K-4330 - Germantown School District

advertisement

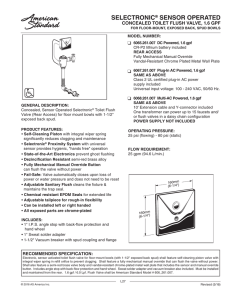

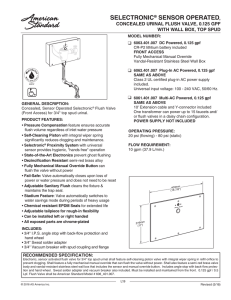

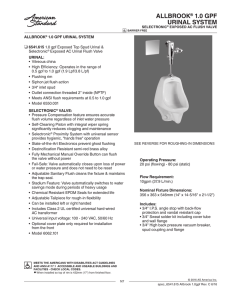

KINGSTONTM Features • • • • • • • • • BOWL K-4330 1-1/2″ top spud Vitreous china Elongated bowl Wall-mount 1.6 gpf (6 lpf) ADA compliant when installed at required height of 17″-19″ from floor to top of seat With bedpan lugs (-L) Siphon jet 12-3/8″ (31.4 cm) x 11-3/8″ (28.9 cm) water area Codes/Standards Applicable Specified model meets or exceeds the following: • • • • • • • ADA ASME A112.19.2 ASME A112.19.6 ICC/ANSI A117.2 Energy Policy Act of 1992 (EPACT) IAPMO/UPC CSA B125 Colors/Finishes • 0: White • Other: Refer to Price Book for additional colors/finishes Accessories • 0: White • Other: Refer to Price Book for additional colors/finishes Specified Model Model K-4330 K-4330-L Description Elongated bowl toilet Elongated bowl toilet with bedpan lugs Recommended Accessories K-4670-C LustraTM open front seat K-4670-CA LustraTM open front seat (with anti-microbial agent) Colors/Finishes ❑ 0 White ❑ Other_____ ❑ 0 White ❑ Other_____ ❑ 0 White ❑ 0 White ❑ Other_____ Product Specification: The elongated bowl shall be wall-mount with a 1-1/2″ top spud. Bowl shall be made of vitreous china. Bowl shall have 12-3/8″ (31.4 cm) x 11-3/8″ (28.9 cm) water area. Bowl shall be 1.6 gpf (6 lpf). Bowl shall be ADA compliant when installed at required height of 17″ (43.2 cm) - 19″ (48.3 cm) from the floor to the top of the seat. Bowl shall have bedpan lugs (-L). Bowl shall have siphon jet. Bowl shall be Kohler Model K-4330-______ Page 1 of 2 112572-4-BC USA: 1-800-4-KOHLER Canada: 1-800-964-5590 kohler.com KINGSTONTM Technical Information Installation Notes Install this product according to the installation guide. ADA compliant Fixture: Configuration top spud, elongated Water per flush 1.6 gallons (6 L)* Spud size 1-1/2″ Passageway 2-1/4″ (5.7 cm) Water area 12-3/8″ (31.4 cm) x 11-3/8″ (28.9 cm) Water depth from rim 5-1/4″ (13.3 cm) Seat post hole centers 5-1/2″ (14 cm) * Designed to flush with 1.6 (6 L) gallons of water when installed with a 1.6 (6 L) gpf flush valve. Included components: Spud 18357 Flush valve requirements: Refer to manufacturer and local codes. Finished Wall 1/16" (2 mm) 2-3/4" (7 cm) 25-5/8" (65.1 cm) 16-3/4" (42.5 cm) 9" (22.9 cm) 1-1/2" Spud 2-1/2" (6.4 cm) 1-5/8" (4.1 cm) 7-1/2" (19.1 cm) CL Of Outlet 5" (12.7 cm) Finished Floor Product Diagram KINGSTONTM BOWL Page 2 of 2 112572-4-BC 13-1/4" (33.7 cm) Model 8110/8111 Battery Powered Flushometers t Buy Ac t • n om C plia • Ac t • om £ Model 8111 Low Consumption (1.6 gpf/6.0 Lpf) £ Model 8110 Water Saver (3.5 gpf/13.2 Lpf) n n u Flush Cycle C u • u e r i ca Am e r i ca Am Description Exposed, Battery Powered, Sensor Operated G2® Model Water Closet Flushometer for floor mounted or wall hung top spud bowls. Buy u n t OPTIMA SYSTEMS plia Specifications Quiet, Exposed, Diaphragm Type, Chrome Plated Closet Flushometer for either left or right hand supply with the following features: • PERMEX® Synthetic Rubber Diaphragm with Dual Filtered Fixed Bypass • Flex Tube Diaphragm designed for improved life and reduced maintenance • ADA Compliant OPTIMA Plus® Battery Powered Infrared Sensor for automatic “No Hands” operation • Infrared Sensor with Multiple-focused, Lobular Sensing Fields for high and low target detection • Latching Solenoid Operator • Engineered Metal Cover with replaceable Lens Window • User friendly three (3) second Flush Delay • Courtesy Flush® Override Button • Four (4) Size AA Batteries factory installed • “Low Battery” Flashing LED • Infrared Sensor Range Adjustment Screw • Initial Set-up Range Indicator Light (first 10 minutes) • 1” I.P.S. Screwdriver Bak-Chek® Angle Stop • Free Spinning, Vandal Resistant Stop Cap • Adjustable Tailpiece • High Back Pressure Vacuum Breaker Flush Connection with One-piece Bottom Hex Coupling Nut • Spud Coupling and Flange for 1½” Top Spud • Sweat Solder Adapter with Cover Tube and Cast Set Screw Wall Flange • High Copper, Low Zinc Brass Castings for Dezincification Resistance • Fixed Metering Bypass and No External Volume Adjustment to Ensure Water Conservation • Flush Accuracy Controlled by CID™ Technology • Diaphragm, Stop Seat and Vacuum Breaker to be molded from PERMEX® Rubber Compound for Chloramine resistance • 100% of the energy used in manufacturing is offset with Renewable Energy Sources – Wind Energy u u Valve Body, Tailpiece and Control Stop shall be in conformance with ASTM Alloy Classification for Semi-Red Brass. Valve shall be in compliance with the applicable sections of ASSE 1037, ANSI/ASME A112.19.2. Installation conforms to ADA requirements. u Made with Renewable Energy u ADA Compliant Automatic Sloan G2 Optima Plus® Flushometers activate via multi-lobular sensor detection to provide the ultimate in sanitary protection and automatic operation. A battery powered infrared sensor sets the flushing mechanism after the user is detected and completes the flush when the user steps away. Functional & Hygienic Made with Touchless, sensor operation eliminates the need for Renewable user contact to Energy help control the spread of infectious diseases. The G2 Optima Plus Flushometer is provided with an Override Button to allow a "courtesy flush" for individual user comfort. u Economical Sloan installed batteries speed installation and provide years of metered flushing to control the use of water and energy. Batteries can be changed without turning off the water. Warranty 3 year (limited) Special Finishes £ PB £ BN £ SF Polished Brass (PVD Finish) Brushed Nickel (PVD Finish) Satin Chrome See Accessories Section and OPTIMA Accessories Section of the Sloan catalog for details on these and other OPTIMA Plus® Flushometer variations. This space for Architect/Engineer approval Job Name Date Model Specified Quantity Variations Specified Customer/Wholesaler Contractor Architect G2 Optima Plus 8110 S.S. — Rev. 1a (06/11) The information contained in this document is subject to change without notice. Model 8110/8111 u Description Exposed, Battery Powered, Sensor Operated G2® Model Water Closet Flushometer for floor mounted or wall hung top spud bowls. u Flush Cycle 2¼” MIN. (57 mm) £ Model 8111 Low Consumption (1.6 gpf/6.0 Lpf) £ Model 8110 Water Saver (3.5 gpf/13.2 Lpf) 4 ¾” (121 mm) 5” (127 mm) ELECTRICAL SPECIFICATIONS u u Control Circuit Solid State 6 VDC Input 8 Second Arming Delay 3 Second Flush Delay u OPTIMA Sensor Type Active Infrared u OPTIMA Sensor Range Nominal 22” - 42” (559 mm -1067 mm), Adjustable ± 8” (203 mm) Battery Type (4) AA Alkaline 16½” (419 mm) u Battery Life 3 Years @ 4,000 Flushes/Month u Indicator Lights Range Adjustment/Low Battery u Operating Pressure 15 - 100 psi (104 - 689 kPa) u Sentinel Flush Once Every 24 Hours After the Last Flush C/L OF SUPPLY 1” I.P.S. SUPPLY (DN 25 mm) 11½” (292 mm) C/L OF FIXTURE C/L OF FIXTURE OPERATION 1. A continuous, invisible light beam is emitted from the OPTIMA Plus Sensor. 2. As the user enters the beam’s effective range (22” to 42”) the beam is reflected into the OPTIMA Plus Scanner Window and transformed into a low voltage electrical circuit. Once activated, the Output Circuit continues in a “hold” mode for as long as the user remains within the effective range of the Sensor. 3. When the user steps away from the OPTIMA Plus Sensor, the circuit waits 3 seconds (to prevent false flushing) then initiates an electrical signal that operates the Solenoid. This initiates the flushing cycle to flush the fixture. The Circuit then automatically resets and is ready for the next user. VALVE ROUGH-IN Typical Water Closet Installation Alternate ADA Installation Lower water supply rough-in to 10” (254 mm) and mount grab bar at the 36” (914 mm) maximum allowed height. Model 8110/8111 2¼” (57 mm) MIN. 11½” (292 mm) FINISHED WALL 16½” (419 mm) 1” I.P.S. (25 mm DN) SUPPLY C/L OF FIXTURE C/L OF WASTE FINISHED FLOOR 2¼” (57 mm) MIN. 36” (914 mm) 4¾” (121 mm) 10” (254 mm) When installing the G2 Optima Plus in a handicap stall: Per the ADA Guidelines (section 604.9.4) it is recommended that the grab bars be split or shifted to the wide side of the stall. If grab bars must be present over the valve, use the Alternate ADA Installation as shown to the right. FINISHED WALL 15” (381 mm) 18” (457 mm) C/L OF WASTE FINISHED FLOOR SLOAN VALVE COMPANY • 10500 SEYMOUR AVENUE • FRANKLIN PARK, IL 60131 Phone: 1-800-9-VALVE-9 or 1-847-671-4300 • Fax: 1-800-447-8329 or 1-847-671-4380 • www.sloanvalve.com Copyright © 2011 Sloan Valve Company G2 Optima Plus 8110 S.S. — Rev. 1a (06/11) BRANHAMTM Features • • • • • URINAL K-4920-T Vitreous china Washout stall 3/4″ rear spud ADA compliant 1 gpf (3.78 lpf) Codes/Standards Applicable Specified model meets or exceeds the following: • • • • • • ADA ASME A112.19.2 IAPMO/UPC ICC/ANSI A117.1 Energy Policy Act of 1992 (EPACT) CSA B45 Colors/Finishes • 0: White • Other: Refer to Price Book for additional colors/finishes Accessory: • 0: White • G: Brushed Chrome • NA: None applicable Specified Model Model K-4920-T Description 3/4″ top spud stall urinal Colors/Finishes ❑0 ❑ Other_____ Recommended Accessories K-9172 Strainer with china grate K-9183 Strainer with stainless steel beehive grate ❑ NA ❑ NA Optional Accessories K-4931 Seam cover [for urinal set on 21″ (53.3 cm) centers] K-4932 Seam cover [for urinal set on 24″ (61 cm) centers] K-13686 Touchless battery-powered urinal flush valve, fixture mounted ❑0 ❑0 ❑G ❑ Other_____ ❑ Other_____ Product Specification Washout stall urinal shall be made of vitreous china with a 3/4″ top spud. Urinal shall be ADA compliant. Urinal shall use 1 gpf (3.78 lpf). Urinal shall be Kohler Model K-4920-T-_______. Page 1 of 2 105106-4-CC USA: 1-800-4-KOHLER Canada: 1-800-964-5590 kohler.com BRANHAMTM Technical Information Installation Notes Install this product according to the installation guide. Fixture is ADA compliant. Fixture: Configuration Top spud Water per flush 1 gal* (3.78 L) Spud inlet size 3/4″ * Designed to flush with one gallon (3.78 L) of water when installed with a water-saving flush valve. Included component: Spud For proper drainage, install lip of urinal below floor level. Refer to manufacturer’s instructions and local codes for flush valve requirements. 18774 8" (20.3 cm) 3" (7.6 cm) 3/4" Spud 38-1/2" (97.8 cm) Top of Lip 4" (10.2 cm) 8-1/2" (21.6 cm) 1-1/2" (3.8 cm) 16-1/8" (41 cm) Product Diagram BRANHAMTM URINAL Page 2 of 2 105106-4-CC 18-1/4" (46.4 cm) Model 8186 Battery Powered Flushometers t Buy Ac t • n om C plia • Ac t • om n n £Model 8186-0.5 (0.5 gpf/1.9 Lpf) £ Model 8186-1.0 Low Consumption (1.0 gpf/3.8 Lpf) £ Model 8186 Water Saver (1.5 gpf/5.7 Lpf) C u Flush Cycle • u e r i ca Am e r i ca Am Description Exposed, Battery Powered, Sensor Operated G2® Model Urinal Flushometer. Buy u n t OPTIMA SYSTEMS plia Specifications Quiet, Exposed, Diaphragm Type, Chrome Plated Urinal Flushometer for either left or right hand supply with the following features: • PERMEX® Synthetic Rubber Diaphragm with Dual Filtered Fixed Bypass • Flex Tube Diaphragm designed for improved life and reduced maintenance • ADA Compliant OPTIMA Plus® Battery Powered Infrared Sensor for automatic “No Hands” operation • Infrared Sensor with Multiple-focused, Lobular Sensing Fields for high and low target detection • Latching Solenoid Operator • Engineered Metal Cover with replaceable Lens Window • Courtesy Flush® Override Button • Four (4) Size AA Batteries factory installed • “Low Battery” Flashing LED • Infrared Sensor Range Adjustment Screw • Initial Set-up Range Indicator Light (first 10 minutes) • ¾” I.P.S. Screwdriver Bak-Chek® Angle Stop • Free Spinning, Vandal Resistant Stop Cap • Adjustable Tailpiece • High Back Pressure Vacuum Breaker Flush Connection with One-piece Bottom Hex Coupling Nut • Spud Coupling and Flange for ¾” Top Spud • Sweat Solder Adapter with Cover Tube and Cast Set Screw Wall Flange • High Copper, Low Zinc Brass Castings for Dezincification Resistance • Fixed Metering Bypass and No External Volume Adjustment to Ensure Water Conservation • Flush Accuracy Controlled by CID Technology • Diaphragm, Stop Seat and Vacuum Breaker to be molded from PERMEX® Rubber Compound for Chloramine resistance • 100% of the energy used in manufacturing is offset with Renewable Energy Sources – Wind Energy Valve Body, Tailpiece and Control Stop shall be in conformance with ASTM Alloy Classification for Semi-Red Brass. Valve shall be in compliance with the applicable sections of ASSE 1037, ANSI/ASME A112.19.2. Installation conforms to ADA requirements. Made with Renewable Energy u u u u ADA Compliant Automatic Sloan G2 Optima Plus® Flushometers activate via multi-lobular sensor detection to provide the ultimate in sanitary protection and automatic operation. A battery powered infrared sensor sets the flushing mechanism after the user is detected and completes the flush when the user steps away. Functional & Hygienic with Touchless, sensor operation eliminates the need for Renewable userMade contact to Energy help control the spread of infectious diseases. The G2 Optima Plus Flushometer is provided with an Override Button to allow a "courtesy flush" for individual user comfort. Economical Sloan installed batteries speed installation and provide years of metered flushing to control the use of water and energy. Batteries can be changed without turning off the water. u Warranty 3 year (limited) u Special Finishes £ PB £ BN £ SF Polished Brass (PVD Finish) Brushed Nickel (PVD Finish) Satin Chrome See Accessories Section and OPTIMA Accessories Section of the Sloan catalog for details on these and other OPTIMA Plus® Flushometer variations. This space for Architect/Engineer approval Job Name Date Model Specified Quantity Variations Specified Customer/Wholesaler Contractor Architect G2 Optima Plus 8186 S.S. — Rev. 1a (06/11) The information contained in this document is subject to change without notice. Model 8186 u Description Exposed, Battery Powered, Sensor Operated G2® Model Urinal Flushometer. u Flush Cycle £Model 8186-0.5 (0.5 gpf/1.9 Lpf) £ Model 8186-1.0 Low Consumption (1.0 gpf/3.8 Lpf) £ Model 8186 Water Saver (1.5 gpf/5.7 Lpf) ELECTRICAL SPECIFICATIONS u Control Circuit Solid State 6 VDC Input 8 Second Arming Delay 24 Hour Sentinel Flush u OPTIMA Sensor Type Active Infrared u OPTIMA Sensor Range Nominal 15” - 30” (381 mm - 762 mm), Adjustable ± 8” (203 mm) u Battery Type (4) AA Alkaline u Battery Life 3 Years @ 4,000 Flushes/Month u Indicator Lights Range Adjustment/Low Battery u Operating Pressure 15 - 100 psi (104 - 689 kPa) u Sentinel Flush Once Every 24 Hours After the Last Flush OPERATION 1. A continuous, invisible light beam is emitted from the OPTIMA Plus Sensor. 2. As the user enters the beam’s effective range (15” to 30”) the beam is reflected into the OPTIMA Plus Scanner Window and transformed into a low voltage electrical circuit. Once activated, the Output Circuit continues in a “hold” mode for as long as the user remains within the effective range of the Sensor. 3. When the user steps away from the OPTIMA Plus Sensor, the Sensor initiates an electrical signal that operates the Solenoid. This initiates the flushing cycle to flush the fixture. The Circuit then automatically resets and is ready for the next user. VALVE ROUGH-IN Typical Urinal Installation Model 8186 ¾” I.P.S. (20 mm DN) SUPPLY 2¼” (57 mm) MIN. 11½” (292 mm) 16½” (419 mm) C/L OF FIXTURE 4¾” (121 mm) Note: Lens Deflector no longer needed for targeting children or wheel chair users. FINISHED WALL FINISHED FLOOR SLOAN VALVE COMPANY • 10500 SEYMOUR AVENUE • FRANKLIN PARK, IL 60131 Phone: 1-800-9-VALVE-9 or 1-847-671-4300 • Fax: 1-800-447-8329 or 1-847-671-4380 • www.sloanvalve.com Copyright © 2011 Sloan Valve Company G2 Optima Plus 8186 S.S. — Rev. 1a (06/11) MG-3 ® Express Lavatory System – MG-Series • • • • ADA and TAS Compliant Serves One to Three Users at a Time Standard Lavatory Spacing on 30" Centers Continuous Bowl, Sprayhead and End Caps are Constructed of Terreon® or Terreon®RE Solid Surface Material • Available in 32 Colors • Reliable Plug-in, Battery or ndite® Infrared Activation, Push Button Air Valve, or TouchTime® Metering Control • Optional Electric Tankless Water Heater Specifications The flowing “wave” design accommodates one to three users. Units handle washroom traffic quickly and economically, while providing each user with their own personal space. Lavatories for the system are positioned on 30" centers. The preassembled sprayhead module is equipped with independent aerators, each served by separate infrared sensing module and solenoid valve (Model MG-3/IR) or (Model MG-3/NDT), push button air metering valve (Model MG-3/AST4), push button TouchTime electronic metering control (Model MG-3/TT) or independent battery IR sensor and batteries (Model MG-3/BIR3). Operating range is 20–80 PSI. Flow restrictor keeps flow rate constant at all pressures. Flow rate: .5 GPM. Construction Bowl, Sprayhead and Pedestal End Caps Constructed of Terreon, a densified solid surface material composed of polyester resin, or TerreonRE, a densified solid surface material composed of a bio-based resin and preconsumer recycled granules. Terreon and TerreonRE are resistant to chemicals, stains, burns and impact. Surface damage can be easily repaired with everyday cleansers or fine grit abrasives. Terreon and TerreonRE are certified by NAHB to meet ANSI Z124.3, Z124.6 and ANSI/ICPA SS-1-2001. Terreon and TerreonRE are GREENGUARD® certified as low-emitting materials. MG-3/BIR3 Code Compliance and Certifications ANSI Standards Terreon and TerreonRE are NAHB certified to meet ANSI Z124.3, Z124.6 and ANSI/ ICPA SS-1. cUPC Approval Express Lavatory Systems are Uniform Plumbing Code (UPC), International Plumbing Code (IPC) and National Plumbing Code of Canada (NPC) approved through the International Association of Plumbing and Mechanical Officials (IAPMO). Manufactured in compliance with IGC 156, CSA B45 Series (R08) & ASME A112.18.1/CSA B125.1. This plumbing fixture is designed for hand washing only. It is not Intended to dispense water for human consumption through drinking or for preparation of food or beverages. Standard Height Mounting The Express Lavatory System model MG-3 mounted at standard height is designed to comply with all ADA guidelines on reaches, clearances and operation. To comply with ADA, the rim height of the Express Lavatory System bowl must be 33.5" maximum above the finished floor. D PR O DU IFIE 4 940 br c.o -2 30 1 rg RT CT CE Support Frame and Access Panel Bowl assembly and pedestal end caps are secured to a heavy gauge stainless steel Juvenile Height Mounting support frame mounted to the wall. The contoured front access panel is constructed of The Express Lavatory System model MG-3 is designed to mount at different heights to comply with guidelines on reaches, clearances and operation for various codes 300 series stainless steel. including, ADA Accessibility Guidelines for Buildings and Facilities (ADAAG) and TAS Vandal Resistance (Texas Accessibility Standards). Always check your local and state codes. The molded solid surface sprayhead is an integral part of the bowl module. A free-spinning collar protects the aerator from vandalism. The infrared sensor will automatically shut off water flow after 30–45 seconds if a vandal attempts to trigger constant operation by covering the sensor, or by placing a stationary object in the sensor’s detection area. Push buttons are secured to the unit from inside the sprayhead. Air valves, water supplies and waste are concealed within the pedestal/support frame assembly. 00 .na ww w h Verify all rough-in dimensions prior to installation. Consult local and national codes. Conformity and compliance to local and national codes is the responsibility of the installer. Plumbing Fixtures Document No. 1052 Page 1 of 5 This information is subject to change without notice. 11/17/2011 © 2011 Bradley Corporation P.O. Box 309, Menomonee Falls, WI 53052-0309 Phone: 800.BRADLEY (800.272.3539) Fax: 262.251.5817 bradleycorp.com MG-3 ® Express Lavatory System – MG-Series Standard Equipment Bowl with three lavatories, pedestal, stainless steel mounting frame (as described above), 110/24 VAC plug-in transformer (Model MG-3/IR and Model MG-3/TT). Batteries are included (Model MG-3/BIR3). The following fittings are provided: P-trap; tailpiece; two flexible stainless steel supply connections; and Navigator® thermostatic mixing valve with stops. Activation Controls Infrared Sensor (Model MG-3/IR) The sensor module uses a conical infrared transmitting beam, creating a wide detection area. Adaptive-style sensor shall learn installation environment upon power-up and react (activate) when the user’s hands enter the detection area. A timing turn-off delay of 2–3 seconds results in a smooth, controlled hand-washing operation. The Bradley adaptive sensor is not affected by varying color tones or darkness. Direct sunlight or bright washroom lights (up to 10,000 foot candles) will not activate the system. • Solenoids – 24V, 50/60 Hz, 1⁄8" NPT. The electronically activated solenoid valve provides reliable performance since there are few moving parts, and its operation is unaffected by most chemicals and minerals often present in municipal water supplies. Neither the solenoid valve nor the infrared sensor module need adjustment for range or timing. • Low Voltage Transformer – A Class II, UL/CSA-listed 110/24 VAC, plug-in transformer powers the solenoid valves. The transformer, furnished as standard equipment, plugs into a standard GFCI protected electrical outlet. Push Button Control (Model MG-3/AST4) Each push button activates a non-hold-open air valve with field adjustable timing from 5–60 seconds. Factory set at 10 seconds. Each push button activates one valve which, in turn, activates one hand washing station. TouchTime Metering Control (Model MG-3/TT) Each low voltage push button actuates a non-hold-open, slow closing anti-hammer solenoid valve that is timed from an electronic potted assembly. Each push button activates one valve, which, in turn, activates one station (streamformer). TouchTime controls water flow at each station through the use of solid-state, digital circuitry. Timing is electronically controlled at 15 seconds. Battery Infrared Sensor (Model MG-3/BIR3) Each battery-powered sensor uses a zone-focused infrared transmitting beam, creating a large detection area. The sensor is not affected by varying skin tones or darkness. When hands enter the detection area, the sensor starts water flow by opening the valve electronically. When hands leave the detection area, the sensor stops the flow of water by closing the valve. The 6-volt DC, electronically activated solenoid valve has few moving parts, providing reliable operation that is unaffected by most chemicals and minerals often present in municipal water supplies. Each station is powered by a single lithium battery. Battery type is Duracell® DL 223A 6-volt lithium or rquivalent (batteries included) with a life expectancy of 4–5 years or approximately 200,000 cycles. ndite Infrared Control (Model MG-3/NDT) The photovoltaic cells are permanently embedded in the top of the sprayhead with a clear version of Terreon or TerreonRE. The ndite power management module is a proprietary unit that stores and provides power to the sensors and solenoid. This efficient module allows the system to work without batteries, eliminating the need to change or dispose of batteries. Each ndite-powered sensor uses a conical-shaped transmitting beam, creating a wide detection area. The detection area projects forward 15° to each side and 15° below horizontal. The adaptive infrared sensor automatically adapts to the bowl after power is turned on. The electronically activated solenoid valve has few moving parts providing reliable operation that is unaffected by most chemicals and minerals often present in municipal water supplies. Each lavatory system is powered by one ndite power management module. Restrooms with 400 lux of lighting will provide a sufficient amount of light to power the system. For more information on ndite technology, visit bradleycorp.com. Optional Equipment Express Lavatory System Thermostatic Electric Tankless Water Heater The optional tankless electric water heater is equipped with a microprocessing temperature control capable of maintaining outlet temperature accuracy of +/- 1° F. Factory preset at 105º F. Flow switch activates heater only on demand with 99% efficiency. For easy service, the heater features a replacement cartridge element. Heaters not available with BIR3 or NDT. Model KW VAC Amps Temp. Rise @ 1.5 GPM EX95TMLB 9.5 240/208* 40 43° F EX100TMLB 10 277 36 46° F *240 volt can also be rated 208 volts with a 25% reduction in power. Soap Dispensers Two horizontally-mounted pump-style valves are located over the drains. Soap tank is located within the stainless steel frame. Soap tank is refillable through an easily accessible exterior filler cap. Filler cap is vandal resistant and opens with special spanner wrench included. Soap tank capacity is ¾ gallon. For information on Terreon and TerreonRE Waste Receptacles for the Express MG-Series, visit bradleycorp.com. Verify all rough-in dimensions prior to installation. Consult local and national codes. Conformity and compliance to local and national codes is the responsibility of the installer. Plumbing Fixtures Document No. 1052 Page 2 of 5 This information is subject to change without notice. 11/17/2011 © 2011 Bradley Corporation P.O. Box 309, Menomonee Falls, WI 53052-0309 Phone: 800.BRADLEY (800.272.3539) Fax: 262.251.5817 bradleycorp.com MG-3 ® Express Lavatory System – MG-Series Dimensions 84" (2134mm) 72" (1829mm) 15" (381mm) 15" (381mm) Top View 30" (762mm) 30" (762mm) Front View 57" (1445mm) 77" (1956mm) 22" (559mm) 9½" (241mm) Side View 21½" (546mm) *39" (991mm) *33½" (851mm) *17½" (445mm) AD A• *29½" (749mm) C O MPL IA NT Verify all rough-in dimensions prior to installation. Consult local and national codes. Conformity and compliance to local and national codes is the responsibility of the installer. Plumbing Fixtures Document No. 1052 Page 3 of 5 This information is subject to change without notice. 11/17/2011 * Subract 4" from all vertical dimensions for Juvenile Height Mounting. * Subract 3½" from all vertical dimensions for TAS Juvenile Height Mounting (grades Pre-K through 5 or 6). * Subract 1½" from all vertical dimensions for TAS Juvenile Height Mounting (grades 6 through 8 or 9). © 2011 Bradley Corporation P.O. Box 309, Menomonee Falls, WI 53052-0309 Phone: 800.BRADLEY (800.272.3539) Fax: 262.251.5817 bradleycorp.com MG-3 ® Express Lavatory System – MG-Series Rough-Ins Mounting for Standard Height Is Shown Centerline of Fixture 40½" (1029mm) 40½" (1029mm) 28" (711mm) 28" (711mm) Cold or Tempered Supply 12" (305mm) 2¾" (70mm) Hot Supply A A B A E D A A C G A *31½" (800mm) A E F A 7¼" (184mm) *28¼" (718mm) 4" (102mm) 4" (102mm) *26" (660mm) *24" (610mm) 9" (229mm) *19½" (495mm) Floor Std. Height Chart 1 Vertical Height Adjustments Codes A, B, C, D, E, F and G Chart 2 * None Standard Height * Subtract 4" Juvenile Height * Subtract 1½" TAS, Grades 6 through 8 or 9 * Subtract 3½" TAS, Pre-K through Grades 5 or 6 Fixture Style Code A B C D Description Qty. ⁄8" Wall Anchors with a minimum pull out force of 1,000 lbs. 8 ½" Nominal Copper Tubing for Hot Supply, Stub-Out 2" from Wall ½" Nominal Copper Tubing for Cold or Tempered Supply, Stub-Out 2" from Wall 1½" NPT Drain, Stub-Out 2" from Wall 1 3 1 1 E 110V GFCI Protected Electrical Outlet. I.R. and TouchTime Only 1 F Optional Heater, Electric Box Location 6" L x 3" W x 6" H – Option 1 1 G Optional Heater, Electric Box Location 6" L x 3" W x 6" H – Option 2 1 Verify all rough-in dimensions prior to installation. Consult local and national codes. Conformity and compliance to local and national codes is the responsibility of the installer. Plumbing Fixtures Document No. 1052 Page 4 of 5 This information is subject to change without notice. 11/17/2011 © 2011 Bradley Corporation P.O. Box 309, Menomonee Falls, WI 53052-0309 Phone: 800.BRADLEY (800.272.3539) Fax: 262.251.5817 bradleycorp.com MG-3 ® Express Lavatory System – MG-Series Standard Selections (Must select one from each category) Sprayhead Sprayhead w/Infrared Control IR Sprayhead w/Air Valve Control AST4 Sprayhead w/TouchTime Control TT Sprayhead w/Battery Infrared Control BIR3 Sprayhead w/ndite Infrared Control * NDT Soap Dispenser (select one) Liquid Soap Dispenser (MG-3) LSD-3 No Soap Dispenser NSD Water Supply (select one) Navigator Themostatic Mixing Assembly (Hot and Cold Supplies) TMA Single Tempered Line TL Color of Terreon Bowl/Sprayhead Cover (select one) Standard Colors Empire Gray E-GRAY GRAPH Mesa Bone BONE LANNON Peppered White PEP-WHT COBBLE Sandtrap SAND WHT-SAND Designer White DS-WHT FIESTA Charcoal Gray CHAR LONDON Jade JADE O-TAUPE Graphite Lannonstone Cobblestone White Sand Fiesta London Gray Organic Taupe Designer Colors* (available at an additional charge) Arctic Chip COFFEE ARC-CHIP Summer Sage CORN S-SAGE Riverstone BLUESKY RIVER Mystic Moss HILLSIDE MYSTIC-M Stardust MOUNTAIN STAR-D Coffee Bean Cornfield Blue Sky Hill Side Mountain Top TerreonRE Colors* (available at an additional charge) BIRCH-BARK Birch Bark MAIZE Maize OCEAN-MIST Ocean Mist DUSK Dusk MOONDUST Moon Dust OLIVE Olive FERN Fern OAT Oat Optional Selections Heaters (Not Available with BIR3 or NDT Activations): Electric Tankless Water Heater, 277 Volts Heat277 Heat 240-208 Electric Tankless Water Heater, 240/208 Volts P-Trap: S-CHROME Single Chrome-Plated P-Trap *Non-cancelable, non-returnable Verify all rough-in dimensions prior to installation. Consult local and national codes. Conformity and compliance to local and national codes is the responsibility of the installer. Plumbing Fixtures Document No. 1052 Page 5 of 5 This information is subject to change without notice. 11/17/2011 © 2011 Bradley Corporation P.O. Box 309, Menomonee Falls, WI 53052-0309 Phone: 800.BRADLEY (800.272.3539) Fax: 262.251.5817 bradleycorp.com P 1, 11 M BIN l; r: I X T U RES TECHNICAL DATA Terreon® Imperial Wall-Mount Lavatory Model TL-1S (21/1 x lS/I) • • • • • • • ADA, ANSI and UFAS Compliant Superior Vandal Resistance compared to vitreous china lavs Constructed of easy-to-maintain Terreon® solid surface material Includes stainless steel mounting bracket Features built-in overflow Available in 24 colors Ideal tor use with Bradley Aerada™ faucets Specifications The Tcrreon® ImpeIial Wall-mount Lavatory is an ideal alternative for wall-mounted vitreous china lavatoJies. The TL-I8 is available for use with Bradley Aerada wucets or tlllcets by OrJlCrs. The !edged bowl design ensures rJlat water remains in the bowl and not on rJle rest-room floor. Each Terreon® ImpeIial Wall-mount Lavatory provides individual hand-washing space coupled with vandalresistant design . Model TL-18 Shown with optional Aerada™ 900 Series AZ Faucet Construction Bowl: Constructed of Terreon®, a densified solid surface material composed of polyester resin . Ten·eon® is resistant to chemicals, stains, burns, and imp'lct. Surface damage can be easily repaired with everyday cleansers or fine grit abrasives. Sample Specification Support Frame: Lavatory is secured to a heavy gauge stainless steel support frame mounted to the wall. Code Compliance and Certifications ANSI Standards: Terreon® is NAHB certified to meet ANSI Z124.3, ZI24.6 and ANSIjICPASS-I -2001. cjUPC Approval: The Terreon® Imperial Wall-mount Lavatory (TL-18) is Uniform Plumbing Code (cjUPC) approved through tile international Association of Plumbing and Mechanical Officials (IAPMO) for use in tile United States and Canada. The Wall-mounted Lavatory shal.1 be Bradley Terreon® ImpeJiai Wall-mount Lavatory (Model TL-I8). The lavatory shall provide one hand -washing station. Each TL-I8 lavatory shall comply \\~m ANSI and ADA Accessibility Standards. Each station shalJ be constructed ofTerreon® solid surface mateIiaJ, NAHJ3 certified to meet ANSI Z124.3, Z124.6 and ANSIjICPA SS-i-2001. Bowl finish to be a decorative stone. Unit to supported by a heavy dllty stainJess steel mounting bracket. ADA Compliance: The TL-IS is designed to mount at different heights (Adult and Juvenile) to comply wim guidelines on reaches, clearances for various codes including; ADA Accessibility Guidelines for Buildings and Facilities (ADAAF) and TAS (Texas AccessibiJity Standards). Always check your local and state codes. Bradley. IDocument No. 10871 P.O. Box 309, Menomonee Falls, WI 53052-0309 Phone 1-800-BRADLEY FAX 262-251-5817 http://www.bradleycorp.com Thi s information is subject to change without formal notice. © 2003 firadky Corporation 9-23-2005 (4 Pages Total) LSI087.1 P L U M B I N G F I X T U R E S T E C H N I C A L D A T A Aerada™ 1200 Series CS Faucet Model S53-315 • • • Specifications lines. The valve and electronics are enclosed in a water-resistant housing mounted below the fixture. Flow Control/Rate Operating water pressure range is 20-80 psi. Flow regulator keeps flow rate constant at all pressures. The flow is laminar at a rate of .5 gpm. User Operation The faucet utilizes capacitive sensing technology to create an omni-directional detection zone surrounding the spout. Water flow is initiated when the user's hands enter the detection zone regardless of angle of approach. The faucet will shut off after hands are removed from the zone conserving water while users groom or dry hands. Component Operation The Aerada 1200 Series CS faucet uses a 6 VDC battery powered control module to open and close a motor driven valve. The detection zone is automatically set when power is initially supplied to the faucet. Optional 100-120 VAC plug-in adapters are available for both single and multi-faucet applications. The faucet is powered by (4) ‘D’-cell alkaline batteries (included). Batteries are mounted in a separate battery box, which can be remotely located beneath the fixture. Battery life varies by battery. Average battery life will yield approximately 500,000 activations under normal use. The incoming water supply can be tempered or cold. An optional Bradley Vernatherm™ Thermostatic Mixing Valve can be utilized to mix hot and cold supplies and deliver tempered water at a temperature no greater than 105°F. Standard Equipment Body Chrome plated solid brass body. Centershank or 4" centerset mounting (with included trimplate). 8" trimplate available separately. Sanitary Hands-free operation reduces water/soap splatter and addresses the public’s increasing awareness and concern about communicable diseases. Laminar flow reduces the potential for airborne bacteria to contaminate the water stream and reduces backsplash of water when it hits the bowl. Vandal Resistant For maximum vandal-resistance, use of an anti-rotational trimplate (4" included) is recommended. There are no surfacemounted controls to tempt vandals. Due to the type of technology used to create faucet activation, infrared sensor windows are not utilized. The entire spout is solid brass eliminating vandalism to any infrared components. The faucet will only activate when human presence enters the detection zone; a stationary object will not cause water flow. The vandal resistant laminar flow outlet can only be removed with a standard spanner wrench. Code Compliance and Certifications c/UPC Approved Capacitive Sensing Technology The Aerada 1200 Series CS faucet creates an omni-directional detection zone utilizing capacitive sensing technology. The capacitive sensing field triggers faucet activation only when a significant change in the capacitive field occurs. Only human presence will create a significant change in the capacitive field. As such, inanimate objects will not trigger faucet activation. The faucet is unaffected by varying skin tones, other infrared presence and soap scum build-up. Valve ASME A112.18.1 The 1200 Series CS faucet meets the A112.18.1 standard for plumbing fixture fittings. ADA Compliance Capacitive sensing technology creates an omni-directional detection zone which allows even severely disabled users to easily activate the faucet regardless of angle of approach, thereby meeting guidelines provided by ANSI A117-1. UP C DA •CO The electronically activated motor driven valve provides reliable performance since there are few moving parts. The valve includes an in-line filter to trap debris and is unaffected by most chemicals and minerals found in municipal water supplies. Valve features a factory-set maximum water run-on duration of 15 seconds. Valve control module features a manual override control for applications requiring periodic flushing of the water The 1200 Series CS faucet is Uniform Plumbing Code (c/UPC) approved through the International Association of Plumbing and Mechanical Officials (IAPMO) for use in Canada and the United States. M PLIA N T • • ADA Compliant Hands-free Activation c/UPC Approved by IAPMO Activation Utilizes Capacitive Sensing Technology Omni-Directional Detection Zone Delivers Superior Customer Satisfaction Faucet Operation Reduces Water Consumption 6 VDC Control Powered by (4) ‘D’-cell Alkaline Batteries (Included) Optional 100-120 VAC Plug-in Adapter Optional 100-120 VAC 6-Unit Plug-In Adapter Includes 4" Anti-Rotational Trimplate A • • • • C R Document No. 3048 This information is subject to change without formal notice. © 2005 Bradley Corporation 9-20-2005 (2 Pages Total) FA3048.1 P.O. Box 309, Menomonee Falls, WI 53052-0309 Phone 1-800-BRADLEY FAX 262-251-5817 http://www.bradleycorp.com P L U M B I N G F I X T U R E S T E C H N I C A L D A T A Aerada™ 1200 Series CS Faucet Model S53-315 Sample Specification OPTIONAL SELECTIONS Hands-free capacitive sensing faucet shall be Bradley Aerada™ 1200 Series CS faucet (S53-315) with battery powered valve control module. Capacitive sensing technology creates an omni-directional detection zone enabling faucet activation to occur regardless of angle of approach and requires no infrared sensors. The faucet will only activate when human presence enters the detection zone; inanimate objects will not cause faucet activation. The omni-directional detection zone is automatically calibrated when power is initially supplied to the faucet. The 6 VDC faucet is powered by (4) ‘D’-cell alkaline batteries (included) concealed inside a remotely located battery box. The electronically activated motor control valve is enclosed in a water-resistant housing mounted beneath the fixture. Valve control module to have maximum water run on duration of 15 seconds providing increased water conservation. Faucet shall feature chrome-plated solid brass spout with centershank, or 4" centerset mounting with included anti-rotational trimplate. Faucet shall be c/UPC approved. Part No. Trimplate: ❏ 159-428 MODELS – Part No. ❏ S53-315 Faucet with Trim Plate Plug-in Adapter: ❏ 153-443 100-120 VAC plug-in adapter (Single Faucet) ❏ 153-444 100-120 VAC 6-Unit adapter (2-6 Faucets) ❏ 269-1841 Wire for 6-Unit Adapter (1 per faucet) Water Supply: ❏ S59-4004XS TMA Vernatherm™ Thermostatic Mixing Valve Pre-Pack ❏ S45-2081 TL Single Tempered Line w/ Stop, Strainer, Check Valves Temperature Selection Valve: ❏ S01-515 MM2, User-Adjustable Mixing Valve, High Flow, 3 GPM 6-1/2" 165mm 2-1/8" 54mm 3-3/4" 95mm 2" 51mm 3.125" 79mm 5-1/8" 169mm 7" 178mm 8" Trimplate and Hardware Drain Assembly: ❏ 269-1231 D-ASSY, Drain, Strainer, and Tailpiece Model/Description Aerada 1200 Series CS Faucet, Centershank/ 4" Centerset Mounting (with trimplate) 5.625" 143mm Model/Description OPEN AUTO 5-1/2" 140mm Valve housing can be rotated to desired position 2-3/8" 60mm 4" 102mm 1.625" 41mm This information is subject to change without formal notice. 9-20-2005 (2 Pages Total) FA3048.2