low voltage vacuum contactor

advertisement

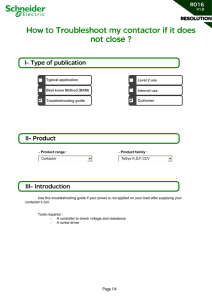

LOW VOLTAGE VACUUM CONTACTOR I N D U S T R I A L G R O U P TAVRIDA ELECTRIC AXCA 670200.009 Version 06 In Effect Since 03.09.2007 Contents 2 CONTENTS Technical Manual 3 Presentation 3 Product range 4 Design 5 Overall design 5 Switching module 6 Control module 7 Auxiliary contact units 8 Surge arrester unit 8 Small wiring termination 8 Operation 9 Closing 9 Opening 10 Emergency trip 10 Technical specification 11 General 11 Rated operational power of AC motors (AC3 and AC4) 12 Auxiliary circuits 13 “Power supply” 13 “Control Input” 13 Auxiliary contacts unit 13 Surge arresters 14 Electromagnetic Compatibility (EMC) 15 Dielectrical Strength Dimensional drawings 15 16 Application guide Selection 17 Incoming inspection 17 Mounting 18 Main terminals connection 19 Wiring and earthing 21 Commissioning test 23 Maintenance 24 Operation test 24 High voltage test 24 Insulation resistance test 24 Contact resistance test 24 Failure analyses and handling 24 Replacement of auxiliary contacts 25 Replacement of surge arresters unit 25 Replacement of control module 25 Routine test 26 Type test 26 Disposal 26 Technical Manual Presentation 3 Technical Manual Presentation Low voltage vacuum contactors (hereinafter con tactor) are based on the latest switching and electronic control technologies. The contactor can be used as a core component of low voltage switchgears and as a standalong unit. Switching of heavyduty AC motors is main intent of the contactor. Main distinctive of the contactor’s design is application of microprocessorbased incorporat ed control unit. Lightduty operation instruc tions are applied to corresponding input of the control module. Separate supply input allows withstanding deep voltage sags without dropout. This feature has particular importance when motor’s fed is made from transformers having comparable with the motor power. Contactor has three modifications. LSM/TEL14/400340 is applied at either of low voltage AC systems. LSM/TEL14/400341 and LSM/TEL14/400 342 contactors are used for threephase, four wires AC systems 120/208V and 230/400V corre spondently. In these types of the contactors there is surge arrester unit. Surge arrester unit provides effective motor protection against switching overvoltages. It raises service life of the interconnected electrical equipment. Contactor has specific main terminals in respect with the similars contactors. Contactor allows to be connected with cables without cable lags. If the cables are provided with extra seals, degree of protection of the contactor is IP40. It provides protection from insects and ingress of liquid drops. However, contactor can be connected by busbars and cables with lags through extra adapters. In this case contactor transforms to ordinary contactor. However application of the seals provides abovementioned protection of the contactor. Contactor has four interchangeable auxiliary switches which can be used for linking to sig nalling circuits. Application of advanced technologies provides reliable operation of the contactor during all service life without extra maintenance and adjustments that lowers service costs. Technical Manual Product range 4 Product range Product type Part number Comment Manufacturer Module LSM/TEL14/400340 Contactor for up to 1000 V AC systems (witout surge arresters) Module LSM/TEL14/400341 Contactor for 120/208 V AC systems (with surge arrester unit SAU/TEL230E) Module LSM/TEL14/400342 Contactor for 230/400 V AC systems (with surge arrester unit SAU/TEL400E) Accessory CM/TEL20E Control module Accessory ACU/TEL01 Auxiliary contact unit Accessory SAU/TEL230E Surge arrester unit for LSM/TEL14/400341 Accessory SAU/TEL400E Surge arrester unit for LSM/TEL14/400342 Accessory SAU/TEL001E Case of surge arrester unit (without varistors) Accessory АAHE 296444.003 Special key Accessory ITEA 674152.003 Screw driver Component AAHE 735642.001 Seal MF TEL Component AXCA 716212.001 Adapter MF TEL Component AXCA 745422.017 Installation bar MF TEL Technical Manual Design 5 Design Overall design Vacuum contactor consists from the following main parts: switching module, control module, surge arrester unit and two auxiliary contacts units. Switching module, control module and surge arrester unit are realized as polymericcov ered modules. Auxiliary contacts units are made as PCBbased modules. Surge arrester unit and auxiliary contacts units allow to be easily replaced without any tools. The contactor provides IP40 degree protection if it is connected with up to 240 mm2 cables with out cable lags. The cables are connected directly to main circuit terminals with special wrench and are sealed with rubber seals. To connect cables with lags it is necessary to use special adapters. If the adapters are used together with rubber seals degree protection is also provided at IP40 level. Small wiring termination is provided with WAGO connector that is placed under a cover. The con tactor is earthed through "Earth" stud. Control module Connection board "Earth" stud Surge arresters unit Small wiring terminals Switching module Auxiliary contacts unit Main circuit terminals (load outputs) Cover Main circuit terminals (supply inputs) Seals Adapters Installation bar Technical Manual Design 6 Switching module Switching module consists of three vacuum interrupters (VI), solenoid actuator, flexible con nectors and rigid busbars with clamps. Vacuum interrupters are a peak of R&D achieve ments of Tavrida Electric. Despite small dimen sions vacuum interrupters insure reliable switch ing of heavyduty circuits providing high inter rupting life. Vacuum interrupter armature is rigidly coupled to the frame which operates to VI’s moving contacts by linear drive insulators. This provides direct linear movement in both directions and avoids the use of rotating shafts, bearings and bell cranks. As a result the contactor is maintenance and trouble free during all mechanical life. The actuator has two end positions: OPEN and CLOSED. In Open position the armature is forced by opening spring to provide the gap between base yoke and armature. To close the actuator it is necessary to inject the closing current into the coil. In CLOSED position the gap between base yoke and armature is miserable. Holding current that is injected into actuator's coil leads corre sponding magnetic flux. The flux produces hold ing force between base yoke and armature and holds the magnetic system in close position. Tripping of the actuator is provided by holding current chopping. Position of the actuator is indicated with internal function auxiliary con tact that is connected with control module through intermediate printed circuit board. In contrast with majority of conventional con tactors there is level motion between the actua tor and vacuum interrupters. The actuator's Armature Frame Contact pressure spring Bracket Function auxiliary contact Opening spring Actuator coil Basechannel Flexible connector Guade yoke Base yoke Clamp Drive insulator Terminal Vacuum interrupter Busbar Technical Manual Design 7 Control module Microprocessorbased control module transfers external lowpowered control signal into internal operation instruction which are applied to mag netic actuator coil. There are two inputs: "Power supply" and "Control input". "Power supply" input is intended for charging of internal closing capacitor bank and supplying of incorporated source of holding current. After initial power application the contactor needs preparation time to charge the capacitor bank. “Control input” is intended to accept external close instructions. Capacitor bank is charged into actuator's coil and it injects closing current that is independent from quality of power supply. After closing of magnetic actuator the control module generates stabilized holding current into the coil. Then close instruction is finished the holding current is chopped and the contactor is tripped. Between sequences of CO operations the contactor needs a time for charging of capacitor bank. For indica tion of main contact's position. Control module has internal thermosensor. The first function of the thermosensor is generation a signal when inside temperature of control mod ule exceeds Overheating Indication Temperature. It can be caused by overloading of the contactor or exceeding of internal temperature into switchgear above level specified as maximum operating temperature. The second function of the thermosensor is generation of internal Emergency Trip Instruction if the temperature inside control module exceeds Emergency Trip Temperature. In this case the contactor is tripped and corresponding indicator starts to blink. Control module has three LED indicators on the front panel. Greencolor indicator "Power" is intended for sig naling of applying of power supply on correspon ding inputs and it signals about readiness of the contactor for execution of closing instruction. Control module executes monitoring of internal auxiliary circuits and inside temperature of the contactor. If some malfunction is occurred red color indicator "Malfunction" starts to blink suc cessively with intervals. The number of blinks in series corresponds to specific malfunction. Duration of single blink is 150 ms. Interval between neighbour blinks is 450ms. Interval between series of blinks is 1.5 ms. Redcolor indicator "Closed" reflects position of the contactor. Correspondence between modes of the contactor and indicators is shown in the following table. LED indication mode Contactor's condition "Power" "Malfunction" "Closed" No light No light No light Preparation time for closing Blinks No light No light Opened state Light No light No light Closed state Light No light 1 blink in series* 2 blinks in series 3 blinks in series 4, 5 or 6 blinks in series Light Continuous lost of "Power supply" Lost of "Power supply" and "Control input" Overheating Indication Temperature exceeds specified level Opened state after execution of Emergency Trip Instruction Nonconformity of the contactor * During not less than 30 sec. ** Light if the contactor is closed; No Light if the contactor is opened. No light Light Blinks Light ** ** No light ** Technical Manual Design 8 Auxiliary contact units Contactor is provided with two auxiliary contact units (ACU). Each unit has one normally opened (NO) and one normally closed (NC) contacts. The contacts are controlled by frame of the actuator They are used for position indication of the con tactor for external signalling circuits. Surge arrester unit Contactors LSM/TEL14/400341 and LSM/TEL 14/400342 include SAU/TEL type surge arrester units. The first contactor is supplied with SAU/TEL230 and the second one with SAU/TEL 400. Each unit include three varistors that are Y connected with earthed midpoint. Surge arrester units are intended for protection of intercon nected electrical equipment from overvoltages that can be occurred at switching operations of the contactor and other reasons. The units limits the surge voltage, so, service life of electrical equipment become higher if the units were not used. Contactor LSM/TEL14/400340 is provided with case of surge arrester unit. There are no any varistors inside. So, this unit does not provide overvoltage protection of the equipment. In this case protection of equipment shall be arranged with extra protection elements. Small wiring termination Contactor has auxiliary inputs and outputs in accordance with the diagram nearby. Outgoing arrows indicate outputs, incoming arrows indicate inputs. Potential zones corresponding to electrically iso lated terminals are separated with lines. Auxiliary Contact NO1 "Power Supply" Auxiliary Contact NC1 "Control Input" Auxiliary Contact NO2 Auxiliary Contact NC2 "Earth" Technical Manual Operation 9 Operation Closing ■ ■ The initial position of the contactor is open. Vacuum interrupters are held in opened position by opening springs which operate to their pulling insulators through the frame. To launch the con tactor into operation it is necessary to energize corresponding WAGO terminals with "Power sup ply" rated voltage. Control module starts charg ing of internal closing capacitor bank. "Power" indicator stars to blink. If preparation time is over specified value the indicator lights that means readiness of the contactor for closing. Contactor can be closed if the following condi tions are met: Contactor is open; “Close” capacitors are charged, LED indicator “Power” lights continuously. To close the contactor, control voltage shall be applied to “Control Input”. In a period longer than “Close” instruction acceptance time, current pulse from the closing capacitor bank is injected into the coil. The current in the coil produces a magnetic flux in the gap between the base yoke and the arma ture. 1 2 2a 3 3a 4 4а 4b 5 6 State of main contacts Actuator coil current Travel of armature Speed of armature Time Current increment increases the magnetic flux. Electromagnetic attraction between yoke and armature becomes more than restraining force of the opening springs (line 1). The armature, frame, drive insulator and moving contacts start to move. As the armature moves towards the upper yoke the magnetic air gap decreases and consequently the magnetic attrac tion force increases. This increasing force accel erates the armature, drive insulator and moving contact. Acceleration of the armature generates back emf in the coil that reduces the coil current (Line 12). At contact close (line 2) the moving contacts stops but the armature travel continues for 1 mm under rapid deceleration caused by compressing the contact pressure spring. At the limit of its travel the armature latches magnetically to the base yoke (Line 2a). The travel of the armature also compresses the open ing spring in preparation for the next opening operation and operates the auxiliary contacts. The moving armature collapses and the coil cur rent again increases (lines 2a3). When closing impulse duration is expired control module decreases the closing current (line 3) up to holding current (lines 3a4). The contactor stays in closed position for unlimited period of time even if mechanical vibration conditions and voltage drops are occurred Technical Manual Operation 10 Opening To open the contactor, “Control Input” shall be deenergized. In a period of time longer than “Trip” instruction acceptance time, instruction is accepted and holding current is cut off (line 4 4b). Magnetic flux and correspondantly holding force of the armature decrease and when sum of charged opening and the contact pressure spring forces become more then holding force the arma ture is released and accelerated rapidly (line 4a). After free travel it engages with drive insulators and VI’s contact are opened. The peak force produced by the armature ensures easy breaking of any microwelds at the contact surfaces which can appear due to short circuit current action. The moving contact accelerates rapidly, ensuring a high interrupting capacity. Main contacts return to their initial position (line 5). If the contactor breakes loaded circuit the inter rupting current initiates a socalled «vacuum arc» that burns essentially in plasma originating from evaporated contact material. The current continues to flow through this plasma until a cur rent zero. At this moment the arc is extinguished and transient recovery voltage appears across the open gap. If the contact surface is locally over heated it produces a lot of vapour, resulting in deterioration of the vacuum followed by electri cal breakdown. To avoid this, optimum combina tion of contact material and electrode shape is applied resulting in development the smallest vacuum interrupter ever existed. At full travel (line 6) the armature, drive insula tor and moving contact assembly is again held open by the opening spring force. Contactor is also opened at the same way if “Power Supply” is lost in approximately 1 second even if “Control Input” is energized. In this case, to close contactor it is necessary to deenergize “Control Input”, to apply “Power Supply”, to energize “Control Input” when “Power” indicator is lit. Emergency trip If inside temperature of the control module exceeds level of Emergency trip temperature the contactor trips itself even if "Control Input" volt age is applied. To close the contactor it is neces sary to remove closing instruction and apply it once more after than the temperature downs less than Overheating indication temperature and elimination of overheating reason. Technical Manual Technical specification Technical specification Applicable standards: IEC 9474190 General Rated voltage, V LSM/TEL14/400340 LSM/TEL14/400341 LSM/TEL14/400342 Rated frequency, Hz Conventional thermal curent, A Rated breaking capacity, kA Rated making capacity, kA Rated over current capacity, 10s, kA Mechanical life, CO operations Operational frequency, CO operations per hour mechanical AC1 AC3 AC4 Switching capacity, CO operations at rated current at breaking current at other currents Closing time, ms, not more than Drop out time, ms, not more than Opening time, ms, not more than Overheating Indication Temperature, °C Emergency Trip Temperature, °C Main contact resistance, microOhm Current heat loss, at 400A, w Ambient air temperature open, °C enclosed, °C storage, °C Climatic proofing Maximum altitude above sea level, m Degree of protection Mechanical vibration withstand capacity stationary vibration, sinusoidal, g nonstationary vibration, shock, g Weight, kg, not more than * According IEC 60068188 (C Damp heat (steady state); D Damp heat (cyclic). ** IP00 at flat strip conductor or busbar connection. *** According IEC 6072134. 11 1000 230 400 50, 60 400 4 4 3.2 2 000 000 600 600 500 300 2 000 000 50 see diagram 50 60 80 70±3 80±3 90 50 40...+55 40...+40 40...+60 C, D* 2000 IP40 (IP00)** Class 3M4 (IEC 72134)*** 1 10 10,0 Technical Manual Technical specification 12 Rated operational power of AC motors (AC3 and AC4) Rated operational power, kW Rated voltage, V LSM/TEL14/400340 LSM/TEL14/400341 LSM/TEL14/400342 220 125 125 125 230 130 130 130 240 135 135 135 380 200 200 400 220 220 415 240 240 440 255 500 290 660 340 690 360 1000 500 Switching capacity 10000 4000 Current, А 1000 100 10 1 10 100 1000 10000 100000 Interrupting life, operations 1000000 Technical Manual Technical specification Auxiliary circuits “Power supply” Power supply rated voltage, V AC Operating range, V AC Power consumption, VA, not more than during preparation time (charging of closing capacitor) in opened position in closed position Preparation time, s, not more than after initial power application after previous open operation Maximum withstand voltage, V, peak 220 187242 35 8 15 10 5.5 420 “Control Input” Control input rated voltage, V AC 220 Operating range, V AC, Minimum accepted level of close instruction, V AC, not less than Minimum holding level of close instruction, V AC, not less than Maximum accepted level of trip instruction, V AC, not more than "Close" instruction acceptance time, ms, not more than "Trip" instruction acceptance time, ms, not more than 44242 132 88 44 30 30 Auxiliary contact units Maximum operating voltage, V (AC&DC) Rated voltage, V (AC&DC) Breaking capacity (AC, cos=0.8), VA Maximum carrying current, A Minimum switching current, A (AC&DC) Dielectric strength, VDC Interrupting life at maximum breaking cur rent, CO cycles Mechanical life, CO cycles 400 250 750 10 0.1 750 50 000 1 000 000 13 Technical Manual Technical specification 14 Surge arresters Type Rated Voltage , V AC SAU230 SAU400 220, 230, 240 380, 400, 415 Surge Current, A (8/20 m s) Energy Absorption, J (2 ms) 8000 8000 100 135 1,0 1,0 Voltagecurrent characteristics of different SAU are shown below Voltage, V 2000 1000 SAU400 SAU230 0 1E3 0,01 0,1 1 10 Current, A Maximum surge current, A Derating curves of different SAU are shown below. Impulse duration, m s Average Power Dissipation, W 100 Technical Manual Technical specification 15 Electromagnetic Compatibility (EMC) Parameter Level Characterizations Immunity criteria in accordance with IEC 6094741 Electrical fast transient/burst immunity in accordance with IEC 6100044: for "Power supply 4 A "for "Control input" 4 A Surge immunity in accordance with IEC 6100045 4 3 common 4 kV differential 2 kV B B Power frequency magnetic field immunity in accordance with IEC 6100048 5 100 A/m 1000 A/m A A Pulse magnetic field immunity in accordance with IEC 6100049 5 1000 A/m A Damped oscillatory magnetic field immunity in accordance with IEC 61000410 5 0,1 and 1 MHz 100 A/m A Voltage dips, short interruptions and voltage variations immunity in accordance with IEC 61000411 5 A Oscillatory waves immunity in accordance with IEC 61000 412 taking into account IEC 255221 3 1 MHz, 0,1 MHz 2 kV A Electrostatic discharge immunity inaccordance with IEC 6100042 3 A Dielectrical Strength Power frequency voltage between main contacts between main contacts and auxiliary circuits between auxiliary circuits Lighting impulse 1,2 m s/50 ms/0,5 J between main contacts between main contacts and auxiliary circuits between auxiliary circuits and “Earth” between isolated auxiliary circuits between NO and NC of ACU Insulation resistance between isolated potentional zones at 500 VDC, not less than 3,5 kV 3,5 kV 2,0 kV 8,0 kV 8,0 kV 4,0 kV 4,0 kV 4,0 kV 5,0 MOhm Technical Manual Dimensional drawings Dimensional drawings 16 Application Guide Selection Incoming inspection 17 Application guide Selection Selection of the contactor is made in accordance with following table: Type LSM/TEL14/400340 LSM/TEL14/400341 LSM/TEL14/400342 AC System Rated voltage, V AC Threephase, threewire or fourwire systems Threephase, fourwire systems Threephase, fourwire systems up to 1000 220, 230, 240 380, 400, 415 Incoming inspection Each contactor before installation shall be sub jected under physical control. Inspection shall be made in accordance with the table below. If contactor’s appearance has any nonconformi Inspection tyes customer has to made a decision in respect with application of the contactor. In any cases customer shall arrange activity in accordance with Complaints handling procedure. Conformity criteria Packaging Absence of severe damages resulted from: product drops excessive moistening of package package deformation caused by external impacts excessive external load applied to package Compliance of box label to order dataAbsence of undamaged seals Sealing Absence of undamaged seals Plastic parts Absence of mechanical damages, scratches and colored spots Metal parts Absence of mechanical damages, scratches and corrosion on painted surfaces and galvanized terminals. Application Guide Mounting 18 Mounting The contactor can be installed directly on low voltage switchgear's panel or through extra installation bars AXCA745422.017 The last way is used if there is no access from the back side of low voltage switchgear panel. Each contactor is provided with paper template to make marking on switchgear's panel. Mounting holes, required fasteners and torques are shown below. 1...4 155±0.2 8 Screws 4,2 8 Washers 4 Screws M6х20 4 Spring Washers 4 Washers Torque 10 N.m 155±0.2 115±0.2 168±0.2 210±0.2 8 holes 3.2* 40±0.2 4 holes 7 5 168±0.2 210±0.5 235 * for 1..2 mm thickness of the panel, f3.7 mm if thickness is more than 2 mm 50 2 40 2 holes 7 10 Application Guide Main terminals connection 19 Main terminals connection Primary connections to the contactor shall be made using unprepared copper* or aluminum cables which types and sizes are shown below. ■ Third step cut seals at appropriate size Crosssection Conductor sectional stranded core mm2 AWG 70 240 00 500 sectional solid core 95 300 000 600 round stranded core 50 185 0 350 round solid core 70 240 00 500 ■ Fourth step fit seal on cables Connecting cables shall be inserted through rub ber seals as the figure below. The seals shall be cut in accordance with the diameter of cable in accordance with the table below. ■ First step cut cable isolation at 30 mm length ■ Fifth step fix cables with special key tightly * Note: Cupper cables shall be tinned ■ Second step find cutting line of seal in accor dance with the following table and outline Cutting line 50 70 95 120 150 185 240 1 1 1 1 2 2 1 1 1 2 2 2 3 30 11 17 24 34 Line 3 Conductor of 1–phase cable Line 2 Conductor of 3–phase cable Line 1 Cable crosssection, mm2 Attention: The load shall be connected to termi nals near surge arrester unit ■ Sixth step fit seals on the contactor Application Guide To provide connection with busbars or cables with lags additional adapters shall be used. Sequence of connection is shown below. ■ Main terminals connection ■ Fourth step fit seals on the contactor ■ Fifth step connect cables 20 First step cut seals at appropriate size ■ Second step fit seals over adapters ■ Third step fix cables with special key tightly Attention: If prospective shortcircuit current of the circuit exceeds of rated parameters of the con tactor extra shortcircuit protective device (SCPD) shall be connected seriously. SCPD shall provide overcurrent discrimination between contactor and shortcircuit currents. Application Guide Wiring and earthing To connect "Power Supply", "Control Input", aux iliary contacts and "Earth" circuits push the clamp of the cover and move it towards the arrow. Connection is made through WAGO connector’s "Power Supply" and "Control Input" terminals. The circuits are connected with (0.51.5) mm2 singlecore or multicore wires. The insulation of the wires shall be reared on 610 mm. Connection is made with special screw that is included in delivery set. Terminal 1 2 3 4 5 Designation “Control Input” (1) “Control Input” (2) Free “Power Supply” (1) “Power Supply” (2) The contactor shall be earthed through M5 stud. The "Earth" stud shall be connected with not less than 2.5 mm2 wire that is tagged with 5 mm diam eter lag. Wiring and earthing 21 Application Guide Wiring and earthing 22 Auxiliary contacts connection Terminals of auxiliary contact units are not numerated. The order of the terminal corre sponds to the following figure. Terminal 1 Designation 2 “Auxiliary contact (1)” (NO) “Auxiliary contact (1)” (NO) 3 “Auxiliary contact (2)” (NC) 4 “Auxiliary contact (2)” (NC) Wires of auxiliary contacts with “Power supply”, “Control input” and “Earth” wires are placed together and are fixed by strips. The cover has four plugs, so the plug (or two plugs if necessary) shall be broken with pliers and sharp edges on the cover shall be smoothed with knife or round file. To place the cover it is necessary to align joggles on the cover and corresponding holes in the switching module and to clamp the cover. Application Guide Commission test 23 Commissioning test Before beginning of application each contactor shall be subjected to the following commission ing tests: Operation test Action Apply supply voltage to 4 and 5 terminals Apply control voltage to 1 and 2 terminals Switch off control voltage from 1 and 2 ter minals Apply control control voltage to 1 and 2 ter minals Switch off supply voltage from 4 and 5 ter minals Switch off control voltage from 1 and 2 ter minals High voltage test Use standard method (IEC 94741) to check insulation level. Insulation resistance test Use standard methods to check the insulation resistance of the auxiliary insulation. It shall not Expected reaction contactor shall open "Power" LED shall light "Malfunction” LED shall not light "Closed” LED shall not light contacts 3 and 4 of ACU shall close contacts 1 and 2 of ACU shall open contactor shall close "Power" LED shall light "Malfunction” LED shall not light "Closed" LED shall light contacts 3 and 4 of ACU shall open contacts 1 and 2 of ACU shall close contactor shall open "Power" LED shall light "Malfunction” LED shall not light "Closed" LED shall not light contacts 3 and 4 of ACU shall close contacts 1 and 2 of ACU shall open contactor shall close "Power" LED shall light "Malfunction” LED shall not light "Closed" LED shall light contacts 3 and 4 of ACU shall open contacts 1 and 2 of ACU shall close contactor shall open "Power" LED shall not light (in 5 seconds) "Malfunction” LED shall not light "Closed" LED shall not light contacts 3 and 4 of ACU shall close contacts 1 and 2 of ACU shall open No reaction be below the limits given in the contactor tech nical specification. Main contact resistance test Use standard methods to check resistance of the main contacts of the contactor. Values must not exceed limits specified in the contactor technical specification. Application Guide Maintenance Maintenance 24 Insulation resistance test The contactor is inherently maintenance free. However, if customer has periodical test proce dure the contactor can be subjected under fol lowing commissioning tests. If some nonconfor mity is found the contactor shall be handled as described in subsection Failure analisys and han dling (see below). The insulation resistance shall comply with value that is pointed in subsection Dielectrical strength. In the case of noncompliance try to find the “weak point”. Note that, generally, other devices can be installed in parallel to the contactor. Contact resistance test Operation test The contactor shall be operable as pointed in the chapter above. If contactor has contact resistance which exceeds the specified limit but it is less than twice this limit, continuation of use is possible, if the actual continuous current does not exceed the following value: ___ High voltage test Dielectric strength of vacuum interrupters and support insulation in respect to power frequency withstandability shall not deteriorate in service. During the test, apply voltages as pointed in sub section Dielectrical strength. However, impulse withstandability of vacuum interrupters can decrease in service. So, producer specifies light impulse withstandability on 5 kV level for inter rupters. Impulse withstandability of support insulation shall be the same as for a new contac tor. Ia<Ir √ Rr , Ra where: Ia, Ra actual current and current resistance respectively, Rr rated contact resistance, Ir rated current or conventional enclosed ther mal current, Failure analyses and handling If any nonconformity during commissioning tests, maintenance or in service is occurred the contactor shall be handled in accordance with the following table. Nonconformity In any cases customer shall arrange activity in accordance with Complaints handling procedure. "Malfunction" LED mode Recommended action The contactor is not operatable, "Power" LED indicator is not lighted Unspecified Check and correct power supply voltage If the voltage is in rate replace control module The contactor is in close position, "Closed" LED indicator is not lighted Unspecified Replace contactor Unspecified Replace contactor Unspecified Replace ACU The contactor is in open position, "Closed" LED indicator lights Nonconformity of auxiliary contact Supply voltage is less than permissible limit Other nonconformities of the module 1 Blink Check and correct power supply voltage 4, 5 or 6 successive blinks Replace the contactor Failure of High voltage test Unspecified Replace the contactor Failure of Insulation resistance test Unspecified Replace the contactor Failure of Contact resistance test Unspecified Replace the contactor Failure of surge arrester unit Unspecified Replace surge arrester unit Application Guide Failure analyses and handling Replacement of auxiliary contacts The auxiliary contacts units are maintenance free. However, if damage of auxiliary contact occurs under any circumstances the unit can be replace as follows. ■ ■ ■ ■ 25 Replacement of surge arresters unit ■ ■ ATTENTION: Contactor shall be open before replacement of auxiliary switches. Take off the cover; Press to auxiliary contact block’s slot and draw out the block; Insert a new ACU/TEL01; Install the cover. Order of SAU/TEL replacement is as follows. Press upwards to surge arresters unit’s flanges with two hands simultaneously. Install a new unit that corresponds to rated volt age of the system. Replacing of control module Attention: The contactor shall be competelly powered down. Order of control module’s replacement is as follows: ■ Take off the cover ■ Remove surge arrester unit ■ Screw off four captive screws at connection board ■ Disconnect connection board ■ Disconnect earthing wire from the control module ■ Screw off four captive screws at control module ■ Remove the failed module Install new control module in inverse sequence Perform operation test ■ ■ Application Guide Routine test Type test Disposal 26 Routine test Each contactor before delivery shall be subjected to the following routine test procedure. Malfunction to meet any of the abovementioned requirements means failure to pass routine test procedure Test Conformity criteria Design and visual checks correctness of nameplate data compliance of the module type to order absence of mechanical damages, scratches, colour variations affecting module appearance Mechanical operation tests (1000 CO operations at rated operating voltage) proper operation of main and auxiliary contacts compliance of the closing and opening times with the requirements of technical specification absence of contact bounce Power frequency voltage withstand of the main cir cuits (between open contacts) absence of breakdowns inside vacuum interrupter Power frequency voltage withstand of the auxiliary circuits (between terminals and earth) absence of breakdowns Type tests Type tests shall be arranged in accordance with the following table. Where: NL no limitations: supervisory from test lab is not required Type test TEL supervisory from TEL is required. It includes approval of the test program, order and prepara tion of test samples and possible participation at tests with test lab of Tavrida Electric. Standard Type test features IEC 9474190 TEL GOST 3001196 TEL IEC 9474190 NL GOST 3001196 NL IEC 9474190 NL GOST 3001196 NL IEC 9474190 NL GOST 3001196 NL IEC 9474190 NL GOST 3001196 NL IEC 9474190 NL GOST 3001196 NL Dielectric tests Temperature rise tests Making and breaking tests Shorttime withstand current tests Mechanical life tests Measurement of resistance of the main circuit Disposal Modules do not contain any materials that are hazardous for environment or personnel. No spe cial methods of disposal are required. Attention: Only electronic version of this document distributed through designated channels to designated users can be considered valid. List of changes № 1 2 Page Before Now Reason