Products, Solutions and Expertise for the Energy Networks

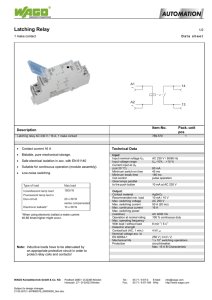

advertisement