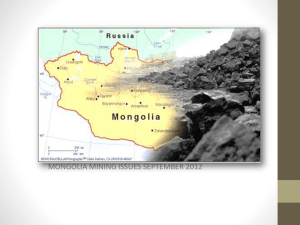

2013 Oyu Tolgoi Technical Report, March 2013

advertisement