Structural statics and dynamics on axial fan blades - TLT

advertisement

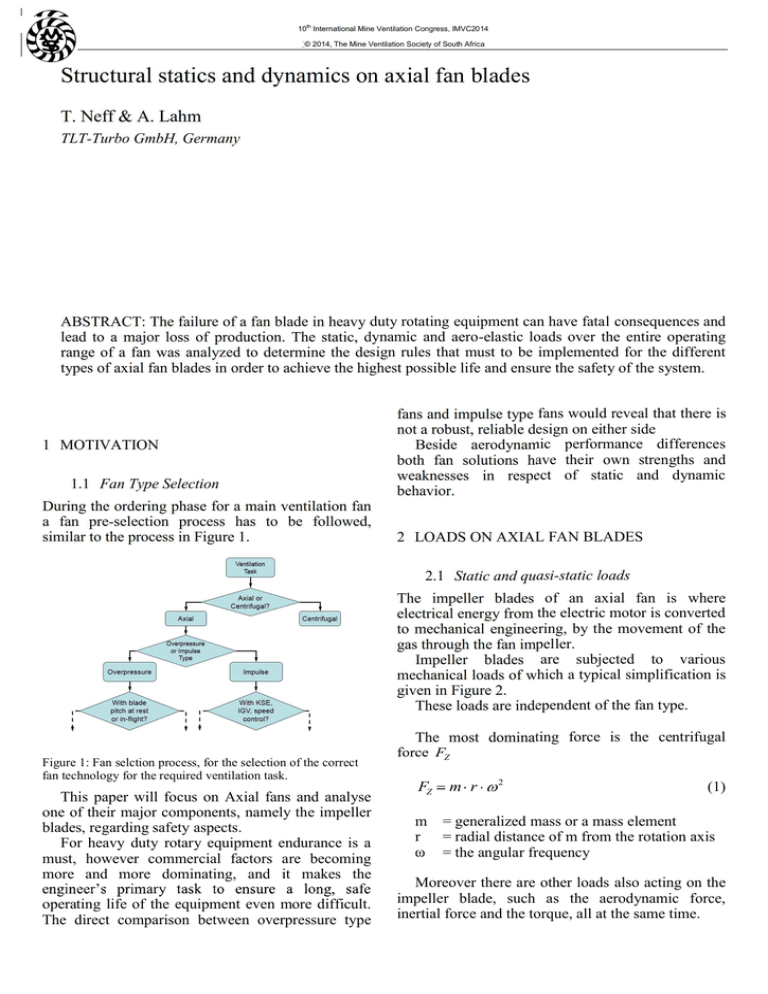

10th International Mine Ventilation Congress, IMVC2014 `© 2014, The Mine Ventilation Society of South Africa Structural statics and dynamics on axial fan blades T. Neff & A. Lahm TLT-Turbo GmbH, Germany ABSTRACT: The failure of a fan blade in heavy duty rotating equipment can have fatal consequences and lead to a major loss of production. The static, dynamic and aero-elastic loads over the entire operating range of a fan was analyzed to determine the design rules that must to be implemented for the different types of axial fan blades in order to achieve the highest possible life and ensure the safety of the system. 1 MOTIVATION 1.1 Fan Type Selection During the ordering phase for a main ventilation fan a fan pre-selection process has to be followed, similar to the process in Figure 1. fans and impulse type fans would reveal that there is not a robust, reliable design on either side Beside aerodynamic performance differences both fan solutions have their own strengths and weaknesses in respect of static and dynamic behavior. 2 LOADS ON AXIAL FAN BLADES 2.1 Static and quasi-static loads The impeller blades of an axial fan is where electrical energy from the electric motor is converted to mechanical engineering, by the movement of the gas through the fan impeller. Impeller blades are subjected to various mechanical loads of which a typical simplification is given in Figure 2. These loads are independent of the fan type. Figure 1: Fan selction process, for the selection of the correct fan technology for the required ventilation task. This paper will focus on Axial fans and analyse one of their major components, namely the impeller blades, regarding safety aspects. For heavy duty rotary equipment endurance is a must, however commercial factors are becoming more and more dominating, and it makes the operating life of the equipment even more difficult. The direct comparison between overpressure type The most dominating force is the centrifugal force FZ FZ m r m r 2 (1) = generalized mass or a mass element = radial distance of m from the rotation axis = the angular frequency Moreover there are other loads also acting on the impeller blade, such as the aerodynamic force, inertial force and the torque, all at the same time. 10th International Mine Ventilation Congress, IMVC2014 © 2014, The Mine Ventilation Society of South Africa fn,j = j n / 60 j = rotational multiples (3) In case the structural elements in front of the impeller that are not equally distributed, each i leads to a frequency fsup,i fsup,i i i Figure 2. Typical load vectors representing the static and dynamic forces on an axial fan blade during operation. As the impeller blades are typically twisted for aerodynamic efficiency improvements, not all of the blade mass is concentrated on a single plane or a central axis. It is due to these offset masses that additional inertial forces subsequently increasing the internal blade material stresses. The aerodynamic forces are initiated by the pressure distribution at the airfoil. They can be fractionalized into a circumferential part, acting against the rotation and a tangential part, acting against the direction of flow. For more details, see Eckert&Schnell (1980). 2.2 Dynamic Loads In order to keep the hub in it s place in many cases, it cannot be avoided that structural support ribs are placed upstream of the fan impeller. Depending on the form and thickness of the support ribs, the intensity of vortices and wake turbulences downstream will vary. Each impeller blade with its own natural frequencies fbl,i will be subjected to various other disturbances, within a single rotation of the impeller blade. This blade passing frequency fpass is the most important one fpass = Zbl n / 60 (2) Zbl = number of rotor blades n = rotations per minute. Another important and powerful excitation is the rotational speed and its multiples fn,i i n / 60 (4) = angle between two structural elements = consecutive number The downstream static guide vanes are also a source for generating vibrational excitations within the rotating blades, typically these guide vanes are equally spaced and the excitation frequency due to these guide vanes fgv can be described as: fgv = Zgv n / 60 (5) where: Zgv is the number of guide vanes Furthermore the electrical power supply frequency fel and 2 fel shall be checked for resonances with fbl,i, too. It is the challenging task of the blade design engineer to ensure that: fbl,i pass n,i fsup,i gv el fel (6) To ensure that the above equation (6) holds true the blade stiffness can be altered. It is therefore advisable not only to tailor the blade from root to top according to stress calculations, but moreover to also increase the thickness locally that will have an influence on the blade stiffness. A blade with a high stiffness will have a high natural frequency and vice versa. What is the magnitude of stresses at the rotating blades, caused by aerodynamic excitation from structural support elements upstream and downstream of the impeller? As shown by Staiger (1991) the stress amplitudes can be considerably high and careful positioning can improve the load situation of the impeller significantly. The blades of an axial test rotor, with 12 blades were equipped with strain gauges and the influence of different strut configurations on the blade stresses were tested. In the worst case, the comparison between no struts and three equally distributed, radial struts of cylindrical shape gave a stress amplification factor of eight. 2 10th International Mine Ventilation Congress, IMVC2014 © 2014, The Mine Ventilation Society of South Africa When a fan is operated in conditions the gas might contain elements which may cause abrasion and adhesion effects on the impeller blades. Abrasion is the removal of original blade material (weight reduction) by the working gas while adhesion is increasing the blade mass due to particles in the working gas sticking to the original blade material. Both abrasion and adhesion will alter the natural frequency of the blades and can cause unwanted resonances additional to the original designed resonances. To complete the picture regarding important loads on axial fan blades, the driving torque variances have to be mentioned as well. These torque forces act as foot excitations to the blades and should not coincide with the natural blade frequencies. When a variable speed drives is used, the pulsations in rotational speed can correlate with e.g. the torsional resonance of the motor / fan impeller system. This could increase the amplitudes of the above mentioned blade foot excitations. It is however very unlikely that the blade will fail earlier than the shaft system. one value per section - the maximum of stress or strain. Other methods like FEA can be used when stress distribution details are essential. This would also enable stress values to be for any point on the relevant component. Figure 3. Sketch about sections (A-A I-I) for conventional blade calculation 3.2 Determination of natural frequencies 3 DESIGN RULES 3.1 Conventional engineering approach Three decades ago, when computers and Finite Element Analysis (FEA) tools were much less powerful than today, the engineers had to simplify complex blade geometry in order to calculate the various blade stresses. The sectional approach the most common calculation method during that time. This method is still in use today. The blade is split from foot to tip into portions (Fig 3) and each of these is loaded according to its radial position. While at the base (AA) the centrifugal forces of all elements above are responsible for the sectional stresses, at the top (HH) there is only the element itself that contributes to the load. In case the blade has a circular foot to be connected to the impeller, it can be assumed that within an angle of 45° the flux of force is developing. Accordingly, the loaded section is reduced (Fig 3, A-A, B-B and C-C). By approximation, the section modulus can be derived from the geometry together with the bending moment, the bending stresses per section can be superimposed to the tensional stresses. Usually von Mises combined stresses are compared with the selected material properties. This kind of conventional stress calculation develops only Most ambitious was - and still is - the estimation of the blade natural frequencies. The influence of the supporting structure and consequently the fixing of the impeller blade to the hub is essential. Blade to shaft connection Figure 4: Typical impeller of a blade pitch axial fan with the pivot-mounted blade shaft and the bolted connection to the blade It is obvious that a bolted blade (Fig 4) will behave different from a welded blade (Fig 6). Nevertheless the bolted connection is also very rigid during operation when the very high centrifugal 3 10th International Mine Ventilation Congress, IMVC2014 © 2014, The Mine Ventilation Society of South Africa force FZ stiffens the angular ball bearing of the blade shaft to a remarkable extent. For a fan impeller of Ø3.7m and operated at 750rpm, FZ of one single casted steel blade can reach values of 350kN or even more. In the case of individually mounted blades, measurements of natural frequencies can be conducted on a workbench. The blade is bolted on a big mass when a hammer is used to excite an oscillation and a vibration pick-up sensor records the response. If the measured natural frequency would coincide with one of the possible excitation frequencies, the blades would need a tuning e.g. by mass reduction (grinding, drilling holes from the blade tip), leading to a higher natural frequency. This method allows only small steps in the range of up to 5Hz. When measured frequencies are compared to the calculated excitations during operation, the stiffening influence of the centrifugal force must be considered. More details about the analytical calculation are given in Traupel (1982). It might be a challenging task to find suitable blade dimensions, especially for the first three natural frequencies of the rotating blade fbl,1, fbl,2 and fbl,3 so that no concord with the known excitations (see section 2.2) exists. Figure 5 illustrates it graphically. Figure 5. Graphical overview of possible blade excitation frequencies and the first 3 blade natural frequencies (example). Conservative, safe intervals between fbl,1, fbl,2 and fbl,3 to some of the important excitation frequencies are given in Table 1. Table 1. Recommended safety margin between first three blade natural bending frequencies and selected excitations. fn1 % +30 fn2 % ±20 fn3 % ±10 fsup,i % ±15 fpass % ±10 The analytical calculation of blade frequencies requires a lot of experience and tests for method verification. But there is no compromise possible when safety is of the essence. The impeller of an axial impulse fan (Fig 6) is a completely welded structure and its dynamical behaviour can be compared to that of means, that there is one very dominant base mode which even with a strong punch can be excited, leading to an audible tone. Hub Blades Figure 6. Typical impeller of a mixed flow fan with welded blade to hub connection. And there are the harmonics where packages of blades together are moving contrary to other packages. Although this fan type is commonly known as robust and easy to handle, care has to be taken to avoid any kind of excitation, which may lead to fatigue cracks, Section 5 describes impulse impellers in greater detail. Blade flutter is a serious concern which has to be addressed by the blade engineer as well. This aero-elastic phenomenon is especially critical for long, slender, thin blades. By altering the blade geometry, e.g. the blade thickness in the root portion of the blade, the blade stiffness will be increased and blade flutter would be minimized or avoided all together. 3.3 State of the art calculations The state of the art method for the determination of blade natural frequencies is using F.E.A. simulation software, which is an integrated part of modern, three dimensional mechanical design software. The F.E.A method is an appropriate way to get numerical and animated results regarding various vibrational modes of the blade under investigation. Figure 7 shows typical results of a FEA simulation for a fan blade, where different colors indicate the displacement at the given natural frequency, at various point on the blade surface. When applying the operation loads on the blade, the same model can be used for stress determination as well. 4 10th International Mine Ventilation Congress, IMVC2014 © 2014, The Mine Ventilation Society of South Africa influence the required safety factor include, but are not limited to: material of construction, the quality of surface, the ductility of the blade material, the operation temperature of the fan and the gas quality. Typical values of safety factors against mechanical yield point can vary from 2.0 to 3.0, but may be increased subject to the above mentioned factors. 3.5 Manufacturing boundaries and restrictions While the blade of a mixed flow fan usually is fabricated from a single thickness, formed steel plate, the manufacturing of an airfoil profile of an overpressure fan is usually more complex. There are numerous fabrication methods available for the manufacturing of impeller blades, however a detailed discussion regarding these processes would fall outside the scope of this paper. The preferred method of fabrication for airfoil blades of heavy duty fans would be casting, forging or hot forming. These casted or forged blades must be accurately machined after casting and various quality checks must be performed to verify that the blades are acceptable. 4 QUALITY REQUIREMENTS 4.1 Welded parts Figure 7. Examples of first 3 natural frequency modes with and without the influence of centrifugal force. Red color = largest displacements Impellers of mixed flow fans as well as some small axial fan impellers have their blades directly welded to the hub. This crucial connection should be done with the highest care and checked with the same care afterwards. The quality of the welding seams must be specified and evaluated according to ISO 5817 Group B or another comparable welding standard. Irregularities such as excessive peaking, linear offset or spatters must be avoided at all cost. Regardless of the welding standard utilized a visual inspection followed by a non-destructive (ND) test procedure should be employed to determine any hidden failures (e.g cracks). 4.2 Casted pieces 3.4 Safety factors In order to make fans cost effective, high tip speeds of 190 m/s and even higher are desired. Blade mechanical design limits are defined by the material properties in combination with the necessary safety factors. Each fan supplier may have its own philosophy regarding the required safety factors which would be applied to the blade design.. Other important factors that would typically be considered and which would Typically larger blades are more difficult to cast without flaws. Large casted blades, regardless whether they are made from aluminum, steel, or cast iron should therefore always be subjected to intensive testing. The test methods are defined by the relevant original equipment manufacturer inspection plan may prescribe that from each casting batch at least one blade should be tested with 5 10th International Mine Ventilation Congress, IMVC2014 © 2014, The Mine Ventilation Society of South Africa destructive methods to confirm the correctness of the material properties, both chemical and mechanical. Visual inspection, dye penetrant or magnetic particle testing is the first choice here due to the relative low cost. Cavities, cracks and other irregularities must however be ruled out by additional ND-testing on each blade. On thick section blades it is also worthwhile to employ radiographic or ultrasonic testing procedures as these methods are able to detect failures deep within the material structure. Figure 8 shows an example. there is a high load of acid-forming contents together with moderate amount of medium-sized particles in the air, stainless steel with leading edge protectors would usually be a good choice to maintain the expected lifetime of the impeller blades. However if this crucial step is misinterpreted by the fan engineer, or in-sufficient details from the end user were received, the wear protection might not selected correctly the predicted blade lifetime will be dramatically reduced. Even small defects, which are tolerable during the quality assurance process, will very quickly develop into larger cracks or craters and the blade may fail prematurely. 4.4 Operational experience 4.4.1 Mixed flow fans Figure 8. Colored blade foot regions for zones, indicating different quality requirements (red = higher; green = lower). For each of the sections the blade design engineer has to find the best compromise between acceptable failure sizes and the risk of a blade failure during operation. 4.3 Material selection Mine ventilation is one of the most complex applications in terms of fan blade material selection. In order to achieve long life-cycles, operational considerations regarding gas quality (dusty or abrasive) as well as mechanical considerations have to be made. Dust load and humidity, together with the underground and surface temperature conditions may cause serious problems for the durability of the blades. At worst, the blade material will be subjected to not only particle impacts, but also chemical erosion may occur, by the formation of acids due to the presence of various corrosive elements in the process gas. Due to the variety of mines and the specific operating conditions of each mine, there is no general applicable wear protection method, the selection of a suitable wear protection system is done on a case by case study, which takes into account the specific details for every mine site. This first step in selecting the appropriate surface protection is in the correct selection of a blade base material. Aluminum, SG iron, stainless steel and composite materials are all proven on mining fans. Depending on the primary threat, the base material should be selected and an additional protective coat has to be applied. For example if In Section 3.2 it was mentioned that the operating conditions and the built-in situation has to be considered in order to avoid damages. At low volume flows when the inlet guide vanes are nearly closed, mixed flow fans can deliver only low pressure. The stall line is low and during start-up or part load conditions the operating points may cross that line (Fig 9a). The impeller will subject to severe resonances during this time, and continued operation within the stall zone may lead to premature impeller failure, concentrated at the welds between the impeller blade and hub, due to fatigue cracks caused by the resonance. The installation of a performance curve stabilization ring can raise the stall line at low flow volumes and avoid such dangerous difficulties (Fig 9b). Figure 9. Comparison of mixed flow fan without (9a) and with (9b) performance curve stabilization. As shown by Maddox (1991) there are important features of welds in relation to fatigue. The difference between welded and unwelded materials is significant in respect of endurance and fatigue limits. Maddox (1991) showed that for a BS 4360 6 10th International Mine Ventilation Congress, IMVC2014 © 2014, The Mine Ventilation Society of South Africa Grade 50B steel specimen the stress range for 106 cycles is approx. 300 MPa. When at an equivalent specimen additional material is welded from both sides, the stress range drops down to 100 MPa. At 107 cycles the ratio becomes even worse, namely 270/45. Consequently the quality acceptance have to be of the highest grade for all welds, however the presence of micro-cracks cannot be avoided. Therefore procedures for the fatigue design of welded structures, e.g. according to the European standard EN 1993-1-9 (2005) or equivalent are not negotiable. When mixed flow fans are operated with variable speed drives, the possibility that structural, welded elements of the impeller fall into a resonance zone is realistic. Even when the loads at resonance speeds might be low, the number of cycles will reach millions within some days. The addition of load cycles is like adding something to a reservoir which have limited capacity, eventually it will be full and failure cannot be avoided. Alternatively these fans can be fitted with inlet guide vanes to modulate the airflow at constant driving speed. 4.4.2 Overpressure fans The general arrangement for this type of fan is to have individually mounted airfoil blades which are fixed to a central impeller hub. Duty modulation and energy efficiency would be optimized by blade pitch adjustments. Blade pitch adjustments alter the angle of attack of the blades and thus the airflow can be modulated. Blade pitch adjustments are available in manual or automatic versions. A manual method would mean an artisan will have to stop the fan, adjust all the blades individually and then restart the system, while an automatic system would adjust the blades all at once while the fan is online. Further optimization by using variable speed\frequency drives is possible as well, however these variable speed\frequency drives are still relatively expensive and it is a matter of weighing up investment expenditure versus operational expenditure. Reversal of airflow is also possible with blade adjustments\reversal so that at least 70% of the flow in the reverse direction can be achieved. The advantage of a constant speed drive is evident in respect of rotor dynamics. The risk to run through an aerodynamic unstable condition (stall) is relatively low, because the characteristic curve is similar to Figure 9b. In-flight variable pitch fans can be started with closed blades. This will ensure that the starting torque is kept on the lowest possible level and the flow is started smoothly. For less demanding requirements, simpler fans with blades adjustable at rest are chosen. Auxiliary mining fans are usually constructed using this principle. Designed for onerous and robust conditions they can be used where flow control or energy efficiency are not the dominating factors. 5 CONCLUSION There is no other part of a fan which is of similar importance as its blade. It is the aerodynamic performance which the buyer of a fan is specifying and where his primary focus is on. He will expect that the fan supplier did his utmost to diminish the failure probability of his rotating machinery to an absolute minimum. specification complies with both the aerodynamical and mechanical characteristics of the selected fan type. In this context, the article aimed to provide an insight into how loads, design rules and quality aspects are interwoven in a typical fan design. Following a well-proven engineering approach, will ensure a safe and reliable product, free of failures and with the longest possible service life. 6 REFERENCES Eckert, B. & Schnell, E. 1980. Axial und Radial-kompressoren. Berlin: Springer-Verlag European Committee for Standardisation 2005. EN 1993-1-9: Eurocode 3: Design of steel structures - Part 1-9 Fatigue Maddox, S.J. 1991. Fatigue Strength of Welded Structures. 2nd Edition. Cambridge: Woodhead Publishing Ltd. Staiger, M. et al. 1991. Beanspruchung der Laufschaufeln von Axialventilatoren bei gestörter Zuströmung: 125-145. VDIBerichte Nr. 872. Düsseldorf: VDI-Verlag Traupel, W. 1982. Thermische Turbomaschinen: 405-409. Band II, 3.Auflage. Berlin: Springer-Verlag 7