Everything you require for easy and reliable seismic

advertisement

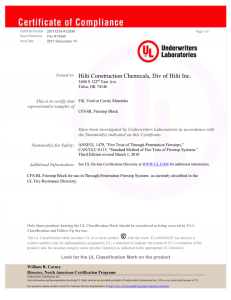

Post-installed anchoring Post-installed rebar Siding and decking Fastening structural and non-structural elements according to new European regulations. Injectable mortar and everything required for the safe installation of concrete-to-concrete connections. Nails and screws tested in accordance with the new AC 70 american standard. Ventilated facade Firestop Installation systems Aluminum sub construction for light ventilated façade systems, system tested for seismic applications. Solutions for pipe and cable penetrations through floors or walls, and for fire rated joint seals to reduce post earthquake impacts. Maximum safety assured by expert design and the use of Hilti standard pre-design solutions. Structure detection Hilti engineering services PS 250 and PS 1000 - Compact, cordless and complete system quickly operational and simple to operate to detect rebar in order not to hit them during drilling. A team of qualified and experienced engineers is available to provide you with more detailed information and to help you determine and design the best solution for your particular project. Contact them by phone at 01 30 12 65 01 (from 8h30 to 12h30 and from 13h30 to 17h00), by fax at 01 30 12 52 40 or by e-mail at fr-servicetechnique@hilti.com Hilti. Outperform. Outlast. Hilti Corporation I 9494 Schaan I Liechtenstein I P +423-234 2111 I F +423-234 2965 I www.hilti.com/seismic Hilti = registered trademark of Hilti Corp., Schaan | © 2015 | Right of technical and programme changes reserved S. E. & O. Everything you require for easy and reliable seismic specifications. HILTI PARTNER OF SPECIFYERS IN SEISMIC DESIGN. Hilti. Outperform. Outlast. 7 8 7 9 10 6 2 Seismic design and specification of seismic products is Seismic-relevant structural applications Structural connections are vital to ensure that the structure responds to a seismic event in a proper, predictable manner. Connections should therefore be clearly detailed in the design phase to make certain that both contractors and building inspectors comprehend project specifications. Firm, well thought out specifications are the best way to ensure that the designed product is the one that is actually used. Seismic-relevant non-structural applications Anchors are often used to fasten non-structural components. Their design and selection is therefore crucial in terms of minimizing both injuries to building occupants and the costs associated with seismic events. As fire is a common byproduct of earthquakes, firestop systems should be specified in accordance with their ability to withstand extreme deformation. Seismic retrofitting (e.g. bracings, shear reinforcement) Secondary steel connections and fastenings for utilities Structural steel element connections to concrete Equipments Post-installed rebar connections Mechanical and electrical supports Shear wall fastenings Ventilated façade systems and curtain walls Siding and decking and roofing on metallic structure Firestop cable and pipe penetrations and joints Page 2 I Edition march 2015 www.hilti.fr/le-risque-sismique Hilti solution for earthquake applications 5 8 7 4 5&EXLOGLQJDYHUDJH 10 6WUXFW 7 1RQVW &RQWH 5&EXLOGLQJDYHUDJH 3 2IILFH 1 7 6WUXFWXUDO 1RQVWUXFWXUDO &RQWHQWV 5&EXLOGLQJDYHUDJH +RWHO crucial in both structural and non-structural applications. 2IILFH 6WUXFWXUDO Repair costs resulting from a seismic event 1RQVWUXFWXUDO &RQWHQWV 20% 40% 20% 18% 5&EXLOGLQJDYHUDJH 8% +RWHO 44% 2IILFH 40% Structural 17% 13% 48% +RVSLWDO Nonstructural Contents 70% 62% 6WUXFWXUDO Average Concrete Building Office Hotel Hospital 1RQVWUXFWXUDO Source: Taghavi S. and Miranda E.: “Seismic Performance and Loss Assessment of Nonstructural Building Components,” Proceedings of 7th National Conference on Earthquake Engineering, Boston, 2002. +RWHO &RQWHQWV +RVSLWDO www.hilti.fr/le-risque-sismique Edition march 2015 I Page 3 New rating classifications for anchor performance under seismic load: C1 and C2 New European testing procedure for determining the seismic suitability of fastenings The seismic pre-qualification of anchors has been regulated since early 2013 in Europe following the release of ETAG 001 Annex E. Anchors subject to this new test procedure must now incorporate in the ETA all the required seismic design technical data . The suitability for seismic loading is classified as: ETA seismic category C1 – similar to U.S. pre-qualification procedure; only suitable for nonstructural applications according to the EOTA TR045 recommendations ETA seismic category C2 – arduous seismic crack movement tests qualify an anchor as suitable for more demanding structural and non-structural applications Structural applications Acceleration (ag.S) < 0.05g 0.05g to 0.1g > 0.1g Non-structural applications Building importance II, III, IV non-seismic ETA C2 Acceleration (ag.S) Building importance II, III < 0.05g Building importance IV non-seismic 0.05g to 0.1g ETA C1 > 0.1g ETA C2 ETA C2 The map above is based on national earthquake data (for ordinary buildings and ground type A) and provides perspective on the relevance of the new ETA guidelines in various countries. For more precise information see national regulations. Page 4 I Edition march 2015 www.hilti.fr/le-risque-sismique Hilti solution for earthquake applications Post-installed anchor seismic design EOTA TR045 sets the fastening seismic design standard EOTA TR045 sets the standard for the seismic design of steel-to-concrete connections until the new EN 1992-4 is released (release date pending confirmation). This code is in full compliance with the standards in the new ETAG 001 Annex E. Three design options The design code incorporates three design approaches which are described below. Note that all three of these approaches are acceptable within their application conditions. a1) Capacity design The anchorage is designed for the force corresponding to the yield of a ductile component or, if lower, the maximum force that can be transferred by the fixture or the attached element. a2) Elastic design The fastening is designed for the maximum load assuming an elastic behavior of the fastening and of the structure. b) Design with requirements on the ductility of the anchors This design for ductile steel failure requires an anchor classified as ductile. Additionally, this approach is applicable only for the tension component and some provisions require to be observed in order to ensure that the cause of failure is steel failure. Hilti seismic qualified anchors M8 M10 M12 M16 M20 C1 C1 C1 C1 C1 C2 C2 C1 C1 C1 C2 C2 C2 C1 C1 C1 C1 C2 C2 C2 C2 M24 M30 ETA seismic category C1 and C2 HIT-HY 200-A mortar + HIT-Z rod (galvanised and stainless) ETA 12/0006 15/03/2013 HST stud anchor (galvanised and stainless) ETA 98/0001 08/05/2013 HDA undercut anchor (galvanised and stainless) ETA 99/0009 06/01/2015 ETA 11/0493 20/06/2013 C1 C1 C1 C1 C1 C1 C1 ETA 07/0260 16/05/2013 C1 C1 C1 C1 C1 C1 C1 ETA 13/1038 13/01/2015 ETA 08/0307 29/04/2014 C1 * C1 * C1 * ETA seismic category C1 HIT-HY 200-A mortar + HIT-V rod (galvanised and stainless) HIT-RE 500-SD mortar + HIT-V rod and HIS-N sleeve (galvanised and stainless) HUS3-H, HUS3-C screw anchor (galvanised) HUS-HR screw anchor (stainless) Post installed anchor accessory Hilti dynamic set Filling washer, conical washer, Doubles shear resistance and prevents loosening. nut and lock-nut. * HUS3-H, HUS3-C, HUS-HR screw anchors are available in size 8, 10 and 14. www.hilti.fr/le-risque-sismique Edition march 2015 I Page 5 Structural rebar applications Approved per CSTB seismic pre-qualification Post-installed structural rebar Reinforced concrete design assumes that concrete has negligible tensile strength while allowing for the design of rebar development length and avoiding brittle concrete failure, in the following two situations: • Transferring tensile loads from one bar to another (overlap splice) • Development length of the tensile force in a bar beyond a node in equilibrium Seismic structural rebar approval French DTA approvals delivered by CSTB, a member of EOTA, recognizes Hilti HIT-RE 500-SD and HIT-HY 200-A injectable mortars as products qualified for structural rebar applications in seismic zones. By applying engineering judgment, engineers can use this French approval when designing seismic structural post-installed rebar connections. Included in the DTAs • The design bond strength fbd,seism of Hilti mortar considered for use in seismic zones • Formatted data for design with Eurocode 2 and Eurocode 8 • Application limit information (e.g. transverse reinforcement, settings instructions) DTA seismic approval Hilti HIT-RE 500-SD Slow-curing anchor mortar. CSTB approval DTA 3/13-746 for seismic rebar applications. Hilti HIT-HY 200-A fast-curing anchor mortar. CSTB approval DTA 3/13-749 for seismic rebar applications. Design tools Design is further simplified by Hilti’s own PROFIS software, which allows users to design fastening systems and rebar connections easily and in accordance with the state-of-the art seismic code framework. Additionally, the printed version of the Fastening Technical Manual (FTM) provides all technical data for both anchoring and rebar connections. PROFIS Anchor Page 6 I Edition march 2015 FTM www.hilti.fr/le-risque-sismique Hilti solution for earthquake applications Siding, decking and roofing applications Tested according to AC 70 acceptance criteria The screws and nails are not covered by any regulation in Europe as far as seismic behaviour is covered. Nevertheless, on seismic jobsite, the specifyer is quite often ask to justify also these fastenings. Reason why Hilti has decided to test some nails and screw according to the quite new AC 70 american acceptance criteria which contains seismic test for nails on metallic base material. If the resistances after the test are not more than 20% below the initial values, the fastening may be qualified for siesmic application without any loss of performance. This is similar to the C1 criteria for anchors. Nails and screw seismic tested Hilti X-ENP 19 Holds the most approvals worldwide for siding and decking Hilti X-BT designed to create a weld to the base material for an extremely strong hold and high loading capacity Hilti S-MD 31 PS, S-MD 33 PS For fastening of venitlated facade panels on aluminium structure PROFIS Rebar FTM Dedicated web page for specifyers www.hilti.fr/le-risque-sismique Edition march 2015 I Page 7 Recommanded firestop products in seismic Fires following earthquakes represent a major risk, both for the safety of human lives and for the protection of facilities and assets. After an earthquake, fire, smoke and water damage can cause severe problems including: ■ Damage to mechanical and electrical equipment ■ Breaking/leaks in pipe systems ■ Damage to electrical lines, including emergency equipment, lighting ■ Damaged communication networks ■ Gas leaks, creating an explosion risk ■ Blocked, unusable escape routes Once these problems have been managed there will also be a need for repair, maintenance and reinspection. Hilti seismic tests Hilti has conducted extensive tests to determine the behavior of firestop products in a seismic event while taking fire integrity and smoke tightness issues in a post-earthquake environment into consideration. Test setup The quasi-static cyclic loads according to FEMA 461* protocol were applied directly on the penetrants, whereas the wall was fixed. Tests were carried out in x-direction (load in same direction as the penetrant), in y-direction (load perpendicular to the penetrant) and in z-direction (rotation with the center in the wall layer). Air/gas tightness was measured during the test with a pressure testing device to reach measurable conclusions about damages of the penetration seal. After the seismic test an additional firestop test was conducted to evaluate permeability of smoke and fire integrity of the relevant firestop system. Results Significant factors that were measured: displacement (mm), movement force, pressure drop (Pa/min), start of pressure drop (mm), % pressure drop, plastic deformation of penetrant (kN), absolute pressure at start (Pa). Determining factors: flexibility-elasticity, adhesion, tightness, damage to penetrants, installation reliability. Outcome: recommendations for suitable and non-suitable firestop products, installation and design recommendations. * Federal Emergency Management Agency: Code for interim testing protocol for determining the seismic performance characteristics of structural and non-structural components. Cable penetration Pipe penetration Firestop foam Hilti CFS-F FX Firestop acrylic sealant CFS-S ACR Firestop block Hilti CFS-BL Firestop plug Hilti CFS-PL Firestop collar Hilti CFS-C P Firestop sleeve Hilti CFS-SL Firestop endless collar Hilti CFS-C EL Firestop acrylic sealant CFS-S ACR Firestop silicone sealant CFS-S SIL Firestop spray CFS-SP ACR For joints applications and curtain walls Joints Page 8 I Edition march 2015 www.hilti.fr/le-risque-sismique Hilti solution for earthquake applications Sub-structures for ventilated facade has been tested in seismic Ventilated facade present a risk of falling down in case of earthquake. The French state of the art defines a seismic test method for the entire system. A design method based on EN 1998-1-1 (Eurocode 8) for non structural elements is also defined (document CSTB 3725 dated January 2013). For more information, please contact our technical back office. Test setup Three tests are defined: Required displacement ■ Parallelogram test: This test is performed to observe the behaviour of the system to follow the movement of the building on which it is fixed. The ventilated facade is installed on a rigid frame (3 000 x 3 000 mm) fixed on the bottom. The support is gradually deformed in its plane (parallelogram) by a static displacement applied at the head according to the cycles predefined. The maximum displacement is ± 60 mm. A visual control is done on fall elements, breakage or deformation of a component system. Parallelogram test Required displacement Gliders Dynamic test ■ Dynamic test: This test is to observe the behavior of the system when the support on which it is mounted is moving in its plane under the action a cyclic reciprocating motion imposed. The ventilated facade is installed on a rigid frame (3 000 x 3 000 mm) on gliders. Cycles of movements are applied around the frequency of the system. The maximum displacement is ± 60 mm. A visual control is done on fall elements, breakage or deformation of a component system. ■ Dynamic perpendicular test: This test is the same as the dynamci test with movement perpendilar to its plane Brackets Profiles Bracket MFT-MFI M For sliding point L Profile In Aluminium, thickness 2,0 mm and 2,5 mm Bracket MFT-MFI L For fixed point T Profile In Aluminium, thickness 2,0 mm and 2,5 mm www.hilti.fr/le-risque-sismique Edition march 2015 I Page 9 Installation systems need to be designed specifically to resist of seismic loads Pipes For pipes installation, the basic principle is that the fastenings have to be designed so that the horizontal seismic loads can be taken in addition to the gravity forces. To take horizontal forces, the pipe fastenings must either be designed to be sufficiently flexurally stiff, or have bracing that can transfer the horizontal forces (Fh). It must be ensured that horizontal loads can be taken transversely and longitudinally in relation to the pipe axis. Horizontal seismic forces Fh,y in direction of pipe axis Threaded rods Horizontal seismic forces Fh,x transverse in relation to pipe axis Channels Hinge MQS-AB For bracing of threated rod to base material Hinge MQS-H For connecting two threaded rods Page 10 I Edition march 2015 Hinge MQS-AC For bracing of channel to base material or to angle Exist in renforced version MQS-ACD Angle MQS-W For connecting two channels Can be installed on MQ 41, MQ 72, MQ 41 D www.hilti.fr/le-risque-sismique Hilti solution for earthquake applications Seismic bracing Braces for a earthquake-resistant installation need to be arranged at a distance (b) from each other that must be assessed in relation to seismic acceleration, the mass of the pipes or (system in general) and the type of braces itself - i.e. the situation of the seismic brace respect to the main axis of the pipe. For this reason, we can distinguish three basic types of seismic-resistant media: ■ Longitudinal bracing: seismic brace arranged longitudinally to the main direction of the plant - resistance to horizontal actions acting along the main axis of the pipe ■ Transversal bracing: seismic brace perpendicular to the main direction of the plant - resistance to horizontal actions acting transversely of the pipe ■ 4-way bracing: structure composed of both longitudinal and transversal braces, therefore able to withstand all of the forces acting on the horizontal plane. It is advantageous for the bracing to be at a spacing that is a multiple of the normal pipe fastening spacing of (s), so that, for example, every third or fourth pipe fastening is braced. Single pipe application Transversal bracing Trapeze with threated rods Transversal bracing Trapeze with threated rods Longitudinal bracing Single pipe application Longitudinal bracing Trapeze with threated rods 4 ways bracing Manuel technique Systèmes de supportage I Février 2014 Design tools Design is further simplified by Hilti PROFIS Installation, which helps users to design installation systems easily and in accordance with the state-of-the art code. Additionally, the Installation systems catalogue provides all technical data for all products MM, MQ and MI. Download the latest version of Hilti PROFIS Installation and the technical data sheets from www.hilti.com. Hilti. Performance. Fiabilité. Manuel technique Système de supportage Service client 0 825 01 05 05 Hilti France I 1 rue Jean Mermoz I 78778 Magny les Hameaux I T +33 1 30 12 50 00 I F + 33 1 30 12 50 12 I www.hilti.fr édition Février 2014 © 02/2014 I Hilti = marque déposée du Groupe Hilti. Photos et textes non contractuels, sous réserve d’erreur typographique I MK homologation I Ref 2038 I 4 000 ex. PROFIS Installation Catalogue www.hilti.fr/le-risque-sismique Edition march 2015 I Page 11