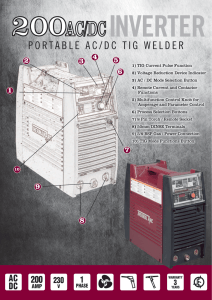

ac dc portable ac/dc tig welder

advertisement

INVERTER PORTABLE AC/DC TIG WELDER 2 1 1) Digital Displays 2) Fault Indicator Light 14 13 12 11 3 3) Down Slope Adjustment Knob 4 5) Torch / Remote Socket 5 7) Water Cooler 6 9) Negative Weld Output 50mm Dinse Terminal 4) 2T/4T Selection Button 6) Positive Weld Output 50mm Dinse Terminal 8) Gas Connection 10) TIG Mode and Pulse Selection Controls 10 11) Stick / TIG Selection Controls 12) Pre-Gas Time Setting 13) Up-Slope Time Setting 7 14) Welding current and Parameter Adjustment Knob 9 8 AC DC AC CC AC DC CV DC 1 3 PHASE CC CV V 230DUAL1CC 350 3 AC 400 AC PHASE AMP DCDC PHASE 400 350 AMP DUAL VOLTAGE 230/115V DUAL WARRANTY 200 3 220 350 DUAL 2230 400 WARRANTY CC VOLTAGE CC CC V AMP CV YEARS 230/115V VOLTAGE VOLTAGE PHASE V AMP CV V AMP PHASE V CV CV 230/115V YEARS 230/115V 3 WARRANTY 2 YEARS DUAL 350 VOLTAGE WARRANTY 2 AMP 230/115V YEARS 2DUAL VOLTAGE WARRANTY WARRANTY YEARS YEARS 230/115V 2 350 AC/DC H F tig In ver ter : The 350 AC/DC is an AC/ DC microprocessor controlled IGBT inverter with Constant Current (CC) output characteristics. Designed for HF TIG AC/DC, LIFT-ARC TIG AC/DC and STICK welding in DC, the 350 AC/DC operates on three phase 400 volt primary input voltage. This unit is supplied with a heavy duty inverter cart and water cooler as standard and is a true full function AC/DC TIG and STICK welding machine for all medium to heavy industrial applications. This truly full function AC/DC TIG and STICK welding machine has automatic hot start and arc force control, adjustable pre-flow and post-flow gas control, independent slope up and slope down control, down slope repeat function, 2/4 step torch switch control, adjustable AC frequency and AC wave balance control, full feature built in pulse facility and large display digital meters for current and voltage.. M ach ine F e atur e s : Thermal Overload and Over Voltage Protection Down Slope Repeat Function Allows operator to switch Indicates temperature overload without damage to the between down slope and main current repeatedly machine Full function Built in Pulse Facility Gives optimum control of Full Remote Control Facility Allows adjustment of output from current to balance heat input to work piece and control weld foot pedal or hand pendant shape Linear Speed Fan Automatic control of fan speed eliminating AC Frequency Control Gives Arc width control at set unnecessary levels of contaminants being drawn into the parameters machine AC Balance Control Allows adjustment of cleaning action and Automatic Hot Start Clean and positive arc striking penetration Digital Meters Accurate preset parameters and actual display DCB Cooling Chamber Design Main PCB and control circuitry out of line with main cooling chamber which improves Automatic Arc Force Easy striking, good arc stability and reliability and machine life avoids electrode sticking M ach i n e S p e c i f i ca t i o n s Independent Slope Function Full current control on slope up Type: Constant Current Maximum Output Welding Amperage Range Rated Output: and slope down Ordering Information Arcmaster 350 AC/DC with HD Inverter Cart, HD Cooler TIG, manual, primary cable and TIG plug Thermal Arc HD Inverter Cart Thermal Arc HD TIG Watercooler RC01 10m Standard Remote Control Remote Foot Control with 7.6m lead & plug Plug for remote / TIG Torch SA18 Water-Cooled TIG Torch with 4m lead Power Source Dimensions: (H x W x D) Power Source Weight Warranty 10-9403 020216/GT 020255 010330 10-9996 C04025 302.050.404 AC/DC Stick & HF TIG Welder 350A 3-350A 300A @ 60% 350A @ 40% 460mm x 279mm x 709mm 39 kg 2 Years P r i ma r y P o w e r Primary Voltage Hertz Phase Protection Class Approvals 400V 50/60 Hz 3 PH IP23 EN 60974-1 Thermadyne UK Tel: (44) 1257 261755 Fax: (44) 1257 224800 Thermadyne Italia Tel: (39) 02 36456801 Fax: (39) 02 36456840 www.thermalarc.com Form No. 350ACDC (18/02/2011) Europe © 2011 Thermadyne Industries, Inc. www.thermadyne.com