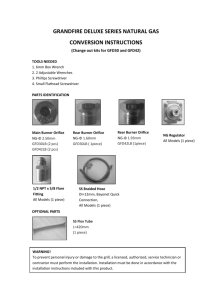

Notice to Installer

advertisement

IMPORTANT THlS GAS APPLIANCE USES A 9 VOLT BATTERY FOR IGNITION. ONE WAS NOT SUPPLIED WlTH THlS UNIT. FOR BEST RESULTS USE A QUALITY ALKALINE BATTERY SUCH AS DURACELL BRAND AND CHECK CONDITION OFTEN. PLEASE REFER TO OWNERS MANUAL FOR CORRECT INSTALLTION PROCEDURE. CORRECT IGNITION DEPENDS ON PROPER ELECTRODE TO BURNER ADJUSTMENT. THlS ADJUSTMENT WAS PRESET AND TESTED AT THE FACTORY, MISALIGNMENT MAY HAVE OCCURED DURING SHIPPING. REFER TO OWNERS MANUAL FOR CORRECT ADJUSTMENT. KEEP BURNER AND ELECTRODE TIP CLEAN TO ENSURE CONSISTENT BURNER IGNITION. TURN ALL BURNERS ON HIGH FOR SEVERAL MIN. WHEN FINISHED COOKING TO BURN OFF EXCESS GREASE. CLEAN ELECTRODE TIP AND BURNER LIGHTLY WlTH SAND PAPER IF IGNITION DOES NOT OCCUR. USE LARGE DIAMETER GAS SUPPLY LINE TO AVOID LINE LOSS DUE TO LONG RUNS. REDUCE AT APPLIANCE MANIFOLD. REGULATE GAS PRESSURE TO 7" W.C. FOR NATURAL GAS AND 11" W.C. FOR L.P A NOISEY VALVE OR REDUCED B.T.U./HR. MAY RESULT FROM UNDERSIZED SUPPLY LINE. THlS GAS APPLIANCE NO LONGER USES THE CERAMIC BRIQUETTES AND BRIQUETTE GRATES AS SHOWN IN THE OWNERS MANUAL (PAGES 12,16,& 20). THESE ITEMS HAVE BEEN REPLACED WlTH A STAINLESS STEEL, TWO TIERED HEAT SHIELD AND REPLACES PART NUMBERS 28-003,28-004,36-003, 36-004, 44-003, AND 44-004. NOTICE TO INSTALLER INSTALLER PLEASE LEAVE THlS NOTICE, OWNERS MANUAL AND WARRANTY CARD WlTH OWNER. THlS GAS APPLIANCE WAS SUPPLIED WlTH AN IN LINE GAS REGULATOR. NEVER MOUNT REGULATOR IN GRILL CHASSIS OR IN A LOCATION THAT MAY BE SUBJECT TO EXCESSIVE HEAT. THlS REGULATOR IS NOT CONVERTIBLE. ALWAYS MAKE SURE REGULATOR PRESSURE CORRESPONDS WlTH GRILL WORKING PRESSURE. 11"W.C. FOR L.P. AND 7"W.C. FOR NATURAL GAS. DO NOT USE THlS REGULATOR IF AN L.P. GRILL IS TO BE MOUNTED TO AN L.P. MOBILE CART (MODELS SGC-28/MC, SGC-36/MC, AND SGC-44/MC) AND A PORTABLE L.P. TANK IS TO BE USED. USE L.P. REGULATOR SUPPLIED WlTH MOBILE CART. REMOVE ALL PACKING MATERIAL ( PVC, STRAPING, AND FOAM ) BEFORE INSTALLATION AND USE. ESPECIALLY FOAM THAT IS LOCATED INSIDE UNIT SlDE BURNER BETWEEN SlDE BURNER PIPING AND BURNER BRACKET (MODELS SGC-16, AND SGC-44 ONLY) APPLICATION INSTRUCTIONS FOR SUPPLEMENTARY CONTROL PANEL LABELING MODELS #SGC-16, SGC-28, SGC-36, AND SGC-44 STEP 1. REMOVE BURNER CONTROL KNOBS. STEP 2. REMOVE BURNER CONTROL KNOB BEZELS WlTH #2 PHILLIPS SCREW DRIVER. STEP 3. REMOVE ALL LOOSE OR FLAKING LETTERING. STEP 4. CLEAN ALL GREASE AND DIRT FROM CONTROL PANEL USING WINDEX AND WlPE DRY. STEP 5. APPLY WINDEX LIBERALLY TO CONTROL PANEL (DO NOT WlPE DRY) STEP 6. PEEL BACKING FROM LABEL AND POSITION LABEL ON CONTROL PANEL. STEP 7. USING PLASTIC CREDIT CARD, PUSH EXCESS AIR BUBBLES AND WINDEX TO THE OUTER EDGES OF LABEL, WlPE DRY. STEP 8. PIERCE SCREW HOLES IN LABEL WlTH PEN TIP OR SHARP OBJECT. STEP 9. REPLACE CONTROL KNOB BEZELS AND CONTROL KNOBS. REMOVAL & INSTALLATION INSTRUCTIONS FOR TUBE BURNERS: STEP 1. WlTH HAMMER AND COLD CHISEL SNAP BURNER TUBE MOUNTING SCREW HEAD OFF AND REMOVE BURNER (REMAINING SCREW CAN BE PUNCHED OUT WlTH HAMMER). STEP 2. CLEAN BURNER MOUNTING SCREW HOLE OF ANY REMAINING SCREW PARTICLES. NOTE: BURNER TUBE MOUNTING HOLES MAY NEED TO BE RETAPED. USE 10-24 TAP. STEP 3. INSTALL NEW BURNERS MAKING SURE THAT THE GAS VALVE HOOD FITS INTO THE END OF THE BURNER. STEP 4. REINSTALL SCREWS WlTH #2 PHILLIPS SCREW BIT. STEP 5. TEST FIRE GRILL.