View - OhioLINK Electronic Theses and Dissertations Center

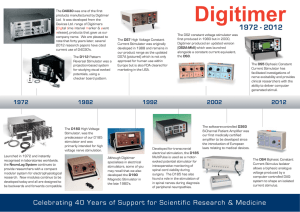

advertisement