A 0.07µm CMOS Flash Analog-to-Digital Converter for High Speed

advertisement

A 0.07µm CMOS Flash Analog-to-Digital Converter

for High Speed and Low Voltage Applications

Jincheol Yoo

Kyusun Choi

Jahan Ghaznavi

Department of Computer Science and Engineering

Pennsylvania State University

University Park, PA 16802

{jyoo,kyusun,ghaznavi}@cse.psu.edu

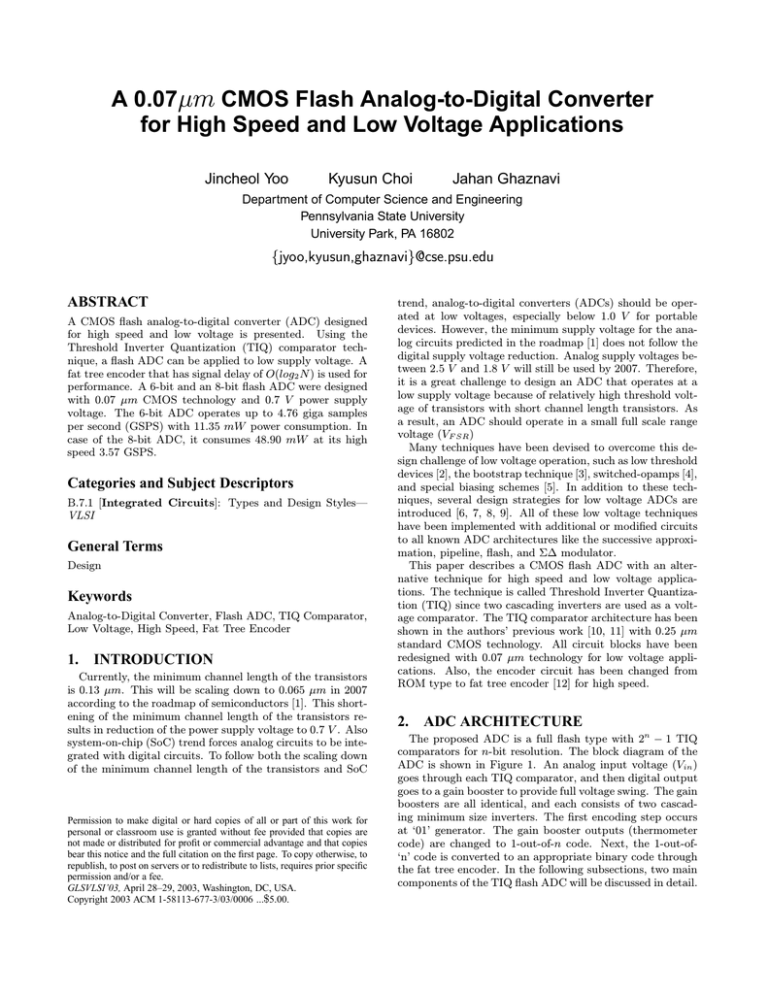

ABSTRACT

A CMOS flash analog-to-digital converter (ADC) designed

for high speed and low voltage is presented. Using the

Threshold Inverter Quantization (TIQ) comparator technique, a flash ADC can be applied to low supply voltage. A

fat tree encoder that has signal delay of O(log2 N) is used for

performance. A 6-bit and an 8-bit flash ADC were designed

with 0.07 µm CMOS technology and 0.7 V power supply

voltage. The 6-bit ADC operates up to 4.76 giga samples

per second (GSPS) with 11.35 mW power consumption. In

case of the 8-bit ADC, it consumes 48.90 mW at its high

speed 3.57 GSPS.

Categories and Subject Descriptors

B.7.1 [Integrated Circuits]: Types and Design Styles—

VLSI

General Terms

Design

Keywords

Analog-to-Digital Converter, Flash ADC, TIQ Comparator,

Low Voltage, High Speed, Fat Tree Encoder

1.

INTRODUCTION

Currently, the minimum channel length of the transistors

is 0.13 µm. This will be scaling down to 0.065 µm in 2007

according to the roadmap of semiconductors [1]. This shortening of the minimum channel length of the transistors results in reduction of the power supply voltage to 0.7 V . Also

system-on-chip (SoC) trend forces analog circuits to be integrated with digital circuits. To follow both the scaling down

of the minimum channel length of the transistors and SoC

Permission to make digital or hard copies of all or part of this work for

personal or classroom use is granted without fee provided that copies are

not made or distributed for profit or commercial advantage and that copies

bear this notice and the full citation on the first page. To copy otherwise, to

republish, to post on servers or to redistribute to lists, requires prior specific

permission and/or a fee.

GLSVLSI’03, April 28–29, 2003, Washington, DC, USA.

Copyright 2003 ACM 1-58113-677-3/03/0006 ...$5.00.

trend, analog-to-digital converters (ADCs) should be operated at low voltages, especially below 1.0 V for portable

devices. However, the minimum supply voltage for the analog circuits predicted in the roadmap [1] does not follow the

digital supply voltage reduction. Analog supply voltages between 2.5 V and 1.8 V will still be used by 2007. Therefore,

it is a great challenge to design an ADC that operates at a

low supply voltage because of relatively high threshold voltage of transistors with short channel length transistors. As

a result, an ADC should operate in a small full scale range

voltage (VF SR )

Many techniques have been devised to overcome this design challenge of low voltage operation, such as low threshold

devices [2], the bootstrap technique [3], switched-opamps [4],

and special biasing schemes [5]. In addition to these techniques, several design strategies for low voltage ADCs are

introduced [6, 7, 8, 9]. All of these low voltage techniques

have been implemented with additional or modified circuits

to all known ADC architectures like the successive approximation, pipeline, flash, and Σ∆ modulator.

This paper describes a CMOS flash ADC with an alternative technique for high speed and low voltage applications. The technique is called Threshold Inverter Quantization (TIQ) since two cascading inverters are used as a voltage comparator. The TIQ comparator architecture has been

shown in the authors’ previous work [10, 11] with 0.25 µm

standard CMOS technology. All circuit blocks have been

redesigned with 0.07 µm technology for low voltage applications. Also, the encoder circuit has been changed from

ROM type to fat tree encoder [12] for high speed.

2. ADC ARCHITECTURE

The proposed ADC is a full flash type with 2n − 1 TIQ

comparators for n-bit resolution. The block diagram of the

ADC is shown in Figure 1. An analog input voltage (Vin )

goes through each TIQ comparator, and then digital output

goes to a gain booster to provide full voltage swing. The gain

boosters are all identical, and each consists of two cascading minimum size inverters. The first encoding step occurs

at ‘01’ generator. The gain booster outputs (thermometer

code) are changed to 1-out-of-n code. Next, the 1-out-of‘n’ code is converted to an appropriate binary code through

the fat tree encoder. In the following subsections, two main

components of the TIQ flash ADC will be discussed in detail.

Analog Input

Voltage

Thermometer

Code

1-out-of-n

Code

Binary

Code

Fat Tree

Encoder

‘01’ Generator

max Vm

MSB

Vin

TIQ

Comparator

Gain

Booster

‘01’

Generator

Fat Tree

Encoder

LSB

min Vm

Figure 1: Block diagram of the ADC

TIQ Comparator

Gain Booster

2.1 TIQ Comparator

The TIQ comparator has been designed for high speed

ADCs in SoC applications. As shown in Figure 1, its architecture is very simple and fast compared to the differential input voltage (DIV) comparator. The inverter, which

is known for the fastest digital circuit, has been used to

compare the Vin to the built-in reference voltage, Vref .

The key difference between the DIV comparator and the

TIQ comparator is how to provide the Vref . Most DIV comparators utilize the external Vref source such as a resistor

ladder circuit. In the TIQ comparator, all 2n − 1 reference voltages for n-bit ADC are internally determined by

the size of each inverter. All DIV comparators are identical, duplicated for 2n − 1 times. On the other hand, each

TIQ comparator is different from all the others. Each comparator has unique reference voltage (Vm ). The 2n − 1 comparators’ reference voltages equally divide full scale range

voltage, VF SR . Achieving an optimal layout of such TIQ

comparator is very time consuming. Automatic generation

of the TIQ comparator has been developed by the authors

to reduce the linearity errors [13]. Figure 2 shows an 8-bit

TIQ flash ADC layout from the automatic generation. One

can notice systematic descending and ascending size of the

TIQ comparator.

The main advantage of the TIQ comparator is highly

adaptable for the high speed and low voltage. Especially, it

does not need any external Vref source. These advantages

enable the TIQ comparator to operate at a low voltage with

ultra-fast speed. On the other hand, the process parameter variation causes offset and gain errors due to internally

fixed reference voltages. Also the noise problem is one of the

challenges of the single-ended input TIQ comparator. According to the previous fabrication and measurement of the

TIQ flash ADC chip, this noise problem affects the sampling

rates of the ADC. Now, the authors are planning to design

an alternative comparator that reduces the noise problem.

Figure 2: 8-bit TIQ flash ADC layout

The 1-out-of-8 code, which is the output of the ‘01’ generator, is represented at the leaf nodes (from a7 to a0 ) of the

tree. The 3-bit binary output (d2 , d1 , and d0 ) is located at

the root of the tree. The output is obtained by a logical

ORing of the leaf nodes depending on the truth table shown

on the right in Figure 3. As shown in the tree, the number

of edges increases from leaf to root. So, this new encoder

type is named the fat tree encoder.

The fat tree encoder’s signal delay is O(log2 N), much

faster than the ROM type encoder. Also, all multiple OR

gates can be changed to NOR and NAND gates for more efficient implementation. Moreover, the fat tree encoder can

be easily pipelined at each height in the tree. However, the

fat tree is a 3-dimensional circuit topology, the design automation of the fat tree encoder is very challenging.

3. SIMULATION RESULTS

The proposed TIQ flash ADC has been simulated with

HSPICE 0.07 µm predictive model from the University of

California at Berkeley. Table 1 shows the summary of simulation results. The 6-bit and the 8-bit ADC can respectively operate at the speed of 4.76 GSPS and 3.57 GSPS

without any missing codes. The SPICE simulation result

of the 8-bit ADC is shown in Figure 4. Both the differential non-linearity error (DNL) and the integral non-linearity

a7

a6

a5

a4

2.2 Fat Tree Encoder

The previous encoder for the TIQ flash ADCs [10, 11]

was a ROM type, which has signal delay of O(N). The

encoder was the bottleneck of the TIQ flash ADC. A new

tree type encoder architecture has been developed by the

authors [12]. This new architecture is necessary for high

speed applications.

Figure 3 shows an example of the 3-bit fat tree encoder.

a3

d2

d1

d0

a7

a6

a5

a4

a3

a2

a1

a0

0

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

0

0

1

0

0

0

0

0

0

0

d(2:0) 000 001 010 011 100 101 110 111

a2

a1

a0

d2 = (a4 + a5) + (a6 + a7)

d1 = (a2 + a3) + (a6 + a7)

d0 = (a1 + a3) + (a5 + a7)

Figure 3: Example of the 3-bit fat tree encoder

Table 1: Simulation results

Vin

* hspice file created from 8b007adc_flat.ext - technology: mmi07

400m

300m

bit7

600m

bit6

0.05

0.05

INL(LSB)

0.1

0

−0.05

0

−0.05

−0.1

0

20

40

output code

60

−0.1

0

20

40

output code

60

(b) INL of the 6-bit

(a) DNL of the 6-bit

0.2

0.2

0.1

0.1

0

−0.1

0

−0.1

0

600m

−0.2

0

0

600m

bit5

0.1

INL(LSB)

8-bit

0.07 µm

0.7 V

3.57 GSPS

48.88 mW

0.24 V - 0.46 V

0.81 mV

185.1µA

0.1684 LSB

0.1234 LSB

0.0625 mm2

DNL(LSB)

6-bit

0.07 µm

0.7 V

4.76 GSPS

11.32 mW

0.24 V - 0.46 V

3.43 mV

78.5µA

0.0075 LSB

0.0062 LSB

0.0170 mm2

DNL(LSB)

resolution

CMOS tech.

power supply

max. speed

power consumption

VF SR

VLSB

leakage current

DNL

INL

ADC Area

50

100

150

output code

200

(c) DNL of the 8-bit

0

250

−0.2

0

50

100

150

output code

200

250

(d) INL of the 8-bit

bit4

600m

0

Figure 5: Linearity errors of the ADC

bit3

600m

0

bit2

600m

3.2 Voltage and Temperature Variations

0

bit1

0

bit0

600m

600m

0

0

20n

40n

Time (lin) (TIME)

60n

Figure 4: SPICE simulation result

error (INL) shown in Figure 5 are less than 0.01 LSB for

the 6-bit and 0.20 LSB for the 8-bit ADC. Table 2 compares these results with other ADCs. The TIQ flash ADCs

show the highest speed but they also show the largest power

dissipation compared to the other low voltage ADCs.

3.1 Component power consumption

The other ADCs in Table 2 consume small amounts of

power. The TIQ flash ADC architecture is a pure flash

type and all 2n − 1 comparators turn on at the same time.

The TIQ flash ADC dissipates more power than the others.

Table 3 shows the component power consumption of the TIQ

flash ADC at the maximum sampling rate.

Most power consumption of the ADC occurs in the comparator as expected. Especially, the comparator’s power dissipation becomes very large as it changes to the higher resolution. Therefore, comparator section is the critical component for low power consumption. It is hard to reduce power

consumption in the flash architecture when the comparators are operating. However, the power consumption can be

managed in the TIQ comparator since the TIQ comparator

can be easily turned off. The authors are now working this

power management method in the TIQ flash ADC to save

power consumption.

In the TIQ flash ADC implementation, there are two problems that affect changes in the offset, gain, and linearity:

static variation and dynamic variation. The static variation is the process variation. The dynamic variations are

power supply voltage and temperature variation. The internal reference voltages, which are fixed by the size of the

transistors, are the cause of these variations. To correct

them, one can use digital signal processing (DSP) on the

ADC output. Unfortunately, there is no representative process parameters available for 0.07 µm technology. So, only

dynamic variations have been simulated.

Table 4 shows the variation parameters from the 8-bit

ADC simulation results as a result of the power supply voltage and temperature variations. The “default” condition is

a 0.7 V power supply voltage at 25o C. There are changes in

both the offset and gain variations. The temperature variations show an especially large amounts of expansion (at

85o C) or contraction (at −40o C) of full scale range of the

reference voltages. As a result of these changes, all characteristics of the ADC including the sampling rates are degraded. However, by using the optimal design method [13],

the DNL of the ADC shows less sensitive over the variations

than the INL. A new design method for INL optimization is

currently investigated to prevent the degrading performance

of the ADC as the temperature or power supply varies.

4. CONCLUSIONS

The TIQ flash ADC has been simulated with the 0.07 µm

CMOS technology to verify the functionality at low power

supply voltage. Both the 6-bit and the 8-bit ADC worked

correctly at a 0.7 V with high speed sampling rate and small

values of DNL and INL. The static and dynamic variations

affect the gain and offset errors. The overall simulation

shows that the TIQ technique can be adapted to the future

CMOS technology.

Table 2: Comparison with other ADCs

ADCs

TIQ

TIQ

[2]

[3]

[4]

[5]

[6]

[7]

architecture

flash

flash

Σ∆

successive approximation

pipeline

successive approximation

flash-interpolation

Σ∆

resolution

6-bit

8-bit

10-bit

10-bit

9-bit

8-bit

6-bit

14-bit

power supply

0.7 V

0.7 V

1.0 V

1.0 V

1.0 V

1.0 V

0.8 V

1.1 V

Table 3: Component power consumption

TIQ flash ADC

total

comparator

gain booster

‘01’ generator

fat tree encoder

6-bit (mW )

11.314 (100 %)

10.618 (93.8 %)

0.043 (0.4 %)

0.088 (0.8 %)

0.565 (5.0 %)

8-bit (mW )

48.882 (100 %)

47.983 (98.1 %)

0.083 (0.2 %)

0.085 (0.2 %)

0.731 (1.5 %)

Table 4: Power supply voltage and temperature

variations from the 8-bit ADC

0.665 V

0.735 V

−40o C

85o C

default

5.

min. Vm

0.239831

0.264819

0.276854

0.226461

0.251036

max. Vm

0.431048

0.491096

0.423492

0.490242

0.456555

DNL(LSB)

0.1874

0.1446

0.2345

0.1745

0.1684

INL(LSB)

0.7083

1.3165

2.1280

2.9707

0.1234

ACKNOWLEDGMENT

The authors wish to thank the Device Group at UC Berkeley which provided the 0.07 µm Berkeley Predictive Technology Model (BPTM)SPICE model.

6.

REFERENCES

[1] Semiconductor Industry Association (SIA). The

International Technology Roadmap for Semiconductors.

2001.

[2] Y. Matsuya and J. Yamada. 1 V Power Supply,

Low-Power Consumption A/D Conversion Technique

with Swing-Suppression Noise Shaping. IEEE Journal

of Solid-State Circuits, 29(12):1524–1530, December

1994.

[3] C.J.B. Fayomi, G.W. Roberts, and M. Sawan. A 1-V,

10-bit Rail-to-Rail Successive Approximation

Analog-to- Digital Converter in Standard 0.18µm

CMOS Technology. IEEE International Symposium on

Circuits and Systems, pp. I-460–I-463, 2001.

[4] M. Waltari and K.A.I. Halonen. 1-V 9-Bit Piplined

Switched-Opamp ADC. IEEE Journal of Solid-State

Circuits, 36(1):129–134, January 2001.

[5] S. Mortezapour and E.K.F. Lee. A 1-V, 8-Bit

Successive Approximation ADC in Standard CMOS

Process. IEEE Journal of Solid-State Circuits,

35(4):642–646, April 2001.

[6] J. Lin and B. Haroun. An Embedded 0.8V/480µW

6b/22MHz Flash ADC in 0.13µm Digital CMOS

Process using Nonlinear Double-Interpolation

Technique. IEEE International Symposium on

Solid-State Circuits, pp. 308, 468, 2002.

CMOS tech.

0.07 µm

0.07 µm

0.5 µm

0.18 µm

0.5 µm

1.2 µm

0.13 µm

0.35 µm

sampling rate

4.76 GSPS

3.57 GSPS

384 KSPS

200 KSPS

5 MSPS

50 KSPS

25 MSPS

16 KSPS

power consumption

11.32 mW

48.88 mW

1.56 mW

1.6 mW

0.34 mW

480 µW

[7] F. Muñoz, A.P. VegaLeal, R.G. Carvajal, A. Torralba,

J. Tombs, and J. Ramírez-Angulo. A 1.1V Low-Power

Σ∆ Modulator For 14-b 16KHz A/D Conversion. IEEE

International Symposium on Circuits and Systems, pp.

I-619–I-622, 2001.

[8] B.-S. Song. Analog Front-End Macro Circuit Design.

International Symposium on VLSI Technology,

Systems, and Appications, pp. 223–226, 1999.

[9] F. Gerfers and Y. Manoli. A Design Strategy for

Low-Voltage Low-Power Continuous-Time Σ∆ A/D

Converters. Design, Automation and Test in Europe,

pp. 361–368, 2001.

[10] J. Yoo, K. Choi, A. Tangel. A 1-GSPS CMOS Flash

A/D Converter for System-on-Chip Applications. IEEE

Computer Society Workshop on VLSI, pp. 135–139,

2001.

[11] J. Yoo, D. Lee, K. Choi, and A. Tangel. Future-Ready

Ultrafast 8Bit CMOS ADC for System-on-Chip

Applications. 14th Annual IEEE International

ASIC/SOC Conference, pp. 455-459, 2001.

[12] D. Lee, J. Yoo, K. Choi, and J. Ghaznavi. Fat Tree

Encoder Design for Ultra-High Speed Flash A/D

Converters. To appear in IEEE Midwest Symposium on

Circuits and Systems, 2002.

[13] D. Lee, J. Yoo, and K. Choi. Design Method and

Automation of Comparator Generation for Flash A/D

Converters. IEEE International Symposium on Quality

Electronic Design, pp. 138–142, 2002.