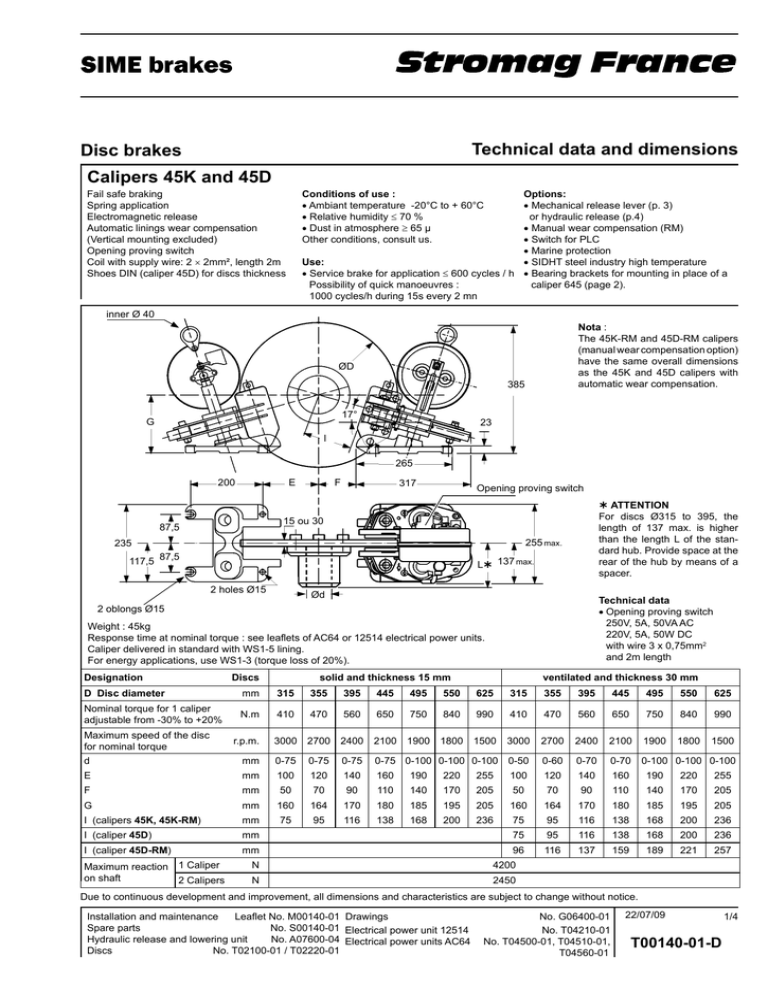

Disc brakes Technical data and dimensions

advertisement

Technical data and dimensions Disc brakes Calipers 45K and 45D Conditions of use : • Ambiant temperature -20°C to + 60°C • Relative humidity ≤ 70 % • Dust in atmosphere ≥ 65 µ Other conditions, consult us. Options: • Mechanical release lever (p. 3) or hydraulic release (p.4) • Manual wear compensation (RM) • Switch for PLC • Marine protection Use: • SIDHT steel industry high temperature • Service brake for application ≤ 600 cycles / h • Bearing brackets for mounting in place of a Possibility of quick manoeuvres : caliper 645 (page 2). 1000 cycles/h during 15s every 2 mn Fail safe braking Spring application Electromagnetic release Automatic linings wear compensation (Vertical mounting excluded) Opening proving switch Coil with supply wire: 2 × 2mm², length 2m Shoes DIN (caliper 45D) for discs thickness inner Ø 40 Nota : The 45K-RM and 45D-RM calipers (manual wear compensation option) have the same overall dimensions as the 45K and 45D calipers with automatic wear compensation. ØD 385 17° G 23 l 265 200 F E 317 Opening proving switch ATTENTION For discs Ø315 to 395, the length of 137 max. is higher than the length L of the standard hub. Provide space at the rear of the hub by means of a spacer. 15 ou 30 87,5 255 max. 235 117,5 87,5 L 137 max. 2 holes Ø15 Ød Technical data • Opening proving switch 250V, 5A, 50VA AC 220V, 5A, 50W DC with wire 3 x 0,75mm2 and 2m length 2 oblongs Ø15 Weight : 45kg Response time at nominal torque : see leaflets of AC64 or 12514 electrical power units. Caliper delivered in standard with WS1-5 lining. For energy applications, use WS1-3 (torque loss of 20%). Designation Discs solid and thickness 15 mm ventilated and thickness 30 mm D Disc diameter mm 315 355 395 445 495 550 625 315 355 395 445 495 550 625 Nominal torque for 1 caliper adjustable from -30% to +20% N.m 410 470 560 650 750 840 990 410 470 560 650 750 840 990 3000 2700 2400 2100 1900 1800 1500 3000 2700 2400 2100 1900 1800 1500 0-100 0-100 0-100 Maximum speed of the disc for nominal torque r.p.m. d mm 0-75 0-75 0-75 0-75 0-100 0-100 0-100 0-50 0-60 0-70 0-70 E mm 100 120 140 160 190 220 255 120 140 160 190 220 255 F mm 50 70 90 110 140 170 205 50 70 90 110 140 170 205 G mm 160 164 170 180 185 195 205 160 164 170 180 185 195 205 I (calipers 45K, 45K-RM) mm 75 95 116 138 168 200 236 75 95 116 138 168 200 236 I (caliper 45D) mm 75 95 116 138 168 200 236 I (caliper 45D-RM) mm 96 116 137 159 189 221 257 Maximum reaction 1 Caliper on shaft 2 Calipers 100 N 4200 N 2450 Due to continuous development and improvement, all dimensions and characteristics are subject to change without notice. Installation and maintenance Leaflet No. M00140-01 Spare parts No. S00140-01 Hydraulic release and lowering unit No. A07600-04 Discs No. T02100-01 / T02220-01 Drawings No. G06400-01 Electrical power unit 12514 No. T04210-01 Electrical power units AC64 No. T04500-01, T04510-01, T04560-01 22/07/09 T00140-01-D /4 Technical data and dimensions Disc brakes Calipers 45K and 45D Bearing bracket for mounting in place of a caliper 645 (Dimensions in mm) The bearing bracket allows to mount a caliper 45K or 45D in place of a 645 caliper. It is fitted with 4 fixing holes Ø13,5 as the base plate of the 645 caliper. It is designed in 3 versions depending on the disc diameter (see the table below). B ØD G 50° Oblong holes for adjustment on site E 92 A Bearing brackets Dimensions 947-58870 947-58880 947-58890 D mm 315 355 395 445 495 550 625 A mm 329 349 369 394 419 449 484 B mm 485 485 485 500 500 520 520 E mm 173 193 213 238 263 293 328 G mm 95 80 80 70 65 65 45 Due to continuous development and improvement, all dimensions and characteristics are subject to change without notice. Installation and maintenance Leaflet No. M00140-01 Spare parts No. S00140-01 Hydraulic release and lowering unit No. A07600-04 Discs No. T02100-01 / T02220-01 Drawings No. G06400-01 Electrical power unit 12514 No. T04210-01 Electrical power units AC64 No. T04500-01, T04510-01, T04560-01 22/07/09 T00140-01-D /4 Technical data and dimensions Disc brakes Calipers 45K and 45D Mechanical release with lever (Dimensions in mm) The mechanical release allows to open progressively the caliper by actuating a lever for lowering a load. All values indicated below correspond to a release lever length 240 mm (not provided by Stromag France). Working stroke for air gap = 0 : U = 70mm Maximum force (not to exceed) : F = 270 N 470 U Ø19 30 0 F 475 inner diameter Due to continuous development and improvement, all dimensions and characteristics are subject to change without notice. Installation and maintenance Leaflet No. M00140-01 Spare parts No. S00140-01 Hydraulic release and lowering unit No. A07600-04 Discs No. T02100-01 / T02220-01 Drawings No. G06400-01 Electrical power unit 12514 No. T04210-01 Electrical power units AC64 No. T04500-01, T04510-01, T04560-01 22/07/09 T00140-01-D /4 Technical data and dimensions Disc brakes Calipers 45K and 45D Hydraulic release (Dimensions in mm) The hydraulic release allows to open progressively the caliper via a hydraulic jack by acting on a lowering unit or a hand pump for lowering the load. Manual release Ø90 Purge screw 235 Oil inlet M14x1,5 173,5 291 Principle diagram Pressure to reduce the nominal torque to zero bar 126 Oil volume displaced to open the caliper cm3 1,5 Lowering unit 947-62000 947-61990 with manual control valve with solenoid valve 24VDC Flexible pipe with connections Depending on the distance between brake and lowering unit Mineral oil recommended Conform to standard ISO6743/4 Grade HV32 to 46 Jack Inlet M14x1,5 Hydraulic connection Output 1/4"G Lowering unit Due to continuous development and improvement, all dimensions and characteristics are subject to change without notice. Installation and maintenance Leaflet No. M00140-01 Spare parts No. S00140-01 Hydraulic release and lowering unit No. A07600-04 Discs No. T02100-01 / T02220-01 Drawings No. G06400-01 Electrical power unit 12514 No. T04210-01 Electrical power units AC64 No. T04500-01, T04510-01, T04560-01 22/07/09 T00140-01-D /4