Section A

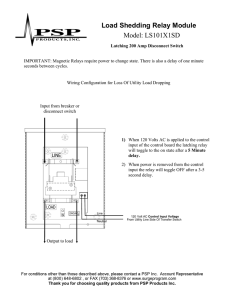

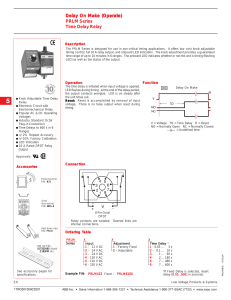

advertisement