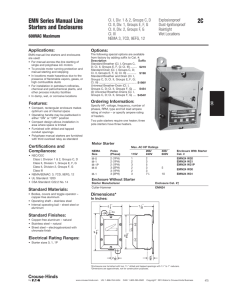

Motor Control

advertisement