CE ONLINE

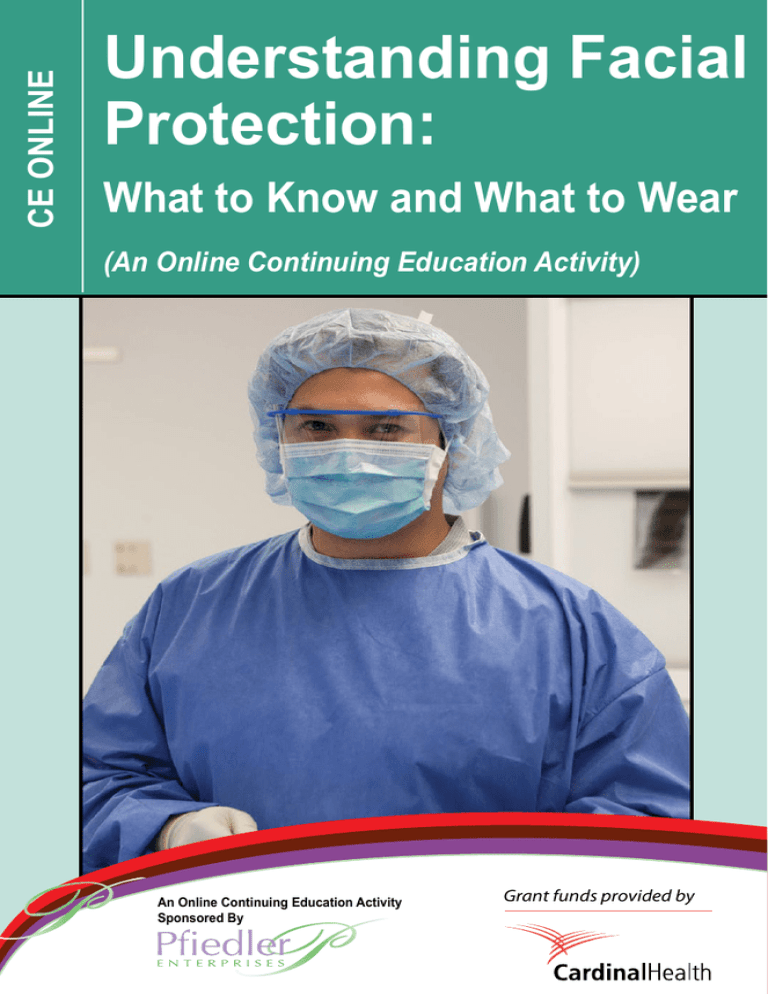

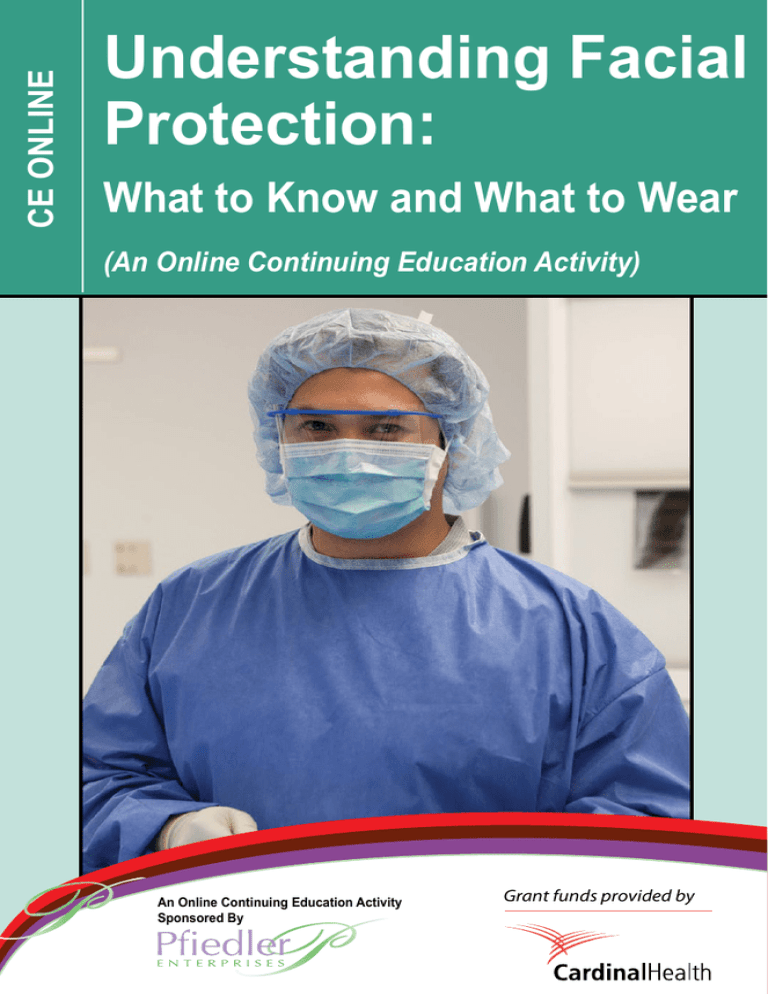

Understanding Facial

Protection:

What to Know and What to Wear

(An Online Continuing Education Activity)

An Online Continuing Education Activity

Sponsored By

Grant funds provided by

Welcome to

Understanding Facial

Protection:

What to Know and What to Wear

(An Online Continuing Education Activity)

CONTINUING EDUCATION INSTRUCTIONS

This educational activity is being offered online and may be completed at any time.

Steps for Successful Course Completion

To earn continuing education credit, the participant must complete the following steps:

1. Read the overview and objectives to ensure consistency with your own learning needs and objectives. At the end of the activity, you will be assessed on the

attainment of each objective.

2. Review the content of the activity, paying particular attention to those areas that reflect the objectives.

3. Complete the Test Questions. Missed questions will offer the opportunity to re-read

the question and answer choices. You may also revisit relevant content.

4. For additional information on an issue or topic, consult the references.

5. To receive credit for this activity complete the evaluation and registration form.

6. A certificate of completion will be available for you to print at the conclusion.

Pfiedler Enterprises will maintain a record of your continuing education credits

and provide verification, if necessary, for 7 years. Requests for certificates must

be submitted in writing by the learner.

If you have any questions, please call: 720-748-6144.

CONTACT INFORMATION:

© 2014

All rights reserved

Pfiedler Enterprises, 2101 S. Blackhawk Street, Suite 220, Aurora, Colorado 80014

www.pfiedlerenterprises.com Phone: 720-748-6144 Fax: 720-748-6196

Overview

Originally, face masks were designed to minimize the risk of wound infection for surgical

patients by preventing the spread of microorganisms expelled from the nose and mouth

of operating room (OR) personnel. Today, confronted with the challenges of new

and drug-resistant pathogens, facial protection devices are used in the perioperative

practice setting to protect health care workers from a variety of potential bloodborne

and inhalation hazards. Furthermore, the proper use of facial protection devices is a key

component in the implementation of Standard Precautions in the OR. The purpose of this

continuing nursing education activity is to provide a review of the clinical considerations

regarding the appropriate selection and use of facial protection devices in various

surgical practice settings. It will provide an overview of the health hazards inherent to the

perioperative environment. The various types of facial protection devices available today

will be reviewed, followed by a discussion of the relevant regulations and professional

recommendations for both the manufacture and use of facial protection devices. Finally,

criteria for appropriate selection and use of facial protections devices will be outlined.

Learner Objectives

Upon completion of this continuing education activity, the participant should be able to:

1. Identify the various occupational health hazards inherent to the surgical practice

setting.

2. Describe the types of facial protection devices available today and their

components.

3. List the regulations governing the manufacture and performance standards of facial

protection devices.

4. Discuss pertinent regulations and professional recommendations regarding the use

of facial protection in the OR.

5. Identify key criteria in the selection and use of facial protection devices for specific

clinical applications.

Intended Audience

This independent learning activity is intended for use by perioperative nurses, certified

surgical technologists, and other healthcare professionals who are interested learning more

about the importance of selecting and using facial protection devices appropriately in the

OR.

3

Credit/Credit Information

State Board Approval for Nurses

Pfiedler Enterprises is a provider approved by the California Board of Registered Nursing,

Provider Number CEP14944, for 2.0 contact hours.

Obtaining full credit for this offering depends upon attendance, regardless of circumstances,

from beginning to end. Licensees must provide their license numbers for record keeping

purposes.

The certificate of course completion issued at the conclusion of this course must be retained

in the participant’s records for at least four (4) years as proof of attendance.

AST Credit

This continuing education activity is approved for 4.5 CE credits by the Association of

Surgical Technologists, Inc., for continuing education for the Certified Surgical Technologists

and Certified Surgical First Assistant. This recognition does not imply that AST approves or

endorses any product or products that are discussed or mentioned in enduring material.

IACET

Pfiedler Enterprises has been accredited as an Authorized Provider by the International

Association for Continuing Education and Training (IACET).

CEU Statements

• As an IACET Authorized Provider, Pfiedler Enterprises offers CEUs for its programs

that qualify under the ANSI/IACET Standard.

• Pfiedler Enterprises is authorized by IACET to offer 0.2 CEUs for this program.

RELEASE AND EXPIRATION DATE

This continuing education activity was planned and provided in accordance with accreditation

criteria. This material was originally produced in June 2014 and can no longer be used after

June 2016 without being updated; therefore, this continuing education activity expires in June

2016.

DISCLAIMER

Accredited status as a provider refers only to continuing nursing education activities and does

not imply endorsement of any products.

SUPPORT

Grant funds for the development of this activity were provided by Cardinal Health.

4

Author/Planning Committee/Reviewer

Rose Moss, RN, MN, CNOR

Nurse Consultant/Author

Moss Enterprises

Elizabeth, CO

Judith Pfister, RN, BSN, MBA

Program Manager/Planning Committee

Pfiedler Enterprises

Aurora, CO

Penny Austin, CSTAurora, CO

Surgical Technologist/Planning Committee/Reviewer

Medical Center of Aurora

Julia A. Kneedler, RN, MS, EdD

Program Manager/Reviewer

Pfiedler Enterprises

Aurora, CO

DISCLOSURE OF RELATIONSHIPS WITH COMMERCIAL ENTITIES FOR

THOSE IN A POSITION TO CONTROL CONTENT FOR THIS ACTIVITY

Pfiedler Enterprises has a policy in place for identifying and resolving conflicts of interest for

individuals who control content for an educational activity. Information below is provided to

the learner, so that a determination can be made if identified external interests or influences

pose potential bias in content, recommendations or conclusions. The intent is full disclosure

of those in a position to control content, with a goal of objectivity, balance and scientific rigor

in the activity. For additional information regarding Pfiedler Enterprises’ disclosure process,

visit our website at: http://www. pfiedlerenterprises.com/disclosure

Disclosure includes relevant financial relationships with commercial interests related to the

subject matter that may be presented in this continuing education activity. “Relevant financial

relationships” are those in any amount, occurring within the past 12 months that create a

conflict of interest. A commercial interest is any entity producing, marketing, reselling, or

distributing health care goods or services consumed by, or used on, patients.

Author/ Planning Committee/Reviewer

Julia A Kneedler, RN, MS, EdD

Co-owner of company that receives grant funds from commercial entities

Judith Pfister, RN, BSN

Co-owner of company that receives grant funds from commercial entities

Rose Moss, RN, MN, CNOR

No conflicts of interest

Penny Austin, CST

No conflicts of interest

5

Privacy and Confidentiality Policy

Pfiedler Enterprises is committed to protecting your privacy and following industry best

practices and regulations regarding continuing education. The information we collect

is never shared with other organizations for commercial purposes. Our privacy and

confidentiality policy covers the site www.pfiedlerenterprises.com and is effective on

March 27, 2008.

To directly access more information on our Privacy and Confidentiality Policy, type

the following URL address into your browser: http://www.pfiedlerenterprises.com/

Privacypolicy.pdf or View the Privacy and Confidentiality Policy using the following link:

http://www.pfiedlerenterprises.com/online_courses.htm

In addition to this privacy statement, this Website is compliant with the guidelines for

internet-based continuing education programs.

The privacy policy of this Website is strictly enforced.

CONTACT INFORMATION

If site users have any questions or suggestions regarding our privacy policy, please

contact us at:

Phone: 720-748-6144

Email:

registrar@pfiedlerenterprises.com

Postal Address: 2101 S. Blackhawk Street, Suite 220

Aurora, Colorado 80014

Website URL:

http://www.pfiedlerenterprises.com

6

Introduction1,2,3

Perioperative personnel are well aware of the value of wearing masks and other types

of facial protection devices during operative procedures. Originally, surgical face masks

were developed to contain and filter droplets of microorganisms expelled from the mouth

and nasopharynx during talking, sneezing, and coughing. This practice promotes a high

level of cleanliness and hygiene within the operating room (OR), thereby protecting the

patient by providing the best possible environment for surgical intervention. In recent

decades, with the increasing awareness and prevalence of epidemiologically significant

diseases, such as hepatitis B, acquired immunodeficiency syndrome (AIDS), a variety of

types of influenza A viruses (e.g., A [H1N1], A [H3N2]), one or two influenza B viruses,

and the recognition of the hazards of surgical smoke, face masks and other respiratory

protection devices are now being worn to protect the health care worker as well as the

patient. Ultimately, when the appropriate products are combined with education and

the implementation of effective workplace strategies, facial protection devices serve to

protect perioperative personnel in all surgical practice settings.

Hazards in the OR: The Danger is Real

Before reviewing the various types of facial protection devices available today, it is first

helpful to examine the dangers present in the perioperative practice setting, which,

by its nature, places staff members at higher risk for exposure to potentially harmful

and infectious substances. Some of the hazards unique to the OR environment which

increase the risk for exposure incidents include:

• Airborne particles (generated by the use of powered surgical equipment such as

saws and/or drills);

• Gases and vapors (e.g., waste anesthetic gases, use of certain materials such as

bone cement); • Smoke/plume (generated during the use of electrosurgery, lasers, and ultrasonic

devices); and

• Large particle droplets from infected patients or health care workers during:

Coughing.

Sneezing.

Talking.

Therapeutic manipulations.

Potential Hazards Transmitted via Blood and Respiratory Routes 4,5,6,7

In the perioperative practice setting, employees are exposed to potentially hazardous

substances on a daily basis. During the 1980s, health care workers became concerned

about the risk of occupational exposure to the human immunodeficiency virus (HIV)

after its transmission was first reported in the literature. Other pathogens which were

identified as significant included hepatitis B (HBV) and hepatitis C (HCV). In 1991, the

Occupational Safety and Health Administration (OSHA) issued its Bloodborne Pathogens

7

Standard, with the intent to help protect workers from occupation exposure to blood and

other potentially infectious material (OPIM). In 2003, the transmission of severe acute

respiratory syndrome-associated Coronavirus (SARS-CoV), a variant of the Coronavirus,

in emergency departments by patients and family members during the SARS outbreaks,

highlighted the need for vigilance, as well as new strategies, to contain respiratory

diseases. Other organisms of interest today include:

• Multidrug resistant organisms (MDROs):

o Bacteria with extended-spectrum betalactamase resistance.

oMethicillin-resistant Staphylococcus aureus (MRSA).

oVancomycin-resistant enterococci (VRE).

oVancomycin-intermediate Staphylococcus aureus.

oVancomycin-resistant Staphylococcus aureus.

• Clostridium difficile (C.diff).

• Crutzfeldt-Jakob disease (CJD).

• Avian flu.

• Norovirus.

Most recently, the Middle East Respiratory Syndrome (MERS) has been identified as an

emerging threat in the U.S. This viral respiratory illness, which was first reported in 2012

in Saudi Arabia, is caused by the coronavirus MERS-CoV. The majority of people with

confirmed MERS-CoV infection have developed severe, acute respiratory illness with a

cough, fever, and shortness of breath. Moreover, approximately 30% of those confirmed

to have MERS-CoV infection have died. In the U.S., two cases were identified in early

May 2014; both cases involved travelers who came from Saudi Arabia, but are not linked.

On May 16, 2014, an Illinois resident who had contact with the first case of MERS in the

U.S. tested positive for MERS-CoV. Standard Precautions, previously known as Universal Precautions, have become the

primary tool for reducing disease transmission from patients to health care workers. Standard Precautions are based on the principle that all blood, body fluids, secretions,

and excretions may contain transmissible infectious agents. These precautions apply in

any health care practice setting and to all patients, regardless of suspected or confirmed

infection status. More recently, the strategy to contain respiratory diseases has been

termed “Respiratory Etiquette” and should be incorporated into infection control practices

a new component of Standard Precautions. One key element of Standard Precautions

is the use of appropriate personal protective equipment, which includes the use of facial

protection devices, and will be explored throughout this study guide.

Surgical Smoke 8,9

In addition to the potential health risks posed by blood, other body fluids, and respiratory

diseases, the dangers of surgical smoke have also become a recognized health hazard

8

for perioperative personnel. Surgical smoke, which is both seen and smelled, results

from the interaction of tissue and mechanical tools or heat-producing equipment that are

used for hemostasis and/or tissue dissection, such as electrosurgery, lasers, ultrasonic

devices, and powered surgical instruments. Smoke is also generated by mixing

chemicals in the OR, such as methyl methacrylate bone cement.

Surgical smoke is composed of 95% water or steam and 5% cellular debris in the form

of particulate matter. This particulate matter contains chemicals, blood and tissue

particles, viruses, and bacteria. The smoke and aerosol are potential vehicles for the

transmissions of infectious agents. Since the mid-1970s, there is a growing body of

evidence documenting the hazardous components of surgical smoke. The gaseous

component of smoke generated by electrosurgery units (ESU) produces the noxious

odor. This smoke also can contain chemical by-products similar to other smoke plumes

(e.g., cigarette smoke), including benzene, carbon monoxide, formaldehyde, hydrogen

cyanide, methane, phenol, styrene, and toluene (see Table 1 for a listing of the chemical

contents of surgical smoke). These by-products also are known to have mutagenic

potential and to be carcinogenic. Surgical smoke has been found to contain toxic gases

and vapors, as well as bioaerosols and viruses; in high concentrations, it can cause

adverse health conditions (see Table 2).

Particle size and the number of particles are also important factors in surgical smoke.

The mass median aerodynamic diameter of the particles contained in surgical smoke

and aerosol is 0.31 microns (µm), with a range of 0.10 to 0.80µm. This is also the most

dangerous particle size, because it is the optimal size to be deposited in the lower

respiratory tract. The sizes of some of the most significant human pathogens are as

follows:

• Hepatitis B virus: 0.042 µm

• Human Immunodeficiency Virus: 0.180 µm

• Human Papilloma Virus: 0.045 µm

• Mycobacterium Tuberculosis: 0.500 µm

• Fungal Spores: 2 - 5 µm

• Viruses: .02 - .30 µm

The actual numbers of particles present in surgical smoke and aerosol can vary

depending on the type of surgery and its duration, but generally range from 1,000,000 to

1,000,000,000 particles.

The distribution of airborne particles associated with surgical smoke is an important

consideration in respiratory protection from surgical smoke. Due to the required air

exchanges in the OR, smoke is evenly distributed throughout the room; smoke particles

travel at about 40 mph. Further, with electrosurgery use, the concentration rises from

60,000 particles per cubic feet to over 1 million within five minutes of ESU activation; it

takes 20 minutes after electrosurgery is used to return to normal.

9

Table 1 - Chemical Contents of Surgical Smoke*

Acetonitrile

Acetylene

Acroloin

Acrylonitrile

Alkyl benzene

Benzaldehyde

Benzene

Benzonitrile

Butadiene

Butene

3-Butenenitrile

Carbon dioxide

Creosol

1-Decene

2,3-Dihydro indene

Ethane

Ethyl benzene

Ethylene

Formaldehyde

Furfural

Hexadecanoic acid

Hydrogen cyanide

Indole

Methane

2-Methyl butenal

6-Methyl indole

4-Methly phenol

2-Methyl propanol

Methyl pyrazine

Phenol

Propene

2-Propylene nitrile

Pyridine

Pyrrole

Styrene

Toluene

1-Undecene

Xylene

* Barrett, W.L. & Garber, S.M. Surgical smoke – a review of the literature. Business Briefing:

Global Surgery. 2004: 1-7.

Table 2 - Risks of Surgical Smoke*

Acute and chronic inflammatory respiratory changes (i.e., asthma, chronic bronchitis, emphysema)

Anemia

Anxiety

Carcinoma

Cardiovascular dysfunction

Colic

Dermatitis

Eye irritation

Headache

Hepatitis

HIV

Hypoxia or dizziness

Lacrimation

Leukemia

Lightheadedness

Nasopharyngeal lesions

Nausea or vomiting

Sneezing

Throat irritation

Weakness

* Alp, E., Bijl, D., Bleichrodt, R.P., Hansson, A., Voss, A. Surgical smoke and infection control. J

Hosp Infect. 2006;62(1): 1-5.

10

Types and Components of Facial Protection Devices10,11,12

Overview

In order to understand how facial protection devices protect healthcare workers in the OR

from blood, body fluids, and aerosols released into the atmosphere, it is first helpful to

review the various types of devices available today. As noted, facial protection is intended

to protect both the patient (from the sneeze or cough respiratory droplets of health

care workers – see Figure 1) and the health care worker from exposure to blood, other

potentially infectious material, and airborne contaminants (by removing them from the air

before they are inhaled).

Figure 1 – Respiratory Droplets

Types of Facial Protection Devices

A facial protection device is a loose-fitting, disposable device that creates a physical

barrier between the mouth and nose of the wearer and potential infectious contaminants

in the immediate environment. These devices are constructed in various thicknesses

and with different abilities to protect the wearer from contact with liquids and in some

cases, airborne particulates. These properties may also affect how easily the wearer can

breathe through the face mask and also how well the face mask protects the wearer. The design and construction of facial protection devices will be reviewed later in this

study guide.

Today, because facial protection devices are used in a wide range of hospital and health

care settings and are intended for various applications and levels of protection, there

are a number of options available. In general, there are three basic categories of facial

protection devices, based upon their intended use and their donning mechanism: flat

masks, specialty masks, and N95 respirators. These devices are described below and

summarized in Table 3.

• Flat masks are defined as either procedure or surgical masks (see Figure 2).

oThese masks are frequently made with three layers of material.

oProcedure masks are used when non-invasive procedures are performed on

11

patient floors. It is held in place by earloops rather than surgical ties, which

means it can be donned quickly. However, some find that this mask to be

uncomfortable (too tight) or find it difficult to obtain a tight seal on the sides

of the face.

o Surgical masks are worn in the OR and in other clinical areas where

invasive procedures are performed. These masks have ties instead of

earloops, which provide a better fit and level of protection through face seal. Figure 2 – Flat Masks

Ear loops Ties

• Specialty masks are high-filtration masks designed for specific surgical

procedures, such as procedures involving the use of lasers and electrosurgical

devices (during which smoke plume is generated) and other procedures using

powered equipment that generate airborne particulates (see Figure 3). These

masks are constructed with an advanced filter that blocks plume particles as

small as 0.1 micron. Surgical masks may not filter chemical contaminants,

therefore OR personnel should consult the facility’s policy to ensure they are

using the correct mask for the procedure. Fluid resistant masks can also be

categorized as specialty masks. Another type of specialty mask is the cone mask

(see Figure 4). This type of mask is often selected, as it is economical, fluid

resistant, easy to don (with an elastic, adjustable head strap and nosepiece) and

is often perceived to be more comfortable than a typical flat mask. Figure 3 – High Filtration Mask

12

Figure 4 – Cone Mask

• An N95 respirator is a respiratory protective device designed to achieve a

very close facial fit that forms a seal that provides a physical barrier to block

splashes, sprays, and large droplets. Additionally, an N95 respirator is designed

to prevent the wearer from breathing in very small airborne particles (0.3 microns

or larger in diameter) that cause infectious diseases (e.g., microorganisms that

cause tuberculosis [TB], SARS, and avian flu). The ‘N95’ designation means

that the respirator blocks at least 95% of these small particles. In order to work

properly, an N95 respirator requires a proper fit. To determine the proper fit, the

wearer should don the respirator and adjust the strap(s) so that it fits tightly, but

comfortably to the face (see Figure 5). If properly fitted, the filtration capabilities

of N95 respirators exceed those of face masks. However, even a properly

fitted N95 respirator does not completely eliminate the risk of illness or death.

OSHA requires that all N95 respirators are certified by the National Institute for

Occupational Safety and Health (NIOSH). Figure 5 – N95 Respirators

One-strap Two-strap

13

Table 3 – Categories/Applications of Facial Protection Devices

Categories / Type(s) of Facial

Protection Device

Flat Masks

► Procedure Masks

►

Surgical Masks

Specialty Masks

► High-filtration Flat

Masks

► Cone Masks

N95 Respirators

Donning Mechanism

►

Earloops

►

Ties (vertical or

horizontal)

►

Applications

►

Noninvasive procedures in

any general clinical setting

► Surgical procedures in the

OR; invasive procedures

in other areas

Ties (vertical or

horizontal)

► Elastic head

strap

►

►

► Procedures

Straps (single

or double)

Components of Facial Protection Devices

Procedures using laser,

electrosurgery, and/

or powered surgical

equipment where

protection against airborne

particulates is needed

during which

very small airborne

particles (0.3 microns or

larger) are generated in

patients known to have

an infectious airbornetransmitted disease

Facial protection devices are constructed of various materials (see Table 4) in four

multiple layers: inner; middle (filtering – which is designed to trap particulate matter

away from the wearer’s face - and non-filtering); and outer. The types of fabrics used in

facial protection devices typically include polypropylene, either spunbonded, meltblown,

or wetlaid; and other materials such as metals, for example, used in nose features;

colorants; elastic materials, e.g., used in devices with ear loops; foam and other anti-fog

materials; and face shield materials. While two surgical masks may be generally similar

in their construction, for example, each consisting of four layers of material, the same

type of donning mechanism, and a nose wire, they may be distinctly different in their

feel and performance. Facial protection devices are generally composed of nonwoven

fabrics, which are engineered materials that are bonded together by mechanical, thermal,

or chemical means. Nonwoven fabrics are made directly from natural or plastic fibers

or plastic film. Nonwoven fabrics have both single use and multiple use applications, all

face masks, with the exception of N95 respirators, are intended for single use only.

14

Table 4 – Materials Used in the Manufacture of Facial Protection Devices

Inner Layer

►Cellulose

►Spunbond

polypropylene

►Tissue

►Carded polyester

Middle Layer

(Filtering)

Middle Layer

(Non-Filtering)

►Meltblown

►Film

►SMS

(polypropylene)

►Other non-woven

(polypropylene)

►Other non-woven

►Cellulose

►SMS

polypropylene

Outer Layer

(polypropylene)

►Spunbound

polypropylene

►Tissue

Regulation and Testing of Facial Protection Devices13,14

The U.S. Food and Drug Administration (FDA)15,16

The FDA is the U.S. government agency that oversees most medical

products; within FDA, the Center for Devices and Radiological Health

(CDRH) oversees the safety and effectiveness of medical devices.

Personal protective equipment (PPE) that is intended for use in

preventing or treating disease (including surgical masks and N95

respirators) is subject to regulation under the device provisions of the

Federal Food, Drug, and Cosmetic Act. Surgical face masks and N95

NIOSH certified respirators are considered a Class II Medical Devices.

Before these devices can be sold in the U.S., the FDA evaluates the

manufacturer’s new product applications (i.e., premarket notifications

or 510[k]s) to ensure that the new devices are similar to (substantially

equivalent to) existing products already on the market. The FDA refers

to this as clearing the products for market. Once the FDA has cleared

the products, it:

• Maintains databases of those products and their manufacturers;

• Ensures that manufacturers use reliable methods for manufacturing and

packaging the products (e.g., Good Manufacturing Practices); and

• Reviews and analyzes reports concerning problems with medical devices.

If the FDA finds ongoing problems with a medical product, it may oversee a

manufacturer›s recall, recommend changes to the labeling or instructions, or

propose corrective actions.

The FDA recommends that manufacturers demonstrate surgical mask performance in

four areas: fluid resistance, filtration efficiency, differential pressure, and flammability. These will be discussed in greater detail later in this study guide. The FDA requires no

minimum level of filter performance.

Occupational Safety and Health Administration (OSHA)17,18

The U.S. Department of Labor’s Occupational Safety and Health Administration’s

Bloodborne Pathogens Standard requires employers to provide appropriate PPE for

workers who could be exposed to blood or other infectious materials (i.e., bloodborne

15

pathogens). OSHA may also require employers to provide PPE to protect against other

hazards at work. Although OSHA requires the use of specific equipment, it does not

regulate the marketing of these devices, nor does it grant claims of disease prevention.

In its Respiratory Protection Standard, OSHA regulates the selection and use of

respirators in a workplace. Facilities are required to have a respirator program that

includes individual medical evaluation, training, and fit testing. OSHA has designated

assigned protection factors that indicate to employers how well respirators in a particular

class will reduce exposure to airborne contaminants. A fit test is then used to evaluate

the fit of a respirator on an individual. The OSHA standards will be discussed in greater

detail later in this study guide.

The National Institute for Occupational Safety and Health (NIOSH)19

The National Institute for Occupational Safety and Health (NIOSH) is a federal agency

and branch of the Department of Health and Human Services (DHHS) whose function is

to identify substances that pose potential health problems and recommends exposure

limits to OSHA. NIOSH conducts in-depth research on safety and health issues, provides

technical assistance, and recommends standards for adoption by OSHA. NIOSH

also performs testing and certification of respiratory protection equipment through its

established certification requirements for various types of respiratory PPE. The NIOSH

tests filters for the effects of loading (particle burden), temperature, and relative humidity

and requires a minimum filtration efficiency of 95%, 99%, or 99.97%. Certification tests

also evaluate effects of oil aerosols for filter designations of N (not resistant to oil), R

(somewhat resistant to oil), and P (strongly resistant - oil proof). NIOSH also evaluates

the fit performance of some respiratory protective devices using human panels with

specified facial dimensions. Certification of filtering face-piece respirators, however, does

not currently include an assessment of fit performance. NIOSH issues a certification for

products that comply with these regulations. However, NIOSH certification evaluates

the performance of respiratory protection equipment in functional terms and not in terms

of claims for use in preventing disease. While NIOSH certification is not required for

a non-medical respirator to be sold, employers subject to OSHA regulation may be

required to provide NIOSH-certified respiratory protection equipment to satisfy the OSHA

requirements. N95 respirators cleared by FDA for use in the healthcare setting are called

surgical N95 respirators. These devices meet some of the same performance standards

as surgical face masks and are also NIOSH certified to meet the N95 respirator

performance requirements.

The shared regulatory approach of NIOSH and OSHA to respiratory protection

recognizes the two most important aspects of respiratory protection: providing known

filtration efficiency while also ensuring the proper use and selection of devices, which

includes initial and ongoing individual fit.

16

Performance Characteristics of Facial Protection

Devices20

As noted, the FDA recommends that manufacturers demonstrate the performance of

surgical masks in four areas: fluid resistance, filtration efficiency, differential pressure,

and flammability. These parameters and the corresponding tests are described below.

Fluid Resistance

Fluid or splash resistance is the ability of the mask’s material to resist the penetration of

blood and body fluids; it tests the mask’s material construction for the ability to minimize

fluids from traveling through the material and potentially coming into contact with the

wearer. The recognized test for fluid resistance is ASTM F1862 Standard Test Method

for Resistance of Medical Face Masks to Penetration by Synthetic Blood.21 This test

method is used to evaluate the resistance of face masks to penetration by a fixed volume

of blood at high velocity over a relatively short period of time (0 to 2.5 seconds). The

test results are intended to enable end-users to objectively compare the performance

of different masks. According to ASTM F 1862, surgical masks are tested on a pass/fail

basis at three velocities corresponding to the range of human blood pressure (i.e., 80,

120, 160 mm Hg). Fluid resistance may be claimed if the device passes ASTM F1862

at any of the three pressures. Any visual evidence of synthetic blood penetration to

the inside of the face mask constitutes failure. At least 29 of 32 samples must pass the

test for the mask to pass at the given blood pressure. Surgical masks that demonstrate

passing results at higher velocities are more fluid resistant, however, labeling is not

required to specify the pressure at which it passed, meaning there is no way for the HCW

to know the specific level of fluid resistance unless the information is requested. It is important to note that all face masks which are labeled as fluid-resistant do not

provide the same level of protection. Additionally, one manufacturer may label a

mask that passed ASTM F1862 at 80mm Hg as “highly fluid resistant,” while another

manufacturer may label a mask that passed at 160mm Hg as “fluid resistant.” In this

scenario, the user would naturally believe that the mask labeled “highly fluid resistant”

provides more protection than the one labeled only “fluid resistant,” when in fact, the

opposite is true.

Filtration Efficiency

For surgical masks that are not NIOSH certified N95 Respirators, the FDA recommends

evaluation of bacterial filtration efficiency through the use of the following test:

• Particulate Filtration Efficiency (PFE): This method tests the ability of face

masks to filter sub-micron particles, generally 0.1µm (0.1 micron) in size. The

ASTM F1215 Standard Test Method for Determining the Initial Efficiency of

Flatsheet Filter Medium in an Airflow Using Spheres uses an unneutralized

aerosol of 0.1-micrometer latex spheres at a challenge velocity between 0.5 cm/

second and 25 cm/second (i.e., approximately 8 L/min to 380 L/min for a 9-cm

mask).22 A PFE test result of 99%, means that the mask has successfully filtered

99% of all particles of 0.1µm size or greater.

17

• Bacterial Filtration Efficiency (BFE): This is a measure of the ability of the

mask’s material to prevent the passage of aerosolized bacteria. BFE is expressed

in the percentage of a known quantity that does not pass through the mask

material at a given aerosol flow rate. The ASTM F2101-07 Standard Test Method

for Evaluating the Bacterial Filtration Efficiency (BFE) of surgical masks using a

Biological Aerosol of Staphylococcus aureus is often used.23 This test uses an

unneutralized 3± 0.3-micrometer Staphylococcus aureus aerosol at a flow rate of

28.3 L/minute.

Breathability

For surgical masks that are not NIOSH certified N95 Respirators, the FDA recommends

evaluation of differential pressure. Differential Pressure (Delta-P) is the measured

pressure drop (measured in mm H20/cm²) across a surgical face mask material, which

determines the resistance of the surgical face mask to air flowing through the mask.24

The pressure drop relates to the breathability and comfort of the surgical mask. Test

results are reported on a scale of 1 to 5; in general, a lower Delta-P translates to

increased breathability (see Table 5). ASTM requires that general use masks have Delta

P value of less than 4.0; fluid resistant masks must have Delta P values of less than 5.0.

Table 5 - Comfort Scale Used in Delta-P Testing

Score

Wearer’s Perception

Above 5.0

Hot

4.0 to 5.0

Very warm

3.0 to 4.0

Warm

2.0 to 3.0

Cool

1.0 to 2.0

Very cool

Flammability

Flammability is defined as the relative ease with which a material can ignite and sustain

combustion; it is determined by igniting the material and testing the time of flame spread.

The FDA recommends one of the three standards below to determine flammability by

class:

• CPSC CS-191-53 Flammability Test Method (16 CFR 1610) Standard for

Flammability of Clothing Textiles.25 The standard provides a test to determine

whether such clothing and fabrics exhibit ‘‘rapid and intense burning,’’ and are

therefore highly flammable. To determine the appropriate classification, the

Standard prescribes the method of testing. The classifications are defined as

follows:

oClass 1 – Normal Flammability. Class I textiles exhibit normal flammability;

the burn time is 3.5 seconds or more).

oClass 2 – Intermediate Flammability. Class 2 fabrics have a burn time from 4

through 7 seconds.

18

oClass 3 – Rapid and Intense Burning. . Class 3 textiles exhibit rapid and

intense burning (burn time is less than 3.5 seconds) are dangerously

flammable.

• National Fire Protection Association NFPA Standard 702-1980: Standard for

Classification of Flammability of Wearing Apparel.26 In 1987, the NFPA removed

this from their list of current standards, but it is still used as a reference by

manufacturers and the FDA as one of the standards to be used for evaluating the

safety and performance characteristics of facial protection devices.

• Underwriters Laboratories (UL) 2154 Standard for Fire Tests of Surgical Fabrics.27

This is a test that measures the level of atmospheric oxygen required to

propagate flame when ignition is caused by an electrosurgery unit or laser. Higher

levels of oxygen required for flame propagation indicate materials which are more

flame resistant for electrosurgery or laser procedures.

The ASTM requires all face masks to meet or exceed Class 1 flammability. The FDA

recommends that only Class 1 and Class 2 flammability materials be used in surgical

masks intended for use in the operating room. Class 3 surgical masks should have a

flammability warning on their label.

Material Performance

The ASTM F2100-11 Standard Specification for Performance of Materials used in Medical

Face Masks28 covers testing and requirements for materials used in the construction of

medical face masks. Medical face mask material performance is based on the testing

described above, i.e., resistance to penetration by synthetic blood, particulate filtration

efficiency, bacterial filtration efficiency, differential pressure, and flammability. With the

recent revisions to this standard, the following barrier levels can now be applied to face

masks to indicate protection levels based on the barrier performance properties of the

materials used (see Table 6):

oLevel 1 Barrier face mask materials are evaluated for their ability to capture

sub-micron particles, their resistance to synthetic blood penetration at

the minimum velocity (as specified in ASTM F1862), bacterial filtration

efficiency, and differential pressure.

oLevel 2 Barrier face mask materials are tested for their ability to capture

sub-micron particles and are also evaluated for resistance to synthetic blood

penetration at the middle velocity (as specified in ASTM F1862), bacterial

filtration efficiency, and differential pressure.

oLevel 3 Barrier face mask materials are tested for their resistance to

synthetic blood penetration at the maximum velocity (as specified in ASTM

F1862), sub-micron particulate filtration, bacterial filtration efficiency, and

differential pressure.

This revised ASTM standard also states that the primary packaging containing the face

masks must include a graphic representation that prominently and clearly indicates the

19

performance level met (ie, Level 1, 2, or 3, as outlined in Table 6). This new labeling

not only simplifies the mask selection process, but also helps to ensure that health care

workers select the appropriate mask for the task.29

Other elements of performance related to facial protection device design and materials

are outlined in Table 7.

Table 6 – Medical Face Mask Material Requirements by Performance Class

Characteristic

Level 1 Barrier

Level 2 Barrier

Level 3 Barrier

Resistance to Penetration by

Synthetic Blood

(minimum pressure in mmHg for

passing result)

80

120

160

≥ 95 %

≥ 98 %

≥ 98 %

≥ 95 %

≥ 98 %

≥ 98 %

< 4.0

< 5.0

< 5.0

Class 1

Class 1

Class 1

Sub-micron Particulate

Filtration Efficiency at 0.1

micron (%)

Bacterial Filtration Efficiency

(%)

Differential Pressure

(mm H2O/cm²)

Flame Spread

Table 7 – Facial Protection Devices: Elements of Performance

Feature

Filtration

Fit

Speech

Purpose

Function of

Allow permeation of air

during inhaling/exhaling.

Prevent respiratory

distress i.e. Low work of

breathing.

Prevent penetration of

particles, bio-aerosols,

smoke, plume.

Stay sealed during usual

physical maneuvers of

head and neck.

Allow coherent

communication.

20

Mask material

Priority

High

High

High

Mask design

High

Mask design and

material

Low

Clinical Considerations: Regulations and

Recommendations Regarding Appropriate Selection and

Use of Facial Protection Devices

In addition to the regulations outlined for the design and manufacture of facial protection

devices, various regulatory agencies and professional associations have outlined

standards, guidelines, and recommended practices for their effective and appropriate

use, as outlined below.

OSHA

Bloodborne Pathogens Standard30

As noted, the OSHA Bloodborne Pathogens Standard outlines the required use of

facial protection when there is a reasonable likelihood of occupational exposure to

blood or body fluids. In these situations, the employer shall provide, at no cost to the

employee, appropriate personal protective equipment such as, but not limited to, gloves,

gowns, laboratory coats, face shields or masks and eye protection, and mouthpieces,

resuscitation bags, pocket masks, or other ventilation devices. Personal protective

equipment will be considered “appropriate” only if it does not permit blood or other

potentially infectious materials to pass through to or reach the employee’s work clothes,

street clothes, undergarments, skin, eyes, mouth, or other mucous membranes under

normal conditions of use and for the duration of time which the protective equipment will

be used. Masks, in combination with eye protection devices, such as goggles or glasses

with solid side shields, or chin-length face shields, shall be worn whenever splashes,

spray, spatter, or droplets of blood or other potentially infectious materials may be

generated and eye, nose, or mouth contamination can be reasonably anticipated.

Respiratory Protection Standard31

Surgical masks are not a substitute for respirators because they are not designed

to prevent inhalation of airborne contaminants. However, bacteria and viruses are

particles that can be filtered by particulate respirators such as N95 respirators. OSHA’s

Respiratory Protection Standard requires the use of a NIOSH certified respirator, as well

as the implementation of a comprehensive respiratory protection program. This standard

also outlines three measures that must be taken before a health care worker uses a

respirator:

• Employees must be medically evaluated and approved to wear a respirator. Medical evaluations can be performed by using a medical questionnaire or by

performing an initial medical evaluation that obtains the same information as

the medical questionnaire. This evaluation must be conducted during normal

working hours or at a time that is convenient to the employee and employers are

responsible for paying for the service.

• The employee must be fit tested to ensure that the respirator is working

effectively. OSHA requires that N95 respirators be fit-tested either quantitatively

or qualitatively to ensure that every worker is provided with the correct size and

type of respirator.

21

o Quantitative fit testing – this test involves two measurements:

▪▪ Aerosolized particles inside the respirator (using a sampling probe);

and

▪▪ Air leakage into the respirator.

These two measurements are taken while the individual is wearing the respirator, and

is performing various test exercises, e.g., normal breathing, deep breathing, turning

the head, moving the head up and down. The result of this testing is a numerical “fit

factor, “which is based on the ratio of the concentration of the aerosolized particles in

the ambient air to the concentration of the aerosolized particles inside the respirator

while it is being worn. Regardless of the numerical result of the testing, the wearer is still

questioned about the comfort of the respirator. If the individual considers the respirator

unacceptable, the testing must be repeated using another type of N95 respirator.

oQualitative fit testing – this is a pass/fail test in which, first the worker

subjectively assesses the comfort of the respirator using the following

criteria:

▪▪

▪▪

▪▪

▪▪

▪▪

▪▪

▪▪

▪▪

Position of the mask on the nose.

Room for eye protection.

Room to talk.

Position of the mask on the face and cheeks.

Proper placement of the chin.

Adequate strap tension, but not overly tight.

Fit across the bridge of the nose.

Respirator of proper size to span the distance from the nose to the

chin.

▪▪ Tendency of the respirator to slip.

▪▪ Self-observation in a mirror to evaluate fit and respirator protection.

The individual, while wearing the mask and a hood, is then asked to detect odors and

tastes associated with selected aerosolized test solutions. If the worker is able to smell

or taste the test aerosols while wearing the respirator, of if he/she finds the fit of the

respirator unacceptable, then the fit testing must be repeated with a different respirator.

This test is referred to as an individual’s fit factor, which must be equal to or greater than

the assigned protection factor multiplied by a safety factor. In the case of a filtering face

piece respirator, an individual’s fit factor must be greater than 100 (assigned protection

factor = 10; safety factor = 10).

• The employee must be trained to use the respirator.

22

Pandemic Influenza Preparedness and Response

Guidance for Healthcare Workers and Healthcare

Employers32

In 2009, OSHA published its Pandemic Influenza Preparedness and Response Guidance

for Healthcare Workers and Healthcare Employers, recognizing that seasonal, avian,

and pandemic influenza can occur in humans; therefore, it is important to have a basic

understanding of these terms as well as the appropriate prevention strategies. The

General Duty Clause requires employers to provide their employees with a workplace

free from recognized hazards that are likely to cause death or serious physical harm. A successful infection control program for pandemic influenza is comprised of the same

strategies that are implemented for any infectious agent; these include engineering (ie,

facility and environmental) controls; administrative controls (e.g., standard operating

procedures; personal protective clothing and equipment; and safe work practices. These

strategies form the basis of standard precautions and transmission-based precautions.

Because the exact transmission pattern or patterns are not known until after a pandemic

influenza virus emerges, transmission-based infection control strategies may have to be

modified to include additional engineering controls, administrative controls, PPE, and/or

safe work practices. Special Considerations for Pandemic Preparedness

Respiratory protection against pandemic influenza will be more effective when employers

are prepared appropriately. The establishment of a comprehensive respiratory protection

program with all of the elements specified in OSHA’s Respiratory Protection standard

is necessary to achieve the highest levels of protection. Acquiring an adequate supply

of the appropriate respirators, ensuring that they properly fit key personnel, conducting

appropriate training, and performing other aspects of respiratory protection can all

be accomplished before an outbreak of pandemic influenza. These measures should

be repeated annually, before a pandemic is declared, in order to assure ongoing

preparedness.

Centers for Disease Control and Prevention (CDC)

The CDC also outlines recommendations for protecting health care workers from

infection, including the use of a surgical mask in health care settings.

Guideline for Isolation Precautions: Preventing Transmission of Infectious Agents in

Healthcare Settings, 2007 33

The CDC’s Guideline for Isolation Precaution in Hospitals, originally issued in 1995,

provides recommendations related to mask and respirator use by providing two tiers

of precautions (i.e., standard and transmission-based precautions) to help prevent

transmissions of infections from both recognized and unrecognized sources in hospitals. The three categories of transmission-based precautions are:

• Contact precautions should be used when providing care for patients who are

known or suspected to be infected or colonized with microorganisms that are

23

transmitted by direct or indirect contact with patients or items and surfaces in

patients’ environments (e.g., herpes simplex, impetigo, infectious diarrhea,

smallpox, MRSA, and VRE). Contact precautions include wearing a mask when it

is anticipated that aerosolized exposure to infectious microorganisms is possible. • Droplet precautions should be used when caring for patients who are known

or suspected to be infected with microorganisms that can be transmitted by

infectious large particle droplets (i.e., those larger than 5 microns in size) and

generally travel short distances of three fee or less (e.g., diphtheria, pertussis,

influenza, mumps, pneumonic plague). Droplet precautions include wearing a

mask when within three feet of infectious patients.

• Airborne precautions should be used when caring for patients who are known

or suspected to be infected with microorganisms that can be transmitted by

the airborne route (e.g., rubeola, varicella, tuberculosis [TB], and smallpox). Microorganisms carried by airborne transmission (e.g., droplet nuclei or dust

particles) can be widely dispersed by air currents, remain suspended in the air for

extended periods, and may become inhaled by a susceptible host within the same

room or over a longer distance from the source patient. Airborne precautions

should include NIOSH-approved N95 respirators worn by health care personnel.

This guideline was updated and expanded in 2007, based on the following

developments:

• The transition of healthcare delivery from primarily acute care hospitals to other

healthcare settings (e.g., home care, ambulatory care, free-standing specialty

care sites, long-term care) created a need for recommendations that can be

applied in all healthcare settings using common principles of infection control

practice, yet can be modified to reflect setting-specific needs. Accordingly,

the revised guideline addresses the spectrum of healthcare delivery settings.

Furthermore, the term “nosocomial” infections was replaced by the term

“healthcare-associated” infections (HAIs) to reflect the changing patterns in

healthcare delivery as well as the difficulty in determining the geographic site of

exposure to an infectious agent and/or acquisition of infection.

• The emergence of new pathogens (e.g., SARS-CoV associated with the

severe acute respiratory syndrome [SARS], avian influenza in humans),

renewed concern for evolving known pathogens (e.g., C. diff, noroviruses,

community-associated MRSA [CA-MRSA]), development of new therapies (e.g.,

gene therapy), and increasing concern for the threat of bioweapons attacks,

established a need to address a broader scope of issues than in previous

isolation guidelines.

• The successful experience with Standard Precautions, first recommended in

the 1996 guideline, has led to a reaffirmation of this approach as the foundation

for preventing transmission of infectious agents in all healthcare settings. New

additions to the recommendations for Standard Precautions were the Respiratory

Hygiene/Cough Etiquette and safe injection practices, including the use of a

24

mask when performing certain high-risk, prolonged procedures involving spinal

canal punctures (e.g., myelography, epidural anesthesia). As noted, the need

for a recommendation for Respiratory Hygiene/Cough Etiquette grew out of

observations during the SARS outbreaks where failure to implement simple

source control measures with patients, visitors, and health care workers with

respiratory symptoms may have contributed to SARS-CoV transmission. The

recommended practices have a strong evidence base. The continued occurrence

of outbreaks of hepatitis B and hepatitis C viruses in ambulatory settings indicated

a need to re-iterate safe injection practice recommendations as part of Standard

Precautions. The addition of a mask for certain spinal injections grew from recent

evidence of an associated risk for developing meningitis caused by respiratory

flora.

• Evidence that organizational characteristics (e.g., nurse staffing levels and

composition, establishment of a safety culture) influence healthcare personnel

adherence to recommended infection control practices, and therefore are

important factors in preventing transmission of infectious agents, led to a

new emphasis and recommendations for administrative involvement in the

development and support of infection control programs.

• Continued increase in the incidence of HAIs caused by MDROs in all healthcare

settings and the expanded body of knowledge concerning prevention of

transmission of MDROs created a need for more specific recommendations for

surveillance and control of these pathogens that would be practical and effective

in various types of healthcare settings.

Guidelines for Preventing the Transmission of Mycobacterium tuberculosis

in Health-Care Settings, 2005 34

In 1994, the CDC first published its Guidelines for Preventing the Transmission of

Mycobacterium tuberculosis in Health Care Facilities. These guidelines were issued

in response to a resurgence of TB disease that occurred in the United States in the

mid-1980s and early 1990s, including the documentation of multiple high-profile healthcare--associated (previously called nosocomial) outbreaks related to an increase in

the prevalence of TB disease and HIV coinfection; lapses in infection control practices;

delays in the diagnosis and treatment of persons with infectious TB disease; and the

appearance and transmission of multidrug-resistant TB strains. The guidelines presented

recommendations for TB infection control based on a risk assessment process. In this

process, health-care facilities were classified according to categories of TB risk, with a

corresponding series of environmental and respiratory protection control measures.

In 2005, these guidelines were updated to reflect the evidence-based science that was

used to support its recommendations for the health care environment today. All health

care settings need a TB infection control program designed to ensure prompt detection,

airborne precautions, and treatment of persons who have suspected or confirmed TB

disease (or prompt referral of persons who have suspected TB disease for settings in

which persons with TB disease are not expected to be encountered). Such a program is

based on a three-level hierarchy of controls, described below:

25

• Administrative Controls. The first and most important level of TB controls is the

use of administrative measures to reduce the risk for exposure to persons who

might have TB disease. Administrative controls consist of, but are not limited to,

the following activities:

o Assigning responsibility for TB infection control in the setting;

o Conducting a TB risk assessment of the setting;

o Developing and instituting a written TB infection control plan;

o Ensuring the timely availability of recommended laboratory processing,

testing, and reporting of results to the ordering physician and infection

control team;

oImplementing effective work practices for the management of patients with

suspected or confirmed TB disease; and

oEnsuring proper cleaning and sterilization or disinfection of potentially

contaminated equipment.

• Environmental Controls. The second level of the hierarchy is the use of

environmental controls to prevent the spread and reduce the concentration of

infectious droplet nuclei in ambient air. Primary environmental controls consist of

controlling the source of infection by using local exhaust ventilation (e.g., hoods,

tents, or booths) and diluting and removing contaminated air by using general

ventilation. Secondary environmental controls consist of controlling the airflow to

prevent contamination of air in areas adjacent to the source and cleaning the air

by using high efficiency particulate air (HEPA) filtration.

• Respiratory Protection Controls. The first two control levels minimize the number

of areas in which exposure to M. tuberculosis might occur and, therefore, aim

to minimize the number of persons exposed. These control levels also reduce,

but do not eliminate, the risk for exposure in the limited areas in which exposure

can still occur. Because persons entering these areas might be exposed to M.

tuberculosis, the third level of the hierarchy is the use of respiratory protective

equipment in situations that pose a high risk for exposure. Use of respiratory

protection can further reduce risk for exposure of health care workers to infectious

droplet nuclei that have been expelled into the air from a patient with infectious

TB disease. The following measures can be taken to reduce the risk for exposure:

o Implementing a respiratory protection program;

o Training health care workers on respiratory protection; and

o Training patients on respiratory hygiene and cough etiquette procedures.

Recommendations for Facemask and Respirator Use to Reduce Seasonal

Influenza 35

The CDC recently published Prevention Strategies for Seasonal Influenza in Healthcare

Settings, which supersedes the previous 2009 guidance for both seasonal influenza and

the H1N1 influenza in health care settings since a safe an effective vaccine for the 2009

26

H1N1 virus became available and the overall risk of hospitalization and death among

those infected with this strain is now known to be considerably lower than pre-pandemic

assumptions. Also, recently presented or published information indicates that the use

of a face mask and hand hygiene decrease the risk of influenza infection in health

care, as well as household, settings; therefore, an update of the recommendations was

warranted. In regards to facial protection, the recommendations include:

• For patients or persons with symptoms of any respiratory infection, before and

upon arrival to a health care setting, appropriate prevention actions (eg, wear

a facemask upon entry; adhere to respiratory hygiene, cough etiquette, hand

hygiene; and follow triage procedures) should be taken throughout the duration of

the visit. The patient should wear a facemask, if possible, and follow respiratory

hygiene and cough etiquette and hand hygiene, if he/she must be transported

from his/her room

• Health care workers should adhere to Standard Precautions and Droplet

Precautions. They should don a facemask when entering the room of a patient

with either suspected or confirmed influenza, remove it when leaving the patient’s

room, dispose of it in an appropriate waste container, and then perform hand

hygiene. If a facility chooses to provide its employees with alternative PPE,

this equipment should offer the same nose and mouth protection from splashes

and sprays as that provided by facemasks (eg, face shields, N95 respirators,

or powered air purifying respirators). Health care workers should also wear

respiratory protection that is equivalent to a fitted N95 filtering facepiece respirator

or equivalent N95 respirator (eg, powered air purifying respirator, elastomeric)

when participating in aerosol-generating procedures. When respiratory protection

is needed in a workplace setting, respirators must be used in the context of a

comprehensive respiratory protection program that includes training and fittesting, as mandated in OSHA’s Respiratory Protection standard.

Recommendations for Facemask and Respirator Use to Reduce MERS36

As noted above, the first cases of MERS have been identified in the U.S. Standard,

contact, and airborne precautions are recommended for management of hospitalized

patients with known or suspected MERS-CoV infection, based on CDC’s case definition

for a patient under investigation (PUI). Additional infection prevention precautions may

be needed if a MERS-CoV patient has other conditions or illnesses that require specific

measures (e.g., TB, Clostridium difficile, or multi-drug resistant organisms).

Recommendations for health care workers in regards to facial protection include the

use of respiratory protection that is at least as protective as a fit-tested NIOSH-certified

disposable N95 filtering facepiece respirator. A facemask should be worn in situations

where a respirator is not available; however, respirators should be made available as

quickly as possible. The recommended PPE should be worn by health care workers

upon entry into patient rooms or care areas for any reason (eg, clinical care, specimen,

environmental cleaning, etc.). When leaving the room or care area, PPE should be

removed and either discarded or cleaned and disinfected according to the manufacturer’s

instructions (for reusable PPE); hand hygiene should be performed after PPE is

removed.

27

Patients should be placed in an airborne infection isolation room (AIIR); while pending

placement in the AIIR, the patient should wear a face mask and be placed in a singlepatient room with the door closed. Once the patient is in the AIIR, his/her face mask can

be removed; however, when outside of the AIIR, the patient should wear a face mask to

contain secretions.

The Association of periOperative Registered Nurses (AORN)

AORN addresses facial protection devices in three of its recommended practices, as

outlined below.

• Recommended Practices for Surgical Attire37

o Recommendation VI states that “all individuals entering restricted areas

should were a surgical mask when open sterile supplies and equipment

are present.” The recommendation goes on to say that a single surgical

mask should be worn to protect the health care worker from contact with

infectious materials from the patient and also protect the patient and sterile

field from transmission of respiratory microorganisms expelled by the health

care worker during talking, sneezing and coughing. A mask should fully

cover both the nose and mouth and be secured in a manner that prevents

venting. The practice of using a double mask does not increase filtration;

furthermore, because it creates an impediment to breathing, this practice

is not recommended. Other recommendations include that a fresh, clean

mask should be used for every procedure; masks should not be worn

handing down from the neck; and masks should be removed by the ties and

discarded after each procedure, followed by hand hygiene.

• Recommended Practices for Laser Safety in Perioperative Practice Settings38

o Recommendation V states that “potential hazards associated with surgical

smoke generated in the laser practice setting should be identified and

safe practices established.” Surgical smoke should be removed with

a smoke evacuation system during both open and minimally invasive

procedures; local exhaust ventilation (LEV) is the primary measure to

protect perioperative personnel from exposure to laser-generated airborne

contaminants. In regards to facial protection, the recommendations go on

to state that perioperative personnel should wear respiratory protection

(eg, a fit-tested surgical N95 filtering respirator or high-filtration surgical

masks) in procedures where surgical smoke is generated as secondary

protection against residual smoke that is not captured by LEV. While these

masks are specifically designed to filter particulate matter 0.1 micron or

larger in size, they should not be used as the first line of protection against

inhalation of surgical smoke or as protection from the chemical or particulate

contaminants in surgical smoke. Because both surgical and high-filtration

masks do not seal the face, they may permit dangerous contaminants to

enter the wearer’s breathing zone.

28

• Recommended Practices for Prevention of Transmissible Infections in the

Perioperative Practice Setting39

o Recommendation III states that “droplet precautions should be used

throughout the perioperative environment (ie, preoperative, intraoperative,

postoperative) when providing care to patients who are known or suspected

to be infected with microorganisms that can be transmitted by large

droplets. In addition to Standard Precautions, droplet precautions are used

to reduce the risks associated with pathogens that are spread through close

respiratory or mucous membrane contact. Personal protective equipment

should be worn as a component of droplet precautions; in regards to facial

protection, perioperative personnel should wear a surgical mask when in

close contact with a patient requiring droplet precautions. The patient who

requires droplet precautions should wear a mask when being transported.

• Recommendation IV states that “airborne precautions should be used when

providing care to patients who are known or suspected to be infected with

microorganisms that can be transmitted by the airborne route.” Personal

protective equipment should be worn as a component of airborne precautions;

perioperative personnel should wear a surgical mask or N95 or higher level

respirator, based on disease-specific recommendations, prior to entering the room

of a patient requiring airborne precautions. The respiratory protective devices

used during care of a patient with TB should be NIOSH-certified as a nonpowered

particulate filtering respirator (N-, R-, or P-95, 99, or 100), including a disposable

respirator or powered air-purifying respirator with a high efficiency filter. These

devices should be available in various models and sizes to accommodate the

facial characteristics and sizes of perioperative staff members. During transport, a

patient requiring airborne precautions should wear a mask if clinically appropriate.

The Association for Professionals in Infection Control and Epidemiology (APIC)

APIC outlines recommendations for the use of facial protection devices as follows:40

• Procedure masks should be readily available throughout a health care facility for

use by both health care workers and patients.

• A face mask with a fluid resistance of 160 mm/Hg should be worn for any

procedure during which there is any risk of exposure to body fluids.

• A properly fitted N-95 respirator should be worn when there is a risk of exposure

to tuberculosis. In addition, N-95 respirators should be worn by non-immune

health care workers who will have contact with patients who have rubeola or

varicella; health care personnel who are not immune to these diseases should

also wear N-95 respirators in the vicinity of patients who are known or suspected

to have these infections.

29

Infection Control Today

In 2009 there was a debate within the medical community due to conflicting research

and guidelines between government agencies regarding the transmission of H1N1.

Initially, the Association for Professionals in Infection Control and Epidemiology (APIC)

and the Society for Healthcare Epidemiology of America (SHEA) supported the CDC

recommendations of N95’s; however, due to recent research SHEA supported Standard

surgical masks for routine care of patients with H1N1. In November, 2009, APIC and

SHEA issued a letter to President Obama expressing concern over the current federal

guidance surrounding the use of personal protective equipment (PPE) by healthcare

workers in treating suspected or confirmed cases of 2009 H1N1 influenza. The letter

was precipitated by a re-evaluation of a study in which no significant differences were

observed among healthcare workers wearing surgical masks or N95 respirators. Of

note, this study was initially reported to show a significant benefit associated with the

use of N95 respirators; in addition, this preliminary report was cited in the Institute of

Medicine’s Sept. 3, 2009 Letter Report, which recommended the routine use of N95

respirators. APIC reported that in its letter, it urged the Obama administration to modify

the guidance to reflect the position best supported by the available science – which is

first-line use of surgical masks for routine H1N1 patient care. The letter also requested an

immediate moratorium on OSHA’s requirement for healthcare facilities related to the use

of N95 respirators in relation to H1N1 influenza. It was pointed out that permitting OSHA

to continue to enforce a policy not grounded in science will force healthcare facilities to

waste time and resources while working to comply with this requirement, rather than to

enact measures that will significantly benefit patient care and healthcare worker safety

during this national emergency. Additionally, the letter expressed concern over the

existing shortage of respirators, potentially precluding their use in situations where they

are most needed. The letter detailed the advantages of surgical masks by providing

appropriate protection for all routine patient encounters.41

Facial Protection Devices: Selection and Use Criteria

As discussed throughout this study guide, facial protection devices are worn by health

care personnel to provide protection against the spread of infections by reducing the

passage of bacterial particles from the wearer into the environment. They also protect

the wearer from blood and body fluid splash or spatter and inhaling airborne infectious

agents originating from the patients’ or staffs’ respiratory tract during talking, coughing,

or sneezing. Facial protection devices, which are available in a variety of shapes with

different features, are selected based on the wearer’s protection needs, as well as

personal preference of style and fit. Other selection criteria are described below.

Protection

The level of protection needed should be a primary consideration in the selection and

use of facial protection devices; the appropriate level of protection will vary based on

the clinical application. In some clinical situations, high filtration efficiency might be

important; in other uses, high fluid resistance might be needed. The discussion of the

various types of mask demonstrate how different levels of protection are appropriate

30

for different clinical applications. There are basically three types of procedure masks

– tissue-tissue, polypropylene-polypropylene, and fluid resistant. Tissue-tissue masks

provide minimal protection to the clinician and the patient. It is most often preferred

because it is very lightweight and comfortable. It is appropriate for use when there is NO

risk of splash or other exposure to blood or body fluids; therefore, it is not recommended

for respiratory etiquette protocols. Polypropylene-polypropylene masks are the most

commonly used and offer more protection than tissue-tissue, as some may pass at the

lowest level of fluid resistance; therefore this mask is often preferred for use in respiratory

etiquette protocols. Fluid resistant procedure masks should be worn if there is the risk

of fluid exposure. In clinical situations that require health care workers to be in contact

with patients who are known or suspected to be infected with microorganisms that are

transmitted via the airborne route (most commonly TB), wearing a NIOSH approved, N95

particulate respirator is indicated.

Features

Because the selection of facial protection devices is a highly personal decision, certain

device features may influence an individual’s decision. Specific features are built into

some masks for special applications; these include fog-free foams, adhesive tapes or

films, eye shields (also mandated by the OSHA Bloodborne Pathogens Standard), and

materials designed to avoid skin sensitivity (see Table 8). The design and means of

attachment of eye shields vary. For example, an eye shield may be glued to the mask

or sonically welded to it. A disadvantage of glued-on eye shields is that the glue may

degrade over time, causing a noxious odor or skin irritation. With the increased use of

eye protection, the importance of devices with features to reduce or eliminate fog, due

to moisture from the wearer’s breath, has also increased. The three most common of

these features are foam, film, and tape; of these, the most commonly used is foam, for

example, a foam strip with a moisture trap or flap may be preferable. Alternatively, some

masks use a vapor film to trap moisture and prevent fogging. Tape may also be used,

although the tape often used to prevent fogging can cause dermal irritation.

Table 8 – Features of Facial Protection Devices

Feature

Fog-Free

Nose Wire

Donning Mechanism

Tie Attachment

Eye Shield

Options

• Foam

• Film

• Tape

• Aluminum

• Coated

Steel

• Earloops

• Ties – vertical and

horizontal

• Strap –single or

double

• Inside

• Outside

• Sewn, stapled,

glued

• Sonically welded

• Polyester

Film

• Anti-glare

Film

Fit

Facial protection devices are effective only if worn properly. The fit should assure that the