Catalogue

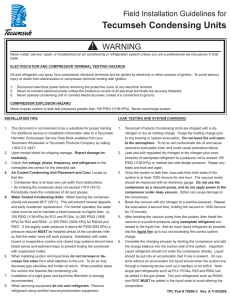

advertisement