EN-US - Getinge

733HC-E SERIES STEAM STERILIZERS

FOR HEALTHCARE

Safety without compromise.

2 | GETINGE GEW 2100LS Cage and Rack Washer - Preventing contamination in animal care

GETINGE 733HC-E | 3

RAISE THE BAR

ON PERFORMANCE

When you face increasing demands to provide quality care while keeping costs down, Getinge provides complete solutions to help you achieve these goals. When you need to process more instruments in a shorter time, Getinge develops innovative new products to make this possible.

The Getinge 733HC-E Series is the newest edition of state-of-the-art sterilizers from the world’s leading brand in infection control. These steam sterilizers continue to perfect the effi cient performance, superior productivity and reliability advantages you depend on from Getinge.

Getinge 733HC-E Series Sterilizers are compact, versatile and reliable, combining high capacity with cost effi ciency and environmental benefi ts.

• Designed for centralized and decentralized sterile processing departments with sterile stores and distribution, including outsourcing

• Ideal for surgery centers and laboratories

• Exceptional safety and reliability built into all aspects of design and operation

• AAMI ST8 compliant for trays up to 25 pounds each

• Validated with programs for both gravity and pre-vacuum cycles at either 132ºC or 135ºC

Getinge’s leadership in sterilization is based on over 60 years of accumulated experience, fused with skillful engineering, specialized technology, and application expertise. The result is a continuing series of leading-edge features, high-quality manufacturing, secure control systems, and versatile software programs that raise the bar on sterilizer performance.

Our most important delivery is not machines.

It’s our vision that instruments are always ready for use when needed; that the fl ow of sterile goods is safe, smart, effi cient and ergonomic, and that your total cost is as low as possible.

Good patient outcomes depend on sterile instruments being in the right place, at the right time.

4 | GETINGE 733HC-E

GET BETTER PERFORMANCE BY DESIGN

Quality construction. Outstanding performance. Simplified operation.

Just one look will confirm that a Getinge 733HC-E Series Sterilizer is designed with safety, productivity and longevity in mind. It features a chamber and jacket constructed of 316L stainless steel – selected for its superior post-weld corrosion resistance.

Along with form comes great functionality and performance. The new

8.4" touchscreen display makes it easier than ever to custom name cycles for fast, accurate identification. The Getinge 733HC-E Loading

Car provides increased loading capacity – up to 33% compared to older

24" x 36" sterilizers. It’s an ideal choice for new construction or replacing older models, offering increased loading capacity within the same wall openings and footprints of many current units.

Rectangular chambers assure maximum loading area from the top to the bottom. Select from three chamber sizes with a standard crosssection of 26.5" wide x 36" high (672 mm x 920 mm); with lengths of

39" (1000 mm); 53" (1350 mm); and 61" (1550 mm).

Type 316L stainless steel chamber, jacket and doors provide superior corrosion resistance and structural integrity – backed by Getinge’s

15-year chamber warranty. This commitment to quality and uninterrupted performance is reflected in an industry-best one year parts and labor guarantee.

The reliability you expect from Getinge

• Chamber interior polished to a high-luster finish to reduce build-up of steam-water deposits

• Chamber and door constructed of 316L stainless steel

• Power operated door slides to clear head ring, then swings open for complete access

• Copper/brass piping standard; stainless steel piping optional

• Water-ejector vacuum standard; mechanical vacuum pump optional

• All components easily accessible for maintenance from front and side

• Clean, modern design helps ensure long-term aesthetic appeal for every work environment

GETINGE 733HC-E | 5

TAKE TOTAL CONTROL OF YOUR STEAM STERILIZATION

Intuitive touchscreen control streamlines operations

Getinge 733HC-E Series Sterilizers feature the latest generation of user-friendly, high-resolution AVANTI technology touchscreens. The AVANTI’s 8.4" touchscreen offers optimal ergonomics with a clear overview from all angles in the control area.

• Intuitive, simplified interface and menus

• Remarkably clear, distinct text – even when viewed from a distance

• Control panel includes –

– AVANTI touchscreen text is remarkably distinct, color graphics are vivid smooth, quiet operation pressure gauges

– Status indicator light

– Controls on/off switch power is disconnected when working in the chamber

6 | GETINGE 733HC-E

SELECT THE CYCLES AND

CHAMBER SIZES TO MATCH

YOUR NEEDS

Getinge 733HC-E Series Sterilizers offer cycles that employ either gravity/downward displacement with positive pulse conditioning for air removal – or pressure/vacuum pulsing for dynamic air removal. Typical applications include wrapped and unwrapped porous and non-porous hard goods, utensils, gowns or towel packs and liquids in self-venting or unsealed containers.

• Access up to 23 cycles in two easy steps

• 21 cycles can be assigned custom cycle names and reprogrammed to meet IFU instructions for steam sterilization

• All cycles sequenced and monitored by PACS control system

The Getinge 733HC-E Series Sterilizer has a standard chamber cross-section of 26.5" wide x 36" high, and is available in three chamber lengths –

• 39" (1000 mm) – 21.5 cu ft (616L)

• 53" (1350 mm) – 29.3 cu ft (831L)

• 61" (1550 mm) – 33.7 cu ft (955L)

Twenty three factory cycles include:

• Eight gravity cycles

• Ten high-vacuum cycles

• One immediate-use cycle for unwrapped goods

• One Bowie & Dick cycle

• Two liquid cycles

• One vacuum-leak test cycle

GETINGE 733HC-E | 7

CUSTOMIZE YOUR 733HC-E STEAM STERILIZER

The large AVANTI 8.4” SVGA color display makes on-screen navigation, cycle selections and adjustments easier than ever.

Custom name cycles for quick and accurate identification. Select from four cycle-process output data screens –

Circle Graph: Displays time remaining as a large easy-to-read circle graph

Plot Graph: Displays cycle temperature and pressure in a color graph plotted over time

Bar Graph: Displays temperature and pressure in a bar graph with large, easy-to-read time remaining in the center

Detail Display: Displays real time process information in text form

AVANTI touchscreen interface advantages:

• Password protected menu tree

• Quick, on-screen editing of cycle parameters

• Text messages in lieu of codes or symbols

• Audible and visual feedback

• T-DOC instrument tracking interface capability

• User accessible connection for downloading cycle records to a USB flash drive, or directly printing to a USB printer

• NetCOM-enabled Ethernet connection for remote monitoring

8 | GETINGE 733HC-E

DELIVER SAFETY WITHOUT

COMPROMISE

Validated 25 pound sterilizer tray loads

The Getinge 733HC-E Series Sterilizer is compliant with AAMI ST8 for processing wrapped tray sets up to 25 pounds each.

This means that productivity can increase without risking SPD staff health or patient safety.

Model

733HC-E-39

733HC-E-53

733HC-E-61

Chamber dimensions

26.5"W x 36"H x 39"L

26.5"W x 36"H x 53"L

26.5"W x 36"H x 61"L

Trays per load

10

15

20

Pounds per tray

25

25

25

Pounds per load

250

375

500

135˚C and 132˚C validated cycles

Medical devices are becoming more complex and now manufacturer’s written instructions are becoming more differentiated.

Now, patient safety doesn’t have to be at risk when one device IFU requires a 135˚C (275˚F) three-minute cycle, and a second

IFU requires a 132˚C (270˚F) four-minute cycle. Thanks to validated gravity and pre-vacuum cycles at the AAMI ST79 minimum exposure time for each exposure temperature, sterile processing gets easier and provides greater peace of mind.*

Cycle type

GRAVITY 2

GRAVITY 3

PREVAC 1

PREVAC 4

Exposure temperature

135˚C (275˚F)

132˚C (270˚F)

135˚C (275˚F)

132˚C (270˚F)

*Deviation from pre-programmed cycle parameters requires user validation

Exposure time

10 min

10 min

3 min

4 min

Clean steam construction

Getinge 733HC-E Series Sterilizer models can be fitted with stainless steel piping to the jacket and chamber for clean steam applications. Stainless steel piping allows the use of steam produced from treated water such as RO. High-quality steam can prolong instrument life.

Vacuum source

The water ejector provides cost-effective, maintenance-free vacuum. The Getinge 733HC-E

Series Sterilizer offers the option of mechanical vacuum pump for dynamic air removal of the chamber. The liquid-ring vacuum pump provides quick, efficient chamber air evacuation. Combined with a heat exchanger and a temperature regulated cooling system, the vacuum pump will pull a deep vacuum, resulting in faster cycle times with excellent drying results.

BENEFIT FROM ECO-FRIENDLY

DESIGN AND OPERATION

Getinge is constantly working to reduce the environmental impact of our steam sterilizers, without sacrificing quality, reliability or cycle times. Getinge 733HC-E Series Sterilizers have been validated to

AAMI ST8 with an upper limit of 25 pounds per tray. The result is that the per cycle productivity of Getinge 733HC-E Series Sterilizers increased by more than 50% by instrument weight, without increasing utility consumption. You can now sterilize more instruments, in less time, with less energy and water.

The Getinge 733HC-E Series Sterilizers offer several systems to help reduce water consumption and save on energy and utilities.

Vacuum pump option

• Consume up to 80% less water per cycle, compared to vacuum

ejector design without water-saver

• Pre-vacuum cycles are more efficient

• Reduce overall cycle time by up to 10%, while reducing steam consumption by approximately 5%

RTD sensors

• Control drain discharge temperature at less than 140°F (60°C)

• RTD sensors help conserve water by cooling the steam condensate effluent only when needed

Utilities control system

• Provides a seven-day timer for programmed startup and shutdown of the sterilizer

• When activated, the control system shuts OFF water and steam to the sterilizer to conserve energy

Vacuum ejector water-saver with water-chiller option

• Reuse up to 80% of vacuum ejector water

depending on load and cycle parameters

• Connect water-saver to building chilled water loop to cool recycled ejector water

GETINGE 733HC-E | 9

10 | GETINGE 733HC-E

ACCESS INTEGRATED DATA

SOLUTIONS VIA NETCOM

Getinge NetCOM inside

Getinge NetCOM is standard with Getinge 733HC-E Series Sterilizers and enhances the AAMI ST79 requirement for physical monitors. Physical monitoring is needed to detect malfunctions as soon as possible so that appropriate corrective actions can be taken. In addition to the integral thermal paper printed record, the factory installed NetCOM is set to record real-time cycle performance data to a USB port storage device (flash drive), where it can be retrieved at any time to print out selected cycle reports.

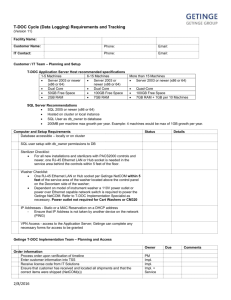

T-DOC cycle

Getinge NetCOM provides the option to connect and interface with T-DOC

Cycle, one of the modules in the T-DOC product portfolio. T-DOC Cycle provides a direct interface with Getinge sterilizers and washer-disinfectors, enabling a real-time overview of important cycle parameters. You can digitally log process data and view cycle parameters while the machine is running.

• Implement paperless process documentation

• Optimize production and minimize maintenance costs

• Utilize extensive management reporting tools

• Ensure compliance with regulatory standards

T-DOC instrument traceability and asset management

Getinge NetCOM provides the option to connect to T-DOC via Ethernet cabling. T-DOC, a modular, PC-based system provides comprehensive instrument traceability, along with process quality assurance through real-time data logging of washer-disinfector and sterilizer cycle performance – including immediate-use steam sterilization cycle documentation.

• Document all instruments in production from purchase through most recent sterilization cycle

• Link instruments, implants and disposables to a patient or procedure number

• Track instruments and mobile equipment via barcodes, 2D codes and RFID

• Achieve total traceability of sterile goods

• Assure the quality of production

• Increase production efficiency and plan according to demand

• Improve instrument utilization and optimize inventories

• Implement best practices and streamline processes

NETWORK

Get maximum uptime with Getinge Online

Getinge NetCOM provides the option to connect the Getinge 733HC-E Series Sterilizer to Getinge Online via Ethernet and your existing Internet connection. Web-based communication makes Getinge Online secure, easy to implement, and offers unsurpassed availability. Simply log on with a browser from your computer or smartphone – anywhere, anytime – and access real-time data and status for your Getinge equipment. Get notified when your sterilizer completes a cycle or encounters a process delay – via SMS/text or E-mail.

GETINGE 733HC-E | 11

ACCESSORIZE FOR

QUALITY ASSURANCE

CONFIGURATION OPTIONS

• Recessed or Freestanding With Cabinet Package

• Single or Double-Door for Pass-Thru Operations

• Water-Ejector Vacuum or Vacuum Pump

• Stainless Steel Piping to Jacket and Chamber

LOADING ACCESSORIES

• Interior Rack With Extendable Shelves

• Removable Load Car With Transport Trolley

STERILITY ASSURANCE ACCESSORIES

• BIOSIGN Steam-24 Biological Indicator (BI)

• BIOSIGN SSI Test Pack

• Getinge Assure AccuFast Biological Test Pack

• CHEMISIX Family of Chemical Sterilization Monitors

• Steam Sterilization Integrators

• Assure S.M.A.R.T Green Bowie & Dick Test Pack

INSTALLATION, SERVICE AND SUPPORT

• National project management and installation at all levels

• Complete product IQ, OQ and PQ services

• Service contracts and life cycle technical support

• Performance optimization for maximum uptime performance

• Proactive remote online monitoring system

ATP CONTAMINATION MONITORING SYSTEM

The Getinge Assure SafeStep Contamination Monitoring

System verifies the cleanliness of surfaces, endoscopes and cannulated instruments in just 15 seconds. By detecting ATP (adenosine triphosphate) – an indicator of residual contamination – SafeStep gives you the testing power to minimize HAIs and optimize patient and staff safety.

COMPLETE SOLUTIONS FOR INFECTION CONTROL

Getinge is the world’s leading provider of solutions for effective cleaning, disinfection and sterilization in the healthcare and life science sectors. We are dedicated to helping our customers provide better care at a lower cost. We do this by offering well-thought-through and customized solutions. This means that we are with our customers all the way from architectural planning and education to traceability and support – with complete solutions, long-term commitment and global presence.

Getinge – Always with you.

Getinge USA, Inc.

1777 East Henrietta Road

Rochester, New York 14623-3133

U.S.A.

Phone: 800.475.9040

Fax: 585.272.5033

www.getingeusa.com

GETINGE GROUP is a leading global provider of products and systems that contribute to quality enhancement and cost effi ciency within healthcare and life sciences. We operate under the three brands of ArjoHuntleigh, GETINGE and

MAQUET. ArjoHuntleigh focuses on patient mobility and wound management solutions. GETINGE provides solutions for infection control within healthcare and contamination prevention within life sciences. MAQUET specializes in solutions, therapies and products for surgical interventions and intensive care.