TidWeb Construction Standards Test Only

TID WATER & POWER

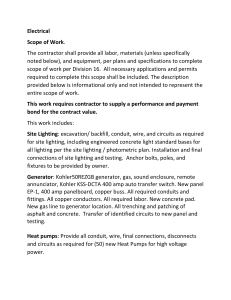

OPERATIONS COMPLEX

Turlock California

SECTION 26 50 00

ELECTRICAL

PART 1 - GENERAL

1.01

RELATED DOCUMENTS

A.

Drawings and general provisions of the Contract, including General and Supplementary Conditions and

Division 1 Specification Sections, apply to the Work of this Section.

B.

Comply with the requirements of the TID OPERATIONS COMPLEX DESIGN CRITERIA Turlock

Irrigation District Prepared By: Parsons Brinckeroff and HKIT Architects dated REVISED August 5,

2008.

C.

The following sections apply to Work of this Section.

1.

Section 26 00 10, “Common Work Results for Electrical.”

2.

Section 26 00 20, “Design Phase Services.”

1.02

DESIGN CRITERIA

A.

The following design criteria shall be verified and updated by the design-build contractor as the design progresses, subject to review and approval by the Owner and Architect.

B.

Load Densities:

Area Description

Open Office Areas

Enclosed Offices

Volt-Amperes/Sq. Ft.

Receptacles Lighting

5.0 1.2

5.0 1.2

Conference / Meeting Rooms

Dining / Break Rooms

Data Center / Network Racks / Communications room Located in the Power and Operations Building shall have UPS and

Emergency Generator backup power distributed Via a dual path A/B redundant source design.

MDF/IDF Rooms

Electrical, Telephone, Mechanical Rooms

Maintenance shops

15.0

2.0

Per Owner and

Control Center consultant

Per telecom consultant

0.5

8.0

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 1

1.4

1.1

1.6

1.6

1.0

1.6

ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

Area Description

Security Rooms

Volt-Amperes/Sq. Ft.

Receptacles Lighting

Per security consultant

1.4

Storage Rooms 2.0 0.6

Dock Area

Parking Lot

1.0

0.25

0.6

0.6

* Plus additional equipment loads described in the requirements of the TID OPERATIONS COMPLEX

DESIGN CRITERIA Turlock Irrigation District Prepared By: Parsons Brinckeroff and HKIT Architects dated REVISED August 5, 2008.

C.

Illumination Levels:

Coordinate with the requirements of the TID OPERATIONS COMPLEX DESIGN CRITERIA Turlock

Irrigation District Prepared By: Parsons Brinckeroff and HKIT Architects dated REVISED August 5,

2008.for site and parking lot lighting, landscape lighting, interior public space, and office lighting.

Illumination levels shall be as follows:

Area Description

Open Office Areas

Enclosed Office Areas

Average Maintained Footcandles

50

50

Lobby 20

Corridors 10

Conference / Meeting Rooms

Dining / Break Rooms

50

50

Data Center

Shops / Repair Bay

MDF/IDF Rooms & network racks

Electrical, Telephone, Mechanical Rooms

Elevator Machine Rooms

Security Rooms

50

70

50

20

20

50

Restrooms 20

Storage Rooms 20

Dock Area 20

Exit Signs As Required

D.

Power Distribution

1.

Separate feeders shall be provided for HVAC, plumbing, fire protection and elevator loads.

2.

Spare capacity shall be provided in transformers, power distribution panels, feeder circuits, and branch circuit panelboards. Spare capacity shall be approximately as follows: a.

Branch circuit panelboards: 25% spare capacity. b.

Power distribution panels: 25% spare capacity.

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 2 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California c.

Main power panels: 25% spare capacity. d.

Transformers and feeder circuits: Spare capacity equivalent to associated equipment but not less than 10%.

3.

Power System Study: Fault currents shall be obtained from utility company and utilized for short circuit current calculations to obtain and indicate fault current ratings on all electrical equipment throughout the buildings. Design-build Contractor shall perform an ARC Flash Study and a short circuit and coordination study in order to make final settings for all protective devices in the electrical system. The settings will be determined from the study that uses the exact characteristics of the installed equipment. ARC flash labels shall be installed on all panels, transformers, switchboards, transfer switches and Main switchboards.

4.

Provide power connections to: a.

All electrical, electronic, HVAC, plumbing and fire protection equipment. b.

Uninterruptible power source systems. c.

Overhead cranes d.

Welders, Compressors and equipment. e.

Shop Equipment. f.

Telephone equipment. g.

Rolldown doors. h.

Electrically operated doors and gates. i.

Dock levelers. j.

Electric water coolers. k.

Irrigation controllers. l.

Illuminated signs. m.

Trash compactors. n.

Gas shut-off valves. o.

Computer systems and equipment. p.

Lighting fixtures and lighting controls. q.

Master units of fire alarm and detection systems, building automation system, lighting control system, etc. r.

All equipment for security system and public address system. s.

Underfloor leak detection system (Data Center).

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 3 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California t.

Fuel Islands / Fuel Pumps. u.

Pressure Washers v.

Electric Car Chargers. w.

Coordinate equipment connections with the requirements of the TID OPERATIONS

COMPLEX DESIGN CRITERIA Turlock Irrigation District Prepared By: Parsons

Brinckeroff and HKIT Architects dated REVISED August 5, 2008

5.

Provide surge protective devices at each panelboard serving electronic equipment.

E.

Branch Circuiting:

1.

Branch circuit design shall be based upon a maximum of 1,600 volt-amperes per 20 ampere, 120 volt circuit (maximum of 4 receptacles per circuit).

2.

Branch circuit design shall be based upon a maximum of 3,700 volt-amperes per 20 ampere, 277 volt circuit

3.

For electrified furniture feeds, branch circuit design shall be based upon one 120V, 20A circuit serving a maximum of 4 workstations.

4.

Receptacles circuits for the exterior of building shall be provided with ground fault interrupters.

F.

Lighting:

1.

General interior and exterior lighting shall be provided throughout.

2.

Additional lighting shall be provided and installed per Architect’s drawings and specifications.

3.

Emergency exit lights and emergency egress lighting shall be provided throughout including but not limited to restrooms and public spaces as required by code. In buildings served by a generator emergency egress lighting fixtures shall be served generator emergency power.

4.

It shall be the responsibility of the electrical design build contractor to ensure that lighting densities meet California Energy Code.

5.

Coordinate light fixture requirments with the requirements of the TID OPERATIONS COMPLEX

DESIGN CRITERIA Turlock Irrigation District Prepared By: Parsons Brinckeroff and HKIT

Architects dated REVISED August 5, 2008

G.

Lighting Controls:

1.

Lighting in enclosed offices shall be controlled by a combination manual light switch and occupancy sensor; bi-level manual On, and time delay automatic Off.

2.

Lighting in open offices shall be controlled by building lighting control system; time control On, and time control Off, with local override capability.

3.

Provide automatic dimming of electric lights via photosensors in daylit spaces.

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 4 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

4.

Restroom lighting shall be controlled by occupancy sensor; automatic On, and time delay automatic Off.

5.

Janitor closet and storage room lighting shall be controlled by occupancy sensor; automatic On, and time delay automatic Off.

6.

Electronic multi-scene lighting control wallstations shall be considered for conference rooms.

Dimming ballasts for lighting fixtures shall be provided as required.

H.

Receptacles and Outlets:

1.

Maintenance receptacles shall be provided in corridors and lobbies at 50-foot intervals.

2.

Maintenance receptacles shall be provided in service areas, restrooms, storage rooms, dock area, and at exterior of building.

3.

Maintenance receptacles on standby power shall be provided in electrical rooms, mechanical rooms, and security rooms.

4.

120V, 20A duplex GFCI receptacles with weatherproof covers shall be provided on the roof with each piece of mechanical equipment.

5.

Dedicated 20A, 120V branch circuits shall be provided to the following components: a.

Irrigation controllers.

I.

b.

Fire alarm control panel (emergency power). c.

BMS controllers.

6.

Flush floor mounted combination power/data receptacles shall be provided in the conference rooms.

7.

Coordinate receptacle requirements with the requirements of the TID OPERATIONS COMPLEX

DESIGN CRITERIA Turlock Irrigation District Prepared By: Parsons Brinckeroff and HKIT

Architects dated REVISED August 5, 2008

Emergency/Standby Power:

1.

Building “Power and Operations” emergency/standby power generation system shall be sized for the full load of the building, including: a.

Emergency lighting in “Power and Operations” Building , and exterior lighting (e.g. exit illumination; exit signs; electrical; telephone; security electronics and mechanical equipment rooms; control rooms; building management system room; restrooms; etc.) b.

Fire Sprinkler System. c.

Fire detection, alarm and communications. d.

Security and alarm systems. e.

Telephone equipment.

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 5 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California f.

MDF/BDF/IDF room equipment. i.

j.

g.

Miscellaneous critical loads (i.e. power generation auxiliary equipment, building management system, boiler control panel). h.

Data center equipment and support spaces.

Meeting Rooms, which function as command centers during emergencies.

Coordinate emergency power requirements with the requirements of the TID

OPERATIONS COMPLEX DESIGN CRITERIA Turlock Irrigation District Prepared By:

Parsons Brinckeroff and HKIT Architects dated REVISED August 5, 2008

2.

Building “Power and Operations” generator shall be housed in a sound-attenuated enclosure, and shall include a sub-base fuel tank with a capacity for 24 hours of runtime at 100% load.

3.

All Buildings except the “Power and Operations” building emergency/standby power generation system shall be sized for the following loads and shall be fed from the “Power and Operations

Generator” : a.

Emergency lighting in and exterior lighting (e.g. exit illumination; exit signs; electrical; telephone; security electronics and mechanical equipment rooms; control rooms; building management system room; restrooms; etc.) b.

Fire Sprinkler System. c.

Fire detection, alarm and communications. d.

Security and alarm systems. e.

Telephone equipment.

J.

i.

j.

f.

MDF/BDF/IDF room equipment. g.

Miscellaneous critical loads (i.e. power generation auxiliary equipment, building management system). h.

Meeting Rooms, which function as command centers during emergencies.

One Fuel Pump. One compressor.

Coordinate emergency power requirements with the requirements of the TID

OPERATIONS COMPLEX DESIGN CRITERIA Turlock Irrigation District Prepared By:

Parsons Brinckeroff and HKIT Architects dated REVISED August 5, 2008

Telephone / Data Service:

1.

The telephone company service cables will terminate in the MPOE. Service raceways (including trenching and back filling) shall be provided to connect to the telephone company raceways system. Raceways shall be provided from the MPOE to each IDF room.

2.

A grounding system shall be provided at the MPOE, IDF rooms and security rooms.

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 6 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

3.

Coordinate telephone requirements with the requirements of the TID OPERATIONS COMPLEX

DESIGN CRITERIA Turlock Irrigation District Prepared By: Parsons Brinckeroff and HKIT

Architects dated REVISED August 5, 2008

K.

Fire Detection and Alarm System:

1.

The building fire detection and alarm system shall be addressable, electrically supervised, Class A and shall consist of fire alarm control panel, annunciator panels, manual pull stations, surface mounted smoke and heat detectors, air handling system duct-mounted smoke detectors, fire smoke damper smoke detectors, audible/visual alarms, and fire protection system water flow detection and valve position indication.

2.

Coordinate fire alarm requirements with the requirements of the TID OPERATIONS COMPLEX

DESIGN CRITERIA Turlock Irrigation District Prepared By: Parsons Brinckeroff and HKIT

Architects dated REVISED August 5, 2008

L.

Security System:

1.

Required infrastructure such as backboxes, raceways, and 120V power shall be provided.

2.

Coordinate security system requirements with the requirements of the TID OPERATIONS

COMPLEX DESIGN CRITERIA Turlock Irrigation District Prepared By: Parsons Brinckeroff and HKIT Architects dated REVISED August 5, 2008

M.

Public Address System:

1.

Required infrastructure such as backboxes, raceways, and 120V power shall be provided.

2.

Coordinate paging system requirements with the requirements of the TID OPERATIONS

COMPLEX DESIGN CRITERIA Turlock Irrigation District Prepared By: Parsons Brinckeroff and HKIT Architects dated REVISED August 5, 2008

N.

Grounding System:

1.

Provide complete grounding system that complies with requirements of authorities having jurisdiction, including required grounding sections of National Electrical Code. Provide an equipment grounding conductor in each feeder and in each branch circuit raceway.

1.03

SYSTEMS DESCRIPTION

A.

Electrical Service (Buildings 1, 2 and 3):

1.

TID Company is the local electric utility provider.

2.

The service to each building is planned to be 480Y/277V, 3Ø, 4 Wire, Grounded. How each building is served electric power is to be negotiated and confirmed with TID by the Design Build

Contractor.

3.

Each building’s main switchboard shall be provided with a connection point for 480Y/277V, 3Ø,

4 Wire feeds for future expansion.

4.

The 480Y/277V, 3Ø, 4 Wire service will provide power for all interior and exterior lighting,

HVAC, and equipment loads. All other loads shall be served at 208Y/120V, 3Ø, 4 Wire via distribution systems (dry-type transformers and 208Y/120V panelboards) located in local electrical rooms or wall mounted at the shop locations.

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 7 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

5.

A 480Y/277V, 3Ø, 4 Wire panelboard (site lighting) and a 208Y/120V, 3Ø, 4 Wire panelboard

(house loads, such as irrigation controller, etc.) shall be located in the main electrical room.

6.

Dedicated panelboards located in specific areas (such as shops, MDF//BDF/IDF rooms) may be required.

7.

Provide a 480Y/277V, 3Ø, 4 Wire lighting panelboard, a step-down transformer, and a

208Y/120V, 3Ø, 4 Wire receptacle panelboard, at a minimum, in each local electrical room.

Provide additional 208Y/120V, 3Ø, 4 Wire receptacle panelboards as needed to accommodate circuit requirements.

B.

Branch Circuit Distribution

1.

Power feeds to electrified furniture shall be raceways routed in the 1 st

floor ceiling space.

2.

Ground Floor: The following three options are being considered: a.

Combination of wall furniture feeds and infloor furniture feeds. b.

Infloor wire and cable management system.

C.

Data Center “Power and Operations”

1.

The Data Center includes the main data center room, plus various support spaces. The architectural drawings show the layout of the various rooms.

2.

Coordinate Data Center requirements with the requirements of the TID OPERATIONS

COMPLEX DESIGN CRITERIA Turlock Irrigation District Prepared By: Parsons Brinckeroff and HKIT Architects dated REVISED August 5, 2008

3.

Electrical System Serving the Data Center:

4.

Integrated Fire Protection: Clean Agent Fire Suppression Systems, Addressable

Detection/Controls, Emergency Power Shutdown System, Pre-action Sprinkler System: Refer to

Fire Protection Specifications 21 30 00 and provide the following: a.

120V power to the fire suppression system b.

120V power to the pre-action system c.

120V power to each VESDA system d.

Control interface between fire suppression panel and shutdown of all CRAC units serving the Data Center e.

Interface with the building fire alarm control panel f.

Interface with BMS system g.

Interface with security system

D.

Grounding System

1.

Grounding system and equipment grounding shall be provided. Switchboards, transformers, panelboards, wiring systems, etc. shall be effectively grounded. Ground conductors shall be bonded to cold water mains, ground rods, and building steel.

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 8 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

E.

Lighting System

1.

The following three options are being considered for the open office areas: a.

Recessed indirect/direct fluorescent, T8 lamps. b.

Recessed indirect/direct fluorescent, T5HO lamps. c.

Suspended indirect/direct fluorescent, T8 lamps. d.

Suspended indirect/direct fluorescent, T5HO lamps.

2.

For areas other than the open office areas, provide fixtures utilizing the same lamps as the open office areas to minimize the stocking of spare parts.

3.

Coordinate Lighting requirements with the requirements of the TID OPERATIONS COMPLEX

DESIGN CRITERIA Turlock Irrigation District Prepared By: Parsons Brinckeroff and HKIT

Architects dated REVISED August 5, 2008

F.

Lighting Control System

1.

Interior Lighting: Provide a digital lighting control system, fully compliant with California Title

24 requirements, to control all tenant lighting fixtures. Programming requirements shall be coordinated with Owner.

2.

Exterior Lighting: Site and parking lot lighting shall be controlled by photocell and astronomic timeclock; provide interface with building automation system.

PART 2 - PRODUCTS

2.01

ELECTRICAL PRODUCTS

A.

Manufacturers listed below are intended to set a standard of quality. Other manufacturers may be acceptable as equal if approved by Owner.

2.02

ELECTRICAL IDENTIFICATION

A.

Cable/conductor and raceways shall be properly identified with color-coded identification bands and markers; use colors prescribed by ANSI A13.1 and NFPA 70. Conform to ANSI A13.1 Table 3 for minimum size of letters for legend and minimum length of color field for each raceway or cable size.

B.

Operation instructions, danger and warning signs shall be provided.

C.

Underground Line Warning Tape: Permanent, bright-colored, continuous-printed vinyl tape not less than

6 inches wide by 4-mils thick, compounded for permanent direct burial service, with embedded continuous metallic strip or core, and printed legend indicating type of underground line.

D.

Equipment/system identification signs: use colors prescribed by ANSI A13.1 and NFPA 70. Engraving stock, melamine plastic laminate, white letters on black face (normal power), white letters on red face

(emergency/standby power), punched for mechanical fasteners. Wording to indicate source of electrical supply and sized to suit equipment for which it is provided.

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 9 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

E.

Receptacles:

1.

Panelboards and circuit numbers shall be identified on receptacle with P-touch labels.

2.

Emergency/standby power – Same as above.

2.03

ELECTRICAL EQUIPMENT VIBRATION ISOLATION

A.

Vibration isolation shall be provided for transformers.

B.

Flexible conduits shall be provided at transformer connections, at motors and other vibrating equipment.

2.04

CONDUIT

A.

Provide conduit for conductors except armored cable. For 4”-1/2” diameter conduit, provide EMT

(thinwall) galvanized, electrical metallic tubing complete with factory made bends where site bending is not possible, and joints and terminations made with set screw type connectors. For short branch circuit connections to motorized equipment and transformers (minimum length 18 inch, maximum length 24 inch) provide liquid-tight galvanized steel flexible metallic conduit complete with liquid-tight flexible conduit connectors at terminations. For surface mounted conduit at height less than 4 feet, provide rigid galvanized steel complete with fittings, connectors and rigid couplings.

B.

Empty raceways shall be provided with pull lines.

C.

Support and secure conduit at spacing in accordance with code requirements by means of galvanized pipe straps, conduit clips, ring bolt type hangers, or by other proper manufactured devices. Provide conduit fittings constructed of same materials as conduit and suitable for application. Square and properly ream ends of site cut conduit. Generally, conduit is sized on drawings. Size conduit not sized on drawings in accordance with code. Meet code required minimum radii for conduit bends, with no kinking and no flaking or cracking of finishes.

2.05

CONDUCTORS

A.

Provide conductors, sized in accordance with code, and increased to suit length of run and voltage drop.

Provide cable support system accessories that are required for proper installation.

B.

Conductors shall be single conductor copper, 75 degrees C rated, color coded, PVC insulated. Do not exceed the NEC 60 degree C ampacity for conductor sizes No. 1 AWG and smaller.

C.

Branch circuit conductors up to and including No. 10 AWG shall be solid. Conductors in sizes larger than No. 10 AWG shall be stranded. Provide conductors constructed of 98% conductive copper and approved for 600V. Do not use conductors smaller than No. 12 AWG unless otherwise noted.

2.06

OUTLET BOXES, PULLBOXES AND JUNCTION BOXES

A.

Provide UL approved stamped galvanized steel outlet box for each luminaire, etc. Refer to drawings for locations of outlets. Confirm exact locations prior to roughing-in.

B.

Provide pullboxes and junction boxes wherever necessary to facilitate conductor/conduit installations.

Generally, provide conduit runs exceeding 100 feet in length, or with more than three 90 degree bends, with pullbox installed at convenient and suitable intermediate accessible location. Provide junction

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 10 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California boxes and pullboxes sized in accordance with code to suit number and size of conduits and conductors.

Boxes shall be galvanized or prime coated plate steel complete with screw-on or hinged cover and knockouts. Boxes shall be accessible after work is complete.

C.

Size, arrangement and type of boxes shall be suitable for application. Provide blank coverplates on existing obsolete boxes that are to remain. Clearly identify pull or junction boxes with color coding of the systems for identification:

1.

Lighting - yellow;

2.

Normal power - blue.

3.

Emergency/Standby – orange.

4.

Fire Alarm - red.

D.

Where required, supply access doors of minimum No. 12 GA. prime coated steel complete with hinges and frames to give access to boxes and conductor joints and other similar electrical work which may need maintenance or repair, but which is concealed in inaccessible construction. Confirm finishes with

Architect.

2.07

RECEPTACLES, SWITCHES AND FACEPLATES

A.

Provide UL approved specification grade, AC quiet action switches and specification grade premium quality duplex receptacles. Devices shall be of the decorator style. Provide smooth surface nylon faceplates with matching color screws. Confirm color, type and finish of devices with Architect.

B.

Provide AC quiet action rocker type, 20A, 120-277V switches. Provide Hubbell No. 2121 single pole,

No. 2122 two pole, No. 2123 three-way, or No. 2124 four-way.

C.

Provide NEMA 5-20R, 20A-125V, UL listed, 2-pole, 3W, specification grade, duplex receptacle complete with faceplate and matching screws. Provide Hubbell No. 2162.

D.

Provide NEMA 5-20R, 20A-125V, UL listed, Class A, 2-pole, 3W, specification grade, ground fault circuit interrupter duplex receptacle, complete with faceplate and matching screws. Provide Hubbell No.

GF5362.

E.

Where installed in exterior locations, provide weatherproof duplex covers.

F.

Acceptable manufacturers include: Leviton, Pass and Seymour, Arrow-Hart, and Bryant.

2.08

LIGHTING FIXTURES

A.

Provide new lighting fixtures per specifications.

B.

Acceptable lamp manufacturers include: Osram/Sylvania, Advance/Phillips, Magnetek or Motorola.

2.09

LIGHTING CONTROL SYSTEM

A.

Provide a digital lighting control system, incorporating programmable ballasts, digital bus, automatic controls (occupancy sensors, daylight sensors) and manual controls (wall dimmers, and/or handheld remote controls), interface for integration with the building automation system, operator terminal, and all accessories required for a complete working installation. Lutron EcoSystem or approved equal.

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 11 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

B.

Provide required Lutron EcoSystem ballasts in all lighting fixtures.

2.10

FASTENING AND SECURING HARDWARE

A.

Provide proper fasteners and similar hardware required for conduit, conductors, and for equipment hanger and/or support material unless otherwise noted. Explosive powder actuated fasteners will not be permitted unless specific written approval for their use and type has been obtained from the Architect.

Do not use ceiling suspension hangers or grids for support of conduit and conductors.

2.11

FUSES

A.

Provide complete set of fuses for each fusible disconnect or similar fusible equipment. Fuses shall be

Class "J" HRC fuses for constant running equipment, and Class "C" fuses for motor equipment that cycles on and off. Acceptable manufacturers are Bussmann, Gould and Littelfuse.

2.12

DISCONNECT SWITCHES

A.

Provide heavy duty disconnect switches, UL approved, front operated type. Fusible units to be complete with fuse clips suitable for HRC fuses, unless otherwise noted. Enclosures to be sprinkler-proof. Amp rating, number of poles and fuse requirements are as indicated on drawings.

B.

Acceptable manufacturers include General Electric, Cutler Hammer, or Square D.

2.13

SWITCHBOARDS

A.

3000 Amp and Greater: Front-connected, front and rear accessible, fixed, individually mounted main device, panel-mounted branches, and sections rear aligned.

B.

Less Than 3000 Amp: Front-Connected, front accessible, fixed, individually mounted main device, panel-mounted branches.

C.

Ratings: Provide nominal system voltage, continuous main-bus amperage, and short-circuit current ratings as indicated.

D.

Barriers: Between adjacent switchboard sections.

E.

Hinged Front Panels: Allow access to breaker, metering, accessory, and blank compartments.

F.

Buses and Connections: 3 phase, 4 wire, except as otherwise indicated. Features as follows:

1.

Phase- and Neutral-Bus Material: Tin plated aluminum with feeder circuit-breaker line connections.

2.

Ground Bus: ¼-inch by 2-inches minimum size, tin plated aluminum, equipped with pressure connectors for feeder- and branch-circuit ground conductors.

3.

Contact Surfaces of Buses: Silver plated.

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 12 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

4.

Main Phase Buses, Neutral Buses, and Equipment Ground Buses: Uniform capacity the entire length of the switchboard main and distribution sections. Provide for future extensions from both ends.

5.

Isolation Barrier Access Provisions: Permit checking bus bolt tightness.

6.

Neutral Buses: 100 percent of the ampacity of the phase buses, and equipped with approved pressure connectors for outgoing circuit neutral cables.

G.

Molded-Case Circuit Breaker: NEMA AB 1, handle lockable for feeder breakers.

1.

Characteristics: Frame size, trip rating, number of poles, and auxiliary devices as indicated and interrupting capacity rating to meet available fault current.

H.

Multi-function Digital Metering Monitor:

1.

Provide voltmeters, ammeters, CT’s, PT’s and digital multi-function meter ahead of the main protective device in each switchboard. Meter shall be capable of the following 3-phase measurements : Voltage and current (per phase and average), Amps demand, neutral or ground current, kW, kW demand, kWh, kVAR, kVARh, kVA, kVAh, power factor, frequency.

2.

Mounting: Display and control unit flush or semiflush mounted in instrument compartment door.

I.

Acceptable manufacturers include General Electric, Cutler Hammer, or Square D.

2.14

GENERATOR

A.

Steady-State Voltage Operational Bandwidth: 4 percent of rated output voltage from no load to full load.

B.

Steady-State Voltage Modulation Frequency: Less than one Hz.

C.

Transient Voltage Performance: Not more than 10 percent variation for 50 percent step-load increase or decrease. Voltage recovers to remain within the steady-state operating band within 2 seconds.

D.

Steady-State Frequency Operational Bandwidth: 0.5 percent of rated frequency from no load to full load.

E.

Steady-State Frequency Stability: When system is operating at any constant load within the rated load, there are no random speed variations outside the steady-state operational band and no hunting or surging of speed.

F.

Transient Frequency Performance: Less than 2-Hz variation for a 50 percent step-load increase or decrease. Frequency recovers to remain within the steady-state operating band within 3 seconds.

G.

Output Waveform: At no load, harmonic content measured line-to-line or line-to-neutral does not exceed

5 percent total and 3 percent for single harmonics. The telephone influence factor, determined according to NEMA MG 1, does not exceed 50.

H.

Sustained Short-Circuit Current: For a 3-phase, bolted short circuit at the system output terminals, the system will supply a minimum of 250 percent of rated full-load current for not less than 10 seconds and then clear the fault automatically, without damage to any generator system component.

I.

Temperature Rise of Generator: Within limits permitted by NEMA MG 1 when operating continuously at full-rated load, including 2 hours per 24 hours at 110 percent of rated capacity.

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 13 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

J.

Starting Time: Maximum total time period for a cold start, with ambient temperature at the low end of the specified range, is 10 seconds. Time period includes output voltage and frequency settlement within specified steady-state bands.

K.

Acceptable manufacturers include Caterpillar, Cummins/Onan, Detroit Diesel.

L.

Generator shall meet the requirements of the local and state air quality board.

2.15

AUTOMATIC TRANSFER SWITCHES

A.

Automatic transfer switches shall be 480Y/277V, three phase, four wire or 480V, three phase, three wire,

60Hz, with minimum symmetrical withstand and closing current rating as required. All devices shall be accessible from the front of the equipment. All wiring shall be copper. Provide lugs for equipment grounding conductors.

B.

The switches shall be designed for automatically switching electrical loads from an original source to an alternate source upon the loss of the original source. The switches shall be double throw, mechanically held, electrically operated, and incapable of stops in intermediate positions during normal operation. The switches shall be three pole for 480V system and four pole for 480Y/277V system. The main contacts shall be protected against arcing. The switch operating time shall not exceed 0.17 seconds in either direction.

C.

ASCO Power Technologies 7000 Series or equal manufactured by Russelectric, Zenith.

2.16

PANELBOARDS

A.

Power and Distribution Panelboards: Provide dead-front, dead-rear, safety type power distribution panelboards, with anti-turn solderless pressure type main lug connectors approved for copper and aluminum conductors. Construct unit for connecting feeders at top or bottom of panel as required. Equip with copper bus bars, and full-sized neutral bus; provide suitable lugs on neutral bus for outgoing feeders requiring neutral connections; provide a bare uninsulated equipment grounding bar suitable for bolting to enclosure; and provide panelboards fabricated by same manufacturer as enclosures, and which mate properly with enclosures. Provide minimum 8" gutter space at top and bottom of panelboard. Provide panelboards equal to G.E. type S5 for up to 1200, and type S4 for up to 600 A (minimum RMS symmetrical amp rating shall be 42 KAIC). Main circuit breaker, if required, shall be mounted vertically at the top.

B.

Lighting and Receptacle Panelboards: Provide dead-front, dead-rear safety type lighting and appliance panelboards with anti-turn solderless pressure type lug connectors approved for copper and aluminum conductors. Construct unit for connecting feeders at top or bottom of panel, as required. Main circuit breaker shall be mounted vertically at the top. Equip with copper bus bars and full-sized or double-sized neutral bus; provide double-sized neutral bus in receptacle panelboards; provide suitable lugs on neutral bus for outgoing feeders requiring neutral connections; provide a bare uninsulated equipment grounding bar suitable for bolting to enclosure; and provide panelboards fabricated by same manufacturer as enclosures, and which mate properly with enclosures. Provide panelboards equal to G.E., type S2 up to

250 A and S3 up to 600A for 480Y/277 volt operation; and type S1 up to 250A and S3 up to 600 A for

208 Y/120 volt operation (minimum RMS symmetrical amp rating shall be 22 KAIC).

C.

Acceptable manufacturers include General Electric, Cutler Hammer, or Square D.

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 14 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

2.17

TRANSFORMERS

A.

For transformers serving office spaces, provide Harmonics Limited Neutralizer TransMax energy efficient transformers, electrostatically shielded, 115˚C rise, three-phase, 480V delta primary,

208Y/120V secondary, UL labeled, with integral harmonic suppression system.

B.

For transformers serving house loads, provide energy efficient transformers, electrostatically shielded,

115˚C rise, three-phase, 480V delta primary, 208Y/120V secondary, UL labeled, by General Electric,

Cutler Hammer, or Square D.

C.

Provide transformer complete with copper windings, stacked laminations of silicone steel core, suitable lugs or pressure type terminals, 2 above and 2 below normal 2-1/2% full capacity taps, an integral vibration dampening system, ASA 61 grey enamel finish and aluminum ID nameplate.

D.

Secure transformer to concrete pad and connect complete. Test and check voltages and make required adjustments.

2.18

LIGHTNING PROTECTION SYSTEM

A.

Provide exterior ground loop (Building Ground Ring) around building perimeter utilizing ground rods with exothermic welds below grade or finished surface. Provide minimum 24-inches of ground cover where ground rod connections are made.

B.

Bond grounded metal bodies on building within 12 feet of ground to ground loop (Building Ground

Ring) conductor.

C.

Provide lightning protection system for Building “Power and Operations”, including but not limited to air terminals, down conductors, interior conductors, connections, bonding, ground rods, and all accessories for a complete working installation. Comply with UL 96A, LPI-175 and NFPA 780. Coordinate work with roofing contractor.

D.

Bond grounded metal bodies on building within 12 feet of roof to interconnecting loop at eave level or above.

E.

Bond lightning protection components to grounded metal bodies on building at every 60 feet with intermediate-level interconnection loop conductors.

F.

Acceptable lightning protection manufacturers include Harger Lightning Protection, Inc.; Independent

Protection Co., Inc.; Thompson Lightning Protection Co., or approved equal.

2.19

DATA CENTER EMERGENCY POWER SHUTDOWN MANAGEMENT SYSTEM (EPSMS)

A.

Scope:

1.

As manufactured by Fike Corporation Model 20-1181. The purpose of this system is to consolidate, control, and monitor the emergency power off circuits for a given environment. The system shall be constructed using a programmable relay logic controller to manage the system logic. The EPSMS shall be connected to and be monitored by the fire control panel (FCP) that controls the environment the EPSMS serves. The scope described in this specification includes material, installation, sequence of operation, shop drawings, testing, and warranty.

2.

The EPSMS shall be designed, furnished, and installed by:

Intelligent Technologies and Services, Inc.

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 15 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

1031 Serpentine Lane, Suite 101

Pleasanton, CA 94566

(925) 484-3701

Contact: Chris Reimer

3.

Work to be completed by others: Monitoring of the EPSMS by the building management system, building life safety system, and security system shall not be considered part of this work scope.

B.

Applicable Standards

1.

The EPSMS system panel shall be constructed of U.L. approved components. The EPSMS control panel shall be constructed to UL 508A standards for industrial control panels. National

Fire Protection Agency NFPA 75 Standards for the Protection of Information Technology

Equipment. NFPA 70.

C.

Submittals

1.

The installing contractor shall submit the following design information and shop drawings for approval prior to starting the work. a.

One-line general arrangement diagram showing the EPSMS control panel and identifying all devices the EPSMS connects to. b.

Enclosure diagram showing the key switch, indicating LED’s, and labels. This sheet shall contain the enclosure dimensions and a complete bill of materials to be used in the construction of the EPSMS. c.

Sequence of operation detailing the input signals, output logic, monitoring relay operation, and maintenance override operation. d.

Wiring Schematic clearly identifying termination points on terminal blocks within the

EPSMS control panel.

D.

Construction

1.

Enclosure a.

The enclosure shall be NEMA-1 capable of being surface or flush mounted with a swing door and key lock. The enclosure shall be constructed of minimum 18-gauge steel and shall be powder coated inside and out. All components of the EPSMS shall be furnished in one enclosure.

2.

Programmable Relay Logic Controller a.

The logic for the EPSMS shall be controlled by a programmable relay logic controller.

Logic using hardwired relays shall not be acceptable.

3.

Input Power a.

Input power shall be 120V single phase minimum 20 amps. Input power to the enclosure shall be internally fuse protected to 120VAC 10-amp.

4.

Indicating Lamps a.

All indicating lights shall be LED full voltage flush type rated at 120VAC. Indicating lamps for Power (green), Normal (green), Override (Amber), 2nd Alarm Activation (red),

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 16 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

E.P.O. Activation (red), and Discharge Activation (red) shall appear on the front of the panel.

5.

Momentary Reset/Test Switch a.

The reset/test switch shall be a momentary.

6.

Piezo Alert a.

A piezo alert shall give audible annunciation on the front of the panel in accordance with the sequence of operation.

7.

Silence Button a.

A silence button shall be mounted on the front of the panel to silence the piezo alert.

8.

2-Position Keyed Maintenance Override Selector Switch a.

The keyed selector switch shall be a two position locking type.

9.

Output Relays a.

Relays shall be N.O. and N.C. intelligent process interface single type pole rated at 6 AMP

120VAC. Quantity as standard shall be minimum 20 including monitoring relays.

Expandable to 36 total relays. Actual quantity as required to meet the devices quantities as shown on the drawings

10.

Wire a.

All wire shall be 16 gauge THHN stranded color black. All wire shall be routed in base duct slotted wall Panduit.

11.

Terminal Blocks a.

All Terminal blocks shall be screw type single level rated for field wiring. The terminal blocks shall be numbered with identification labels. Hand written or sticker labels are not acceptable.

12.

Labels a.

All labels on the exterior of the enclosure shall be permanent black vinyl lettering. The letters shall be a minimum of ½” high. Labels consisting of stickers or applied labels such as engraved plastic are not acceptable. All relays and LEDS inside the control panel shall be labeled for their function. No handwritten labels shall be accepted.

13.

Drawings a.

A copy of the as-built wiring schematic and sequence of operation shall be furnished and installed inside the enclosure.

14.

Emergency Power Off Buttons a.

The emergency power off switch shall be dual action keyed latching type. The button shall have a flip up protective cover to protect against accidental equipment shutdown. The switch shall be labeled as follows:

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 17 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

EMERGENCY POWER SHUTDOWN

This E.P.O. switch is connected to an Emergency Power

Shutdown Management System (EPSMS) and can be overridden for maintenance purposes b.

Quantity and location of EPO button(s) shall be as shown on the drawings. The EPO button(s) shall be interconnected to the EPSMS. Interconnecting conduit and wire to the

EPO buttons shall be included in this scope of work.

15.

Notification Beacon a.

One amber rotating notification beacon shall be furnished and installed per EPSMS panel.

The beacon shall be located a minimum of three feet above the EPSMS panel. The beacon shall be powered from the EPSMS control panel. The interconnecting wire and conduit shall be included in this scope. The beacon shall be activated when the maintenance override key switch is in the override position.

E.

System Operation

1.

General a.

When the EPSMS receives a second smoke detector alarm signal from the FCP, the

EPSMS shall shut down all 2 nd

Alarm related equipment. After the FCP time delay expires and sends a discharge (water flow if pre-action system only) signal to the EPSMS, the

Discharge equipment shall be shut down. The entire EPSMS shall be equipped with a keyed override switch that disables EPSMS preventing it from shutting any equipment down regardless of any input signals the EPSMS receives. Both local annunciation using indicating LED’s and remote monitoring using dry contacts shall be provided.

2.

Maintenance Override Lock Out Feature a.

The maintenance override feature is critical to proper EPSMS operation in order to prevent the unintended shutdown of equipment when in maintenance override mode and when returning to normal mode after being in maintenance override. The Maintenance Override

Lock Out shall perform the following functions:

1) When the maintenance override switch is in the override position, the 2nd Alarm

Activated, Discharge Activated, and EPO Activated relays shall remain in the normal position (locked out) regardless of the input signals received to prevent accidental shutdown of equipment.

2) When the maintenance override switch is in the override position, if any input signal is received, the corresponding "2nd Alarm Activation", "Discharge

Activation", and "EPO Activation" LEDs shall illuminate.

3) When the maintenance override switch is in the override position, if any input signal is received then cleared, the corresponding 2nd Alarm Activation, Discharge

Activation, and EPO Activation LEDs shall flash indicating the input alarm condition is cleared. The output relays shall remain locked out.

4) Once the maintenance override switch is in the override position, the system cannot be returned to "Normal" without activating the Reset Switch. The Reset Switch

"Unlocks" the maintenance override feature.

5) If the EPSMS panel receives an input signal while in Maintenance Override it cannot be returned to Normal until all input signals are cleared and the panel is

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 18 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California reset. This feature provides a second level of protection against accidental equipment shutdown.

F.

Monitoring

1.

The FCP shall supervise the loss of power trouble relay on the EPSMS according to NFPA 75.

The interconnecting wire, conduit, and controls to the FCP shall be included in this work scope.

2.

Two normally open/normally closed dry contacts shall change state upon loss of power or when maintenance override switch is in override position.

3.

Two normally open/normally closed dry contacts shall change state upon EPO activation.

4.

Supervision of relays by other monitoring systems as shown on the drawings.

G.

Testing

1.

The EPSMS shall be assembled and bench tested to verify proper operation prior to delivery to the job site. Customer may witness the bench test of the EPSMS at the suppliers shop at customer’s option prior to delivery to job site.

2.

Installing contractor shall coordinate field test with other trades to verify proper field operation.

The test shall demonstrate the entire control functions as designed and intended.

H.

Warranty

1.

All system components furnished under this contract shall be guaranteed against defect and workmanship for a period of one year.

PART 3 - EXECUTION

3.01

GENERAL CONDUIT AND CONDUCTOR INSTALLATION REQUIREMENTS

A.

Install conduit and conductors concealed to degree made possible by finishes and provide installations in accordance with local governing authorities. Plan and coordinate locations and routing of services with trades prior to installation. In areas where a multiplicity of services occurs, prepare detail drawings and submit to Architect for review prior to start of affected work.

B.

Where conduit and/or conductors are exposed, arrange same to avoid interference with other work and parallel to building lines. Where horizontal conduits and/or conductors are exposed, install as high as possible. Do not install conduit and/or conductors within 6" of "hot" pipes or equipment unless conduit and/or conductors are associated with equipment.

3.02

PANELBOARDS

A.

Install panelboards where shown complete with:

1.

Box constructed of code GA. galvanized steel with removable box ends, wiring gutter space on sides, and an ASA-61 grey baked, acrylic enamel finish;

2.

Trim for recessed or surface wall mounting as shown, constructed code GA. steel, bonderized, finished with ASA-61 grey baked acrylic enamel and complete with concealed fasteners, concealed hinge, chrome plated door latch and keyed alike lock with key, steel frame holder and circuit directory back of door, and mylar circuit breaker identification strips;

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 19 ELECTRICAL

TID WATER & POWER

OPERATIONS COMPLEX

Turlock California

3.

Drip shield for surface mounted panelboards;

4.

Hard drawn electrical grade copper bus and ground bus;

5.

Copper neutral bus or 200% neutral bus, where indicated;

6.

Copper isolated ground bus, where indicated;

7.

High strength, set screw type, anti-turning wire connectors;

8.

Bolt on molded case circuit breakers;

9.

Main circuit breaker, where indicated.

B.

Support cabinet independent of connecting conduit. Prior to application for substantial completion, turn over to Architect a quantity of two panelboard cabinet keys per panelboard. Identify panelboard breakers in permanent manner, and complete typed circuit directory to owner's approval.

3.03

GROUNDING

A.

Provide complete grounding system that complies with requirements of authorities having jurisdiction, including required grounding sections of National Electrical Code. Connect grounding conductors to existing building ground system. Provide an equipment grounding conductor in each feeder and in each branch circuit raceway. Provide separate insulated ground wire for each isolated ground circuit.

3.04

ELECTRICAL CONNECTIONS FOR MECHANICAL, AND MISCELLANEOUS EQUIPMENT

A.

Provide required electrical connections to apparatus supplied by Division 23, Owner and as part of other divisions. Be responsible for:

1.

Installation and connection of complete, starters and provide "line" and "load" power connections as required;

2.

Provide motor starter panels consisting of No. 14 GA. Steel bolted panels sized to accommodate starters as required;

3.

Unless otherwise indicated on drawings, mount 1-phase starters adjacent to equipment they serve and connect complete;

4.

Coordinate feeder entries to starters and starter assemblies with Division 23;

5.

Provide additional disconnect switches (complete with identification) as indicated on drawings, or as required by code, or for apparatus which cannot be seen from or is in excess of 50 feet from its starter;

6.

Provide interlock wiring indicated on drawings or as required;

7.

Connect required circuits to motor starter panel so as to balance actual loads (wattage).

3.05

TESTING OF GENERAL ELECTRICAL WORK

A.

In addition to tests required by governing authorities and regulations, test work to ensure there are no leaks, grounds or shorts. Ensure devices are commissioned and operable. Connect circuits to panelboards so as to balance actual loads (wattage) within 5%. If required, transpose circuits when work is complete to meet this requirement, and then revise the panel branch circuit directory and the as-built drawings.

END OF SECTION 26 50 00

ECOM Engineering, Inc. 2007-B243.00

AUGUST 28, 2008 26 50 00 - 20 ELECTRICAL