Publication - Oxford Institute for Energy Studies

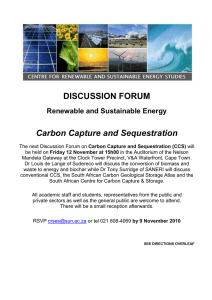

advertisement