On-line flatness measurement of large steel plates using moiré

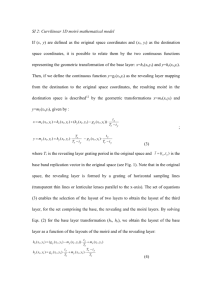

advertisement