Design of a Small Personal Electric Vehicle as an Educational Project

advertisement

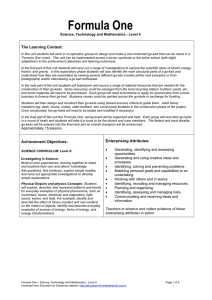

Design of a Small Personal Electric Vehicle as an Educational Project Tiene Nobels, Wim Deprez, Ief Pardon, Stijn Stevens, Ondrej Viktorin, Johan Driesen, Jeroen Van Den Keybus, Ronnie Belmans Kaholieke Universiteit Leuven, Dept. Elektrotechniek, Div. Electa Kasteelpark Arenberg 10, B-3001 Leuven, Belgium URL: http://www.esat.kuleuven.ac.be/electa Phone +32 16 321026 Fax +32 16 321985 Tiene.Nobels@esat.kuleuven.ac.be Ief.Pardon@esat.kuleuven.ac.be Johan.Driesen@esat.kuleuven.ac.be ondrej.viktorin@esat.kuleuven.ac.be Abstract – Engineering education should comprise more than theoretical knowledge. A design project with close relationship to present technology and the student’s environment provides hands-on engineering experience and training of general engineering skills. Electric vehicles are an example of technology. Building an electric go-kart is an economical and real-life educational design project. I. INTRODUCTION The electrical energy-engineering curriculum at the K.U.Leuven comprises 2 years of general science and engineering education, 1 year of general electrical engineering and a 2-year electrical energy specialisation. The design project to be developed is intended for 4th year students. The objectives of the design project are mainly to provide the students with hands-on experience, especially in the domain of electrical installations and drives. Also general engineering skills such as organizing meetings, gathering information and working in team are targeted. Wim.Deprez@esat.kuleuven.ac.be Stijn.Stevens@esat.kuleuven.ac.be Jeroen.Vandenkeybus@esat.kuleuven.ac.be Ronnie.Belmans@esat.kuleuven.ac.be the performance of conventional go-karts for rental purposes. The final goal is an optimal power management of the gokart, such that its velocity and acceleration is similar with that of conventional go-karts. Both the choice of components and the control of these components are part of the students’ assignment. The main components of an electric go-kart are the motor and the batteries, but peripheral equipment such as brakes and sensors are essential for a safe vehicle too. Before the motor and batteries can be selected, the necessary go-kart power, torque and energy have to be determined. However some boundary conditions, mostly of practical nature, will impose limits on the design. • An empty go-kart chassis as depicted in Fig. 1 is available to the students. Although the mechanical design is not the target, space management is important. II. DESIGN SUBJECT Motivation is an important aspect of the learning trajectory. Therefore, the topic has to be relevant, both to the curriculum as to present technology problems. Seeking the design topic in the student’s environment stimulates motivation too. Electric vehicles (EV) represent an emerging and high-tech market [1] in which electrical installation and drive technology are main topics. Go-karts are an example of vehicles students are familiar with. These days most gokarts are still gasoline powered, mostly due to the extremely high energy density of fossil fuel. However, the exhaust gases of such go-karts are intolerable for indoor karting. Electric go-karts offer a solution to this problem. III. ASSIGNMENT The design task is to build an electric go-kart. The performance of this electric go-kart has to be comparable to Fig. 1: Picture of the bare chassis. • A power electronic converter is inevitably necessary for the speed control of any electric motor. At our department a rapid prototyping platform has been developed [2]. This platform consists of a freely programmable processing core and an extendable number of modules, e.g. a precision measurement module, A/D converter module or an inverter comprising 4 half bridges (see Fig. 2). The IGBTs in the half bridges limit the effective current to 23 A, imposing severe limitations. The processing core of the platform is composed of a DSP and an FPGA-board. The DSP program can be written directly in C-code or the user-friendlier MATLAB/Simulink-environment can be used. • encourage the students to bring out the best. Presently however, hardware limitations prohibit a real go-kart race, as only one go-kart chassis is available. open-ended: another important aspect of the design project is the ‘open end’: nor the students, nor the lecturer can predict the (details of the) final result. Students contribute largely in all parts of the project, which incorporates a certain failure risk. On the other hand, satisfaction in case of success will be all the larger. B. Organization Fig. 2: Rapid prototyping platform with A/D converter, DSP and FPGA-board • • Cost is in real life one of the most important limitations. In this project cost will be a factor in making design decisions as well. Last but not least is it important to come to a realistic design: the electric go-kart should not only be designed (on paper/PC) but also built. The understanding of the difference between theory (paper design) and practice (prototype) represents one of the main didactical goals of this project. As this project is a long-term project, many ideas for expansion are at hand. These topics are not essential for the go-kart, but they can improve the efficiency and the novelty of the design. Examples are data logging, efficiency improvement by the implementation of a separate two-wheel drive and the use of renewable energy. For above reasons, the economic value of electric go-karts is probably considerable. Consequently the research may be of interest to the karting industry. IV. DIDACTICAL CONSIDERATIONS A. Design properties Properties of an educationally good design project are e.g. [6]: • a group enables development of teamwork skills. This is of major relevance for later professional life. • motivation plays a major role in the efficiency of education. It can be stimulated for example by the design subject choice, by introducing a competitive aspect or by a substantial student contribution to decision making. • a common project to all groups: different groups with the same task enable learning not only from team members, but also from competitors. Additionally the evaluation will be more consistent. Moreover competition improves motivation, thus a race would The design project is spread over two semesters. Students are arbitrarily split up in two competitive groups. During the first semester students and teaching assistants are embedded in a role-play where both groups of students act as an engineering agency. Teaching assistants act as a company consulting outside engineering agencies. The design evolves as the result of an interaction between students and teaching assistants: the students have meetings, perform basic research and propose solutions, which are subsequently evaluated by the teaching assistants. At the end of the first semester both engineering agencies present their paper design of a go-kart driven by an electric motor. The practical implementation and the final test-drive follow in the second semester. The role-play stops but the students stay in their competitive group. The tools available to both groups include help/support of teaching assistants. C. Evaluation Evaluation is an important aspect of education as it has a large influence on the motivation and the goals of the students. Because a number of general engineering skills are an important part of the objectives, permanent evaluation represents a large amount of the points to be earned. However, to an engineer also the goal is important. For this reason, the final result will be considered as well. V. TECHNICAL DESIGN A. Design specifications The goal is to build an electric go-kart comparable to conventional fuel go-karts for rental purposes. Therefore the design specifications can be based on the characteristics of such karts. Accordingly, we aim at a maximum speed of 50 km/h and heats of 15 minutes. An initial selection of the motor torque is made based on available data from combustion engine driven go-karts, given in Fig. 3. Conventional fuel go-karts for rental purposes have typically a reduction gear ratio of 5 [5]. Consequently a maximum torque of 70 Nm at 550 rpm on the wheels is needed. A 4 kW electro motor, running at 3000 rpm and delivering a torque of approximately 13 Nm, meets the requirement, assuming a reduction ratio of 5 to 6 on the electrical go-kart. disadvantages such as cost and temperature deteriorating. The dc motor can be relatively light, but its main advantage is the easy control compared to alternating current machines. Nevertheless the teaching staff has a preference for an induction motor (with cage rotor) since: • the induction motor is an extremely robust and durable machine that requires little or no maintenance, one of the main reasons why the induction motor is so often used in industry. • the low cost of an induction motor is very attractive. • also didactical reasons play a role: it is the most common type of motor in industry and consequently deserves a place in the engineering curriculum. Moreover a dc motor has already been covered in an earlier design project [4]. Fig. 3: Torque-speed characteristic of a conventional go-kart engine [5]. Taking into account the above mentioned reduction ratio and the wheel circumference, the electro motor has to be able to run at 5000 rpm to satisfy the 50 km/h condition. B. Voltage choice Not only the necessary power and energy, but also the voltage has implications on the motor and battery choice. The batteries always deliver a dc voltage (‘Voltage level 1’ in Fig. 4), but the motor needs an other voltage (‘Voltage level 2’). Voltage level 1 Voltage level 2 An interesting fact is that the students engaged in the pilotproject chose the induction type independently of the teaching staff. The motor manufacturer ELNOR Motors, has in its product range a 4 kW, 400 V, 3000-rpm three-phase induction motor. The motor is operated above its nominal speed. Consequently, flux weakening is used to limit the inverter output voltage. This essentially means that torque reduces above 3000 rpm, similar to conventional fuel go-karts engines (Fig. 3). The available rapid prototyping platform limits the effective output current to 23 A. Consequently, the effective voltage for an induction motor of 4 kW is at least 100 V and accordingly, the dc bus voltage should be at least 142 V. The downsize of a reduced motor voltage is an increased ohmic loss and reduced main inductance. In conjunction with ELNOR Motors, 130 V was selected. They rewound a 4 kW, 400 V, 3000-rpm three-phase induction motor to a 4 kW, 130 V, 3000-rpm three-phase induction motor. When space vector modulation (SVM) is used, the minimally required dc bus voltage Udc is 184 V [7]. U dc = 3 ⋅ Uˆ phase = 2 ⋅ U line Batteries Power Converter (1) Motor Fig. 4: Energy flow. The voltage levels have consequences for the losses in the wiring and the power electronic switches as well. Indeed, as the voltage level increases, the currents are reduced for the same power. Both low wiring ohmic losses and the possibility to use low-cost industry standard IGBTs require the use of a fairly high voltage. However, a high voltage requires many batteries connected in series. Moreover Attention should be paid to safety requirements in case of higher voltages. C. Motor choice Current electrical go-karts employ mostly dc motors [3]. Permanent magnet-machines are interesting due to their extremely high power density, but they also have D. Battery choice In electric vehicles standard car batteries do not serve the purpose: they can deliver large currents, but only for a short time. EVs need deep cycle batteries, which have a certain power capacity but more important a considerable energy content. Standard lead acid batteries can be drained in 15 minutes, but the large weight is an important disadvantage [9]. Nevertheless, they are used in this project for cost reasons. Allowing the batteries to discharge down to 80 %, which is acceptable for standard batteries, means that an initial dc bus voltage of 230 V is needed [8]. This is achieved by connecting 20 12 V batteries in series. The battery capacity was selected based on the observation that the mass of a battery is proportional to its energy content [8]. Complying with the objective of heats of 15 minutes, 20 batteries of 12 V and 12 Ah, weighing nearly 80 kg, are selected. Compared to conventional fuel gokarts the inertia drastically increases, resulting for the electric go-kart in lower acceleration rates or higher torque requirements. Cost issues force us to settle for lower acceleration ratios. For safety reasons and in order not to upset the go-kart’s weight balance, placement of the batteries merits particular attention. mechanical brake device brake brake cylinder pedal E. Control To control the induction motor, Field Oriented Control (FOC) is used. It enables control over both the excitation flux-linkage and the torque-producing current in a decoupled way [7] and is extensively dealt with by the students in earlier courses and laboratory sessions. Implementing FOC implies acquisition of the motor shaft position, using an incremental encoder. Sensorless operation of FOC is avoided due to the added complexity of the control model. In order to control the go-kart I/O is indispensable. Sensors detect the wanted direction, acceleration/deceleration and actual motor position (see Fig. 5). Acceleration Brake Sensors Direction T* slot Fig. 7: Close-up of the brake pedal mechanism Safety precautions enforce the use of a mechanical brake, but energy considerations demand regenerative braking. Implementing a delay in the mechanical brake, during which regenerative braking is active, combines both. Using a slot in the mechanical brake device effects the delay (see Fig. 7). To indicate the wanted direction (for- or backwards) to the control system a binary switch is used. VI. EDUCATIONAL IMPLEMENTATION PE FOC M Rotor position Fig. 5: Control scheme A motor vehicle is typically torque controlled. FOC enables to control the torque-producing current. The accelerator and brake pedal positions are converted into electrical signals with a potentiometer with an A/D converter (see Fig. 6). Fig. 6: Close-up of the gas and brake potentiometer The practical implementation of the go-kart is carried out in the second semester and comprises: • implementing a torque control scheme of FOC for an ac motor drive on the rapid prototyping platform • applying control sensors • mechanical assembly The students do not have to do the mechanical assembly themselves; our competent technicians do it according to the instructions. Additionally they provide a test bench upon which the performance of the motor control system can be fully tested. Both engineering agencies split up their group in two divisions. One division attends to the implementing of a torque control scheme of FOC, the scheme-division, the other division attends to the applying of control sensors, the sensor-division. Possibilities for student guidance range from providing them with a fully working, previously tested control scheme, which they should adapt and optimise or having them build a complete FOC scheme from scratch. An often-recurring question in designing practical labs is which compromise between the two possibilities maximizes the ratio between acquired competence and invested time. In fact, two compromises were offered to the students: the first one comprises a full-fledged control system from a PhD student, which has to be downgraded. The second one is a basic induction motor control simulation model. Both engineering agencies chose the first approach putting a big effort into comprehending the high performance FOC scheme. Because it is possible to program the rapid prototyping platform with MATLAB/Simulink, the scheme can easily be tested off- line with a MATLAB model representing the motor. Students determine the motor parameters by measurements on the test bench. In a next stage the FOC scheme has to be interfaced with the sensors and the general control (see Fig. 5). For use on the test bench a test box with a binary switch and two potentiometers is available. A demonstration on the test bench is followed by the final implementation on the go-kart. In order to allow all-day testing the kart has been cable powered instead of battery powered as no multiple battery packs were available. VIII. CONCLUSIONS An educational design project to provide students with hands-on engineering experience and to train general engineering skills has been presented. The choice of an electric go-kart as a design target encourages intensive student enrolment and, at the same time, is based on a current technological challenge. As this project is meant to be a long-term project, permanent renewal is necessary to maintain the earlier stated “open-end” property. Therefore next year separate two-wheel drive will be implemented (see Fig. 9). Fig. 9: Schematic drawing of a separate two-wheel drive. ACKNOWLEDGMENT Fig. 8: Final test-drive-day The authors kindly thank motor designer ELNOR Motors for providing the authors with the 130 V induction motors. VII. EDUCATIONAL REVIEW OF THE PROJECT A survey of appreciation amongst the students was made. In general students were satisfied with the design project in spite of the fact that it was a pilot-project accompanied with the necessary growing pains. Even though much progress is possible, students found the project to be very instructive and at the end very rewarding. Because of the interaction during the role-play between company and engineering agencies (i.e. teaching assistants and students) the technical design is quasi-identical for both engineering agencies. Both engineering agencies designed an electrical go-kart with a four-quadrant control. Driving backwards and regenerative braking is possible. During the implementation phase the general idea was to let the students sort it out within their group, but we learned that a minimum of coaching is necessary. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] [9] http://www.toyota.com/prius, last visited 25 May 2004. Van den Keybus J., “Development of a universal power measurement and control platform for low-voltage grid-coupled applications in a deregulated electricity market”, PhD dissertation, K.U.Leuven, December 2003. http://www.lynchmotor.com, last visited 25 May 2004. Daems W., De Smedt B., Vanasssche P., Gielen G., Sansen W., De Man H., PeopleMover: An example of interdisciplinary project-based education in electrical engineering, IEEE Trans. on Education, vol. 46, no.1, Feb. 2003, pp. 157-167. http://www.honda-engines.com/gx270.htm, last visited 21 May 2004. Gregson P.H., Little T.A., Using Contests to Teach Design to EE Juniors, IEEE Trans. on Education, vol. 42, no.3, August 1999, pp.229-232. Terörde G., “High performance motion controle of ac motor drives with & without shaft sensor”, PhD dissertation, K.U.Leuven, September 2002. Vincent C. A. & Scrosati B., “Modern Bateries: An introduction to electrochemical power sources”, reference book, second edition, 1997 S.R. Holm, H. Polinder, J.A. Ferreira, P. van Gelder and R. Dill, “A Comparison of Energy Storage Technologies as Energy Bu®er in Renewable Energy Sources with respect to Power Capability”, Young Researchers Symposium, Leuven, February 2002.