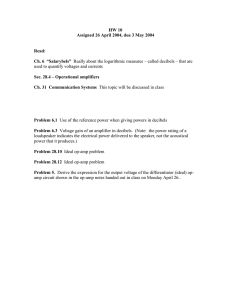

Low-Voltage, Class AB and High Slew-Rate Two

advertisement