Update

Boilers AND pressure vessels/

operating engineers edition

Message

Issue 1

2012

from the Director

By Mike Adams, M.Eng. P.Eng. PMP, Director of Boilers and

Pressure Vessels, and Operating Engineers Safety Program

Having been at the helm of the Technical Standards and Safety Authority’s (TSSA’s)

Boilers and Pressure Vessels, and Operating Engineers Safety Program for just over

a year, I have had the opportunity to fully integrate with staff and industry at large,

through the respective advisory councils and an industry outreach program where I

have had the pleasure of meeting with over 40 representatives of industry.

In this

ISSUE

Incident Prevention Safety Devices:

Low-Water Cut-Offs for Boilers

2

New ASME Certification Mark on Nameplates 3

Pressure Gauge Calibration

4

Prefabricated or Preformed Pressure Parts

Furnished without a Certification Mark

(ASME Section VIII DIV 1, UG-11) 5

ASME Code Issues – Are You Aware?

6

Owner/Users of Boilers and Pressure Vessels:

Mandatory Periodic In-Service Inspection and

Your Responsibility

7

Finite Element Analysis 8

New Technology: Diffusion Welding and

Microchannel Heat Exchangers 9

National Registration Service for Boilers,

Pressure Vessels and Fittings

10

Ontario Power Generation’s Refurbishment

of Darlington Nuclear Station

11

Putting Public Safety First

And, the one thing that stands out for me is the

sincere commitment to public safety – from all

parties – as we continue to steer ahead on

a number of operational activities and key

safety initiatives.

Take for example the extensive and ongoing

work to establish a universal database for

pressure retaining equipment and components

in Ontario. Periodic inspections of boilers and

pressure vessels in the province of Ontario

is a responsibility shared by TSSA and the

insurance industry. As TSSA is responsible for

inspecting uninsured equipment – believed to

be a small percentage of all equipment currently

in use in the province – this leaves the bulk of

insured equipment being inspected by insurance

companies licensed under the Insurance Act

to undertake boiler and pressure vessel

machinery insurance.

TSSA is continuing to work with the insurance

industry, with strong support from the Boilers and

Pressure Vessels Advisory Council, to develop

an electronic process for receiving, collecting,

storing and analyzing data for all pressure

equipment in Ontario.

www.tssa.org

Ultimately, our goal is to develop a

mutually beneficial process by which

the status of all pressure retaining

components in Ontario is known

and tracked and appropriate actions

taken to assure public safety.

Recognizing the vital role that industry plays in

this process and in the provision of the relevant

information, TSSA is committed to seeking to

minimize any burden on insurance agencies.

We are truly appreciative to those companies

who have been and are continuing to participate

and cooperate with us on this very important

initiative. Moving forward, TSSA has identified a

two-pronged approach consisting of verification

of boiler and pressure vessel data and the

introduction of a quality assurance process

this year with respect to BPV inspection quality

assurance programs.

Another key initiative that we are continuing

to forge ahead with is the application of riskinformed decision-making (RIDM) when it

comes to inspecting power plants. This process,

instituted in the Operating Engineers Safety

Program area over four years ago, focuses

TSSA inspection activities on those plants

that are demonstrating a higher level of non-

continued on page 12

2

Issue 1

2012

Incident Prevention Safety Devices:

Low-Water Cut-Offs for Boilers

By John W. B. Coulter, Chief Officer, Operating Engineers, and Cathy Turylo, Engineering Manager, Boilers and Pressure Vessels Safety Program

A low-water cut-off (usually a float switch or level electrode), is a vital

safety device for the prevention of a catastrophic boiler failure due to a

low-water condition.

These devices are designed to shut off the burner or fuel supply to a

boiler, preventing the boiler from operating below a minimum water

level. When a boiler’s water level falls below its safe operating level, the

areas in contact with the heat of combustion will overheat, yield under

pressure and rupture causing a catastrophic boiler explosion. Even

before metal yielding occurs, if a small amount of feed water enters

the overheated boiler, the water instantly boils on contact with the shell

and leads to an explosion that cannot be controlled even by safety

valves. To note, a boiler in this state will not typically trigger the usual

emergency alerts such as a smoke detector or fire alarm.

Boilers not continuously attended by a certified Operating Engineer,

require low-water cut-off devices that can be tested under operational

conditions. This includes registered unattended and attended guarded

steam boilers,1 which must have two devices that are independent of

each other and conform to the fail safe guarded control requirements.2

Automatically fired hot water boilers require only one device and a

flow sensing switch that can also cut off the fuel supply shall be used

for automatically fired hot water boilers requiring forced circulation.3

Selection 4 and proper installation, such as verifying floats can move

and electrodes are not in metal to metal contact, is essential to ensuring

the devices will perform their function correctly.

Like any other mechanical safety device, these devices need to be

tested periodically as floats can become water-logged, floats and

probes can have scale and mud build-up – all of which can prevent

proper movement or sensing of the water level. It is therefore important

that the owner/user review and follow the manufacturer’s instructions for

the frequency of examination and applicable maintenance procedures.

While low-water cut-offs are the topic at hand, we should not lose

sight of high-water cut-offs. These are similar to the low-water units

only they are designed to shut the boiler down in the event of a highwater condition that would lead to water carry over into the steam

system. This is also a potentially very dangerous event that can lead

to the rupture of steam piping. Once again, owner/users need to

follow the examination and maintenance instructions provided by the

manufacturer of the safety device.

1

Ontario Regulation 219/01 (Operating Engineers)

O.Reg.219/01, s.39

2

Refer to CSA B51 Boiler, Pressure Vessel, and Pressure Piping Code, clause 6.3.2.

3

Each safety device covered by ASME Code CSD-1 Controls and Safety Devices for Automatically Fired Boilers requires these devices to be accepted for its intended service by a

nationally recognized testing agency.

4

Putting Public Safety First

www.tssa.org

T S S A B o i le r s a n d p r essu r e v esse ls edi t i o n

New ASME Certification Mark on Nameplates

By Cathy Turylo, Engineering Manager, Boilers and Pressure Vessels Safety Program

When we see it, we all recognize it – the ASME Certification mark. For years, the ‘famous’ clover leaf with a letter marking stamped inside – “U”, “UM”, “S” or “N”, to

name but a few – has been the tell-tale sign to signify the ASME code section to which equipment has been designed and constructed.

Recognized the world over, this version of the certification mark is soon set to ‘retire’ and a single, comprehensive ASME certification mark will replace the 28

separate certification marks currently used on products in more than 100 nations worldwide.

Certified by

Name of Manufacturer

In fact, newly constructed equipment to the ASME Code may already have their nameplates stamped with the newly

identified ASME Certification Mark – the clover leaf with “ASME” lettered diagonally inside.

Pressure ____ at temperature ____

Mark

nator

3

Max. allowable working pressure

Pressure ____ at temperature ____

ASME Certification Mark*

U2

Max. allowable external working pressure

[if specified. see note (1)]

Temperature ____ at pressure ____

Min. design metal temperature

W what

(if arc or happens

So,gas

to the code section identifier and other important details? The code of construction formerly reflected inside the clover leaf, will now be

welded)

RT (if

stamped

underneath

the ASME

certification mark and is referred to as the ‘certification designator’. Other pertinent details such as ‘welded construction’ or

Manufacturer’s

serial number

radiographed)

HT (if postweld

heat treated)

‘non-destructive

examination levels’ will fall directly below this ‘certification designator’. An example of how this would appear on a nameplate is shown below.

Year built

Sample ASME Product Certification Nameplate*

Certified by

Name of Manufacturer

Pressure ____ at temperature ____

Certification Mark

Max. allowable working pressure

Pressure ____ at temperature ____

Certification Designator

U2

W (if arc or

gas welded)

RT (if

radiographed)

HT (if postweld

heat treated)

Max. allowable external working pressure

[if specified. see note (1)]

Temperature ____ at pressure ____

Min. design metal temperature

Manufacturer’s serial number

Year built

Sample ASME Product Certification Nameplate*

Officially, the new mark can be used on all items constructed to the ASME Code 2010 Edition, 2011 Addenda. ASME Code Case 2710, for ASME Sections I, IV,

X and XII and Code Case 2714 for ASME Section VIII, Divisions 1, 2 and 3, allow for use of the former ASME Code symbol stamps until December 31st, 2012.

However, keep in mind that the applicable Code Case number needs to be shown on the Manufacturer’s Data Report.

For more information on ASME’s single certification mark, visit their product certification page on their website at www.asme.org/kb/standards/certification--accreditation/product-certification.

* Reprinted from ASME Certification Mark, by permission of The American Society of Mechanical Engineers. All rights reserved.

4

Issue 1

2012

Pressure Gauge Calibration

By Larry Calvert, Senior Technical Specialist, Boilers and Pressure Vessels Safety Program

Many quality programs and procedures require that calibrated gauges be

used for pressure testing of equipment such as boilers, pressure vessels,

piping and fittings.

What is pressure gauge calibration?

Document any deficiencies noted during the initial testing and the method

for their resolution, including how to deal with damaged items that cannot

be adjusted, or repaired. Re-test after any required adjustments have

been performed, and calibration has been completed. Document required

certification and calibration status (including expiry date) on completion.

Pressure gauge calibration is a comparison between measurements – one

of known accuracy made or set with an instrument such as a Dead Weight

Tester or Master Gauge that has traceability to a National Measurement

Standard, and another measurement made in as similar a way as possible

with the pressure gauge that is being calibrated.

Pressure gauge calibration may be called for:

Why do we calibrate pressure gauges?

• when a gauge has been dropped or damaged;

Pressure gauges are calibrated to ensure that accurate readings are being

provided within permissible tolerances to the end user, during testing or

operation of equipment.

• sudden changes in environmental conditions; and/or

How are pressure gauges calibrated?

The pressure gauge manufacturer will often have calibration requirements

detailed in their maintenance literature. This is a good source of information

to help a user to prepare a detailed calibration procedure.

Pressure gauge calibration should be performed in accordance with a

written procedure that addresses all of the requirements to be observed

during the calibration process. The procedure should capture all of the steps

necessary to ensure an acceptable calibration can be performed. It should

include items such as, but not limited to: the type and accuracy of the

calibration standard to be used; the level (percentage) of accuracy required

for the gauge that is to be calibrated; any permissible tolerances applicable

to the calibration process; checking and documenting of gauge damage

prior to calibration; and required documentation of readings taken at

various defined gauge points before, and after, performing any calibration.

Putting Public Safety First

• with a new gauge;

• when a specified time period has elapsed;

• whenever readings appear questionable.

Properly calibrated pressure gauges help to ensure:

• safe operation of equipment during use;

• e quipment is not over pressurized and damaged during testing or

operation; and

• code required pressure tests are properly addressed.

www.tssa.org

T S S A B o i le r s a n d p r essu r e v esse ls edi t i o n

5

Prefabricated or Preformed Pressure Parts Furnished without a

Certification Mark (ASME Section VIII DIV 1, UG-11)

By Stephen Lam, Senior Engineer, Boilers and Pressure Vessels Safety Program

In the 2011 Addendum, the subparagraphs relating to standard pressure parts in UG-11 have been completely rewritten. Here is a summary of the requirements

for these standard parts. There are no significant changes in UG-11(b), the subparagraph for cast, forged, rolled, or die formed non-standard pressure parts.

Requirement

UG-11(c)

UG-11(d)

Cast, forged, rolled, or

die formed pressure

parts

Standard pressure parts that comply with an ASME product standard,

either welded or non-welded.

Standard pressure parts that comply with a manufacturer’s

proprietary standard or a standard other than an ASME

product standard, either welded or non-welded.

Remarks

These are pressure parts that comply with an ASME product standard

accepted by reference in UG-44.

May be supplied by a Certificate Holder (see Note 2) or a

pressure parts manufacturer.

Certificate Holder

Need not be manufactured by a Certificate Holder.

Material

Shall be as permitted by this Division or as specifically listed in the ASME

product standard.

Shall be as permitted by this Division only.

Welding

When welding is performed it shall meet the requirements of UW-26(a),

UW-26(b), and UW-26(c) and UW-27 through UW-40, or the welding

requirements of ASME specification SA-234.

When welding is performed it shall meet the requirements

of UW-26(a), UW-26(b), and UW-26(c) and UW-27 through

UW-40.

Inspection, identification, Pressure parts, such as welded standard pipe fittings, welding caps, and flanges that are fabricated by one of the welding processes

partial data reports

recognized by this Division do not require inspection, identification in accordance with UG-93(a) or UG-93(b), or Partial Data Reports.

Postweld heat treatment

If required, it may be performed at the location of the parts manufacturer or the location of the Manufacturer of the completed vessel.

Radiography or other

volumetric examination

If required, it may be performed at the location of the Manufacturer of the

completed vessel or the location of the pressure parts manufacturer.

If required, it may be performed at the location of the

Manufacturer of the completed vessel, the location of the

pressure parts manufacturer, or the location of the parts

Manufacturer.

Marking

Marked as per the ASME product standard.

Marked with:

a. The name or trademark of the Certificate Holder or the

pressure part manufacturer, and the markings required by the

standard used for the pressure part; and

b. A permanent or temporary marking that will serve to identify

the part with the written documentation of the part.

Responsibilities of the

Manufacturer of the

completed vessel

The Manufacturer of the completed vessel shall ensure that all standard pressure parts comply with applicable rules of this Division and are

suitable for the design conditions of the completed vessel.

When volumetric examination is required, the completed radiographs, properly identified, with a radiographic inspection report, and any other

applicable volumetric examination report shall be obtained.

Fulfillment of

responsibilities

The Manufacturer of the completed vessel shall obtain when necessary,

documentation listed below, provide for retention of this documentation, and

have such documentation available for examination by the Inspector when

requested.

Minimum documentation Material used, the pressure-temperature rating of the part, and the basis for

establishing the pressure-temperature rating.

The Manufacturer of the completed vessel shall obtain when

necessary, documentation listed below, provide for retention of

this documentation, and have such documentation available for

examination by the Inspector when requested.

or;

Perform an analysis of the pressure part in accordance with the

rules of this Division and include in the documentation which

shall be made available for examination by the Inspector when

requested.

Material used, the pressure-temperature rating of the part, the

basis for establishing the pressure-temperature rating, and a

written certification by the pressure parts manufacturer that all

welding complies with Code requirements.

Notes:

1.The rules above shall not be applied to welded shells or heads or to quick-actuating closures.

2. A Certificate Holder may fabricate parts and mark them in accordance with UG-11(d). This Certificate Holder may subcontract to an individual or organization not holding an ASME

Certificate, standard pressure parts that are fabricated to a standard other than an ASME product standard provided all the requirements of UG-11(e)(1) to UG-11(e)(10) are met.

6

Issue 1

2012

ASME Code Issues – Are You Aware?

By Caslav Dinic, Senior Engineer, Boilers and Pressure Vessels Safety Program

Maximum Permitted Carbon Content for Welding of

Materials

ASME design codes do not permit welding of materials with carbon content

over 0.35%. Bolts and nuts such as SA-193 Gr. B7 and SA-194 Gr. 2H

very often have higher carbon content than 0.35% and therefore cannot be

attached to pressure boundary items by welding. Examples of situations to

be aware of include: tack welding of nuts to flanges or weld nuts for shell or

heads for attachment of insulation or other items.

Washers and Flanges

Washers are not allowed on ASME B16.5 flanges. Flange designs per ASME

Section VIII Division 1, Appendix 2 do not account for washers and special

considerations are required if washers are used. In those cases, washers are

pressure load bearing material requiring ASME Code specification marking –

also note, for plate material a Material Test Report (MTR) is required.

Hubbed Flanges

Pressure Tests

As per ASME Section VIII, Division 1, 2011 Addenda, it is not permitted to

have a valve between the pressure vessel and the test pressure gauge during

hydrostatic or pneumatic pressure tests. (See UG-102).

Hydrostatic Test Pressure Calculation

ASME Section VIII, Division 1, 2010 Edition, introduced revised requirements

for the hydrostatic test pressure calculation. Bolting is no longer required to be

included in the lowest stress ratio (LSR) calculation, see UG-99(b). This can

affect the required hydrostatic test pressure for some pressure vessels. For

example, consider a pressure vessel constructed from SA-516 Gr.70 material,

designed for 500°F and with bolting material SA-193 Gr. B8, and to be tested

at ambient temperature. Per previous Code rules, LSR would have been 1.45

(taking into account bolting), and with the current Code LSR is now 1.

Pressure Vessels with Corrosion Allowance

ASME Section VIII Division 1, Appendix 2 specifies rules for hubbed flanges

machined from bar stock and do not allow machining of hubbed flanges from

plate material. What is a hubbed flange? If in calculation, value h (hub length),

g0 (thickness of hub at small end) and g1 (thickness of hub at back of flange)

are not equal to 0 then the flange is hubbed.

All ASME Section VIII, Division 1 pressure vessels, with corrosion allowance

not equal to 0 must be equipped with an opening for a drain per UG-25(f) and

appropriate inspection openings as per UG-46. Where a manhole is required

for the inspection opening, the minimum required size for a circular manhole

is 16 inches internal diameter. To note, standard pipe 16 inches nominal pipe

size has an outside diameter of 16 inches and therefore can not be used for a

circular manhole as a Code required inspection opening.

Putting Public Safety First

www.tssa.org

T S S A B o i le r s a n d p r essu r e v esse ls edi t i o n

7

Owner and Users of Boilers and Pressure Vessels:

Mandatory Periodic In-Service Inspection and Your Responsibility

By Tony Scholl, Senior Technical Specialist, and Cathy Turylo, P.Eng. Engineering Manager, Boilers and Pressure Vessels Safety Program

In accordance with Ontario Regulation 220/01 (Boilers and Pressure

Vessels), owners and users (owners) are responsible to ensure that

the equipment under their control is maintained in a safe working

condition.1 This responsibility includes periodic inspections being

completed by a qualified inspector. Classes of equipment that are exempt

from periodic inspection and the minimum frequency for those that are not

exempt are provided for in section 4.0 of the Boilers and Pressure Vessels

Code Adoption Document (CAD).

Who is required to periodically inspect the equipment?

Qualified inspectors are employed by the TSSA or by an insurer. Insured

boilers and pressure vessels are inspected by the insurer. Uninsured

equipment is inspected by the TSSA inspector.

2

Owners are responsible to provide the inspector with free access to

conduct a periodic inspection under O.Reg.220/01.3

Inspections conducted by the Insurer or TSSA Inspector

The owner is contacted by the insurer or TSSA inspector at the appropriate

time to arrange an inspection date. At that time, the owner may be required to

prepare the boiler or pressure vessel in such a fashion to facilitate access to

the equipment in order for an effective inspection to take place. An inspection

may also include an internal examination. The owner is responsible to ensure

that the inspections are taken place and completed to the satisfaction of

the insurer or TSSA inspector. Insurers and/or TSSA inspectors may issue

instructions as appropriate to ensure the equipment is maintained in a safe

operating condition.

Owners are responsible to comply with any instructions that are issued

by the insurer or TSSA inspector.4

Certificate of Inspection

Boilers and pressure vessels that pass the inspection will be issued a

Certificate of Inspection by the insurer or TSSA as the case may be.

The owner or user, where it’s practical, needs to post the certificate in a

conspicuous place near the boiler or pressure vessel. The certificate will

indicate an expiry date prior to which the next inspection should take place. A

valid Certificate of Inspection is required to operate a boiler or pressure vessel

in the province of Ontario.

Owners are responsible to ensure that a valid Certificate of Inspection is

in place for each boiler or pressure vessel that is in operation.5

The primary purpose of a periodic inspection is to ensure that the equipment

can continue to be operated safely. If you have pressure equipment requiring

periodic inspections – take note of your responsibilities – it is the law.

Ontario Regulation 220/01 (Boilers and Pressure Vessels), s.3 (3).

i. An insurer means a person licensed under the Insurance Act to undertake boiler and machinery insurance as defined by that Act.

ii.An insurer may use an inspection agency that has a certificate of authorization issued by TSSA to perform the periodic inspections for equipment covered under that insurer’s policy.

The Certificate of Inspection is issued from the insurer.

3

O.Reg. 220/01, s.9 (7).

4

O.Reg. 220/01, s.3 (3).

5

O.Reg. 220/01, s.5

1

2

8

Issue 1

2012

Finite Element Analysis

By Stephen Lam, Senior Engineer, Boilers and Pressure Vessels Safety Program

According to ASME Section VIII DIV 1, U-2(g), when rules for the details

of design and construction are not given in the Code, the Manufacturer,

subject to the acceptance of the Inspector, shall provide design and

construction details which will be as safe as those provided by the rules

of the Code.

In this situation, Finite Element Analysis (FEA) is often chosen as the

tool as it is very powerful and relatively inexpensive. Unfortunately,

many designers treat FEA programs as automated tools for design and

ignore the fact that FEA can render solutions that are seriously flawed if

conducted by an inexperienced person. It is therefore very important that

FEA be performed by someone who is experienced in this analysis, the

particular software used and the field of the design.

As FEA is becoming more common, TSSA is receiving more and more

submissions for registration with designs supported by FEA. It should,

however, be understood that FEA may be used only for designs which

are not covered by the rules of the Code. As FEA requires extensive

knowledge and experience, TSSA requires the FEA report be certified

by a professional engineer. The FEA report shall include the following:

7.Type of elements used (triangular, square, rectangular, etc.), mesh

size and the number of elements.

8.Number of Degrees of Freedom of the model.

9.The element order (must be at least second order).

10. The turn angle of the elements in the mesh.

11. The types of elements used (h-elements, p-elements).

12. The method used to estimate the error of the results and the

maximum percentage of combined error.

Results

All results shall be included here. The figures must be in colour and clear

(enlarged sections of some figures may be required). In some cases, the

figures should also be submitted in electronic form to facilitate review.

Explanations and discussions on each figure must be provided. Figures

showing the following shall be provided.

1. The mesh of the model.

2. The displacement/deformation.

Summary

3. The stresses.

The summary shall briefly describe the purpose of the FEA, the

justification of using FEA, the FEA model, the results and the conclusion.

4. Convergence, and/or plot with element stress and a comparison of

nodal (average) stress vs. element (non-averaged) stress.

Introduction

The introduction shall include the assumptions used to perform the

design, the name and version of the software used, and the type of FEA

analysis (elastic, plastic, small deformations, large deformations, etc.).

Conclusion

The conclusion shall include the acceptance criteria of the Code of

construction. The results of the FEA shall be compared with the Code

requirements. Any verification techniques used to check the model and

the results should also be included.

FEA Model

This section must describe the model completely and include the

following.

1.Type of finite element model used (solids, shells, beams, 2D, etc.).

2.Material models utilized for all required physical properties and

strength parameters.

3.Geometry with dimensions.

4.Description of loading and boundary conditions such as loads,

restraints and supports, etc. for all load cases (these must be shown

in the figures).

5. Explanation of partial models, if any, such as ‘due to symmetry’.

6.Description of the finite element model including the division of

elements.

Putting Public Safety First

www.tssa.org

T S S A B o i le r s a n d p r essu r e v esse ls edi t i o n

9

New Technology:

Diffusion Welding and Microchannel Heat Exchangers

By Liliana Constantinescu, Mechanical Engineer, Boilers and Pressure Vessels Safety Program

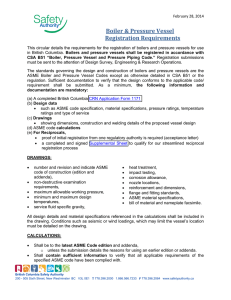

The diffusion welding (also known as diffusion bonding) process is

an important addition in the 2011 addenda to ASME Section IX.1 This

process was previously approved by Code Case 2437-1 to be used in the

manufacturing of microchannel heat exchangers and, in 2011, was included

as a new appendix of ASME Section VIII Division 1.

For examination and testing of the diffusion welded joints, microchannel

welds need to be examined during production in the following sequence:

ultrasonic examination, liquid penetrant examination and a visual

examination. After construction is complete, a hydrostatic or pneumatic test

in accordance with UG-99 or UG-100 must be performed.

The new addendum of ASME Section IX defines diffusion welding as, “a solidstate welding process producing a weld between multiple layers of sheet or

plate by the application of mechanical pressure at elevated temperatures with

no macroscopic deformation or relative motion of the work pieces. A solid filler

metal may be inserted between the faying2 surfaces”.

* Microchannel Heat Exchangers: Small channels are typically less than

2mm in close proximity and diameters are 0.1-0.3mm as compared with

traditional technology for shell and tube diameters are 10-50mm and plate

and frame with 3-10mm. Shims or sheets (e.g. stainless, high nickel alloys)

are pressed with diffusion bonding or welding to form hermetically-sealed

microchannels. This structure yields higher volumetric heat flux, modest

pressure drop and compact hardware ideal for space critical applications

(e.g. off-shore, mobile systems). For scalability, the number of channels

would increase however the size of the channels would remain the same.

Fouling, plugging and corrosion are factors for consideration based on fluid

solids content and chemistry.

In accordance with ASME Section IX, the requirements for the qualification

of a diffusion welding process are as follows:

•

•

•

a Procedure Qualification Record (PQR) is to be prepared by

recording all the essential and non-essential variables observed during

the welding process to create the test joint and also the results of

mechanical testing and examination of that joint. The diffusion welding

variables are listed in the new table - QW-266;

a Welding Procedure Specification (WPS) is to be prepared by

documenting all essential and nonessential variables and providing the

necessary instructions for diffusion welding during production; and

a test block shall be prepared with the minimum dimensions of 8

inches x 8 inches and a thickness of at least 50 interface planes

being welded to qualify the WPS. Three tension test specimens need

to be taken perpendicular to the interface planes and three parallel

to the interface planes. The test results need to be in accordance

with QW-153 requirements. Three cross-sections, one from the

top, centre and bottom of the test coupon, need to be prepared and

examined metallographically. The acceptance criteria are presented

in paragraph QW-185.3.

With respect to diffusion welding operator qualification, the welding operator

needs to be tested by welding a procedure qualification test coupon and

examined metallographically as presented in paragraph QW 185.3.

Diffusion welding has been recognized by ASME to be used in the

manufacturing of microchannel heat exchangers* with specific requirements

for items such as design calculations, examination and testing, provided

in a new mandatory appendix – Appendix 42 - to ASME Code Section VIII

Division 1.

Appendix 42 identifies two methods for proof of design for microchannel

heat exchangers. Using design calculations, formulas from Appendix 13

can be applied using a joint factor of 0.7. Alternatively, proof testing in

accordance with UG-101 can be performed.

Diffusion Welding Process

Diffusion Welding Process

Initial Stage

Dynamic Force

Heat

Heat

Work Piece

Work Piece

Dynamic Force

Final Stage

The material grains diffuse, closing interfacial

voids

Work Piece

Work Piece

Solid bounded materials

2010 Edition, ASME Section IX Qualification Standard for Welding and Brazing Procedures, Welders, Brazers, and Welding and Brazing Operators.

1

“Faying surface” (definition): In welding, that surface of a member which is in contact with, or in close proximity to, another member to which it is to be joined.

2

10

Issue 1

2012

National Registration Service for Boilers,

Pressure Vessels and Fittings

By Tanya Francis and Colleen Ratcliff, Administrative Assistants, Boilers and Pressure Vessels Safety Program

Looking to register a design across Canada or within select

jurisdictions outside of Ontario? If so, you may want to consider the

voluntary ‘National Registration’ service offered by TSSA that allows

you to do exactly that.

By choosing to opt for this service, you could avoiding the potential

challenges that come along with trying to obtain a Canadian

Registration Number (CRN) in various provinces as each province

does have its own jurisdictional authority. Once a CRN is issued for a

boiler, pressure vessel or fitting design in one province or territory, that

same CRN is identified to other jurisdictions and is used as the basis

for the registration number across Canada for these types of designs.

Here’s a snap-shot of what the service is all about and what it can do

for you.

How it works: It’s like a “one-stop service”. When a design is

registered in Ontario, TSSA will then send the required documents to

the requested provincial and territorial jurisdictions for registration. The

file will then be followed and tracked until all requested registrations

are received. The advantage is clear – an applicant comes to one

location instead of having to go to individual jurisdictions.

Fee info: A deposit will be required for national registration (for each

CRN). The deposit amount will be applied to the administrative fee and

the incurred fees for national service (excluding Ontario registration)

as registrations are completed in the requested jurisdictions. Any

charges over and above the deposit amount will be invoiced at that

time. The total costs are calculated on the administration fee plus

the charges incurred from each jurisdiction requested. Note: Design

registration in the province of Ontario is per the Boilers and Pressure

Vessels fee schedule and will be invoiced separately from the national

registration service.

CRN marking: When a design is registered in one province and

subsequently in others, additional digits or letters identifying those

provinces shall be added after the digit or letter representing the original

registering province.1 For example: a design registered in Ontario is

issued the CRN as K4567.5. If this design is then registered in Alberta,

the CRN will be K4567.52, and then in Manitoba: K4567.524. If, however,

the design is registered in all provinces and territories the CRN can

then be shortened to: K4567.5C. And, in those circumstances where a

design is exempt from registration in some provinces and territories but

registered in all the provinces and territories that require registration, then

the CRN may be listed as K4567.5CL (L stands for limited). Specific rules

for CRN markings are outlined in CSA B51, Boilers, Pressure Vessels

and Pressure Piping Code, clause 4.3.

Benefits: Instead of multiple jurisdictions/provinces, your administration

contact is with TSSA. So, everything will be handled for you by TSSA.

This includes everything from the tracking the entire process to invoicing,

thus minimizing the time and energy you would need to spend.

So, if you’re interested in taking advantage of this service visit the

registration section of our Boilers and Pressure Vessels webpage at

www.tssa.org/regulated/boilers/registration/boilersRegistration02.asp

for more information, including resourceful forms and links. As there

have been some changes to some of the required items recently, we

encourage applicants to check TSSA’s website from time to time to

confirm the latest requirements.

1British Columbia starts with the number 1, Alberta is 2 across to Prince Edward Island is 9 and Newfoundland

and Labrador is 0. The territories have letters, Yukon Y, Northwest Territories is T and Nunavut is N.

Putting Public Safety First

www.tssa.org

T S S A B o i le r s a n d p r essu r e v esse ls edi t i o n

11

News from the Nuclear Sector

Ontario Power Generation’s Refurbishment of Darlington Nuclear Station

On March 1, 2012, Ontario Power Generation (OPG) signed a contract with SNC-Lavalin Nuclear Inc. and Aecon Construction Group Inc., in what is

being heralded as a significant step toward the refurbishment of OPG’s Darlington Nuclear Station. Together, they will spend the next three years on

planning and preparation of refurbishing Darlington’s four CANDU (CANadian Deuterium Uranium) reactors. Part of the planning phase will also include

the construction of a life-size replica reactor for training purposes. And, once this gets underway, you’ll be able to spot the location of the mock-reactor,

a first of its kind on this scale, located in the Darlington Energy Complex near the Darlington plant in Durham Region just east of Toronto.

*Photo courtesy of Ontario Power Generation

Actual construction work on refurbishing the nuclear station is targeted to begin in 2016 – with each of the four reactors to be taken off-line one at a

time – and slated for completion by 2024; this work should extend the reactor’s life by another 25 to 30 useful years.

12

Issue 1

2012

Message from the Director

(continued from the front cover)

compliance and ensures that safety inspection resources are applied

in the most effective manner. Through the application of RIDM, the

inspection results are being used by TSSA to generate a risk profile of

power plants and are a source of input for the determination of future

inspection frequencies. The safety outcomes, as evidenced by existing

incident data, are very positive for these sectors. Appreciating that

RIDM is an ongoing and evolutionary process, TSSA is continuing to

refine this process by further validating the risk formulae and identifying

discrepancies between assigned and required risk assignments.

For industry, it means that TSSA can continue to certify companies

as a Certificate of Authorization holder for having the appropriate

qualifications to perform specific work in accordance with relevant and

applicable codes and standards. And while the scopes of work and

authorization are many and varied, nuclear fabrication is a key area

which seems to be picking up momentum. As of late, TSSA has been

processing an increasing number of applications from manufacturers

who wish to be certified for the fabrication of nuclear components. A

harbinger of things to come?

In our field of work, accreditation is a critical element for operation –

both for TSSA and industry. For TSSA, this means operating and being

recognized as an authorized inspection agency and auditing authority

in Ontario, and throughout North America for Ontario. I am pleased

to report that TSSA recently underwent a successful audit by ASME

and has had its ASME Certificate of Accreditation as an Authorized

Inspection Agency renewed for another three-year term.

In closing, I welcome your feedback on how effectively we meet our

commitments and responsibilities. TSSA appreciates the ongoing work

by industry, including the input from the Boilers and Pressure Vessels,

and Operating Engineers Advisory Councils. I look forward to continuing

to work closely and collaboratively with industry in the interest of public

safety in these two very important industry sectors.

Update

B O I L E R S A N D PR E S S U R E V E S S E L S /

O p e r a t i n g e n g i n ee r s E di t i o N

FSC

Logo

here

We welcome your comments and story ideas for future

editions of this newsletter. Please contact:

TSSA UPDATE (Boilers and Pressure Vessels/

Operating Engineers Edition)

3300 Bloor St. West, 14th Floor, Centre Tower,

Toronto ON M8X 2X4

Email customerservices@tssa.org

Fax 416.231.1626

MAIL TO:

41187514