Wiring Devi.. - RGB Architectural Group

advertisement

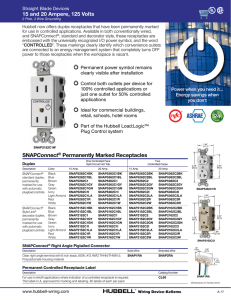

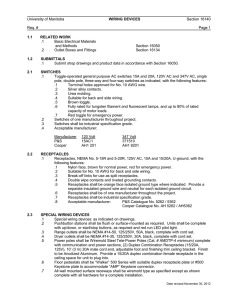

DIVISION 26 ELECTRICAL SECTION 262726 – WIRING DEVICES 1.0 GENERAL 1.01 DESCRIPTION A. 1.02 1.03 1.04 This section specifies the furnishing, installation and connection of wiring devices. All devices shall utilize a pressure plate with a screw termina that shall be approved for side connection of stranded copper cable. RELATED WORK A. Section 260500, GENERAL ELECTRICAL PROVISIONS B. Section 260533, CONDUIT SYSTEMS: Conduits and outlets boxes. C. Section 260519, CABLES AND CONDUCTORS, LOW VOLTAGE (600 VOLTS AND BELOW): Cables and wiring. D. Section 260526, GROUNDING: Requirements for personnel safety and to provide a low impedance path to ground for possible ground fault currents. SUBMITTALS A. Submittal Drawings: 1. Sufficient information, clearly presented, shall be included to determine compliance with drawings and specifications. 2. Include electrical ratings, dimensions, mounting details, construction materials, color, grade and termination information. B. Manuals: Two weeks prior to final inspection, deliver four copies of the following to the Engineer: Technical data sheets and information for ordering replacement units. APPLICABLE PUBLICATIONS A. Publications listed below (including amendments, addenda, revisions, supplements and errata) form a part of this specification to the extent referenced. Publications are referenced in the text by basic designation only. B. National Fire Protection Association (NFPA): National Electrical Code (NEC) C. D. National Electrical Manufacturers Association (NEMA): WD 1 99 General Color Requirements for Wiring Devices WD 6 02 Wiring Devices – Dimensional Requirements Underwriter’s Laboratories, Inc. (UL): 5 PHASE 2 – REED HALL Surface Metal Raceways and Fittings 26 27 26 – 1 1200 04/PH2 20 General Use Snap Switches 231 Power Outlets 467 Grounding and Bonding Equipment 498 Attachment Plugs and Receptacles 943 Ground Fault Circuit Interrupters 2.0 PRODUCTS 2.01 GENERAL USE RECEPTACLES 2.02 A. General: All receptacles shall be listed by Underwriters Laboratories, Inc. 1. Mounting straps shall be plated steel, with break off plaster ears and shall include a self grounding feature. Terminal screws shall be brass, brass plated or a copper alloy metal. 2. Receptacles shall have provisions for back wiring with separate metal clamp type terminals (four min.) and side wiring from four captively held binding screws. B. Duplex receptacles shall be single phase, 20 ampere, 120 volts, 2 pole, 3 wire, and conform to standard NEMA WD 1 heavy duty type. The duplex type shall have break off feature for two circuit operation. The ungrounded pole of each receptacle shall be provided with a separate terminal. 1. Bodies shall color as selected by Architect. 2. Switched duplex receptacles shall be wired so that only the top receptacle is switched. The remaining receptacle shall be unswitched. 3. Ground Fault Interrupter Duplex Receptacles: Shall be an integral unit suitable for mounting in a standard outlet box. a. Ground fault interrupter premium grade and consist of a differential current transformer, solid state sensing circuitry and a circuit interrupter switch. It shall be rated for operation on a 60 Hz, 120 volt, 20 ampere branch circuit. Devices shall meet UL 943. 4. Weatherproof Receptacles: Shall consist of a duplex Ground Fault duplex receptacle, mounted in box with a gasketed, weatherproof, cast metal cover plate and cap over each receptacle opening. The cap shall be permanently attached to the cover plate by a spring hinged flap. Cover plates on outlet boxes mounted flush in the wall shall be gasketed to the wall in a watertight manner. 5. Ground fault type outlets shall be furnished and installed in all wet, moist, and damp areas in basement, in janitor closets, and all washrooms. All water coolers, vending machines, and kitchen appliances shall have ground fault type receptacles. TOGGLE SWITCHES A. Toggle switches shall be totally enclosed tumbler type with bodies of phenolic compound. Toggle handles shall be color as selected by Architect. The rocker type switch is not acceptable and will not be approved. 1. Shall be single unit toggle, butt contact, quiet AC type, heavy duty general purpose use with an integral self grounding mounting strap with break off plasters ears and provisions for back wiring with separate metal wiring clamps and side wiring with captively held binding screws. PHASE 2 – REED HALL 26 27 26 – 2 1200 04/PH2 2. 3. 4. 5. 2.03 2.04 Shall be listed by Underwriters Laboratories, Inc., and meet the requirements of NEMA WD 1, Heavy Duty and UL 20. Ratings: a. 120 volt circuits: 20 amperes at 120 277 volts AC. The switches shall be mounted on the striker plate side of doors. All toggle switches shall be of the same manufacturer. WALL PLATES A. Wall plates for switches and receptacles shall be type 302 brushed stainless steel in student public areas and and smooth nylon in closets and maintenance closets. Oversize plates are not acceptable. B. Nylon wall plate color as selected by Architect. C. Standard NEMA design, so that products of different manufacturers will be interchangeable. Dimensions for openings in wall plates shall be accordance with NEMA WD1. D. For receptacles or switches mounted adjacent to each other, wall plates shall be common for each group of receptacles or switches. E. Wall plates for data, telephone or other communication outlets shall be as specified in the associated specification. SURFACE MULTIPLE OUTLET ASSEMBLIES A. Assemblies shall conform to the requirements of NFPA 70 and UL 5. B. Shall have the following features: 1. Enclosures: a. Thickness of steel shall be not less than 1 mm (0.040 inch) steel for base and cover. Nominal dimension shall be 40 by 70 mm (1 1/2 by 2 3/4 inches) with inside cross sectional area not less than 2250 square mm (3.5 square inches). The enclosures shall be thoroughly cleaned, phosphatized and painted at the factory with primer and the manufacturer's standard baked enamel or lacquer finish. 2. Receptacles shall be duplex See paragraph 'RECEPTACLES' in this section. Device cover plates shall be the manufacturer's standard corrosion resistant finish and shall not exceed the dimensions of the enclosure. 3. Unless otherwise shown on drawings, spacing of the receptacles along the strip shall be 600 mm (24 inches) on centers. 4. Wires within the assemblies shall be not less than No. 12 AWG copper, with 600 volt ratings. 5. Installation fittings shall be designed for the strips being installed including bends, offsets, device brackets, inside couplings, wire clips, and elbows. 6. Bond the strips to the conduit systems for their branch supply circuits. 3.0 EXECUTION 3.01 INSTALLATION A. Installation shall be in accordance with the NEC and as shown as on the drawings. PHASE 2 – REED HALL 26 27 26 – 3 1200 04/PH2 B. Mounting height shall be in compliance with ADA requirements or as noted on the drawings. Areas that are dedicated to handicapped shall have all devices in compliance. C. Ground terminal of each receptacle shall be bonded to the outlet box with an approved green bonding jumper, and also connected to the green equipment grounding conductor. 4.0 PRODUCTS 4.01 INSTALLATION A. All devices shall be commercial grade and shall be ivory, white or brown as selected by the Archtiect. B. Receptacles shall be Leviton type BR20, 20 Ampere, approved for use of stranded cable on side mounting. C. The switches shall be Leviton type 1221, 20 Ampere, approved for use of stranded cable on side mounting. D. Stranded wire and cable must not be “wrapped” around any screw termination. E. After installation the entire unit is to be wrapped with #33 Scotch tape, not less than 3 wraps. END OF SECTION 262726 PHASE 2 – REED HALL 26 27 26 – 4 1200 04/PH2