide a mechanical holder for the LLM or LED, inter-

optics can be purchased to swap out in the modules. They are

changeable optics and attachment to a heat sink. There are two

available in a variety of beam angles to best suit the application.

types of sockets:

TE conforms to de facto beam angle designations for its optics

(1) For use with TE LLMs

families, as depicted in Figure 11.9.

(2) Designed for use with Off the Shelf LED packages

The socket provides optic alignment and mechanical attachment

to the LLM/LED to confirm optimal optics performance. De-

The first type, as typified by the NEVALO CN58 socket, works

pending on the application, TE provides Total Internal Reflective

with the TE LLM and comes in three easily assembled pieces

(TIR) or Reflector based optics. A variety of standard optics

as shown in Figure11.7. The base assembly is preassembled and

styles and patterns are available for each LLM/LED.

includes the base, the LLM, thermal pad and attachment screws.

Optics are simply added and the outer ring brings the assembly

Beam Angle

(FWHM)

Degrees

together.

The second type, as typified by the NEVALO CN88 socket

<10

10 - 20

20 - 30

30 - 40

40+

design, brings the system value of the NEVALO product to a

standard LED package-in this case, the Bridgelux RS. The NEVALO CN88 socket brings interconnectivity to the LED, as well

as thermal monitoring, interchangeable optics, thermal interface material, making the LED an integral part of the system.

Category

Narrow Spot

Spot

Narrow Flood

Flood

Wide Flood

Abbreviation

NS

SP

NF

FL

WF

Figure 11.9 Optics with popular full width at half-maximum (FWHM)

beam angles are offered with NEVALO circular modules.

Additional form factors will soon be available to address other

industry leading LED packages.

- 15 -

www.nevalo.com

phase dimming). Future drivers will accommodate 0-10V dimming, fixed systems (on/off only) and digital technologies.

TE has incorporated circuitry to address issues related to AC

line dimming, such as low power flicker, low power drop out, and

low power system turn on. The NEVALO system has been tested

against all industry standard AC dimmers. Performance specs

are included in the datasheet.

Figure 11.10 Optics available for NEVALO circular LLMs include TIR and

reflector based optics.

With these three control interfaces, the NEVALO system can

interface with industry control systems such as FMS, Demand,

Driver Modules

Daylight Sensing, Occupancy Sensing and more.

The driver modules in the NEVALO system have a compact,

Wiring System

thin form factor for easy mounting and they contain several

important features. The main purpose of the driver module is to

As in any electronic system, the interconnections and wiring pro-

convert the AC power from the utility company to the DC power

vide the critical connectivity. In the NEVALO SSL System, these

required by the LEDs and the electronic circuitry. The driver’s

components have additional system functionality. Not only does

features include a design life matched to the LEDs for optimum

the wiring provide power to the LLMs, the system has a thermal

luminaire design life, the ability to achieve flickerless and quiet

monitoring circuit, as shown in Figure 11.12.

operation and a smart/resettable thermal management scheme.

The SSL System Budget is clearly identified on the driver.

In the NEVALO wiring system, a low-profile, four–wire, 24 AWG

(2.5mm centerline) stranded ribbon cable simplifies the connectivity of LLMs to each other and the driver module. All interconnects employ Insulation Displacement Crimp (IDC) technology

and are connected with simple tooling.

Driver

Figure 11.11 The NEVALO driver,

with system budget identification.

The initial NEVALO system offering (see Table 11.1) includes six

LED

LED

TEMP

TEMP

drivers, but more are planned to address international voltages

and additional control schemes.

Figure 11.12 The NEVALO system bus structure structure has an integrated thermal monitoring circuit connected by orange and green wires.

The heart of the wiring system is keying. The system is keyed

physically and also visually (color coded). Physical keying enables the plug and play aspects of the NEVALO system. The connectors are keyed to specific current ratings. For example, if a

350mA keying option is selected, it will only mate with a 350mA

driver and a 350mA LLM. Systems are designed to operate at

specific currents…any mismatching of driver and LLMs could

shorten the system life, or create an energy inefficient system.

Table 11.1 Six driver modules have been defined for NEVALO systems to

satisfy a range of luminaire requirements.

The NEVALO system’s physical keying prevents this.

The NEVALO system’s color coding is tied to the physical key,

Control

but has several other advantages (refer to Figure 11.13 and 11.14).

•System design/SSL budget

The NEVALO drivers are configured to address most of the common control schemes. The initial driver offering is designed for

•System manufacturing

AC line dimming (most often referred to as TRIAC dimming or

•Inspection on the cable assembly

- 16 -

www.nevalo.com

The NEVALO system has four keying options (Figure 11.13) with

one example shown in Figure 11.14. Keys are selected to match

the ideal driver to the ideal LLM for the application.

System Key to Drive Current (mA)

350

700

1000

2100

orange

red

green

blue

Figure 11.13 NEVALO keying options

Figure 11.16. For build-it-yourself

assemblies a simple “flat rock” tool is used

to attach NEVALO connectors to the cable.

hole. Appendix A has more information on the interconnect

design.

All of the NEVALO connector design attributes meet NEMA’s

requirements in the recently proposed Solid State Lighting—The

Need for a New Generation of Sockets and Interconnects. In fact,

Figure 11.14 A drive current key prevents connecting a LLM board to

an inappropriately rated driver module. The detent confirms that the

connection is made properly during the assembly.

NEVALO connectors go well beyond the proposal to set the

stage for a new standard for SSL connectivity.

Thermal Management

In addition to the thermal monitoring built into the NEVALO

system, TE offers heat sinks matched to the various offered LLM

form factors as shown in Figure 11.17. The TE heat sinks have

been designed to provide heat sinking for worst case conditions.

All components are tested and rated to 50,000 hours of operating life with mean time between failure (MTBF) curves included

in the product specifications. To complete the thermal design

Figure 11.15 Color coding facilitates manufacturing by identifying

compatible elements.

process, a test & validation tool confirms operation within design

limits based on temperature measurements in a variety of operating modes.

The NEVALO system allows you to pick a standard cable assembly for your application. If your system design requires a new

Thermal Monitoring

cable configuration, it is simple to design and build. TE offers

an expert system tool for rapidly designing a custom cable as-

The NEVALO system is designed with a thermal monitoring

sembly, called the NEVALO cable configurator. TE can build that

circuit. As shown in Figure 11.18, the circuit accommodates up

assembly for you, or you may build it yourself from the discrete

to seven LLMs and the thermal device on the LLM determines

components. Numerous connectors are available to allow the

the shutoff temperature of the system. TE has engineered the

creation of many different wiring harnesses.

system to shut off before any LLM exceeds the LEDs maximum

junction temperature.

Additional design goals of the NEVALO SSL system interconnects include:

Thermal Evaluation Tool

• A 3-mm maximum height above the pc board for compact

design

The NEVALO system’s thermal evaluation tool is a microprocessor-based system that includes three components:

• First-Make/Last-Break of the LED ground for safety

1) Thermal test LLM,

• Metal-clad pc-board capable attachment for flexibility

2) Thermal test instrument and cabling, and

One very unique interconnect allows the NEVALO product wiring

3) Test software with Graphical User Interface (GUI) that is run

to be invisible to the LLM. The connector is designed to accom-

on a PC.

modate 0.4 to 0.8-mm thick sheet metal and fit into a round

- 17 -

www.nevalo.com

Figure 11.17 Heat sinks are designed to match the footprint and heat dissipating requirements of different

light engines in the linear NEVALO family of products. The heat sink design for circular products

accommodates cable routing.

With this tool, users confirm the thermal performance of each

LLM in the lighting fixture. The tool allows the user to monitor

the junction temperature of the LEDs under different operating

and environmental conditions. In addition, the tool assists in:

•Analyzing LLM design and correlating the design to the LED

junction temperature;

•Optimizing LLM reliability testing; and

(a)

(b)

Figure 11.19 A seven-LED board (a) and its thermal test board (b)

counterpart. The special connector on the right-hand side of the test

board provides connectivity to a PC through the USB port.

•Optimizing the size of the heat sink required for keeping the

LED in safe operating temperature.

The thermal test LLM (Figure 11.19) is identical to the production

LLM but includes a thermal test circuit (thermistors) and an interconnect for attachment to the thermal test instrument shown

in Figure 11.20.

As shown in Figure 11.21, the GUI allows the tool to display,

record and log the LLM temperature on a PC screen similar to

chart recorders. Temperature readings are made either in °C or

°F with the accuracy of ±0.1°C. In addition to a programmable

temperature range, there are multiple temperature reading devices for better accuracy. While the tool provides rather detailed

information, it also has a simple Go/No Go indication of an

Figure 11.20 The NEVALO thermal test instrument operates to the

thermal test LLM and provides interface to the PC .

aceptable thermal design.

Driver

LED

LED

LED

LED

TEMP

TEMP

TEMP

TEMP

Figure 11.18 The NEVALO SSL’s thermal management system can detect

a problem based on an excessive temperature at one of the LLMs and

responds with power shutdown.

With the data obtained from the thermal evaluation tool, a

complete SSL system can be tested and results documented

that the system performs well enough to meet TE’s warranty

Figure 11.21 The PC GUI display of Thermal Test Tool data provides a

record and log of the LLM temperature.

requirements. The data not only validates the warranty but also

determines the safety factor in the fixture’s design.

- 18 -

www.nevalo.com

Industry Standards, Regulations & Compliance

With all of the components colored orange in this design, the

final system budget check is a total of the orange values on the

When the SSL assembly meets the NEVALO system standard,

LLMs to confirm they are at or below the maximum value of the

the process of obtaining safety agency certification for the light-

driver. Now look at a real example:

ing fixture is greatly simplified :

•Underwriters Laboratories

UL1977, UL8750 (for use in UL1598 devices)

•Electrical Appliance and Material Safety Law of Japan

J60838-2-1, J60998-1, J60998-2-2

•International Electrotechnical Commission

IEC 61984, 60838-1 &-2, 60838-2-2, 60998-1, 61995-1,

60352, 61347-2-13, 61347-1

In addition, the NEVALO system facilitates U.S. Environmental

Protection Agency (EPA) ENERGY STAR compliance.

With all of these certifications, NEVALO system customers

have avoided the time-consuming certification processes of all

Figure 11.23 Example of NEVALO SSL system budget demonstrates the

ease in verifying an acceptable design.

of these agencies, reducing the time-to-market for the newest

energy-saving lighting fixtures. This is just one more vital piece

of the NEVALO systems approach to solid-state lighting. The

Summary

combined package simplifies the path from today’s to tomor-

The rapid growth of SSL offers exciting opportunities for lighting

row’s lighting technology.

fixture manufacturers. But with these opportunities come the

realities of the complex nature of solid state electronics design.

SSL System Budget

Competent SSL design has many considerations, as depicted in