MICROPLASMA BREAKDOWN AND HOT

advertisement

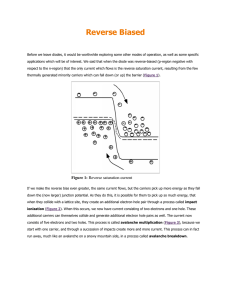

Solar Cells, 26 ( 1 9 8 9 ) 3 3 5 - 3 4 9 335 MICROPLASMA BREAKDOWN AND HOT-SPOTS IN SILICON SOLAR CELLS J. W. BISHOP E S T I Project, Commission o f the European Communities Joint Research Centre, 21020 Ispra, Varese (Italy) (Received February 10, 1989; accepted May 10, 1989) Summary Photovoltaic module hot-spot endurance tests performed at CEC JRC Ispra showed that the temperature distributions in cells subjected to reverse bias heating were non-uniform and reproducible. An investigation of the physical processes causing non-uniform power dissipation in reverse biased silicon solar cells, using IR imaging, scanning electron microscopy, and electrical measurements, is presented here. Hot-spots form in solar cells at defects causing microplasrna breakdown: avalanche breakdown, localized at electric field enhancing structural defects. Visible fight emission from microplasmas near cell front surfaces correlated with hot-spots revealed by IR imaging. Scanning electron microscopy studies of samples containing points of light emission found electron beam induced current (EBIC) enhancement at defects under reverse bias. Measurements of the electrical characteristics of these samples showed that the temperature coefficient of the breakdown voltage was negative, confirming the presence of avalanche multiplication. The defects found in the solar cell samples were pits (approximately 5 #m diameter) in the surface, occasionally contaminated with metals (nickel, aluminium, titanium) from the front contacts. Electron microscopic studies of defects in solar cells were performed in the Materials Science Department of Imperial College, London University. IR imaging studies, and electrical measurements were performed in the ESTI Sector of the Physics Division, CEC JRC Ispra. 1. Introduction Hot-spot heating in photovoltaic arrays is a manifestation of the problem of connecting electrical generators [1]. Interconnected electrical generators must be electrically matched, i.e. they must develop the same current when connected in series, or the same voltage when connected in parallel. A mismatched generator, such as a cracked or shadowed cell, acts 0379-6787/89/$3.50 © Elsevier Sequoia/Printed in The Netherlands 336 as an internal load, dissipating power and producing a hot-spot, while reducing the power o u t p u t of the array. A significant fraction of the array maximum power can be dissipated internally, and since cell encapsulation materials have poor thermal conductivities, temperatures of the order of hundreds of degrees centigrade are easily attained. Such temperatures degrade the optical and mechanical properties of encapsulation materials, reducing array performance and operating life. In severe cases, the melting of interconnections can lead to total failure of the array [2]. Since it is such a severe stress, a hot-spot endurance test is included in the module qualification test programme applied at the ESTI laboratory, CEC JRC Ispra [3]. IR images of modules during the hot-spot test, and of discrete cells reverse biased by a power supply, showed that power dissipation in solar cells was usually concentrated at one or two points, see Fig. l(a). The temperature distributions were reproducible, implying that material defects were associated with hot-spot formation. (a) (b) (e) Fig. 1. Correlation between temperature distributions and light emission patterns on a reverse-biased solar cell: (a) IR image of 10 cm diameter crystalline silicon solar cell; (b) close up IR image of hot-spot; (c) light emission pattern from cell. 337 When discrete cells were reverse biased by a p o w e r supply in a darkened room, light, visible to the naked eye, was emitted from tiny, randomly distributed points. The cells used were selected at random from groups of cells produced b y various manufacturers. In all cells, the light appeared to be white, and the number of points increased with increasing reverse bias. Light emission patterns, see Fig. l ( c ) , correlated with the temperature distributions observed b y IR imaging. This visible radiation could n o t be produced by the ordinary charge carrier recombination processes, which are non-radiative in silicon. However, visible radiation can be emitted from silicon by direct transitions involving the h o t carriers present during avalanche or Zener breakdown. Material defects degrade the electrical characteristics of p - n junctions [4, 5], and, under reverse bias, can act as sites for premature avalanche or Zener breakdown by locally enhancing the electric field. The resulting nonuniform current densities produce hot-spots. Various methods were used to identify the physical processes causing visible light emission from solar cells. The electrical activity of cell samples containing light emitting points was investigated by electron beam induced current (EBIC) measurements in the scanning electron microscope (SEM). The elements present in the electrically active defects found by EBIC were identified by energy dispersive X-ray analysis in the SEM. Finally, measurements of the temperature dependence of the electrical characteristics of the cell samples were made to distinguish between avalanche and Zener breakdown. 2. p - n Junction breakdown 2.1. Br ea kd o w n mechanisms The breakdown of a p - n junction is caused either b y a temperature rise (thermal breakdown), or by an electric field effect such as impact ionization (avalanche breakdown), or tunnelling (Zener breakdown). Thermal and electric breakdown are competing processes, their relative importance depending on factors such as temperature and band gap energy. Thermal breakdown is characterized b y thermal runaway [6], which occurs when the junction exceeds its maximum stable operating temperature, and the semiconductor reverts to intrinsic conduction. Power dissipation in the device then increases exponentially with temperature, while heat losses to the surroundings only increase linearly with temperature. Hence, above the maximum stable operating temperature, the device heats up rapidly until it is destroyed by melting. Microscopic investigations of failed solar cells [7] attributed failure to the formation of point shorts, consisting of melted zones contaminated with metals used in the cell contacts. At normal temperatures, junction b r e a k d o w n is initiated b y impact ionization or tunnelling. Avalanche or tunnelling currents then raise the 338 junction temperature until the semiconductor reverts to intrinsic conduction, leading to thermal breakdown as described above. Zener breakdown [8, 9] requires very high electric field strengths (approximately 106 V cm-l), and very narrow junctions (less than 100 nm). Zener breakdown voltages depend on band-gap energy, and decrease with increasing temperature, as shown by the measured current-voltage (I-V) curves of Fig. 2. Avalanche breakdown occurs when charge carriers, accelerated by the electric field, gain enough energy to ionize lattice atoms, creating secondary charge carrier pairs. The secondary carriers are themselves accelerated to energies sufficient to cause further ionization. Depending on doping concentrations [10], electric field strengths in the range 3 0 0 - 800 kV cm -1 are required to cause avalanche breakdown in abrupt silicon p - n junctions. Avalanche breakdown voltages increase with temperature, see Fig. 3, since the mean free path between scattering events decreases with increasing temperature. Greater applied voltages are therefore required to accelerate carriers to the threshold energy for impact ionization [11]. This temperature dependence is opposite to that of Zener breakdown, and is used to distinguish b e t w e e n the two processes. 2.2. Microplasma breakdown Electric fields in a semiconductor are enhanced by structural defects (dislocations, stacking faults, precipitates etc.), which act as sites for premature avalanche or Zener breakdown. The term microplasma was coined Rppl|ed Voltuge -5,8 5pecl.mn IV] -4.1~ -3.B -Z.I~ .... 5ps©lllmn Current -t- T " Z43 K ~ T - 263 T - 283 K X T - 31~3 K A T = 323 K [] T = 343 K ~> T - K ~ T - K O 363 383 K ~m[q] -Z.B f -3.~] I" -4.B i- -5,B P , .... Rpplted 27E.B , .... Voltuge + , .... 3BE.B , .... , .... 33E.8 , .... Te~ortture , .... 368.E , .... EK] ,... 39e. B IV] I = - I S B mR ~ I - -13 B,1R (a) (b) Fig. 2. Temperature dependence of electrical characteristics of a voltage regulator diode using Zener breakdown (Vmg = - - 2 . 7 V): (a) variation of electrical characteristics with temperature; (b) variation of breakdown voltage with temperature. 339 Rppl led Voltage -14.g Specimen Temperature (V] -IB.O -12.g -8.8 -6.8 .... . .... 278. g , .... , .... 389. g , .... , .... 33B.B , .... , .... 3Gg. fl , .... [K) 398. B , .... -8.8 -18.8 -tL.g -12.8 • F~pplled + T " O T - 283 K 243 K Valtqs [V] 3~ T " 2G3 K + I X T " 383 K O I " -ll.g d I /% T " 3Z3 K [] T " 343 K 0 T - 363 K [] T - 383 K = -I5.g " mR X I mA X I = -9,g mR " -13.8 mR -7.B (a) (b) Fig. 3. Temperature dependence of electrical characteristics of a voltage regulator diode using avalanche breakdown (Vreg =--10.0 V): (a) variation of electrical characteristics with temperature; (b) variation of breakdown voltage with temperature. to describe localized avalanche breakdown in reverse biased p - n junctions [12]. T w o p h e n o m e n a are typical of microplasma breakdown in silicon: (1) production of current noise pulses [13]; (2) emission of visible light from discrete points [14]. Current noise pulses occur at the onset of avalanche breakdown, when the impact ionization process is unstable. Pulse durations increase with reverse bias until the breakdown becomes continuous. Further bias increases may result in the onset of new sets of pulses, as successive regions of the junction break down. Visible light emission is observed from shallow, reverse-biased silicon p - n junctions, and is attributed to transitions involving h o t carriers in the microplasma. The spectral distribution of this radiation is known to be continuous up to 3.3 eV [14]. Absorption of this radiation b y the surrounding silicon determines the apparent colour of the emitted light. Junction depths in m o d e m cells are typically 0 . 3 - 0.5 /~m, hence the white appearance of the observed light emission in Fig. l(c). Microplasmas in deeper junctions appear to emit yellow or red light [14]. Incidentally, the study reported in [14] was performed on very early photovoltaic cells (referred to as solar batteries), with 2/~m junctions. Microplasma b r e a k d o w n has been observed at dislocations [15], stacking faults [ 16 ], precipitates [ 17 ], resistivity striations [ 18 ], and sites of mechanical damage [ 19]. Microplasma effects have generally been eliminated from silicon devices as silicon technology improved, b u t were recently found 340 to cause malfunctions in avalanche photodiodes used in optical fibre data links [20]. 3. Experimental techniques 3.1. Scanning electron microscopy investigations The high resolution and versatility of the SEM make it a useful tool for investigating material defects. The EBIC technique [21 - 2 3 ] , also known as charge collection, or conductive mode microscopy, is particularly useful for studying semiconductors. Solar cell samples were investigated using EBIC and X-ray microanalysis. EBIC measurements were made on a JEOL JSM-35 SEM equipped with an EBIC detection system [24]. Energy dispersive X-ray microanalysis was performed on a second J E O L JSM-35 equipped with an X-ray detector and a Link Systems 860 computer. As complete solar cells were t o o large for the specimen chamber, and their high capacitance made them incompatible with the EBIC detection system, samples containing regions of interest had to be prepared. Ultrasonic cutters (Kerry Ultrasonics KDS 100 and Balzers UDC-010) produced 3 mm diameter samples. Insulating antireflection coatings were removed by etching in 5% HF solution. The samples were fixed to TO-5 transistor headers with colloidal silver paste. Electrical contact to the front surface (the cell emitter) was made by thermocompression bonding of a fine gold wire, Fig. 4. To prevent shunting of the shallow junction by the contact bonder, front surface contacts were made to spots of colloidal silver paste painted on to the front surface. During EBIC observations, samples were reverse biased by an external p o w e r supply. DC bias currents were blocked by a capacitive coupling network, acting as a first order high-pass filter with a pass frequency of 70 Hz, Fig. 5. EBIC measurements were used to detect regions of charge recombination or multiplication. These sites were then observed by Cell~ Rf TO-5header Electr°iitlbeam 2.2 pF I Substratecontact L] B, ' ' I pply Emittercontact Fig. 4. Diagram o f a solar cell sample m o u n t e d on TO-5 header for EBIC and electrical characteristic measurements. Fig. 5. Cell sample biasing and a.c. coupling n e t w o r k used for EBIC investigations. 341 secondary electron (SE) imaging, and any defects thus located were subjected to X-ray microanalysis to identify the elements present. 3.2. Electrical measurements The temperature dependencies of the I - V characteristics of twelve samples from the same cell were measured to identify the dominant breakdown mechanism. Nine samples contained points of visible light emission, while three emitted no light for reverse biases up to --40 V. In addition, two voltage regulator diodes were used as references for these measurements. The breakdown voltages of these diodes w e r e - - 2 . 7 V (dominated by Zener breakdown) and --10.0 V (dominated by avalanche breakdown). I - V characteristics were measured using the experimental set-up of Fig. 6. Samples were placed inside a small climatic chamber, whose temperature could be varied from --40 °C to 120 °C. Ten samples were plugged into TO-5 sockets mounted on a printed circuit board inside the chamber. A switchboard outside the chamber selected samples for measurement. Sample I - V characteristics were measured over the temperature range from --30 °C to 110 °C, at 20 °C intervals. The chamber temperature was monitored by using a platinum resistance thermometer placed amongst the samples. To prevent sample heating, fast (70 Hz), single, triangular voltage pulses were used to sweep sample I - V characteristics. The voltage pulse amplitude was 20 V, from +5 V to --15 V. The voltage drops across the sample, and across a precision resistor (mounted on the switchboard outside the chamber) were measured by a Krenz TRC-4010 transient recorder, and transferred to a Hewlett-Packard HP-9816 personal computer over the IEEE-488 interface. The computer plotted the measured I - V curves, and prepared graphs of breakdown voltage temperature dependence. The temperature dependence plots were obtained by defining a current value, and interpolating the cotClimatic chamber Sweep generator Pt- 100 resistance thermometer Fig. 6. Experimental set-up used for measuring temperature dependencies of cell sample electrical characteristics. 342 responding voltage value from the measured I - V curves. These voltages were then plotted against the temperatures at which the curves were recorded. 4. Results and discussion 4.1. Observations o f reverse biased solar cells The first evidence for the connection between hot-spots in solar cells and microplasma breakdown was obtained during IR observations of discrete cells reverse biased by a bench power supply. All cells were m o u n t e d on a copper vacuum block, acting as a heatsink. Figure l(a) shows the temperature distribution on a reverse biased (--25 V), 10 cm diameter monocrystalline silicon solar cell. Power dissipation is greater along the right hand edge of the cell, and is concentrated in the lower right hand quadrant, beneath the cross-hair. Figure l ( b ) is a closeup of this region. It should be noted that the apparent coolness of the cell contacts, which must be at the same temperature as the underlying silicon, is merely due to their lower IR emissivity. Similarly, the cell circumference appears cooler than the rest of the cell because the antireflection coating is absent, and hence the emissivity changes. The light emission pattern from this cell is shown in Fig. l(c). This pattern was photographed using Polaroid 20000 ASA trace recording film, at an exposure time of 30 s, with maximum aperture. Comparison with Fig. l(a) shows that the position of the hot-spot coincides with the largest concentration of light emitting points. Figure l ( b ) reveals a one-to-one correspondence between points of light emission and local heating. 4.2. Scanning electron microscopy studies o f solar cell samples Some forty samples from five different cells were prepared for scanning electron microscopy studies. The micrographs presented here are all from samples of the cell depicted in Fig. 1, since these were also used in the electrical measurements described in the next section. The defects described here are similar to those observed in other cells. Figures 7(a) and 7(b) are EBIC images of sample 1 at reverse biases of --2 V and --4 V respectively. Sample 1 was obtained from the hot-spot in the lower right hand quadrant of Fig. l(a), and contains the pair of light emitting points visible in the lower right-hand quadrant of Fig. l ( b ) . These t w o points actually consist of five smaller points. The dark spots in Fig. 7(a) are due to local reductions of the EBIC signal, and indicate points of high recombination. EBIC enhancement occurs at --4 V reverse bias, producing the bright region in the centre of Fig. 7(b). This effect is due to local current multiplication, typical of microplasma breakdown. The bright line traversing the micrograph is due to a current noise pulse. At --2 V reverse bias, no current multiplication occurs, and a 343 (a) (b) (c) Fig. 7. Scanning electron micrographs o f cell sample 1 : (a) EBIC m o d e , reverse bias --2 V, beam voltage 30 kV; (b) EBIC mode, reverse bias --4 V, beam voltage 30 kV; (c) SE mode, beam voltage 30 kV. point of reduced EBIC, apparently identical with all the other dark points, is observed, Fig. 7(a). The electron beam travels from right to left in all the micrographs. During photographic recording, the beam scan rate is 25 lines per second. EBIC enhancement therefore occurs at a rate of 25 Hz, and this c o m p o n e n t of the EBIC signal was differentiated by the capacitive coupling network, producing the light-dark contrast. Figure 7(c) is an SE image of the same area shown in Figs. 7(a) and 7(b). EBIC enhancement was centred on the pit near the centre of Fig. 7(c). Electron probe microanalysis of the pit, and its surroundings, only detected silicon. It should be noted how the surface topography shown in the SE images is visible in the EBIC images. Figures 8(a) and 8(b) are SE images of another EBIC enhancing defect in sample 2. The t w o parallel lines running diagonally across Fig. 8(a) are the edges of a plated nickel grid contact finger. Evidently, only the edges of the grid finger were in good contact with the underlying silicon. EBIC enhancem e n t was centred a b o u t the pit shown in detail in Fig. 8(b), and visible near 344 (a) (b) Fig. 8. Scanning electron micrographs of cell sample 2 : (a) SE image, beam voltage 30 kV, showing remains of grid finger contact; (b) SE image, beam voltage 30 kV, clase-up of pit causing EBIC enhancement. Fig. 9. Scanning electron micrograph of cell sample 3, SE image, beam voltage 30 kV, showing EBIC enhancing defect contaminated with foreign material, identified by microanalysis as nickel. the centre o f Fig. 8(a). Despite the location of this pit, beneath the grid c o n t a c t finger, microanalysis only d e t e c t e d silicon. Several EBIC enhancing defects appeared to be pits decorat ed with a foreign material, Fig. 9. In this case, microanalysis identified the foreign material as nickel. 4.3. Electrical measurements on solar cell samples The capacitive coupling n e t w o r k used in the EBIC investigations prevented quantitative electrical measurements (e.g. variation of current multiplication factors with reverse bias, microplasma noise measurements etc.) f r o m being made with the EBIC det ect i on system. Detailed electrical measurements were t h e r e f o r e p e r f o r m e d outside the SEM. The reverse characteristics (and t e m p e r a t u r e dependencies) of the voltage regulator diodes are shown in Figs. 2 and 3. The curves in Fig. 2 are typical o f Zener b r e a k d o w n (breakdown voltage decreases with 345 increasing temperature [25, 26]); while those of Fig. 3 are typical of avalanche breakdown (breakdown voltage increasing with temperature [11, 25]). The reverse characteristics of the cell samples discussed in Section 4.2 are shown in Figs. 10 - 12. Quite different behaviour was shown b y samples w i t h o u t microplasmas, see Fig. 13. The V - T plots in Figs. 10 - 12 are almost horizontal (i.e. insensitive to temperature changes) over most of t h e measured temperature range (243 - 383 K), tending to slope upwards at the higher temperatures. This implies that the electrical characteristics of samples containing microplasmas are insensitive to temperature changes. By contrast, the electrical characteristics of samples w i t h o u t microplasmas are highly temperature sensitive. These observations may be explained as follows. In the absence of microplasmas, the current flowing under reverse bias is the junction reverse saturation current, I0, which through its dependence on the intrinsic carrier density, ni 2o: T3exp(E,JkT), increases with temperature. When microplasmas are present, the reverse current is the sum of t w o components: (1) the junction reverse saturation current I0; (2) the excess leakage current generated by the defect Iex. If _rex is greater than I0, the temperature dependence of the electrical characteristic is determined b y the process generating I~x (Zener or avalanche breakdown). Above some critical temperature, I0 becomes greater than I ~ , and dominates the electrical characteristic from then on. Thus, avalanche breakdown determines the reverse characteristic of sample 2 I~plled -L2.8 Vol~qe -LII.B Sfloctmln Tompertture (V) -0.3 -S.il -4.1l -2.1l 378.8 308. a 338.8 368. O [K] 393.8 -3.8 -S.8 -9.8 -12.1 Rppllsd Voltqe (V] -IS.g (a) -Im T = 2 4 3 K ~ T - 233 K ~" Z - -t8.8 ~ ~ Z = -0.8 O T - 203 K X T - 383 K O ! - -G.a ndq X I " -4,8 A T - 323 K E] T - 343 K /% Z - -2.8 IIR O T - 3G3 K 88 T - 383 K ~q (b) Fig. 10. Electrical measurements on sample 1, containing five microplasmas, visible from --6 V, see also Fig. 7: (a) electricalcharacteristics;(b) temperature dependence of breakd o w n voltage. 346 Rpplled Voltage -7.5 Temperature ~gCliUfl [V] -tO.g -3.g 2FO,O -2.5 338,8 330.0 [K] 3GB.O 398.8 -g.O -12.0 -15,B "~pllod Voltage IV3 -7.5 ~" T - 243 K )~ T " 263 K + mR ~ I - -£.3 mR O T - gg3 K X T m 333 K O I - -5,8 mR X I " -3.5 mR T - 323 K [] T - 343 K A I - -3.g mR T = 383 K ~ T " 333 K O (a) I - -g.a (b) Fig. 11. Electrical measurements on sample 2, containing one microplasma, visible from --6 V, see also Fig. 8: (a) electrical characteristics; (b) temperature dependence of breakd o w n voltage. Rpplted Voltqe -IZ.O -18.8 (v3 -9.0 Spe©lmen T e e p e e | t a r e -G,g -4.0 -2.0 27B.8 3EE.E 330.0 3GELO (K] 390.8 -3.0 -S.e -3. O -L2,B S p e c l m l n Cu rr• n t (mR] App q -t5.O ~- T - 243 K ~( T - g63 K -~ I O T - 293 K X T " 303 K O I - - G . E mR T - 323 K [] T - 343 K Z~ I - -2.8 T " 3G3 K 58 T - 383 K ~> (a) = -lO.8 mA ~ I - -8.8 ~R X I " -4.8 air mR (b) Fig. 12. Electrical measurements on sample 3, containing one microplasma, visible from --11 V, see also Fig. 9: (a) electrical characteristics; (b) temperature dependence of breakdown voltage. 347 RppIled -12.0 Voltlllle -10.0 Splcllln CV) -II. II "G. II -'1.0 .|.n .... , .... 278.B , .... , .... 3OO.O , .... , .... TlIplP|tuel 338.0 , .... , .... 3U,! , .... [K] , .... 3H.0 -3.B -6. g -9. B -12.8 -15.II ~pllod Voltage (V] "I- T - 2#:3 K ~ T " 2B3 K + ! - -10.g mR ~ I - -8,g m~q 0 T " i~O3 I~ X T - 383 K O I - -G.0 mR X I = -4.B mR /% T - 323 K [] T - 343 K A I - -2.g mR 0 T - [] T - 363 K 303 K (a) (b) Fig. 13. Electrical measurements on a sample free of microplasmas, with no visible light emission up to --40 V reverse bias. The marked temperature dependence should be noted: (a) electrical characteristics; (b) temperature dependence. up to approximately 360 K, see Fig. 11, and of sample 3 up to approximately 320 K, see Fig. 12. 5. Conclusions The experimental evidence accumulated during this work shows that microplasma breakdown causes hot-spot formation in reverse biased solar cells. The defects exhibiting microplasma behaviour were pits in the cell surface, occasionally contaminated with metals used to fabricate the cell contacts. This study was performed on commercially produced cells, and since manufacturers were reluctant to divulge the details of their cell fabrication processes, it is only possible to speculate on the origin of these defects. However, since all the cells studied were produced from ingot technology silicon, the pits in the silicon surface m a y be due to sawing damage, incompletely removed b y the etching step performed prior to junction diffusion. If this is the case, then more careful wafer preparation will eliminate these particular defects. However, solar cells, owing to their size, will inevitably contain defects; and microplasma behaviour is k n o w n to occur at several types of defect. Thus, the elimination of one t y p e of defect will n o t prevent hot-spot formation in solar cells, although it will improve cell 348 performance by reducing the number of recombination centres and increasing the cell shunt resistance. A high shunt resistance is of questionable value when considering the effects of mismatched cells on array performance [1 ]. A mismatched cell with a large shunt resistance acts as a large internal load, reducing the power delivered by the array to its application load, while dissipating power within the array. With a better understanding of the origin of cell defects, and of their electrical effects, it may prove possible to control cell reverse characteristics through control of defect densities, without sacrificing cell performance. Bypass diodes would then be unnecessary, reducing module costs, while improving reliability. Acknowledgments This study of the microscopic processes involved in hot-spot heating in photovoltaic cells was conceived by Dr. K. Krebs of CEC JRC Ispra and Dr. D. B. Holt of Imperial College, London University. I wish to thank Dr. E. Napchan of Imperial College for his advice on the detection of microplasmas, and Dr. H. Ossenbrink, and Mr. W. Zaaiman, of CEC JRC Ispra for their help in the electrical measurements. References 1 J. W. Bishop, Computer simulation of the effects of electrical mismatches in photovoltaic cell interconnection circuits, Sol. Cells, 25 (1988) 73. 2 F. A. Blake and K. L. Hanson, The 'hot-spot' failure mode for solar arrays, Proc. 4th Intersociety Energy Conversion Engineering Conf., Washington, September, 1969, American Institute of Chemical Engineers, New York, p. 575. 3 Qualification Tests for PV Modules: Spec. No. 502, Issue 1, Report EUR 9414 EN, 1984 (Commission of the European Communities Joint Research Centre, 21020 Ispra). 4 H. Kressel, A review of the effect of imperfections on the electrical breakdown of p - n junctions, RCA Review, 28 (1967) 175. 5 K. V. Ravi, Imperfections and Impurities in Semiconductor Silicon, Wiley, New York, 1981. 6 N. Klein, Electrical breakdown in solids, Advances in Electronics and Electron Physics Vol. 26, Academic Press, New York, 1969, p. 309 - 424. 7 H. S. Rauschenbach and E. E. Maiden, Breakdown phenomena in reverse biased silicon solar cells, Proc. 9th IEEE Photovoltaic Specialists' Conf., Silver Springs, FL, May 2 - 4, 1972, IEEE, New York, 1972, p. 217. 8 M. S. Tyagi, Zener and avalanche breakdown in silicon alloyed p - n junctions I: Analysis of reverse characteristics, Solid State Electron., 11 (1968) 99. 9 S.M. Sze, Physics o f Semiconductor Devices, Wiley, New York, 1981. 10 S. M. Sze and G. Gibbons, Avalanche breakdown voltages of abrupt and linearly graded p--n junctions in Ge, Si, GaAs, and GaP, Appl. Phys. Lett., 8 (1966) 110. 11 C. R. Crowell and S. M. Sze, Temperature dependence of avalanche multiplication in semiconductors, Appl. Phys. Lett., 9 (1966) 242. 12 D. J. Rose, Microplasmas in silicon, Phys. Rev., 105 (1957) 413. 349 13 K. G. McKay, Avalanche breakdown in silicon, Phys. Rev., 94 (1954) 877. 14 A. G. Chynoweth and K. G. McKay, Photon emission from avalanche breakdown in silicon, Phys. Rev., 102 (1956) 369. 15 A. G. Chynoweth and G. L. Pearson, Effect of dislocations on breakdown in silicon p - n junctions, J. Appl. Phys., 29 (1958) 1103. 16 H . J . Queisser and A. Goetzberger, Microplasma breakdown at stair-rod dislocations in silicon, Philos. Mag., 8 (1963) 1063. 17 A. Goetzberger and W. Shockley, Metal precipitates in silicon p - n junctions, J. Appl. Phys., 31 (1960) 1821. 18 A. Goetzberger, B. McDonald, R. H. Haltz, R. M. Scarlett, Avalanche effects in silicon p - n junctions. II. Structurally perfect junctions, J. Appl. Phys., 34 (1963) 1591. 19 A. Goetzberger and R. H. Finch, Influence o f mechanical damage on avalanche breakdown in silicon p - n junctions, Solid State Electron., 7 (1964) 543. 20 M. Lesniak and D. B. Holt, Defect microstructure and microplasmas in silicon avalanche photodiodes, J. Mater. Sci., 22 (1987) 3547. 21 D. B. Holt, Quantitative Scanning Electron Microscopy, Academic Press, New York, 1974. 22 J. F. Bresse, Quantitative investigations in semiconductor devices by electron beam induced current, Scanning Electron Microsc., I V (1982) 1487. 23 H. J. Leamy, Charge collection scanning electron microscopy, J. Appl. Phys., 53 (1982) R51. 24 M. Lesniak, B. A. Unvala and D. B. Holt, J. Microsc., 135 (1984) 255. 25 M. S. Tyagi, Zener and avalanche breakdown in silicon alloyed p - n junctions II: Effect of temperature on the reverse characteristics and criteria for distinguishing between the two breakdown mechanisms, Solid State Electron., 11 (1968) 117. 26 A. G. Chynoweth and K. G. McKay, Internal field emission in silicon p - n junctions, Phys. Rev., 106 (1957) 418.