Interfaces - Heidenhain

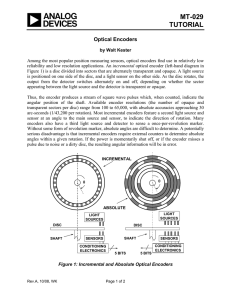

advertisement