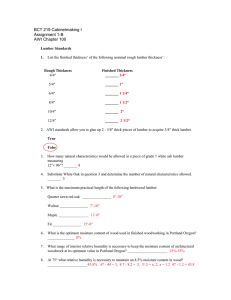

ACQ-Treated Lumber LCA

advertisement