PSU “Moonbuggy” Telemetry Data Logging Base System Designed

advertisement

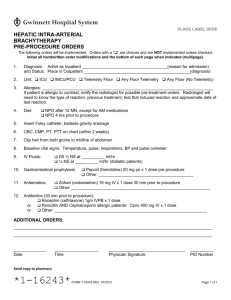

PSU “Moonbuggy” Telemetry Data Logging Base System Designed by Richard Erickson In the past, some of the previous PSU entries into “The great American Moonbuggy Race” have been “over built” in areas that would cause an unnecessary weight addition to the human powered “moonbuggy” thus requiring more “human power” to propel the “moonbuggy” around the race course. While component analysis and simulation is already being performed to determine engineering design possibilities and limitations, as is normal during the design process, it is still a guess without any information about the “real” forces and strains placed on components during the race. The PSU “Moonbuggy” Telemetry Data Logging Base System is designed to measure, gather, store, and transmit “real time” data for the purpose of engineering analysis. The process of acquiring this “real” information in this application presents a number of limitations in the design of a data gathering and logging system. The data gathering components and system must be as unobtrusive as possible and not interfere in any way with the operation of the buggy or its riders. The data logging portion of the system must be onboard and\or wireless to a remote location as the buggy cannot be connected to anything external by hardwires during the competition. The sensor and signal conditioning circuitry in this design will comprise five telemetry sub-systems. Strain gauges will be placed at various locations as recommended by the buggy design team with tri-axis accelerometers placed as close as possible to the four wheels and one on the frame. The strain gauge sensors will be “hard wired” with short leads to the sensor signal conditioning circuitry which will be mounted with or close to the accelerometers. The signal conditioning circuitry will be “overbuilt” with extra sensor input capacity to easily facilitate the connection of additional sensors. In addition to the five subsystems there will be a GPS device to provide precise GPS location data of the “sensor events” when they happen. The data signal output leads and operating power input leads from these five sub-systems and GPS will be wired to the telemetry system’s main data control unit. The telemetry system’s main data control unit will consist of a PIC microcontroller and an “on-board” telemetry data storage setup using a SD memory card connected to a communication bus on the microcontroller. A software program is to be written for the microcontroller system operation and will include the required sampling rates for the different types of sensors used at this time, the processing of sensor data for the on-board data storage medium, and the processing and control of the data to be sent by the RF data transmission component to a remote monitoring location. The RF transmission component shall have a minimum transmission range of one-half (1/2) mile and have the necessary bandwidth and data through-put to accommodate future telemetry system expansion(s) as well as video data transmission so that future additional transmitters (more system weight) will not have to be added to expand the overall system. The transmitter must be of a design that will not add any unnecessary weight or power drain to the overall system. A color video camera will also be onboard, if possible. The design and development of the telemetry system’s main data control unit required including the provisions for adding the requested telemetry system functions of wireless gathering of human bio data and wireless helmet cams. The development of these additionally requested system functions has proceeded concurrently with the main data control unit development through an independent study course. Block Diagram of “Base” Telemetry System XY Z Inputs Sensor Group 1 of 5 Tri-A x is A cc eleromet er St rai n Gauge St rai n Gauge St rai n Gauge St rai n Gauge St rai n Gauge MCP6S28 8 Channel Input PGA DC Power and Ground Feed DC Power and Ground Feed Sensor Data And PGA Control Erickson 11/01/2006 Rev 1 Moonbuggy Telemetry Arthur System Richard 1 Battery Pack DC Power and Ground Feed DC Power and Ground Feed Microhard IP921 RF Modem Transceiver PIC18F4550 Microcontroller SD Card On-Board Data Memory Processed Telemetry Data