FISHER

advertisement

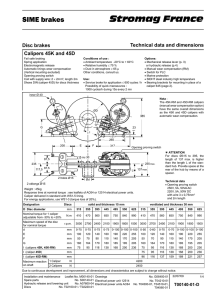

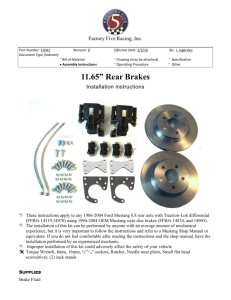

FISHER CONTROLS PRAGMATIC APPLICATION OF GAUGE-MANPOWER CORRELATION Alexandria Stewart, Michael Stinn, Justin Thede, Alicia Wieland FISHER CONTROLS • Fisher Controls is a manufacturer of control valves • Headquartered in Marshalltown, IA • These valves control elements like pressure, flow, and liquid level • They are used in many industries, including nuclear power plants, oil and gas refineries, pulp and paper factories, etc. • Due to these applications, having valves that are within engineering specification is important PROCESS • Fisher’s operators machine parts to specifications set by their engineers • After each machining operation, the dimension machined is measured by the operator and verified as acceptable by an inspector • When machining is complete, each part undergoes a final inspection process • The inspector measures the part, either with a micrometer or a caliper PROBLEM • Parts are being rejected at ±0.001” out of tolerance • Inspectors use their own discretion as to which measurement device is appropriate in a given situation • It is suspected that the current procedures are not producing this kind of accuracy • The objective of this study is to analyze measurement capability and suggest appropriate changes PROCEDURES • Gauge R&R Study • Three operators measured 10 small parts three times each with a caliper • This was repeated using a set of 10 larger parts • Three measurements per part were taken using a micrometer on the 10 small parts by the same three operators Figure 2: 8” Ring Measurement Process Chart Figure 1: 1” Stem Measurement Process Chart DATA ANALYSIS • The measurements were analyzed using JMP statistical software • The resulting output was used to find σ𝑅𝑒𝑝𝑒𝑎𝑡𝑎𝑏𝑖𝑙𝑖𝑡𝑦, σ𝑅𝑒𝑝𝑟𝑜𝑑𝑢𝑐𝑖𝑏𝑖𝑙𝑖𝑡𝑦, σ𝑅&𝑅 , distributions, and Gauge Capability Ratios for each set of data ANALYSIS • Gage Capability Ratio (GCR) Item – Device Gauge Capability Ratio 1” Stem – Caliper 0.266 1” Stem – Micrometer 0.152 8” Ring – Caliper 0.209 • GCR < 0.1 wanted for a gage to be considered appropriate • GCR < 0.01 is preferred for most applications • Micrometer had smallest GCR of either device ANALYSIS • The micrometer variation is consistently smaller than those of the caliper • Caliper variation was consistent Figure 3: Repeatability, Reproducibility, and R&R ANALYSIS • Micrometer measurements are more precise than the caliper • Calibration for accuracy is possible, but imprecision cannot be fixed Figure 4: Range and Distribution of Stem Measurements ANALYSIS • Comparison of operator consistency between 1” stems and 8” rings • Operator 3 consistently lower than 1 and 2 • Variation was independent of part size Figure 5: Average measurements of 1” stems with caliper Figure 6: Average measurements of 8” rings with caliper ANALYSIS • Comparison of measurement devices • Variation between operators was larger using the caliper • Measurements of each part were consistent regardless of the device Figure 5: Average measurements of 1” stems with caliper Figure 7: Average measurements of 1” stems with micrometer ANALYSIS • We can say with 95% confidence, for any single measurement the σ𝑅&𝑅 error will be within 0.00068 and 0.00096 inches • For the calipers we are 95% confident that the σ𝑅&𝑅 error will be within 0.00083 and 0.00398 inches Figure 8: σ𝑅&𝑅 Estimates and 95% Confidence Intervals RECOMMENDATIONS • Create and implement standard protocol for measurement tools • For part features with tolerances less than ±0.005”, always use a micrometer • With calipers, we are 95% sure that a measurement could be skewed nearly as much as 0.004 inches • By using a micrometer, our 95% confident maximum error is less than 0.001”, allowing for a much more accurate measurement • Use this data as an awareness tool to further establish the importance of using the appropriate tool for specific situations • Conduct a training event for the inspectors and establish standard measurement procedures • Standardization across all inspectors on how to hold the device • Digital caliper shows value during measurement – can bias recorded measurement if inspector views screen during process