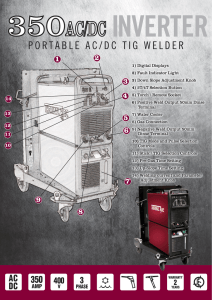

dc portable ac/dc tig welder

advertisement

INVERTER PORTABLE AC/DC TIG WELDER 2 4 3 5 1) TIG Current Pulse Function 6 2) Voltage Reduction Device Indicator 3) AC / DC Mode Selection Button 4) Remote Current and Contactor Functions 1 5) Multifunction Control Knob for Amperage and Parameter Control 6) Process Selection Buttons 7) 8 Pin Torch / Remote Socket 8) 50mm DINSE Terminals 9) 3/8 BSP Gas / Power Connection 10) TIG Mode Functions Button 7 10 9 8 AC CC DC DC CV 1 200 1 PHASE PHASE AMP WARRANTY WARRANTY DUAL 230DUAL1CC CC 200 3 CC DUAL VOLTAGE CC 230 200 230 V230 AMP 175 CV 1 3 ACDC YEARS 230/115V VOLTAGE VOLTAGE PHASE V DC230/115V PHASE CV V YEARS V CV AMP AMP CV 230/115V DUAL 180 VOLTAGE WARRANTY 2 AMP 230/115V YEARS WARRANTY 3 YEARS 200 AC/DC H F tig In ver ter : The Thermal Arc ArcMaster 200 AC/DC is a full digital control, AC/DC, Stick/ Lift TIG/ HF TIG inverter power supply with a high output and expanded input voltage capabilities for maximum user flexibility. Standard features include: High frequency start, lift TIG start, up/ down slope, pulse, repeat (latch) function, spot timer, Job Save & Load and VRD. This is the ultimate unit designed for precision TIG and Stick welding of all weldable materials. Superior, true square wave output combines with highly developed balance and cleaning features to deliver an unbeatable welding performance with extended tungsten life on aluminum and magnesium alloys without the need for continuous high frequency. M ach ine F eatures : Excellent Performance! Embedded microprocessor with digital controls, delivering perfectly smooth, stable arc characteristics for low hydrogen electrodes. Lift Start TIG! Provides TIG arc starting without use of high frequency. Smart Logic® ! Eliminates damage to the internal components if installed to improper voltage. HF Arc Starting! Provides non-contact arc starting that eliminates tungsten or material contamination. Thermal Overload Protection! Alerts the operator if the duty cycle is exceeded or airflow is blocked. True square wave output! Highly developed balance and cleaning features deliver an unbeatable welding performance with extended tungsten life on aluminum and magnesium alloys without the need for continuous high frequency. Remote Receptacle Fitted! Allows remote devices to be connected for controlling amperage and output contactor. Integrated VRD! Voltage Reduction Device reduces the OCV when the power supply is not in use. This all but eliminates the risk of electric shock to the operator from the secondary welding circuit. Job Save & Load! Allows operator to store up to 5 exact optimized welding parameters then digitally recall them with perfect repeatability. Smart Warning Diagnostics! Alerts operator to power supply abnormalities. Hot Start! For easy arc starts when STICK welding. AC Frequency! Gives the operator control over weld bead shape. AC Balance! Allows you to fine tune the AC welding cycle. Rapid pulse output! Provides precision control over pulse on/off, pulse frequency, peak % time, background and peak amperage, initial and final slope times, and amperage. Intelligent heat sensing fan! Operates as needed to cool components & reduce airborne contaminants pulled through the power source. M ach i n e S p e c i f i ca t i o n s Ordering Information Type: Constant Current Maximum Output Arcmaster 200 AC/DC with manual, 10-3099 primary cable and TIG plug Remote Foot Control with 7.6m lead & plug 10-4016 Remote Hand Pendant with 7.6m lead & plug 10-4014 Plug for remote / TIG Torch 10-9811 SA.26.4 TIG Torch with 4m lead 304.090.404 Universal Trolley020212/SA Welding Amperage Range Rated Output: Stick 230V TIG 230V Maximum OCV Volt/DC Power Source Dimensions: (H x W x D) Power Source Weight Warranty AC/DC Stick & HF TIG Welder 200A DC TIG 5-200A AC TIG 10-200A DC STICK 5-160A AC STICK 10 - 160A 160A / 26.4V @ 40% 200A / 18V @ 20% 65V 360mm x 180mm x 420mm 17 kg 3 Years P r i ma r y P o w e r Primary Voltage Hertz Phase Protection Class Approvals 220-230V 50/60 Hz 1 PH IP23S EN 60974-1 Thermadyne UK Tel: (44) 1257 261755 Fax: (44) 1257 224800 Thermadyne Italia Tel: (39) 02 36456801 Fax: (39) 02 36456840 www.thermalarc.com Form No. 200ACDC (15/02/2011) Europe © 2011 Thermadyne Industries, Inc. www.thermadyne.com